Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Ensure impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

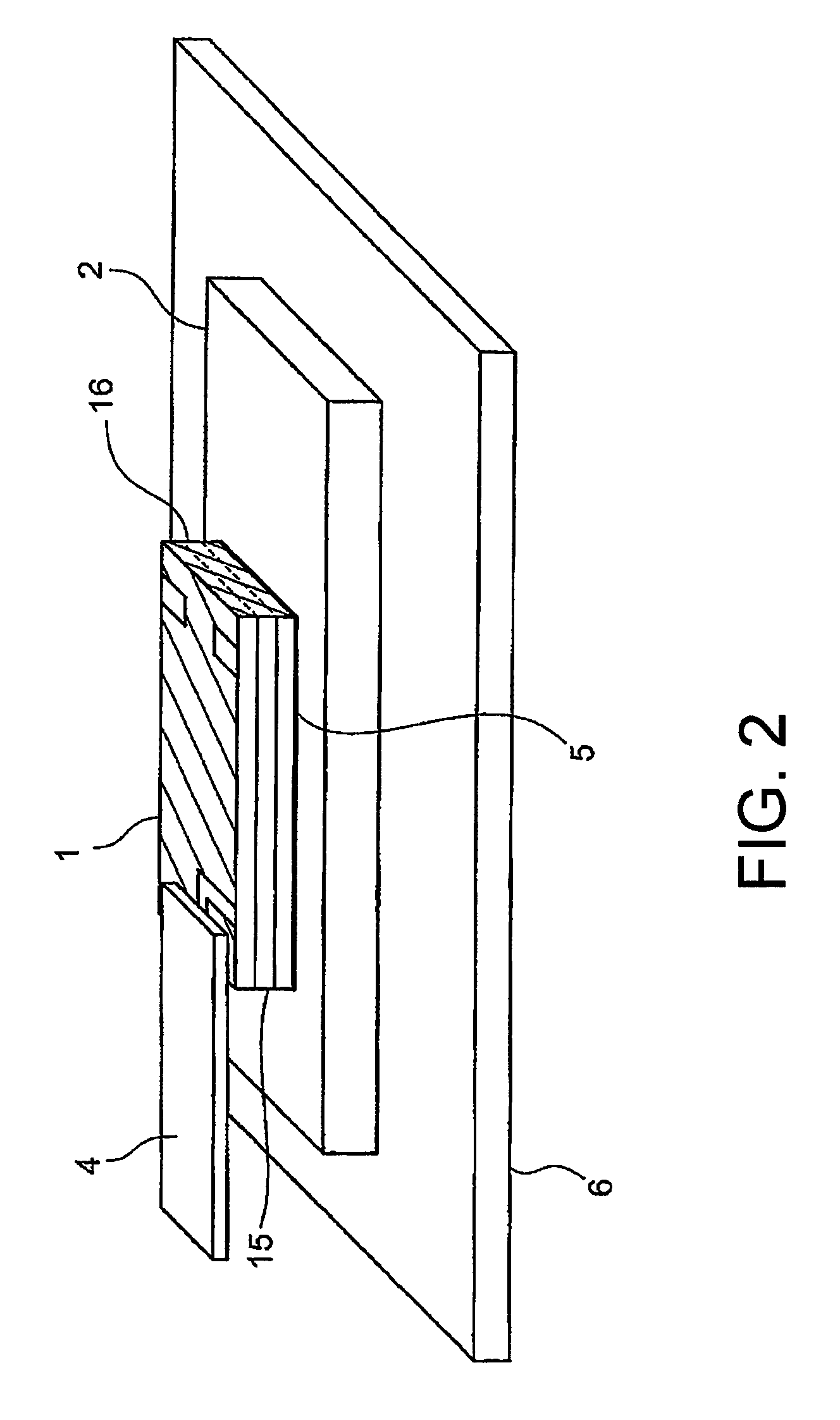

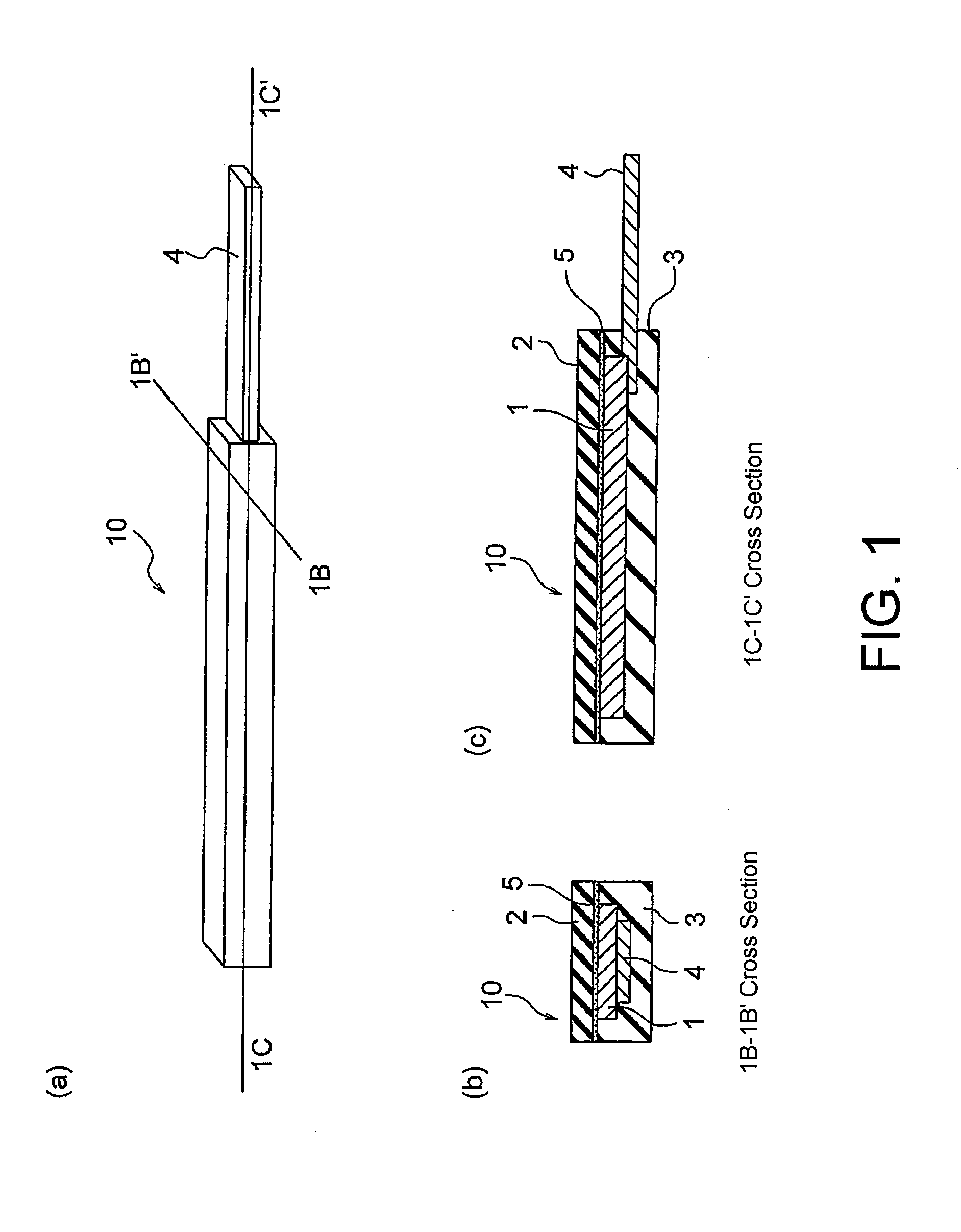

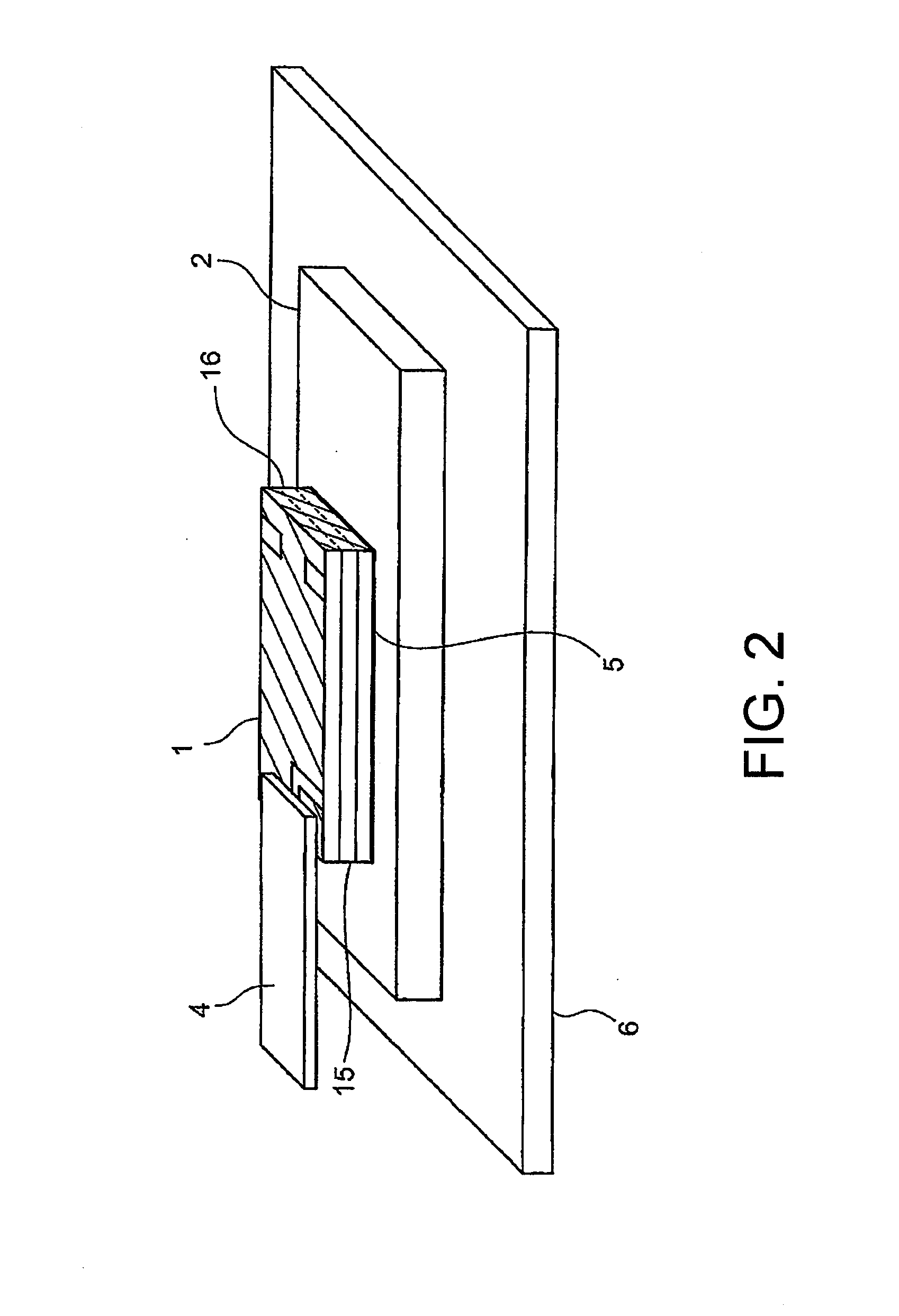

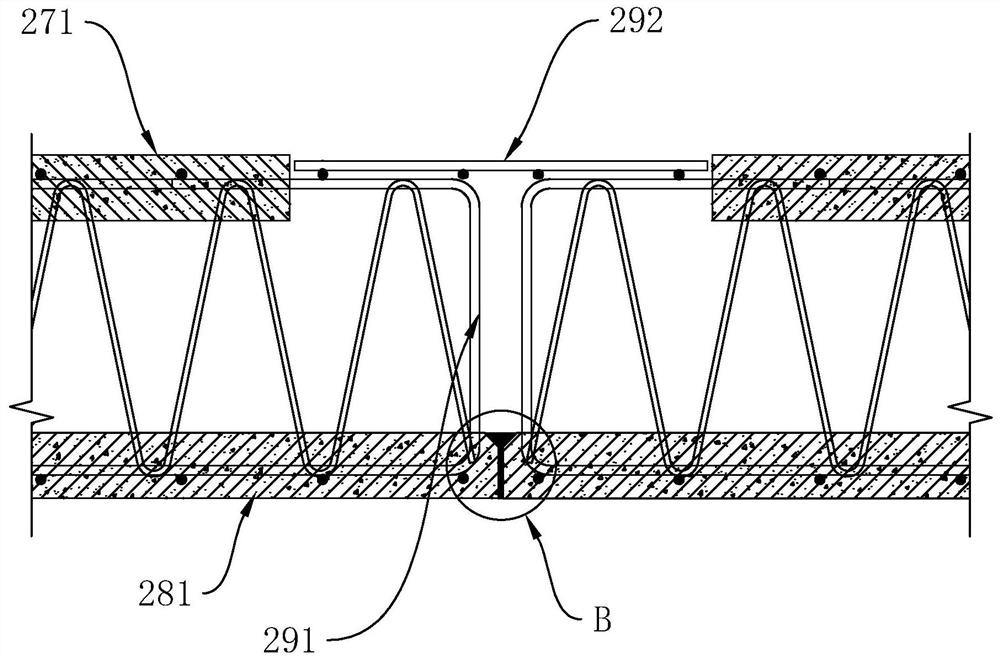

Photovoltaic assembly, lamination structure thereof and preparation method of lamination structure

ActiveCN108022988ALow manufacturing costReduce weightLaminationLamination apparatusPolyesterEngineering

Owner:SUNMAN (ZHENJIANG) CO LTD

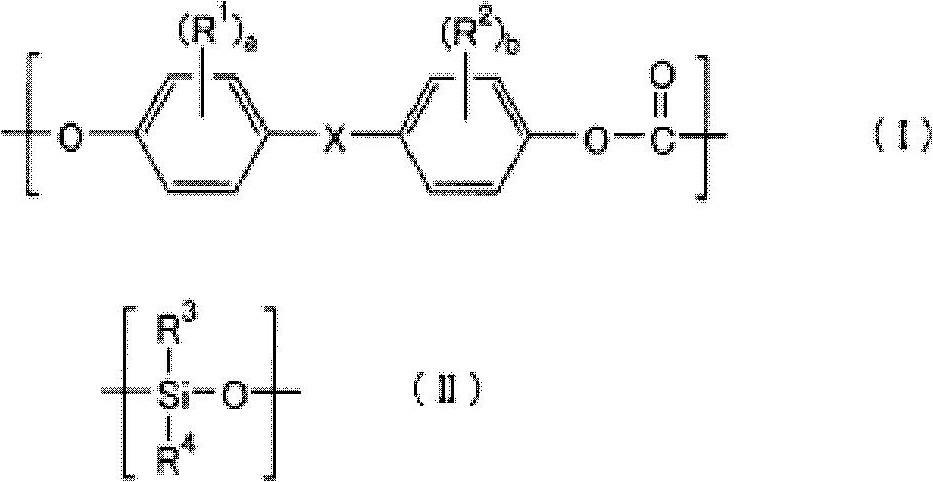

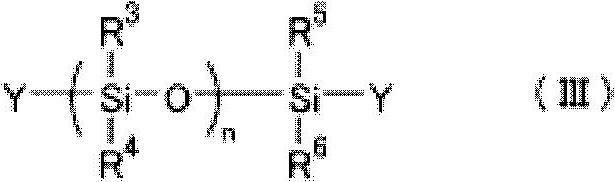

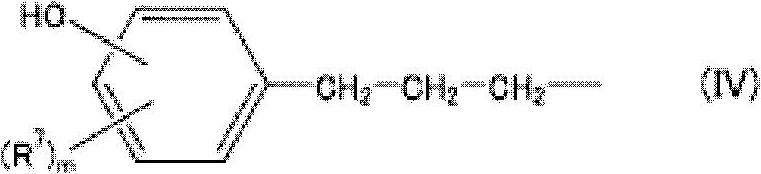

Polycarbonate-polyorganosiloxane copolymer, process for production of the copolymer, and polycarbonate resin containing the copolymer

A polycarbonate-polyorganosiloxane copolymer (A-1) comprising a polycarbonate block composed of a specific constituent unit and a polyorganosiloxane block composed of a specific constituent unit, wherein the copolymer is characterized in that (1) the content of the polyorganosiloxane block moiety is 1 to 30 mass%, (2) the average repeating unit number of constituent units represented by general formula (II) is 70 to 1000, (3) the copolymer has a viscosity average molecular weight of 13000 to 26000, and (4) the content of a phenol residue having an allyl group in the copolymer is 400 ppm by mass or less.

Owner:IDEMITSU KOSAN CO LTD

Modified asphalt material and preparation method thereof

InactiveCN101117443AMaintain wear resistanceEnsure impact resistanceBuilding insulationsSolubilityPolyolefin

The invention discloses a bitumen modified material, which comprises 100 parts by weight of vinyl aromatic hydrocarbon-conjugated diene block copolymer with the flow value being less than 15g / 10 minutes relative to fused mass, 0 to 100 parts by weight of tackifying resin, 5 to 100 parts by weight of blending oil and 10 to 50 parts by weight of polyolefin. In addition, the invention also discloses the method of preparation of the bitumen modified material. Due to adding polyolefin, the invention not only maintains the physical intensity of existing bitumen modified material such as abrasion resistance, impact resistance and fluidity resistance as well as the advantages of excellent dissolubility, processability and storage stability, but also improves high temperature performance of bitumen modified material.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Piezoelectric element, piezoelectric vibration module, and methods of manufacturing the same

ActiveUS9544694B2Ensure impact resistanceEfficient disseminationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersEngineeringSilicone rubber

A piezoelectric vibration module includes a piezoelectric element, a wiring member connected to the piezoelectric element and drawn out to the outside, and an elastic plate bonded to one surface of the piezoelectric element, wherein the elastic plate is made of a silicone rubber.

Owner:TOKIN CORP

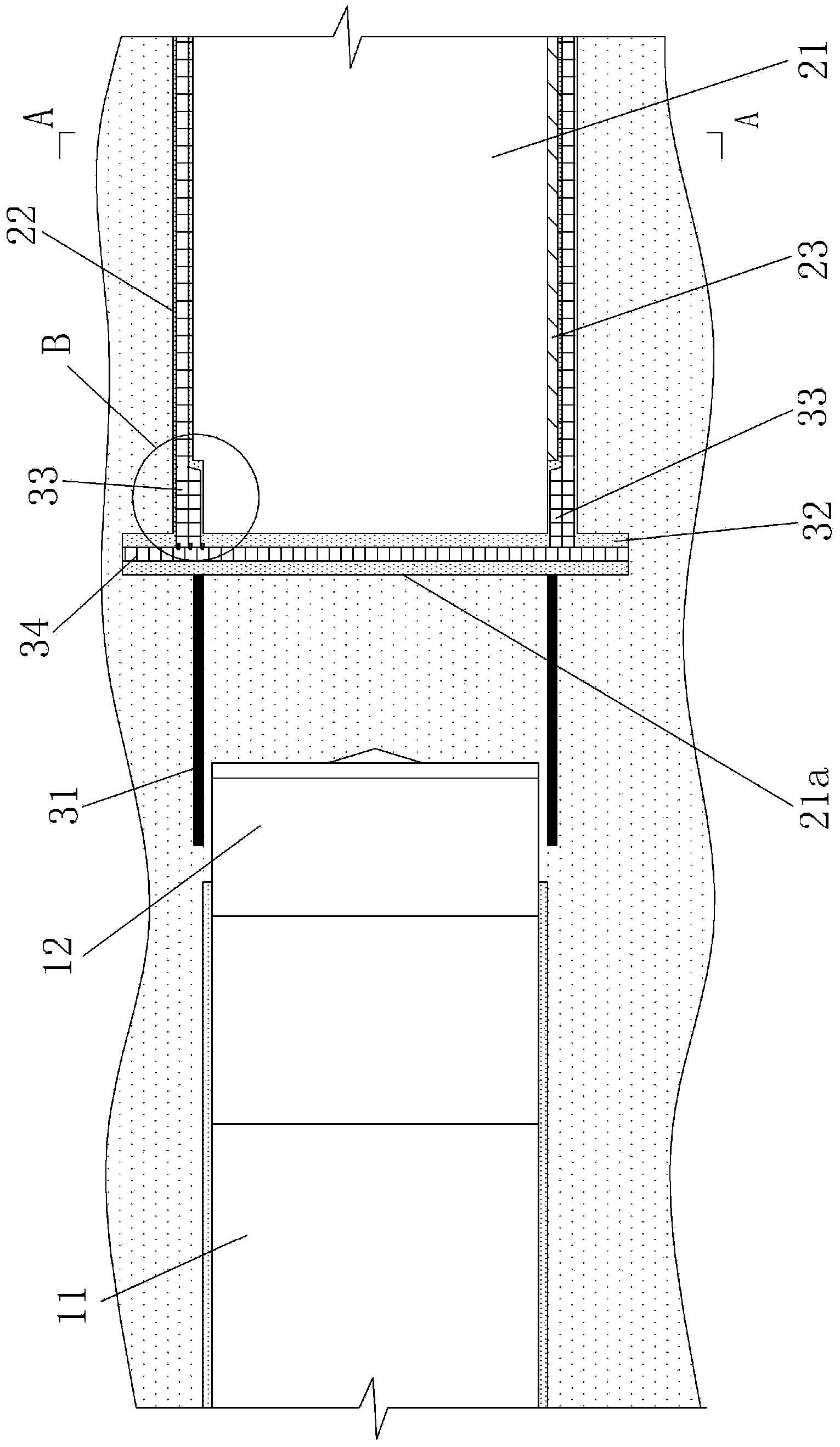

Propelling method for combined portion between shield tunnel segment and mine tunnel segment in subway tunnel

InactiveCN103711504ALow bond strengthLow elastic modulusUnderground chambersTunnel liningGlass fiberShotcrete

Provided is a propelling method for a combined portion between a shield tunnel segment and a mine tunnel segment in a subway tunnel. The propelling method includes the first step that a steel sleeve is horizontally struck into the surrounding rock in front of a tunnel face of the mine tunnel segment after construction of the mine tunnel segment is finished, and then a shotcrete support is applied on the tunnel face; the second step that glass fiber ribs of separation end walls are bound tightly close to the shotcrete support, the glass fiber ribs and steel bars for ring beams behind the glass fiber ribs are connected in a bound mode, next the steel bars for the ring beams are connected with reserved steel bar heads of a primary support of the mine tunnel segment in a welded mode, and then the separation end walls and the ring beams are poured; the third step that an arc-shaped concrete guiding platform is poured at the bottom of the mine tunnel segment; the fourth step that when a shield tunneling machine approaches to the mine tunnel segment, the propelling speed is lowered, the shield tunneling machine is accommodated in the steel sleeve, and then the shield tunneling machine is used for directly cutting and removing the surrounding rock in the steel sleeve, the shotcrete support of the tunnel face and the separation end walls and carrying out grouting and slag removing until the shield tunneling machine passes through the ring beams and is accommodated on the arc-shaped concrete guiding platform. According to the propelling method, construction risks are low, construction is easy, efficiency is high and the cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

Member for reinforcing vehicle body

ActiveCN101132938AImprove energy absorptionImprove impact resistancePedestrian/occupant safety arrangementFurnace typesStraight tubeImpact resistance

A member for reinforcing a vehicle body capable of absorbing more energy than conventional reinforcement members using straight tubes and ''overall length R-bent tubes'' at the time of collision of the vehicle body by applying either of a ''partially R-bent tube'', a ''multi-portion R-bent tube'' and a ''partially recessed and protruded bent tube'' specified in this invention to the member for reinforcing the vehicle body so as to develop excellent impact resistance for reinforcing the vehicle body. The dimensions (outer diameter, wall thickness) of a metal tube used as the member for reinforcing the vehicle body are reduced while maintaining the impact resistance and the shape thereof is reviewed to reduce the weight and cost of the vehicle body. Also, since the member can cope with a requested level for a more and more increasing impact resistance of the vehicle body, it can be widely used as an occupant protective technology.

Owner:NIPPON STEEL CORP +2

Polyolefine resin composition

The present invention relates to a polyolefin resin composition comprising (100) parts by weight of a polypropylene resin, 5-45 parts by weight of an inorganic filler and 2-20 parts by weight of a silicone graft-modified polyethylene. The polyolefin resin composition of this invention is useful for the various kinds of housings in the electric appliances and parts of automobiles because it has little mechanical properties deterioration as well as excellent scratch resistance, resin flowability and mold releasability.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Automobile with one-time formed plastic shell

InactiveCN102328702ASimple manufacturing processIncrease productivitySuperstructure subunitsSuperstructure connectionsEngineeringBody weight

The invention relates to an automobile with a one-time formed plastic shell. The automobile comprises an automobile body and a chassis, wherein the automobile body is a hollow double-layer plastic shell which is integrally formed at one time by a rotational molding process and is provided with an automobile door installation hole and an automobile window installation hole in advance; a plurality of contact reinforcing ribs are formed between an inner-layer wall body and an outer-layer wall body of the hollow double-layer plastic shell; a plurality of convex reinforcing ribs are formed on the external surface of the outer-layer wall body or the inner-layer wall body of the hollow double-layer plastic shell; a chassis embedding groove is formed at the lower end of the external surface of the inner-layer wall body of the hollow double-layer plastic shell; a plurality of threaded sleeves are embedded into the chassis embedding groove; the chassis is embedded into and in threaded connection with the chassis embedding groove; the external surface of the inner-layer wall body of the hollow double-layer plastic shell is provided with door post embedding grooves on two sides of the automobile door installation hole; and the upper end of the chassis is fixedly provided with door posts inserted into the door post embedding grooves. The automobile has the advantages of high strength and surface performance, light body weight, low cost and the like, and is easy to manufacture and convenient to assemble.

Owner:应革

Microbial agent for treatment of sewage and sludge

InactiveCN105062919AReduce generationGrowth inhibitionFungiBacteriaSynechococcusRhodospirillum rubrum

Belonging to the field of microbial environmental protection, the invention provides a microbial agent for treatment of sewage and sludge. The microbial agent mainly includes Rhodospirillum rubrum, rhodopseudomonas palustris, bacillus subtilis, Streptomyces microflavus, streptococcus thermophilus, candida utilis, Streptomyces viridis, pseudomonas aeruginosa, virgibacillus halodenitrificans, and Paracoccus denitrificans 10 bacteria. Each bacterium is subjected to conventional slant culture, shaking culture and seed tank cultivation respectively, the bacteria in the seed tank are mixed and then put into sewage directly, symbiosis of flora is utilized to reach the purpose of treating sewage and reducing sludge generation. The microbial agent provided by the invention can be applied to large-scale production and direct adding, is low in cost, and can adapt to changeful sewage components. And the flora has good impact resistance to sewage.

Owner:XINJIANG JUNYANG HONGTAI ENVIRONMENTAL PROTECTIONTECH CO LTD

Piezoelectric element, piezoelectric vibration module, and methods of manufacturing the same

ActiveUS20150163598A1Stable temperature characteristicsIncrease vibration displacementPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyEngineeringSilicone rubber

A piezoelectric vibration module includes a piezoelectric element, a wiring member connected to the piezoelectric element and drawn out to the outside, and an elastic plate bonded to one surface of the piezoelectric element, wherein the elastic plate is made of a silicone rubber.

Owner:TOKIN CORP

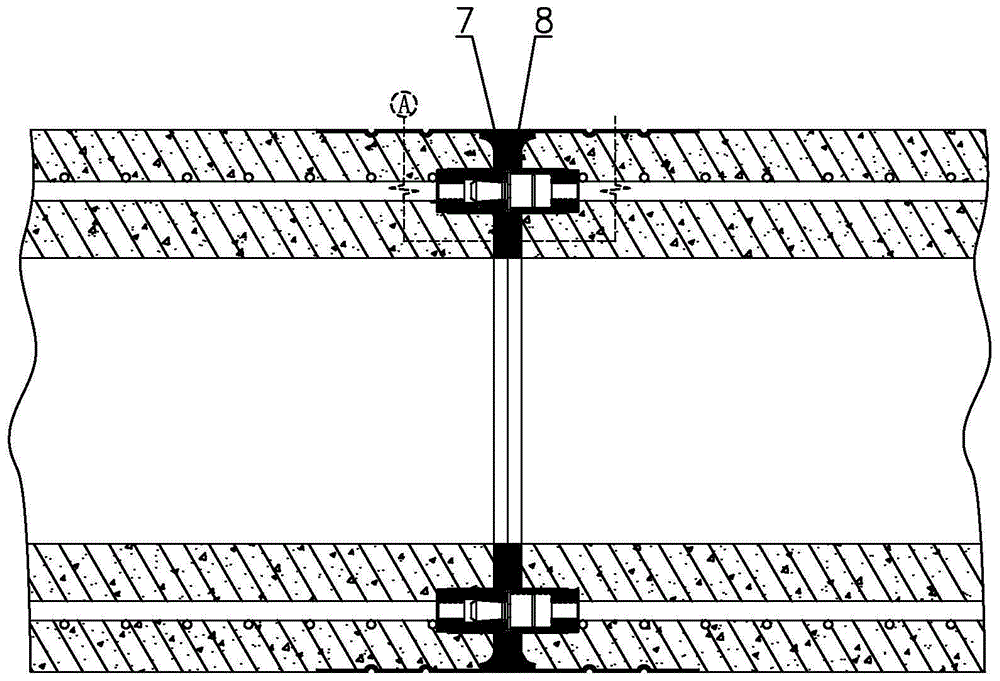

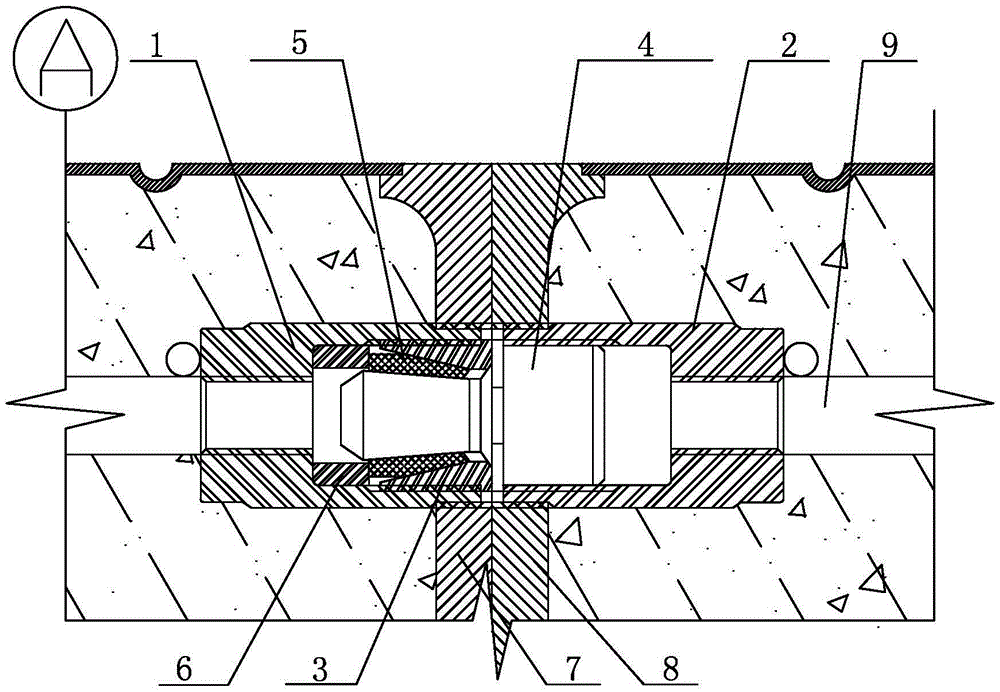

Uplift pile mixed connection structure

ActiveCN105756054AEfficient deliverySolve the problem of impact resistanceBulkheads/pilesAdhesiveStructural engineering

The invention discloses an uplift pile mixed connection structure which comprises a pile head protective sleeve I, a pile head protective sleeve II and a plug connector. The plug connector comprises a first sleeve-shaped fixed positioning sleeve and a second sleeve-shaped fixed positioning sleeve. A clamping piece is arranged in the first fixed positioning sleeve. A plug connection piece is arranged in the second fixed positioning sleeve. The plug connection piece can be inserted into the first fixed positioning sleeve and limited on the clamping piece, and therefore the first pile head protective sleeve and the second pile head protective sleeve can be fixedly connected in a butted mode. Both the first fixed positioning sleeve and the second fixed positioning sleeve are connected with main reinforcement bars and fixedly combined with the pile head protective sleeves through screws. When the uplift pile mixed connection structure is subjected to tensile force, the plug connector effectively connects the upper and lower main reinforcement bars, butt connection of the upper and lower main reinforcing bars on the same axis is achieved, inner stress is effectively transferred, meanwhile, the butted connection faces of the pile head protective sleeve I and the pile head protective sleeve II are in butted connection through a steel adhesive, the uplift resistance is further improved, and the purposes of impact resistance of a pile head end face and shear resistance and corrosion resistance of the connector are thoroughly achieved.

Owner:天海钢棒(张家港)有限公司

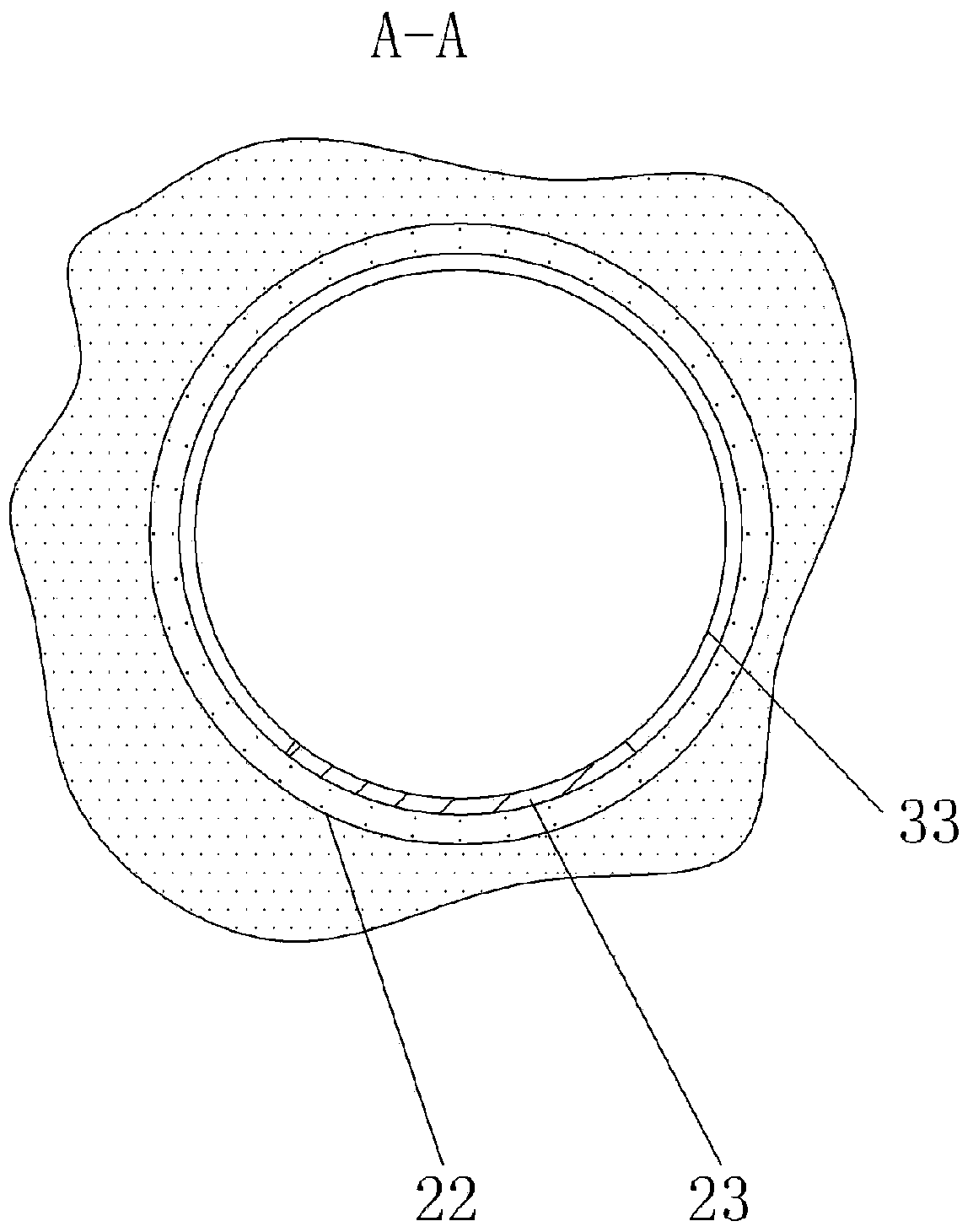

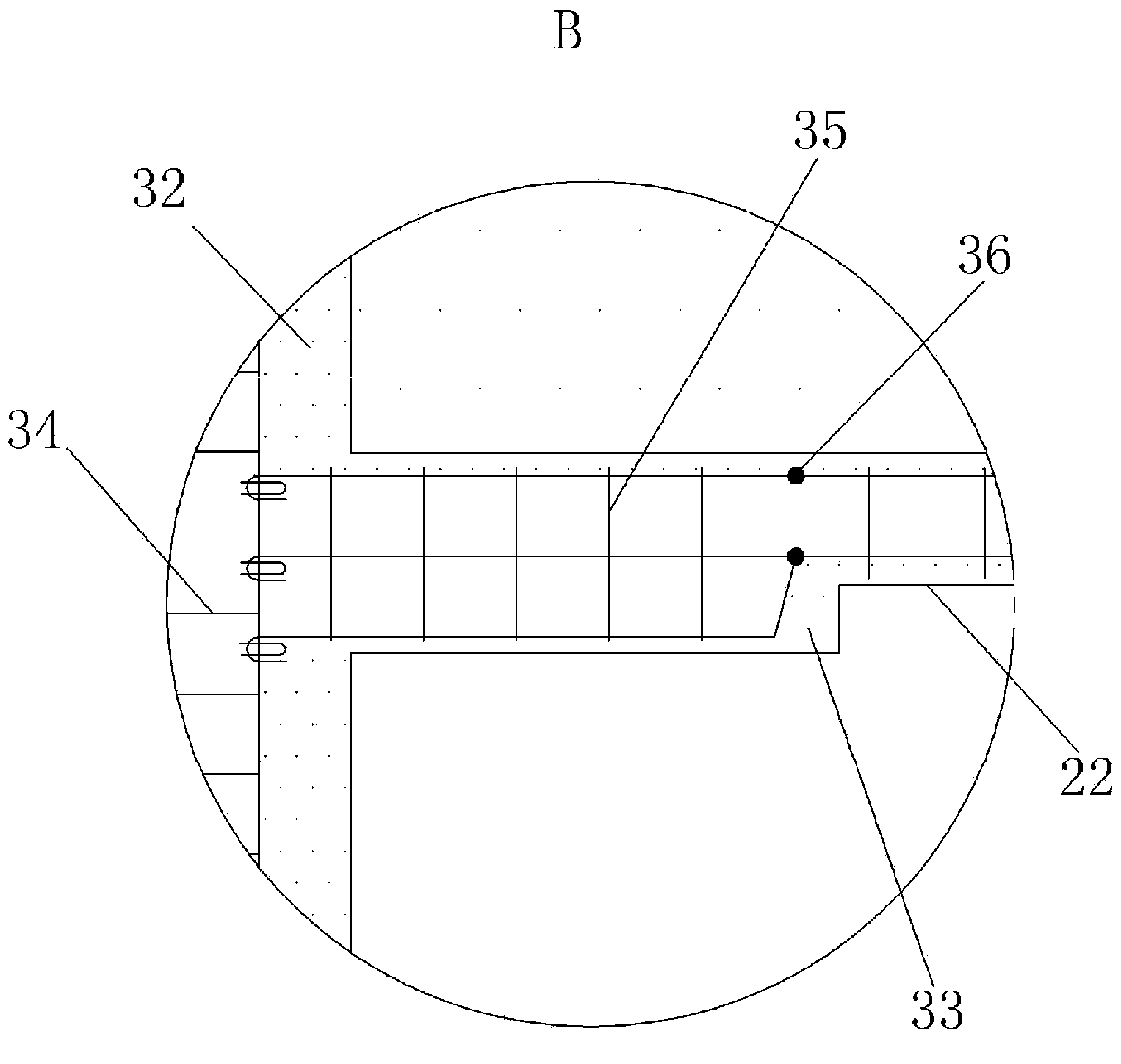

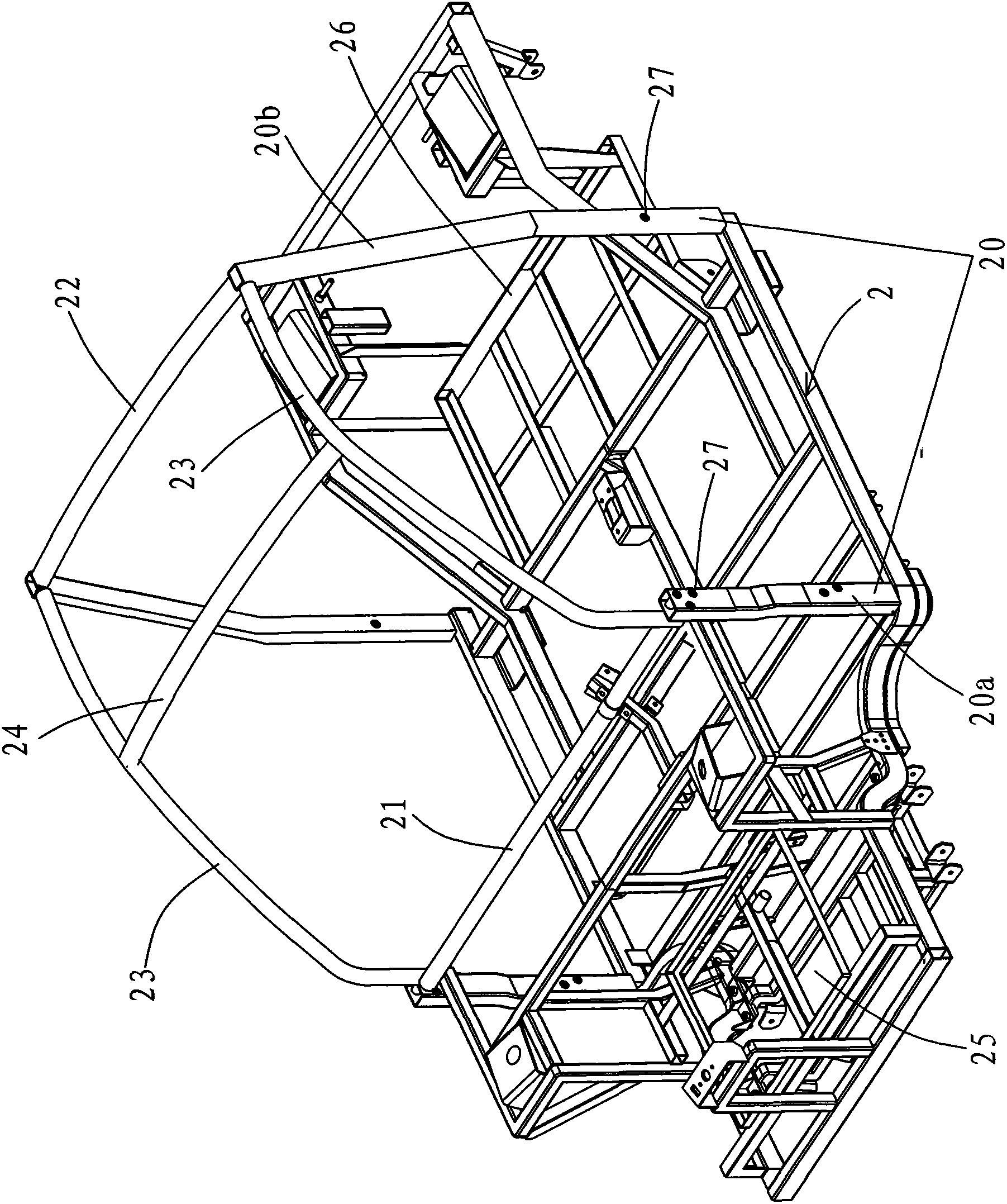

Casting type split reactor

InactiveCN104124043AEnsure consistencyAvoid uneven thicknessTransformers/inductances coils/windings/connectionsInsulation layerCasting types

The invention discloses a casting type split reactor. A coil of the casting type split reactor comprises a first winding and a second winding which are arranged coaxially, and encapsulation parts of the first winding and encapsulation parts of the second winding are arranged alternatively from inside to outside in sequence. A first wire inlet bar and a second wire outlet bar are arranged at an interval radially and fixed at the upper end of the coil, and the other first wire inlet bar and a first wire outlet bar are arranged at an interval radially, connected with a current introducing end of the second winding in a conductive mode and fixed at the lower end of the coil. Each encapsulation part comprises a conductive part formed by winding a plurality of multi-layer round leads, and an insulation part formed by casting epoxy resin in a vacuum mode is arranged outside the conductive part. According to the casting type split reactor, the encapsulation parts are formed by casting epoxy resin in the vacuum mode through a casting mould, consistency of sizes of the insulation layers can be ensured, and uneven thicknesses of the insulation layers are avoided. In addition, no bubbles exist in the windings, partial discharge is reduced, occurrence of air gaps can be avoided effectively, and therefore, insulation performance of the insulation layers can be improved.

Owner:STATE GRID CORP OF CHINA +2

Color photovoltaic module and preparation method thereof

ActiveCN108242473AEasy to operateReduce installation costsPowdery paintsPhotovoltaic energy generationPhotovoltaic industrySolar cell

The invention discloses a color photovoltaic module and a preparation method thereof. The color photovoltaic module comprises a lamination structure which is formed by laminating a first packaging part, a first packaging adhesive film layer, a solar cell string and a second packaging part. The first packaging part comprises a transparent film layer which is prepared from a color thermoplastic high-molecular polymer, and the relative molecular mass of the color thermoplastic high-molecular polymer is greater than 20000. The color photovoltaic module costs low and is light. Under the premise that the technical standard requirements for ultraviolet resistance, aging resistance, impact resistance, fire prevention and insulation resistance in the photovoltaic industry are satisfied, the packaging material of the photovoltaic module is light, the installation cost of the photovoltaic module is reduced on the whole, and the photovoltaic module is very suitable for large-scale promotion and application in the field of photovoltaic building materials. Moreover, the appearance color of the photovoltaic module can be freely selected and changed, and the photovoltaic module looks more beautiful.

Owner:SUNMAN (ZHENJIANG) CO LTD

Laminated structure of a photovoltaic module and preparation method thereof, photovoltaic module

ActiveCN108022988BReduce weightReduce installation costsLaminationLamination apparatusPolyesterFiber

The invention discloses a laminated structure of a photovoltaic module, a preparation method thereof, and a photovoltaic module. The laminated structure includes a first encapsulation layer and a second encapsulation layer, wherein the first encapsulation layer consists of 30-50 parts by weight of fiber cloth and 50 parts by weight. ‑70 parts by weight of the first packaging powder coating is prepared, the first packaging powder coating is evenly coated on the fiber cloth; the second packaging layer is made of 30‑50 parts by weight of fiber cloth and 50‑70 parts by weight of the second packaging powder coating Prepared, the second packaged powder coating is evenly coated on the fiber cloth; wherein, the first packaged powder coating is acrylic powder coating or super weather-resistant polyester powder coating, and the second packaged powder coating is super weather-resistant polyester powder coating; The invention not only has low cost, but also effectively realizes the lightweight of photovoltaic module packaging materials under the premise of meeting the requirements of photovoltaic industry technical standards such as anti-ultraviolet, anti-aging, impact resistance, fire prevention, and anti-insulation, and is very suitable for use in the field of photovoltaics. Scale application.

Owner:SUNMAN (ZHENJIANG) CO LTD

Preparation method of laminated structure of photovoltaic assembly, laminated structure and photovoltaic assembly

ActiveCN108376717AEasy to install and implement applicationsGuaranteed flatnessFinal product manufacturePhotovoltaic energy generationHeating timeEngineering

The invention discloses a preparation method of a laminated structure of a photovoltaic assembly, the laminated structure and the photovoltaic assembly, prepared through a laminating process. The laminating process comprises a first heating stage, a second heating stage and a third pressurization cooling stage, wherein the heating temperature of the first stage ranges from 110 DEG C to 130 DEG C,and the heating time ranges from 100 seconds to 600 seconds; the heating temperature of the second stage ranges from 131 DEG C to 200 DEG C, and the heating time ranges from 100 seconds to 1200 seconds; and the cooling temperature of the third stage ranges from 25 DEG C to 60 DEG C, and the applied pressure ranges from 0.05Mpa to 0.25Mpa. The method has the advantages that the laminating process under a low-temperature environment is realized, the energy consumption is reduced, the flatness of the laminated structure of the photovoltaic assembly is ensured, and the installation and implementation application of the photovoltaic assembly are further facilitated.

Owner:SUNMAN (ZHENJIANG) CO LTD

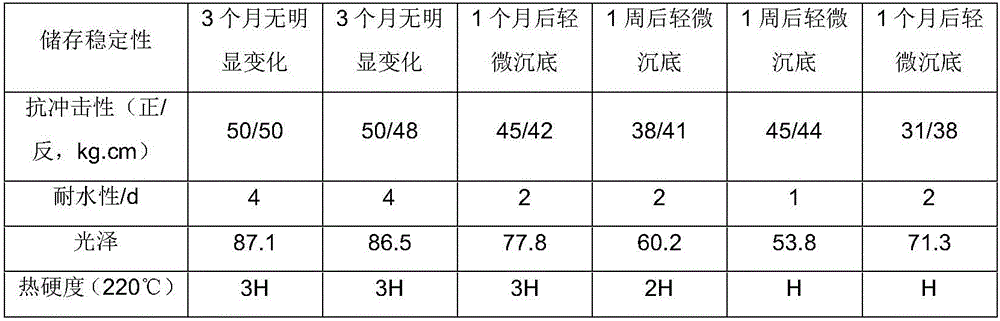

Pure epoxy quickly-cured powder coating and production method thereof

InactiveCN102002303AFast curingEnsure impact resistancePowdery paintsEpoxy resin coatingsEpoxyAntioxidant

The invention relates to the technical field of quickly curing powder coating, in particular to a pure epoxy quickly-cured powder coating and a production method thereof. The powder coating contains the following compounds according to percentages by weight: 52-57wt% of epoxy, 2-3wt% of curing agent, 0.1-1wt% of curing catalyst, 0.1-0.4wt% of benzoin, 0.7-1.4wt% of inlet flatting agent, 0.4-1.0wt% of castor oil, 5-10wt% of pigment, 0.3-1.2wt% of antioxidant and 28-35wt% of blanc fixe. Due to special curing catalyst and curing agent, the coating has high curing speed, and the impact resistance of the coating is guaranteed simultaneously.

Owner:JIANGSU HUAGUANG POWDER

Method for preparing laminated structure of photovoltaic module, laminated structure, photovoltaic module

ActiveCN108376717BEasy to install and implement applicationsGuaranteed flatnessFinal product manufacturePhotovoltaic energy generationThermodynamicsHeating time

A preparation method for a laminated structure of a photovoltaic assembly, the laminated structure and the photovoltaic assembly, which are prepared by using a lamination process. The lamination process comprises a first heating stage, a second heating stage, and a third pressurization and cooling stage. In the first stage, the heating temperature range is from 110ºC to 130ºC, and the heating time range is from 100 seconds to 600 seconds; in the second stage, the hating temperature range is from 131ºC to 200ºC, and the heating time range is from 100 seconds to 1200 seconds; and in the third stage, the cooling temperature range is from 25ºC to 60ºC, and the pressurization range is from 0.05 Mpa to 0.25 Mpa. The lamination process is implemented in a low-temperature environment, power consumption is reduced, and the flatness of the laminated structure of the photovoltaic assembly is ensured, thereby further facilitating the mounting, enforcement and application of the photovoltaic assembly.

Owner:SUNMAN (ZHENJIANG) CO LTD

Valve plate surface treating process

InactiveCN1432749AGuaranteed wear resistanceSimple process operationLiquid surface applicatorsAbrasion apparatusWear resistantSurface finishing

The valve plate surface treating process includes the preparation of base material, treatment of two sections of arcs and spraying treatment of two planes. The preparation of base material includes machining according to drawings and hardening and tempering of 42CrMo; the treatment of two sections of arcs includes blast spraying and one-step spray welding to solve the problems of making the arcs shock resistant and wear resistant; and the spraying treatment of two planes includes blast spraying and high speed flange spraying to make the two plane wear resistant. The valve plate thus produced is wear resistant and shock resistant and the technological process is simple and low in cost.

Owner:广州市天河区金棠表面工程技术有限公司

Low-energy-consumption powder coating for hub coating

InactiveCN111073455AImprove toughnessEnsure impact resistanceWax coatingsPowdery paintsFirming agentBenzoin

The invention discloses low-energy-consumption powder coating for hub coating, and relates to the technical field of powder coating. The low-energy-consumption powder coating comprises epoxy resin, cured polyester resin, a leveling agent, benzoin, auxiliary agents and pigment, and is characterized in that the coating is prepared from, by weight, 200-430 parts of the epoxy resin, 180 to 230 parts of the cured polyester resin, 8-10 parts of the leveling accelerator, 2-3 parts of the benzoin, 10 to 15 parts of the wax powder, 20 to 40 parts of the auxiliary agents and 2 to 10 parts of the pigment; the epoxy equivalent of the epoxy resin is about 650 to 750 g / EQ; the cured polyester resin is carboxyl acrylic polyester the acid value of which is about 50 to 60 mg KOH / g; the leveling acceleratorand the benzoin are respectively an acrylate copolymer and benzoin; the wax powder comprises Clariant degassing wax powder and BYK degassing wax powder; the auxiliary agents comprise a flow auxiliaryagent, a curing agent, a precipitating agent, a polishing agent and barium sulfate; the pigment comprises titanium dioxide, carbon black, iron oxide yellow and zinc chrome yellow; and the coating hasthe characteristics of low fixed energy consumption, good leveling effect and stable adhesion.

Owner:广东睿智环保科技股份有限公司

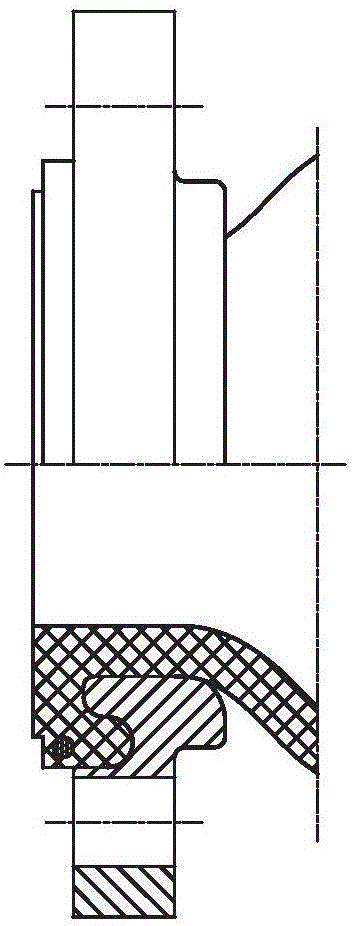

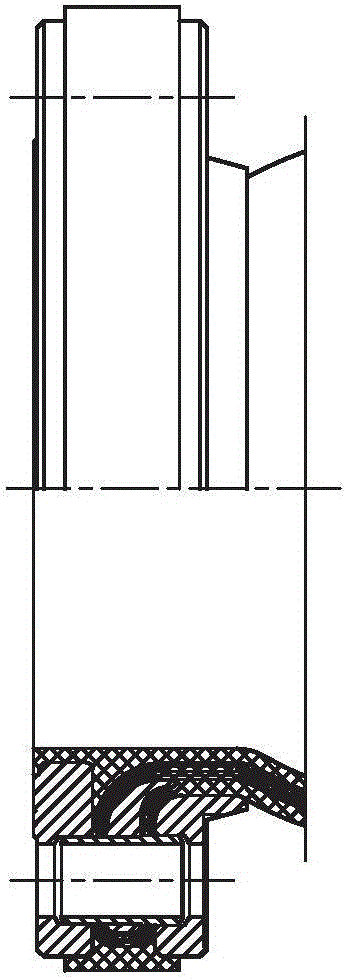

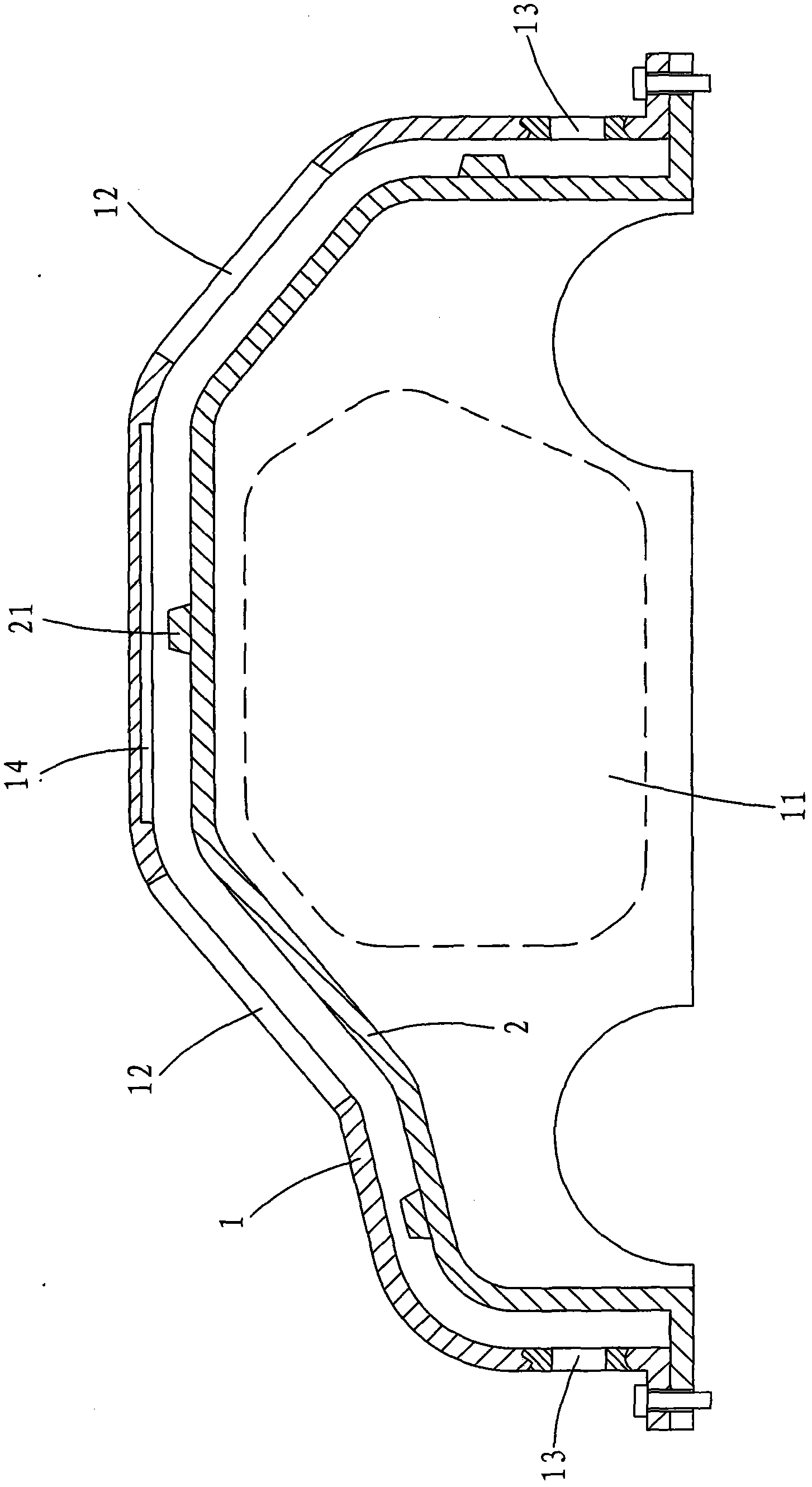

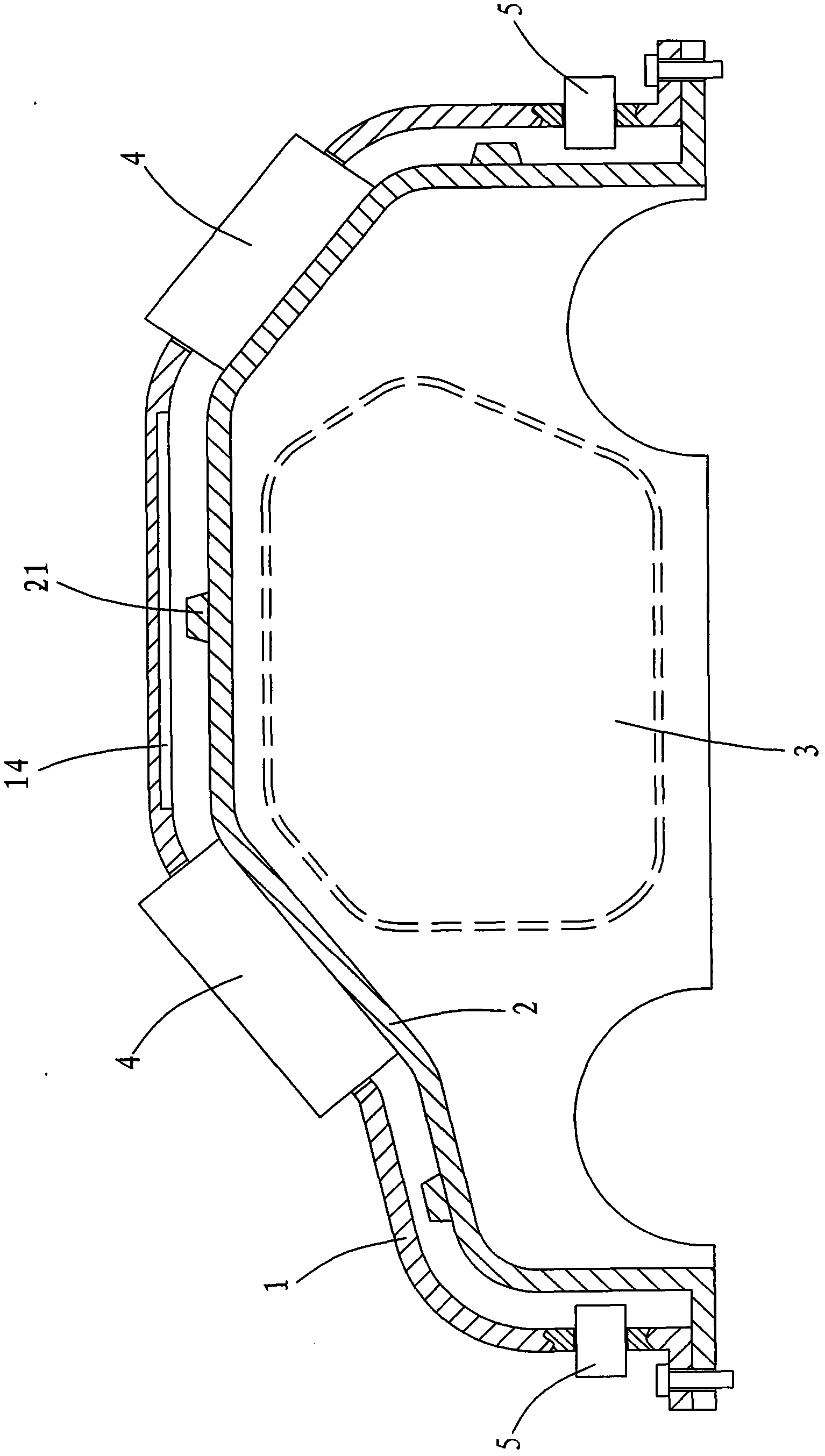

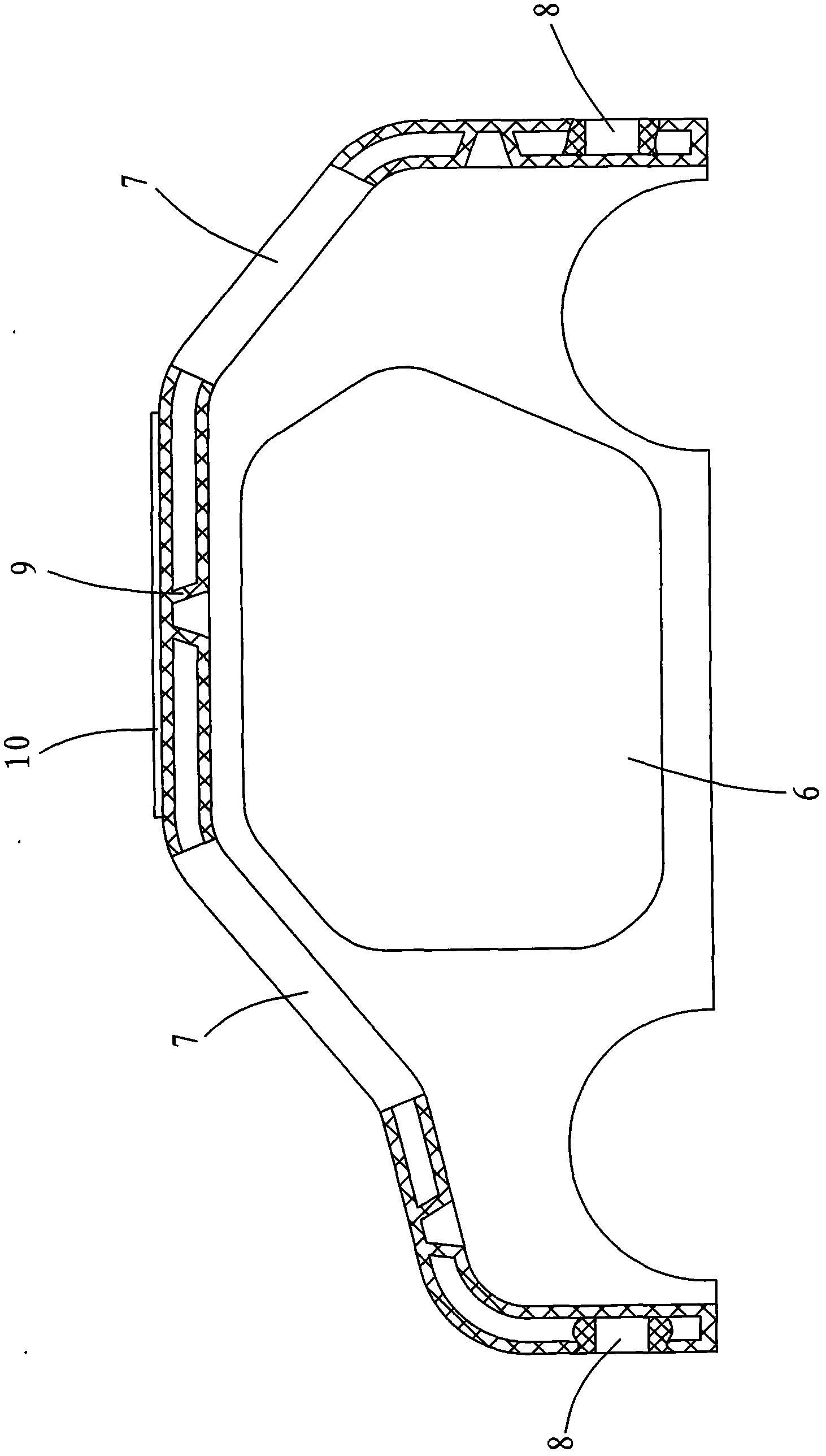

Large-diameter low-rigidity balancing flexible connecting tube for moveable flange and self-locking joint

The invention relates to a large-diameter low-rigidity balancing flexible connecting tube for a moveable flange and a self-locking joint. The connecting tube comprises a flexible tube body and buckling joints, wherein an inner glue layer, a skeleton layer and an outer glue layer are successively arranged in the flexible tube body from inner to outer; the buckling joints are symmetrically arranged at the two ends of the flexible tube body; each of the buckling joints comprises an outer pressing ring and an inner pressing ring; the outer pressing ring is arranged on the exterior of the inner glue layer at the end part of the flexible tube body in a sleeving manner; the front end of the skeleton layer is outward back turned and reversely wrapped on the front end face and the side wall of an annular plate; the inner glue layer, the skeleton layer, the outer glue layer, the outer pressing ring and the inner pressing ring are vulcanized and integrally formed. Through the symmetrical structures at the two ends of the tube body and the structure of the buckling joints, the technical problems of the traditional connecting tube of easiness in creeping, aging and losing efficacy, falling risk, complex joint structure, high dead weight, low flexibility, inferior vibration-reducing noise-attenuating effect, insufficient displacement compensation performance and easiness in cracking of welding joint are solved.

Owner:NAVAL UNIV OF ENG PLA +1

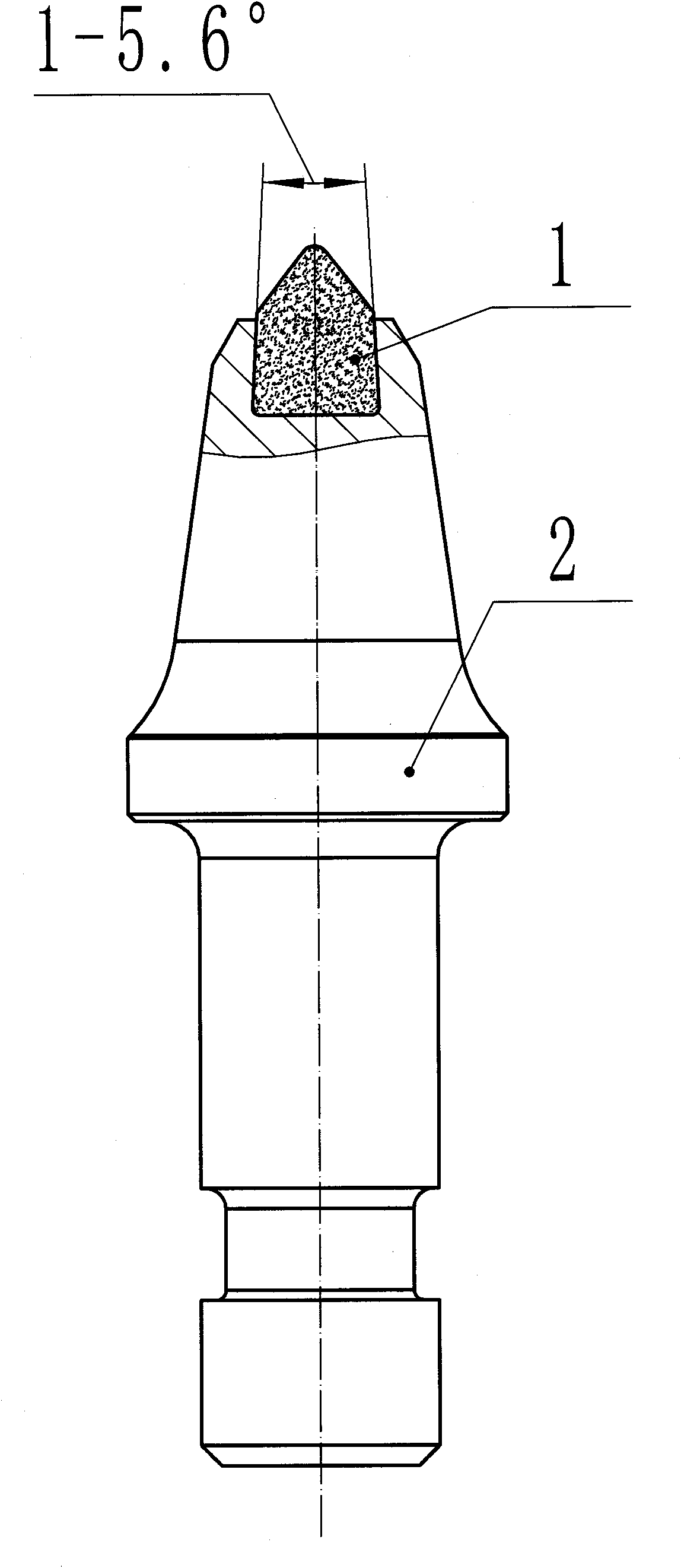

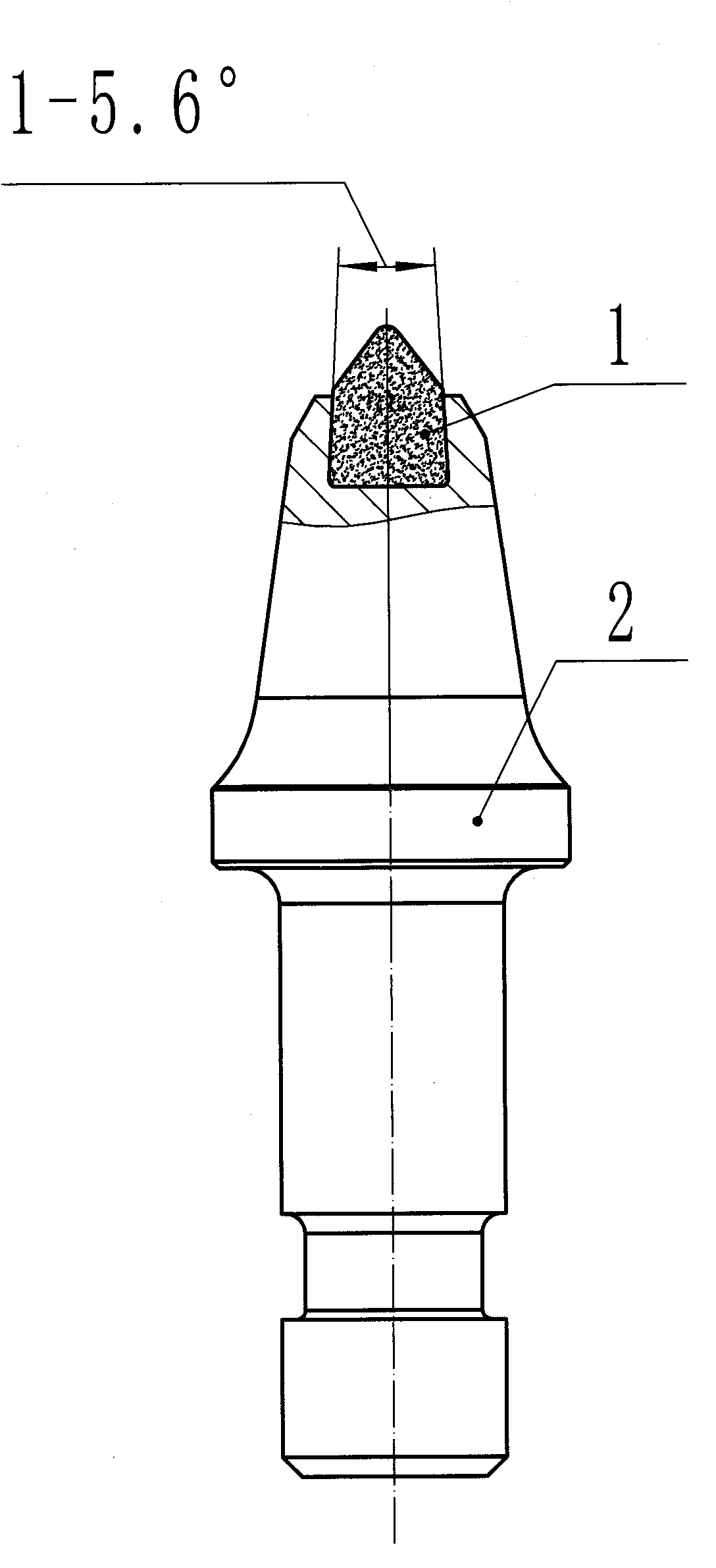

Welding-free cutting bit

InactiveCN101876251AEnsure impact resistanceAvoid welding processSlitting machinesImpact resistanceMaterials science

The invention provides a welding-free cutting bit which relates to a mining tool, in particular to a cutting bit used in the excavating, driving and crushing of mines, roads and the like. The cutting bit comprises a cutting bit body and a hard alloy head fixed on the head of the cutting bit body, wherein the working part of the hard alloy head is a cone, and the angle of cone is 60-130 degrees. The cutting bit is characterized in that the mounting-pressing part of the hard alloy head is a cone, the angle of cone is 1.0-5.6 degrees; the mounting hole on the head of the cutting bit body is a tapered hole with the same shape of the mounting-pressing part of the hard alloy head, and all the surfaces of the mounting hole closely stick to all the surfaces of the mounting-pressing part of the hard alloy head. The invention has the advantage that the firm joint of the cutting bit body and the hard alloy head can be ensured, the impact resistance and twisting resistance of the cutting bit can be ensured in use and the traditional welding technology can be avoided so as to thoroughly eliminate various defects of primitive welding.

Owner:盐城中德精锻股份有限公司

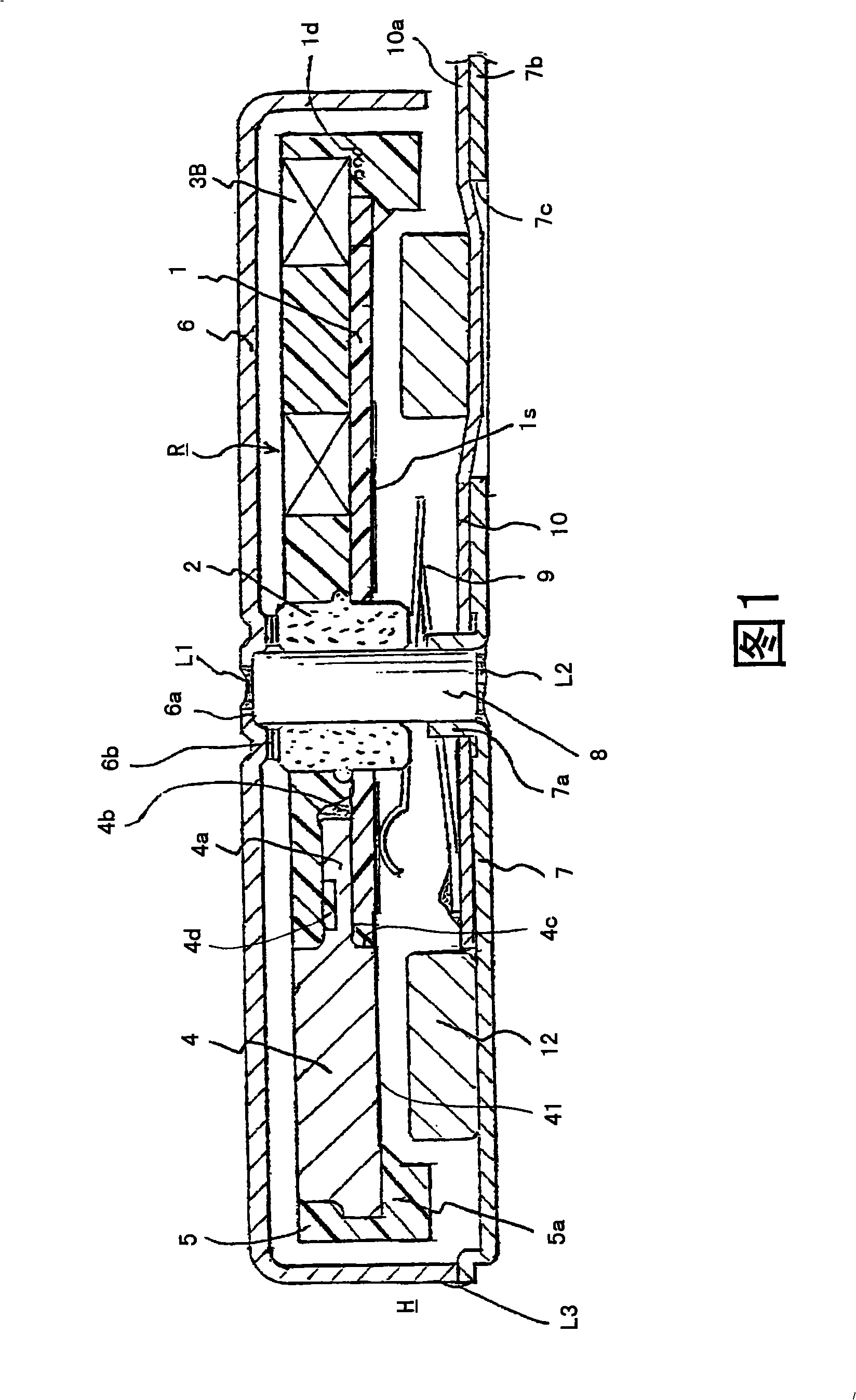

Axial gap type eccentric rotor and axial gap type coreless vibrating motor using said rotor

InactiveCN101330242ASturdyEnsure impact resistanceMechanical vibrations separationDC commutatorSolderingPrinted circuit board

The present invention provides an axial direction gap type eccentric rotor which can fully ensure thin type and strength based on a mounting structure of an eccentric weight, which comprises: winding type coreless armature windings (3A, 3B, 3C), a printed circuit board (1) arranged with a converter (C) on one side and connected with the end connection of the winding type coreless armature windings on the other side, an eccentric weight is soft soldering on the other side of the printed circuit board by a tongue (4a) on the printed circuit board, a bearing (2) arranged at the center of the printed circuit board and a resin (5) making them become one.

Owner:TOKYO PARTS IND CO LTD

A kind of color photovoltaic module and preparation method thereof

ActiveCN108242473BEasy to operateReduce installation costsPowdery paintsPhotovoltaic energy generationPhotovoltaic industryEngineering

The invention discloses a color photovoltaic module and a preparation method thereof. The color photovoltaic module comprises a lamination structure which is formed by laminating a first packaging part, a first packaging adhesive film layer, a solar cell string and a second packaging part. The first packaging part comprises a transparent film layer which is prepared from a color thermoplastic high-molecular polymer, and the relative molecular mass of the color thermoplastic high-molecular polymer is greater than 20000. The color photovoltaic module costs low and is light. Under the premise that the technical standard requirements for ultraviolet resistance, aging resistance, impact resistance, fire prevention and insulation resistance in the photovoltaic industry are satisfied, the packaging material of the photovoltaic module is light, the installation cost of the photovoltaic module is reduced on the whole, and the photovoltaic module is very suitable for large-scale promotion and application in the field of photovoltaic building materials. Moreover, the appearance color of the photovoltaic module can be freely selected and changed, and the photovoltaic module looks more beautiful.

Owner:SUNMAN (ZHENJIANG) CO LTD

One-step molding process of double-layer plastic vehicle shell

InactiveCN102729383ASimple structureSimplify the manufacturing processDomestic articlesCoatingsCooling chamberEngineering

The invention provides a one-step molding process of a double-layer plastic vehicle shell, and the process comprises the steps of: (1) manufacturing a concave die and a convex die respectively based on the contour of a vehicle shell, and manufacturing various loose cores additionally; (2) inserting various the loose cores into the concave die, and adding powdered plastics into the concave die and the convex die; (3) conducting die closing; (4) shifting the dies into a heating chamber, and making them rotate ceaselessly along a main shaft and an auxiliary shaft that are mutually perpendicular, as well as conducting heating; (5) shifting the dies into a mist cooling chamber for mist cooling; (6) shifting the dies into an aeration and pressure maintaining chamber for aeration, pressure maintaining and shaping; (7) shifting the dies into a wind cooling chamber for wind cooling; (8) dismantling all loose cores and releasing the dies so as to obtain a double-layer plastic vehicle shell product with reserved various accessory mounting holes; and (9) shaping the various accessory mounting holes of the product through shaping dies. In the invention, the whole double-layer plastic vehicle shell is molded in one step through the above rotational molding process, so that the manufacturing process and the die structure are greatly simplified. And the molding process of the invention has the advantages of convenient manufacturing, high production efficiency, low manufacturing cost, and good product performance, etc.

Owner:应革

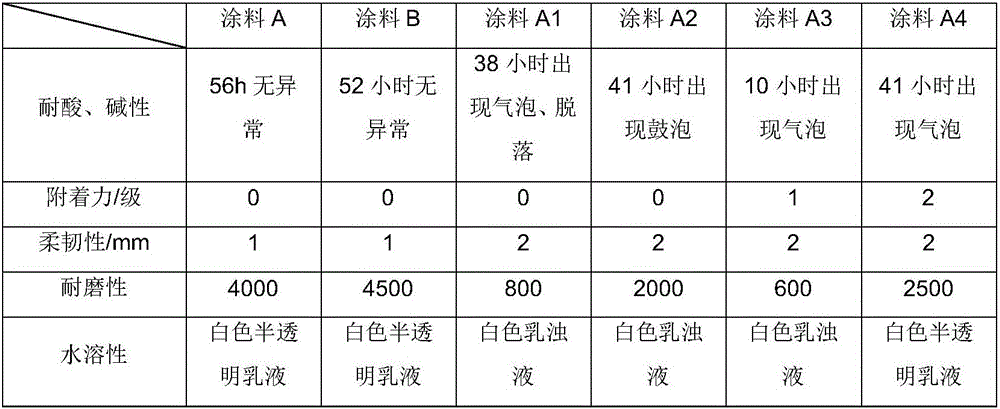

Water-soluble organic silicon coating

The invention provides a water-soluble organic silicon coating which comprises aqueous organic silicon resin, nano silicon dioxide, titanium dioxide, an additive and the balance of water, wherein the weight ratio of the aqueous organic silicon resin to the nano silicon dioxide to the titanium dioxide to the additive is (70-80):(1-5):(0.5-1):(5-20), wherein the nano silicon dioxide is powder of which the average particle size is 100-300 nanometers; the fineness of the titanium dioxide is greater than 6000 meshes; and the aqueous organic silicon resin is modified by using polyester and epoxy resin and has the acid value of 25+ / -10mgKOH / g. The prepared water-soluble organic silicon coating is relatively high in thermal hardness.

Owner:FOSHAN POLIMA ADVANCED TECH & SUPPLIES CO LTD

Laminated structure of double-surface component and manufacturing method thereof, and the double-surface component

ActiveCN108695401AReduce weightReduce installation costsPhotovoltaic energy generationSemiconductor devicesPolyesterPhotovoltaic industry

The invention discloses the laminated structure of a double-surface component. The structure comprises a first packaging layer, a solar cell string and a second packaging layer. The structure is characterized in that the first packaging layer includes a first base fabric layer and a first packaging coating, and the first packaging coating is an acrylic coating or a super weather resistant polyester coating; the second packaging layer includes a second base fabric layer and a second packaging coating, and the second packaging coating is the super weather resistant polyester coating; and the solar cell string is a double-surface cell. In the invention, cost is low, under the condition of satisfying photovoltaic industry technology standard requirements, such as anti-ultraviolet performance,anti-aging performance, anti-shock performance, fireproof performance, anti-insulation performance and the like, the light weight of a photovoltaic component packaging material is effectively realized, a light absorption area is increased, output power is increased too, and the structure is very suitable for scale promotion and application in a photovoltaic field.

Owner:SUNMAN (ZHENJIANG) CO LTD

Thermoplastic resin composition

Owner:TORAY IND INC

Fuel tank for automobile

InactiveCN101332768AImprove rigidityInhibit swellingSynthetic resin layered productsUnderstructuresMobile vehicleSurface layer

Owner:FTS

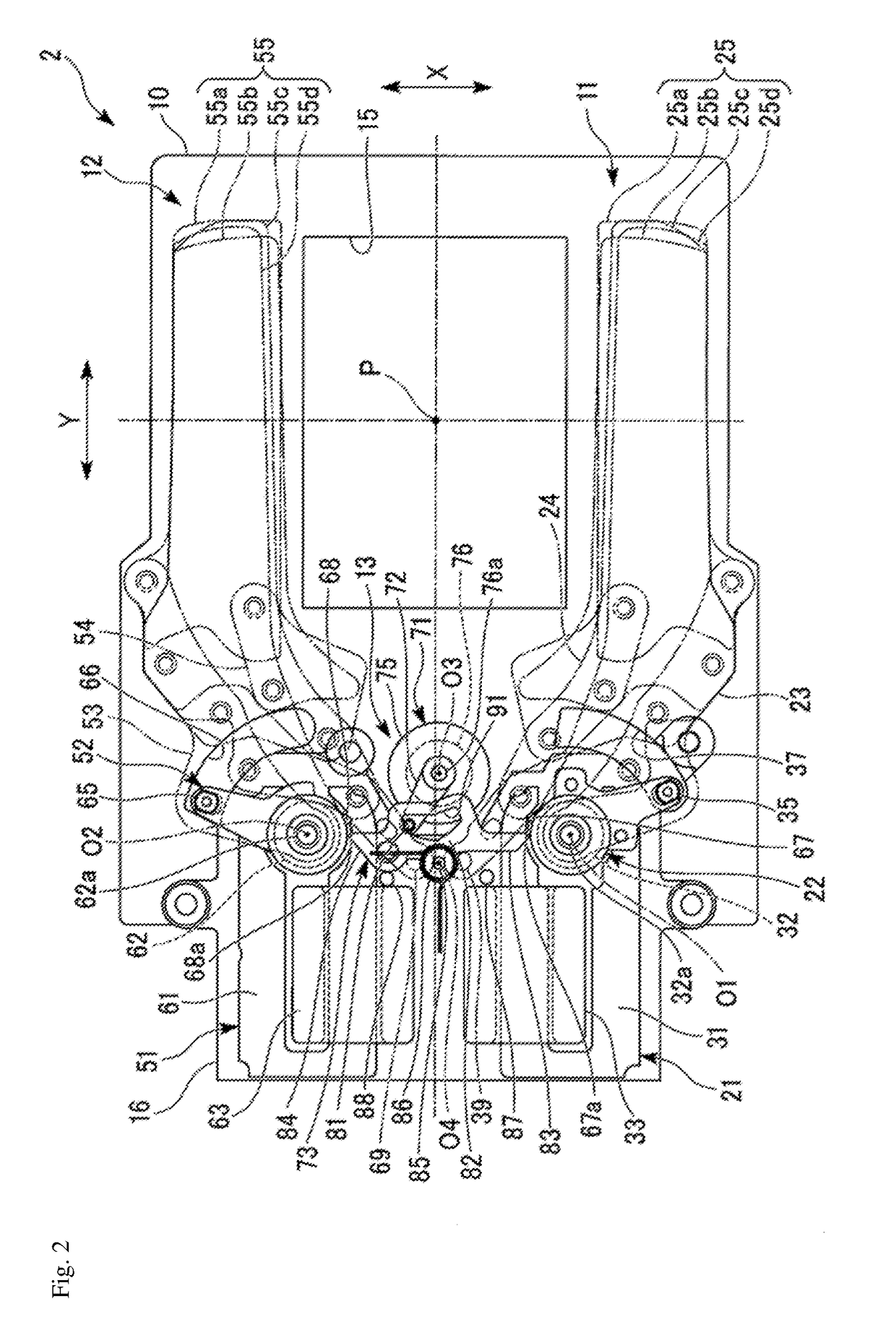

Blade drive device and optical instrument

ActiveUS20180004066A1Impact resistanceLess likely can be quickenedShuttersCamera diaphragmsEngineeringOptical instrument

There is provided a blade drive device including a substrate that has an opening, a front curtain and a rear curtain that are movable along an opening surface of the opening so as to open and close the opening, a front curtain electromagnetic actuator that actuates the front curtain, a rear curtain electromagnetic actuator that actuates the rear curtain, and that is capable of holding the rear curtain at an open position in a state having no power supply, a front curtain locking portion that interlocks with opening and closing operations of the front curtain, a rear curtain locking portion that interlocks with opening and closing operations of the rear curtain, and a blade position holding mechanism that is capable of entry and escape between an entry position which enters each operation trajectory of the front curtain locking portion and the rear curtain locking portion in response to the opening and closing operations of the front curtain and the rear curtain and an escape position escaped from the operation trajectory. At the entry position, the blade position holding mechanism can engage with both the front curtain locking portion and the rear curtain locking portion, thereby regulating the movement of the front curtain and the rear curtain in the closing direction.

Owner:SEIKO GRP CORP

Slope type seawall and construction method thereof

The invention relates to a slope type seawall and a construction method thereof. The slope type seawall comprises a seawall foundation, a water facing slope surface, a water backing slope surface anda seawall top, and is characterized in that the water facing slope surface comprises a prefabricated cushion layer, a prefabricated surface layer, a steel reinforcement framework and a filling concrete layer, the prefabricated cushion layer is formed by splicing a plurality of first prefabricated plates laid on the water facing side of the seawall foundation, and the first prefabricated plates arefixed to the seawall foundation through anchor rods; the prefabricated surface layer is located above the prefabricated cushion layer, the prefabricated surface layer and the prefabricated cushion layer are arranged in parallel, and the prefabricated surface layer is formed by splicing a plurality of second prefabricated plates; the steel reinforcement framework is arranged between the prefabricated cushion layer and the prefabricated surface layer, and the upper side and the lower side of the steel reinforcement framework are fixed to the prefabricated surface layer and the prefabricated cushion layer correspondingly; and a space between the prefabricated cushion layer and the prefabricated surface layer is filled with the filling concrete layer. The slope type seawall has the effect ofimproving the situation that the seawall upstream slope deforms due to sea wave impact in the construction process.

Owner:福建万山水利水电设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com