Propelling method for combined portion between shield tunnel segment and mine tunnel segment in subway tunnel

A technology for shield tunneling and joint parts, which is applied in tunnels, tunnel linings, underground chambers, etc., and can solve problems such as high requirements for shield propulsion deviation control, low allowable deviation error rate, and surface subsidence, so as to reduce construction risks , reduce disturbance, and greatly support the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

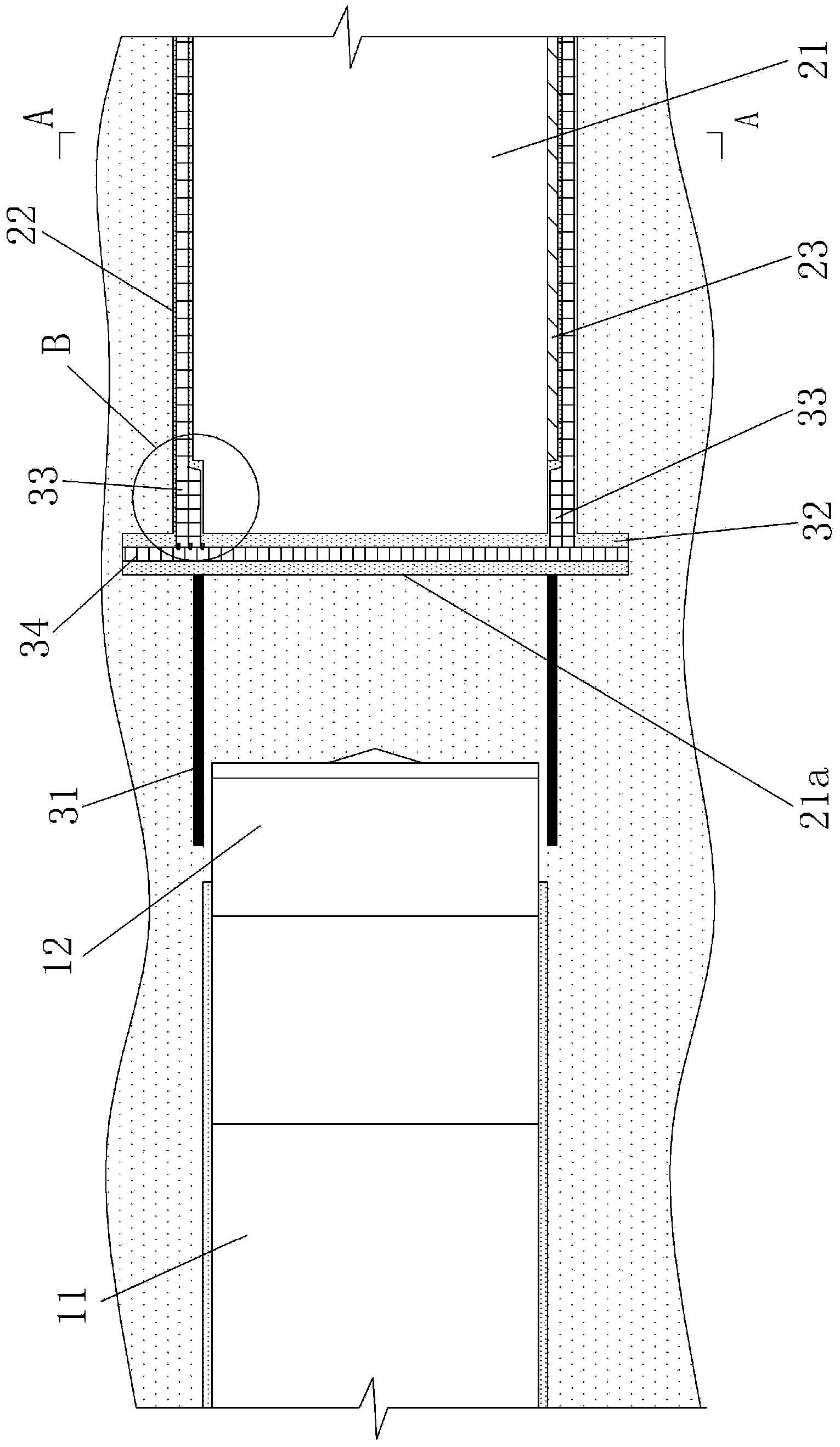

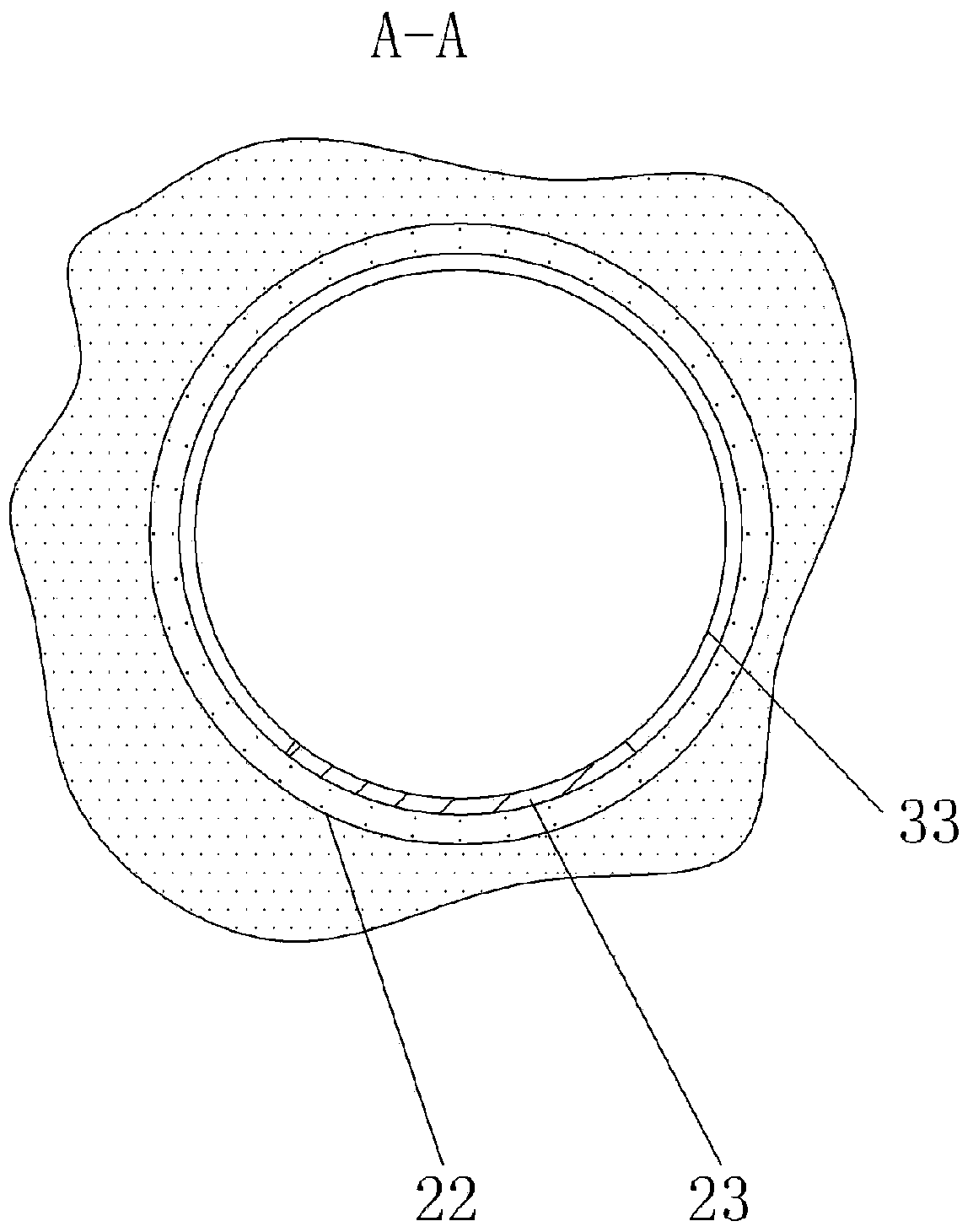

[0023] Figure 1-3 Shown, a kind of embodiment of the present invention is, a kind of advancing method of shield tunnel section and mine tunnel section joint position in a kind of subway tunnel, and its steps are:

[0024] A method for advancing the junction of a shield tunnel section and a mine tunnel section in a subway tunnel, the steps of which are:

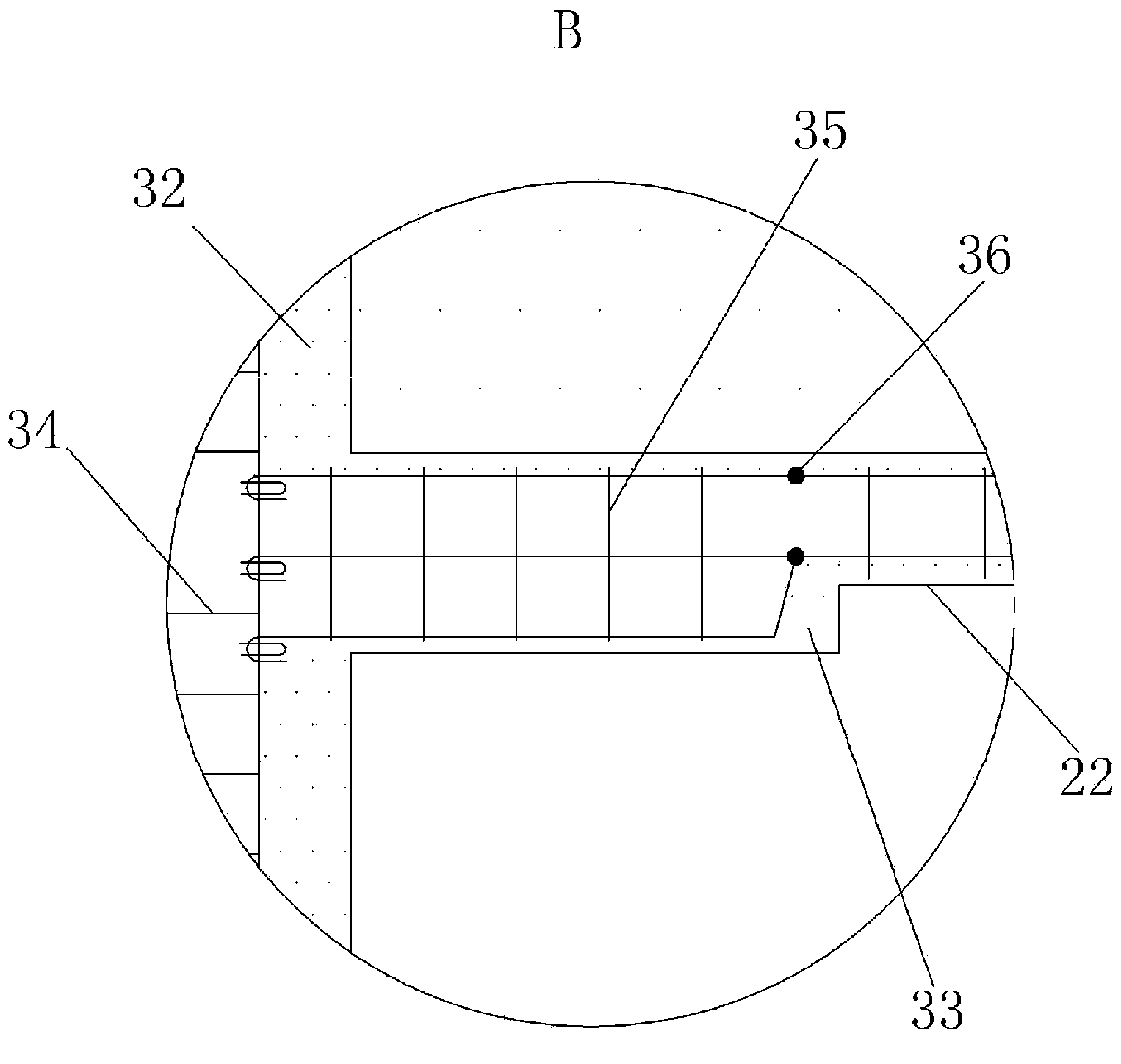

[0025] A. The mine tunnel section 21 is constructed first, and then a circular steel sleeve 31 is horizontally driven into the surrounding rock in front of the mine tunnel section 21 face 21a, and the rear end face of the steel sleeve 31 is flush with the face 21a. Then apply grouting support to the face 21a;

[0026] B. Closely attached to the shotcrete support and binding the glass fiber reinforcement 34 separating the end wall, and the glass fiber reinforcement 34 is bound and connected with the ring beam behind it with a steel bar 35, and the steel bar 35 for the ring beam is connected with the initial support of the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com