Low-energy-consumption powder coating for hub coating

A powder coating, low energy consumption technology, applied in powder coatings, wax coatings, polyester coatings, etc., can solve the problems of difficult adhesion, high curing energy consumption, general leveling effect, etc., to achieve increased toughness, reduced energy consumption, guaranteed The effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

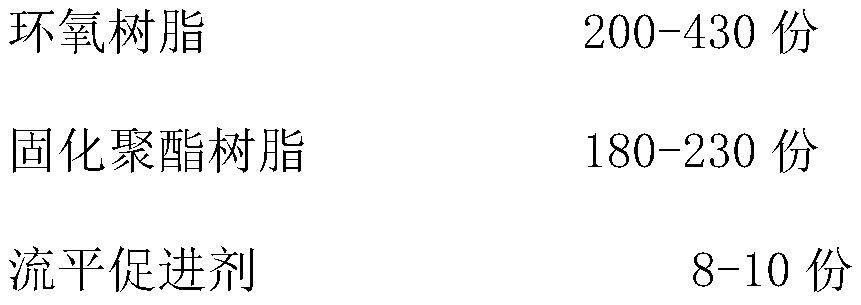

[0021] Prepared from the following components by weight:

[0022]

[0023] Wherein the epoxy equivalent of the epoxy resin is 650g / EQ, and the carboxyl acrylic polyester is 50mg KOH / g.

Embodiment 2

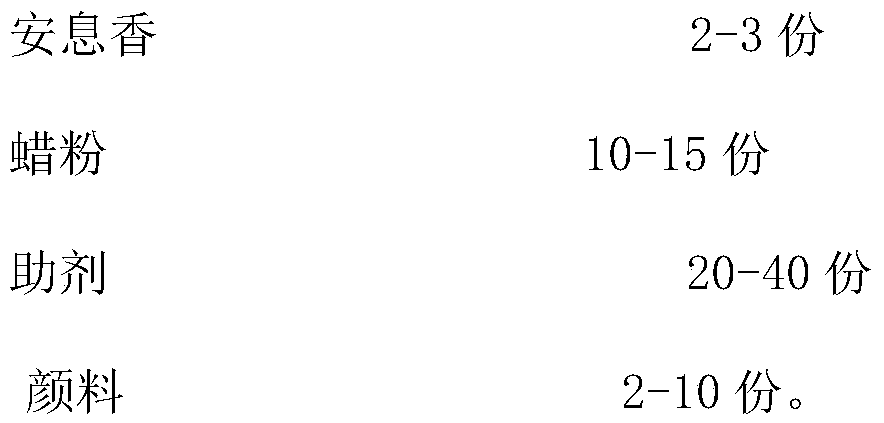

[0025] Prepared from the following components by weight:

[0026]

[0027] Wherein the epoxy equivalent of the epoxy resin is 730g / EQ, and the carboxyl acrylic polyester is 60mg KOH / g.

[0028] Get the experimental result mean value after the experiment to embodiment 1-3:

[0029]

[0030]

[0031] The epoxy equivalent of epoxy resin is about 650-750g / EQ, and the cured polyester resin is carboxy acrylic polyester, and carboxy acrylic polyester is about 50-60mg KOH / g. Since carboxy acrylic polyester is a low-temperature curing polyester resin, According to the above material ratio, the curing temperature during production can be reduced from the traditional 190°C x 15min to 150°C x 20min, so it can reduce the energy consumption during painting production, increase the toughness of the aluminum wheel hub, and ensure the durability of the wheel hub. Impact resistance, carboxylated acrylic polyester reacts with epoxy to obtain a relatively high leveling effect; use hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com