Water-soluble organic silicon coating

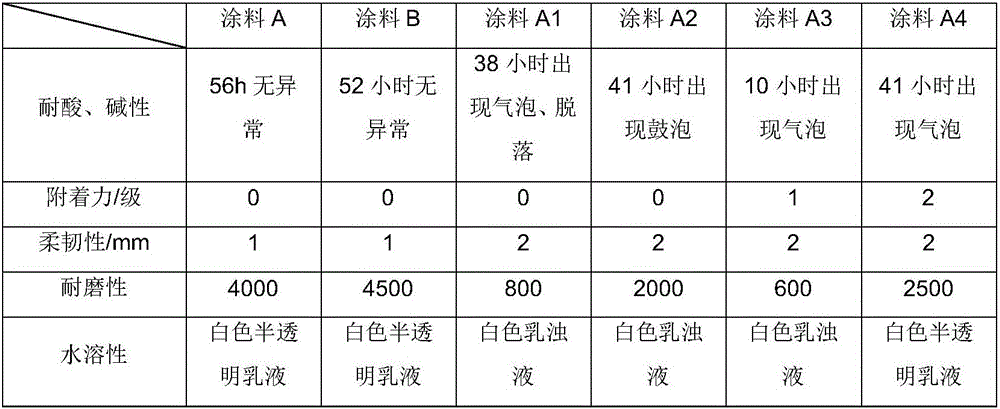

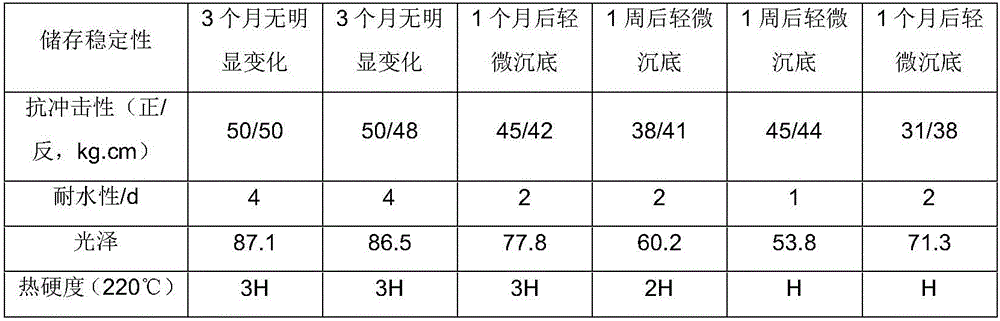

A silicone coating, water-soluble technology, used in fire-resistant coatings, coatings, etc., can solve problems such as poor thermal hardness and other physical properties, and achieve high wear resistance, good thermal hardness, and good hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of water-based silicone resin: Add 20g of trihydric alcohol, 30g of dihydric alcohol, 35g of dibasic acid and 15g of epoxy resin into the reactor, heat it to 170°C, and add 0.4g of phosphoric acid after the material is dissolved and kept for 1 hour Triphenyl ester, control the temperature at 200°C, react until the acid value is less than 8.0, add 75g of methylphenyl silicone resin intermediate, 0.5g of tetrabutyl titanate to react, the reaction temperature is 180°C, and the reaction time is 4 Hours, when the reaction acid value is lower than 8mgKOH / g, dropwise add 5g of trimellitic anhydride to carry out water-based capping, keep the reaction temperature, react for 2 hours, when the acid value is 25 ± 10mgKOH / g, the reaction is completed, and water-based silicone resin A is prepared.

[0046] Preparation of water-soluble silicone coating: 70g of water-based silicone resin A, 4g of nano-silica (a powder with a particle size of 200 nanometers) was blended for 1...

Embodiment 2

[0048] Preparation of water-based silicone resin: Add 25g of trihydric alcohol, 25g of dihydric alcohol, 40g of dibasic acid and 10g of epoxy resin into the reactor, heat it to 170°C, and add 0.3g of phosphoric acid after the material is dissolved and kept for 1 hour Triphenyl ester, control the temperature at 200°C, react until the acid value is less than 8.0, add 75g of methylphenyl silicone resin intermediate, 0.5g of tetrabutyl titanate to react, the reaction temperature is 180°C, and the reaction time is 4 Hours, when the reaction acid value is lower than 8mgKOH / g, dropwise add 5g of trimellitic anhydride to carry out water-based capping, keep the reaction temperature, react for 2 hours, when the acid value is 25 ± 10mgKOH / g, the reaction is completed, and the water-based silicone resin B is prepared.

[0049] Preparation of water-soluble silicone coating: 75g of water-based silicone resin B and 1g of nano-silica (a powder with a particle size of 200 nm) were blended at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com