Electric double-layer capacitor and manufacturing method thereof

A technology for electric double layer capacitors and manufacturing methods, applied in hybrid/electric double layer capacitor manufacturing, hybrid box/housing/packaging, etc., capable of solving problems such as hard-to-separate polar electrode sticking points, shortened service life, and increased internal resistance , to achieve the effect of not easy to reduce deformation, increase adhesive force, and evenly distribute adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

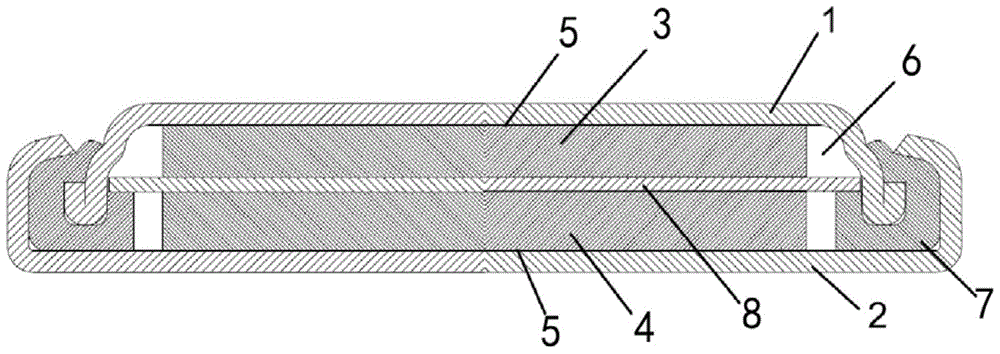

[0027] A method for manufacturing an electric double layer capacitor, comprising the steps of:

[0028] Step 1, manufacture the polarized first electrode and second electrode of a certain diameter and thickness, the raw materials and mass percentages are as follows: 80% coconut water-based activated carbon powder, 10% carbon black conductive agent, 10% concentration is 40% Teflon PTFE adhesive, water (Water) and IPA (Isopropyl Alcohol) dimethylmethanol are used as the solvent, the above raw materials are mixed and manufactured into a cylindrical shape, and then cut into pieces with a diameter of 4mm and a thickness of 0.6mm Polarity electrodes;

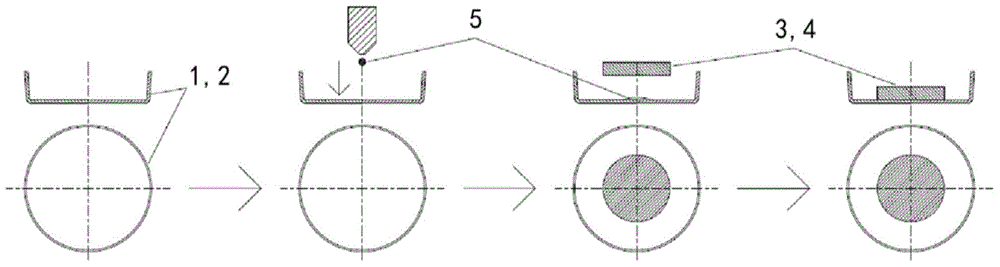

[0029] Step 2, such as Figure 4 As shown, use a screen printer to print the conductive adhesive into a circular conductive adhesive sheet with a diameter of 4 mm and a thickness of 10 μm, and use a Teflon rod to transfer and paste it to the inner wall of the inner shell and the outer shell;

[0030] Step 3. Paste the two polarized ...

Embodiment 2

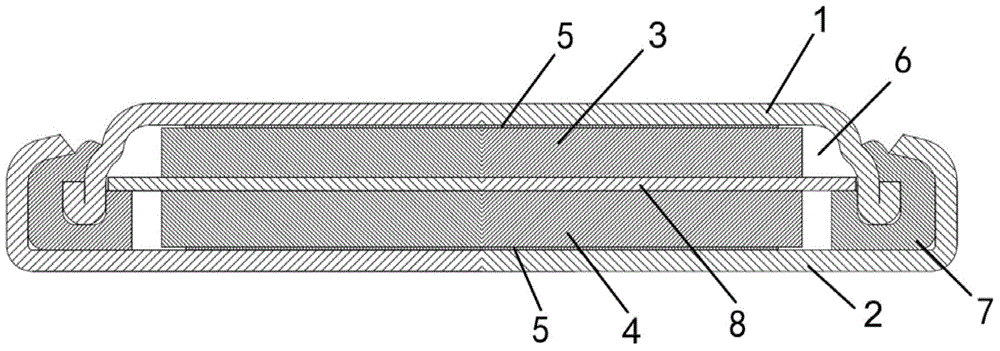

[0035] On the basis of Example 1, different from Example 1, in step 2, the size of the conductive adhesive sheet printed using the screen printing method is 90% of the diameter of the polarized electrode, and the polarized electrode The diameter of the conductive adhesive sheet is 4 mm, the diameter of the conductive adhesive sheet is about 3.6 mm, and the thickness of the conductive adhesive sheet is 10 μm.

Embodiment 3

[0037]On the basis of Example 1, different from Example 1, in step 2, the size of the conductive adhesive sheet printed using the screen printing method is 90% of the diameter of the polarized electrode, and the polarized electrode The diameter of the conductive adhesive sheet is 4 mm, the diameter of the conductive adhesive sheet is about 3.6 mm, and the thickness of the conductive adhesive sheet is 30 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com