Eccentric fan

一种离心风扇、出风口的技术,应用在仪器、电数字数据处理、数字数据处理零部件等方向,能够解决产品不良、生产成本高、舌口厚度大等问题,达到不易收缩变形、降低生产成本、节省原料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

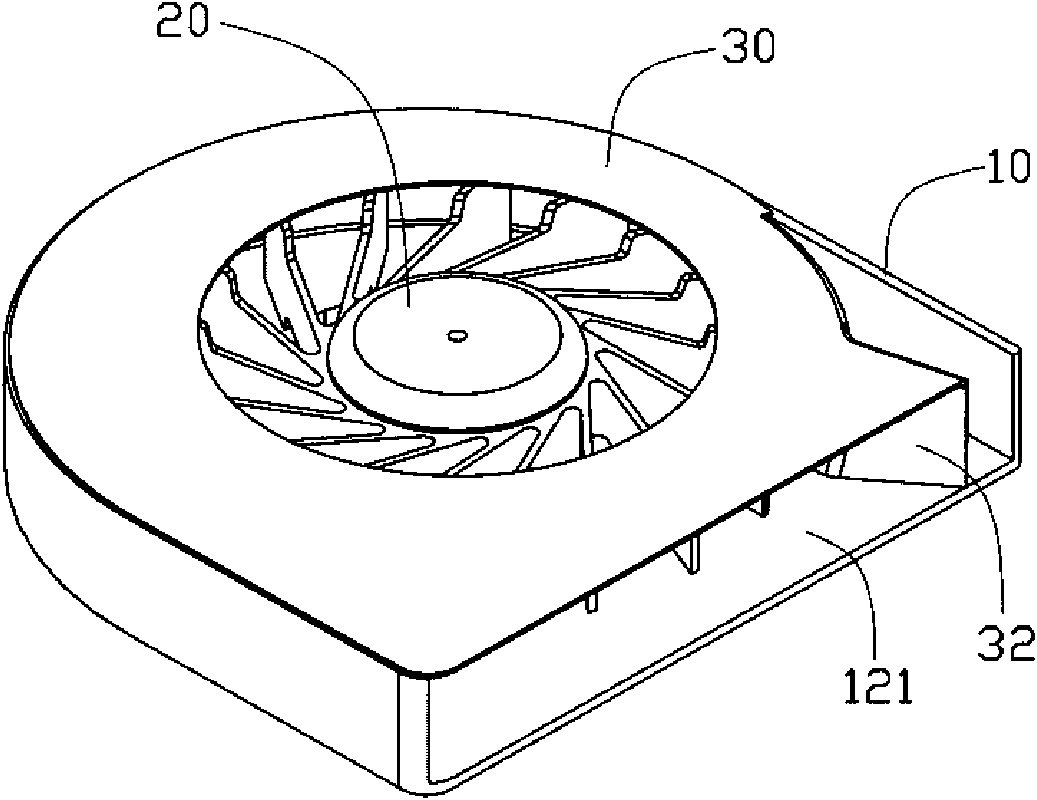

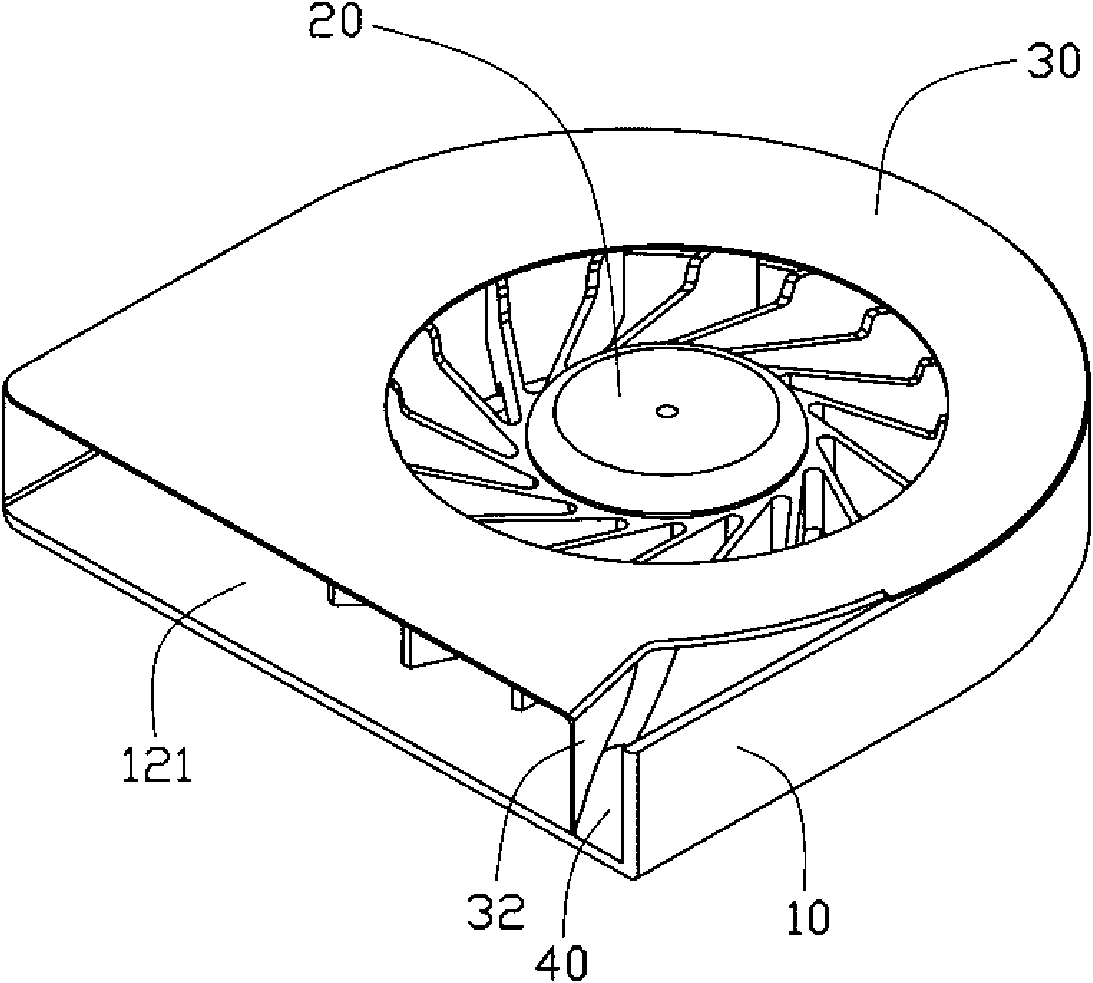

[0016] Please refer to figure 1 and figure 2 , the centrifugal fan includes a base 10 , a stator (not shown) and a rotor 20 accommodated in the base 10 , and a cover plate 30 covering the base 10 .

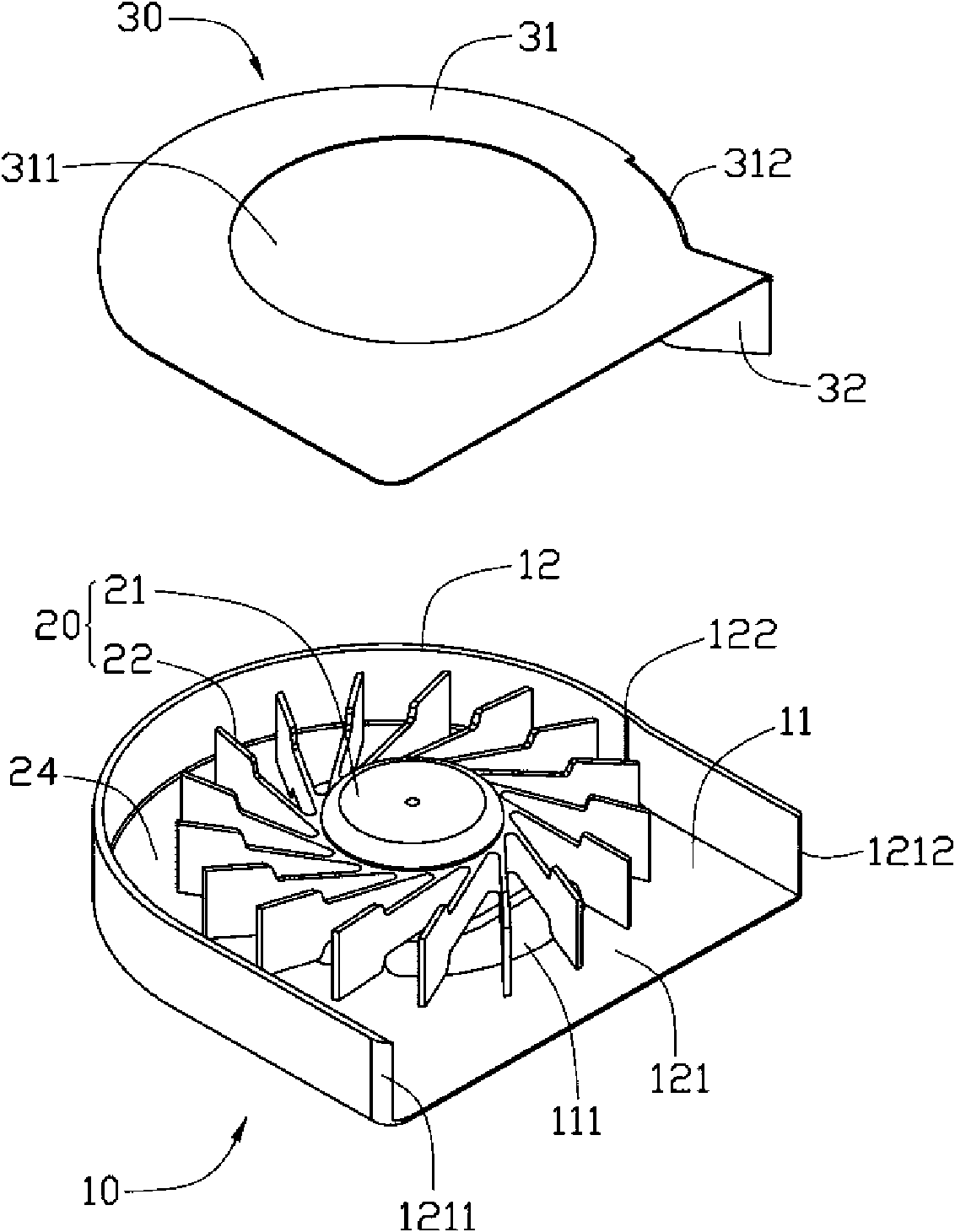

[0017] Please refer to image 3 , the base 10 includes a bottom plate 11 and a side wall 12 extending upward from the periphery of the bottom plate 11 . An air inlet 111 is defined in the middle of the bottom plate 11 corresponding to the position of the rotor 20 . The side wall 12 has a spiral shape, and an air outlet 121 perpendicular to the air inlet 111 is formed on one side thereof. In this embodiment, the rotor 20 rotates counterclockwise, and the air outlet 121 has a near-wind end 1211 on one side and a far-wind end 1212 opposite to the near-wind end 1211 and on the other side. When the centrifugal fan is working, the rotor 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com