Processing method for instant crisp pumpkin chip

A processing method and technology of pumpkin crisps, applied in the field of instant pumpkin crisps processing, can solve problems such as difficulty in guaranteeing product quality, achieve the effects of improving production efficiency, reducing energy consumption, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

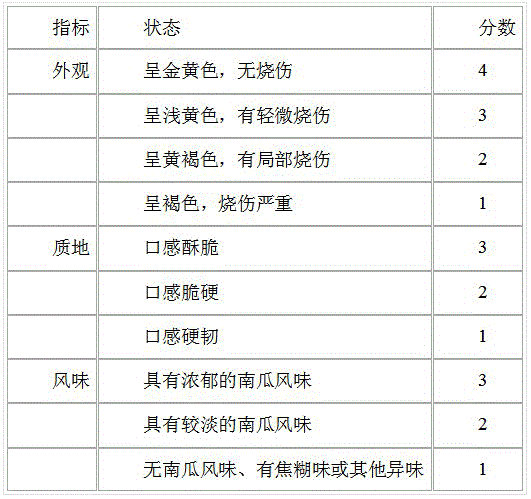

[0021] Choose mature pumpkins with the same size and color, no pests, no damage, and mature pumpkins as raw materials. Wash the pumpkins with tap water to remove the soil and impurities on the surface. Cut the pumpkin in half along the central axis, remove the seeds and pulp, then use a self-made cylindrical mold to cut into cylindrical shapes perpendicular to the central axis, and then use a slicer to cut into 2 mm disc-shaped pumpkin slices. The cut pumpkin slices were blanched in hot water at 75°C for 1.5 min, and cooled with cold water immediately after blanching. Spread the blanched and drained pumpkin slices in a single layer on a microwave plate, which is geometrically symmetrically placed in a microwave vacuum dryer and rotated at a speed of 10 r / min. Under the conditions of microwave intensity of 4 W / g and chamber pressure of 30kPa, the pumpkin slices were vacuum-dried to a moisture content of 4%-6% on a wet basis. Vacuum-pack the product immediately after cooling, a...

Embodiment 2

[0023] Choose mature pumpkins with the same size and color, no pests, no damage, and mature pumpkins as raw materials. Wash the pumpkins with tap water to remove the soil and impurities on the surface. Cut the pumpkin in half along the central axis, remove the seeds and flesh, then use a self-made cylindrical mold to cut into cylindrical shapes perpendicular to the central axis, and then use a slicer to cut into 6 mm disc-shaped pumpkin slices. The cut pumpkin slices were blanched in hot water at 85°C for 1 min, and cooled with cold water immediately after blanching. Spread the blanched and drained pumpkin slices in a single layer on a microwave plate, which is geometrically symmetrically placed in a microwave vacuum dryer and rotated at a speed of 10 r / min. Under the conditions of microwave intensity of 10 W / g and chamber pressure of 20kPa, the pumpkin slices were vacuum-dried to a moisture content of 4%-6% on a wet basis. Vacuum-pack the product immediately after cooling, a...

Embodiment 3

[0025] Choose mature pumpkins with the same size and color, no pests, no damage, and mature pumpkins as raw materials. Wash the pumpkins with tap water to remove the soil and impurities on the surface. Cut the pumpkin in half along the central axis, remove the seeds and flesh, then use a self-made cylindrical mold to cut into cylindrical shapes perpendicular to the central axis, and then use a slicer to cut into 8 mm disc-shaped pumpkin slices. The cut pumpkin slices were blanched in hot water at 95°C for 0.5 min, and cooled with cold water immediately after blanching. Spread the blanched and drained pumpkin slices in a single layer on a microwave plate, which is geometrically symmetrically placed in a microwave vacuum dryer and rotated at a speed of 10 r / min. Under the conditions of microwave intensity of 8 W / g and cavity pressure of 10kPa, the pumpkin slices were vacuum-dried to a moisture content of 4%-6% on a wet basis. Vacuum-pack the product immediately after cooling, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com