High-strength lightweight aggregate concrete and preparation method thereof

A lightweight aggregate concrete, high-strength technology, applied in the field of new building materials, can solve the problems of unfavorable lightweight aggregate concrete stability, little improvement in concrete strength, low activity of stone tailings, etc. Ambient pressure, effects of improving mechanical properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

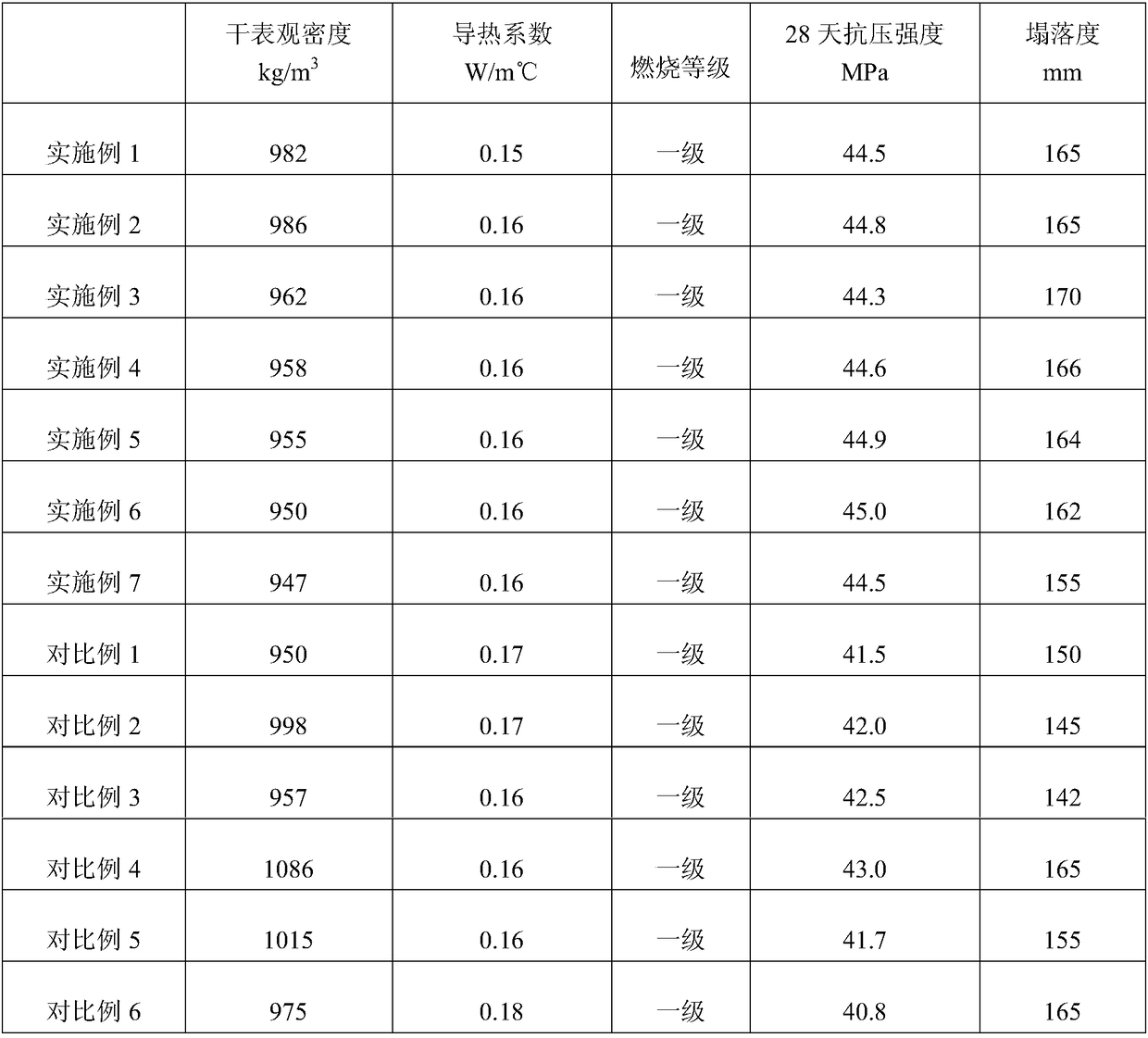

Examples

Embodiment 1

[0042] A high-strength lightweight aggregate concrete, according to parts by weight, including the following raw materials:

[0043] 500 parts of cementitious material, 500 parts of lightweight fine aggregate, 600 parts of lightweight coarse aggregate, 6 parts of admixture, and 160 parts of water.

[0044] The cementitious material is composed of 60% mass fraction of cement clinker and 40% mass fraction of cement admixture, and the mass ratio of the cement admixture is 15:10:1 stone tailings, active construction waste powder and Composition of desulfurized gypsum.

[0045] The lightweight fine aggregate includes 70% mass fraction of fine aggregate ceramsite and 30% mass fraction of active construction waste powder; the lightweight coarse aggregate includes the following components in terms of mass fraction: coarse aggregate pottery Granite 60%, stone tailings 25%, ceramic waste slag 10%, expanded graphite 5%; the fine aggregate ceramsite and coarse aggregate ceramsite include...

Embodiment 2

[0064] A high-strength lightweight aggregate concrete, according to parts by weight, including the following raw materials:

[0065] 400 parts of cementitious material, 450 parts of lightweight fine aggregate, 650 parts of lightweight coarse aggregate, 7 parts of admixture, and 150 parts of water.

[0066] The cementitious material is composed of 75% mass fraction of cement clinker and 25% mass fraction of cement admixture, and the mass ratio of the cement admixture is 20:10:1 stone tailings, active construction waste powder and Composition of desulfurized gypsum.

[0067] The lightweight fine aggregate includes 80% mass fraction of fine aggregate ceramsite and 20% mass fraction of active construction waste powder; the lightweight coarse aggregate includes the following components in terms of mass fraction: coarse aggregate pottery Granite 75%, stone tailings 10%, ceramic waste slag 10%, and expanded graphite 5%; the fine aggregate ceramsite and coarse aggregate ceramsite inc...

Embodiment 3

[0081] A high-strength lightweight aggregate concrete, according to parts by weight, including the following raw materials:

[0082] 550 parts of cementitious material, 600 parts of lightweight fine aggregate, 500 parts of lightweight coarse aggregate, 5 parts of admixture, and 170 parts of water.

[0083] The cementitious material is composed of 55% mass fraction of cement clinker and 45% mass fraction of cement admixture, and the mass ratio of the cement admixture is 10:10:1 stone tailings, active construction waste powder and Composition of desulfurized gypsum.

[0084] The lightweight fine aggregate includes 60% mass fraction of fine aggregate ceramsite and 40% mass fraction of active construction waste powder; the lightweight coarse aggregate includes the following components in terms of mass fraction: coarse aggregate pottery Granite 50%, stone tailings 30%, ceramic waste slag 15%, expanded graphite 5%; the fine aggregate ceramsite and coarse aggregate ceramsite include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com