Preparation method of high-rate lithium ion battery anode slurry

A lithium-ion battery, cathode slurry technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem of difficult dispersion of mixed conductive agents, achieve low internal resistance, high energy density, and avoid agglomeration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

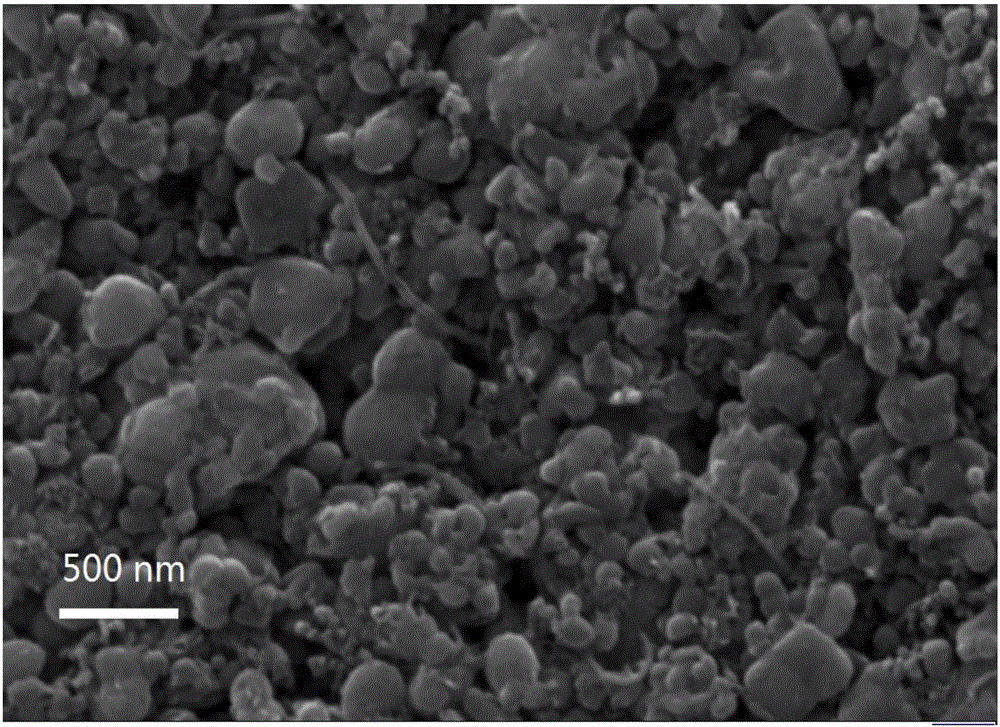

Embodiment 1

[0028] In the preparation method of the high-rate lithium-ion battery cathode slurry in this embodiment, lithium iron phosphate is used as the cathode active material, single-walled carbon nanotubes and Super-p are used as conductive agents, polyvinylidene fluoride is used as a binder, and N-methyl fluoride is used as a binder. Pyrrolidone is the solvent, and the first four components are weighed according to the mass ratio of lithium iron phosphate: polyvinylidene fluoride: Super-p: single-wall carbon nanotube=93:4:2:1, and the preparation steps are as follows:

[0029] 1) Before slurry preparation, firstly, lithium iron phosphate, conductive agent Super-p and single-walled carbon nanotubes were dried at 115°C for 4h under nitrogen protection, and polyvinylidene fluoride was dried at 85°C for 8h under nitrogen protection. After drying, cool down naturally to below 40°C for use;

[0030] 2) Dissolve the polyvinylidene fluoride in N-methylpyrrolidone equivalent to 12 times its ...

Embodiment 2

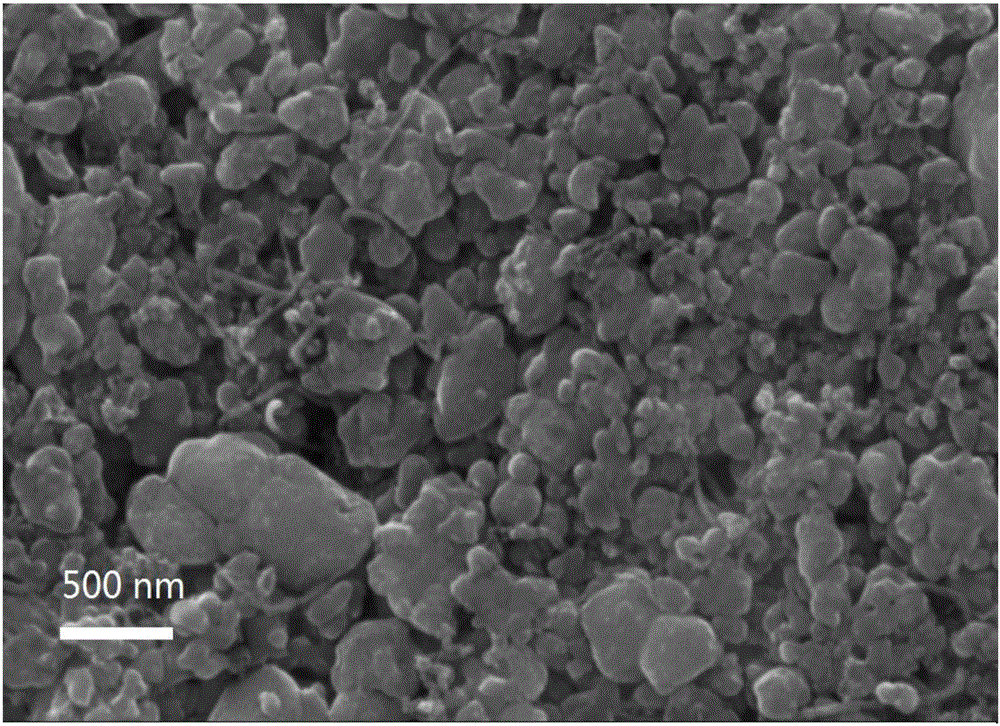

[0038] In the preparation method of the positive electrode slurry for a high-rate lithium ion battery in this embodiment, lithium cobalt oxide is used as the positive electrode active material, double-walled carbon nanotubes and KS-6 are used as conductive agents, polyvinylidene fluoride is used as a binder, and N-methyl fluoride is used as a binder. Pyrrolidone is the solvent, and the first four components are weighed according to the mass ratio of lithium cobaltate: polyvinylidene fluoride: KS-6: double-walled carbon nanotubes=92.5:4.5:1.5:1.5, and the preparation steps are as follows:

[0039] 1) Before slurry preparation, firstly, lithium cobalt oxide, conductive agent KS-6 and double-walled carbon nanotubes were dried at 95°C for 4.3h under nitrogen protection, and polyvinylidene fluoride was dried at 80°C for 7h under nitrogen protection. , After drying, cool down naturally to below 40 °C for use;

[0040] 2) Dissolve polyvinylidene fluoride in N-methylpyrrolidone equiva...

Embodiment 3

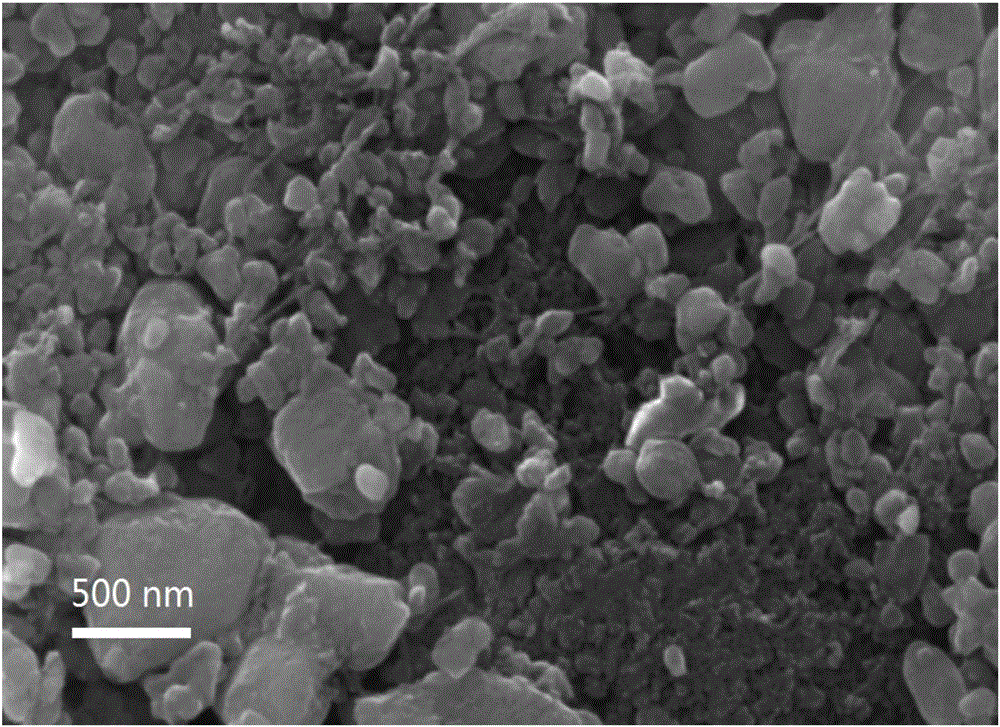

[0048] In the preparation method of the high-rate lithium-ion battery positive electrode slurry in this embodiment, lithium manganate is used as the positive electrode active material, graphitized carbon nanotubes and Super-p are used as conductive agents, polyvinylidene fluoride is used as a binder, and N-methyl fluoride is used as a binder. Pyrrolidone is the solvent, and the first four components are weighed according to the mass ratio of lithium manganate: polyvinylidene fluoride: Super-p: graphitized carbon nanotube=93.7:2.8:2.5:1. The preparation steps are as follows:

[0049] 1) Before slurry preparation, firstly, lithium manganate, conductive agent Super-p and graphitized carbon nanotubes were dried under nitrogen protection at 110 °C for 4.8 h, and polyvinylidene fluoride was dried at 75 °C for 6.5 h under nitrogen protection. h, after drying, cool down to below 40°C naturally for use;

[0050] 2) Dissolve the polyvinylidene fluoride in N-methylpyrrolidone equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com