Method for preparing zirconium oxide ceramic

A zirconia ceramic and zirconia technology, which is applied in the field of preparation of high-performance zirconia ceramics, can solve the problems of high production cost of high-performance zirconia ceramics, difficulty in preparing ceramics with complex shapes, and difficulty in dispersing ultrafine zirconia powders. , to achieve the effect of simplifying vacuum degassing, reducing processing cost and reducing organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

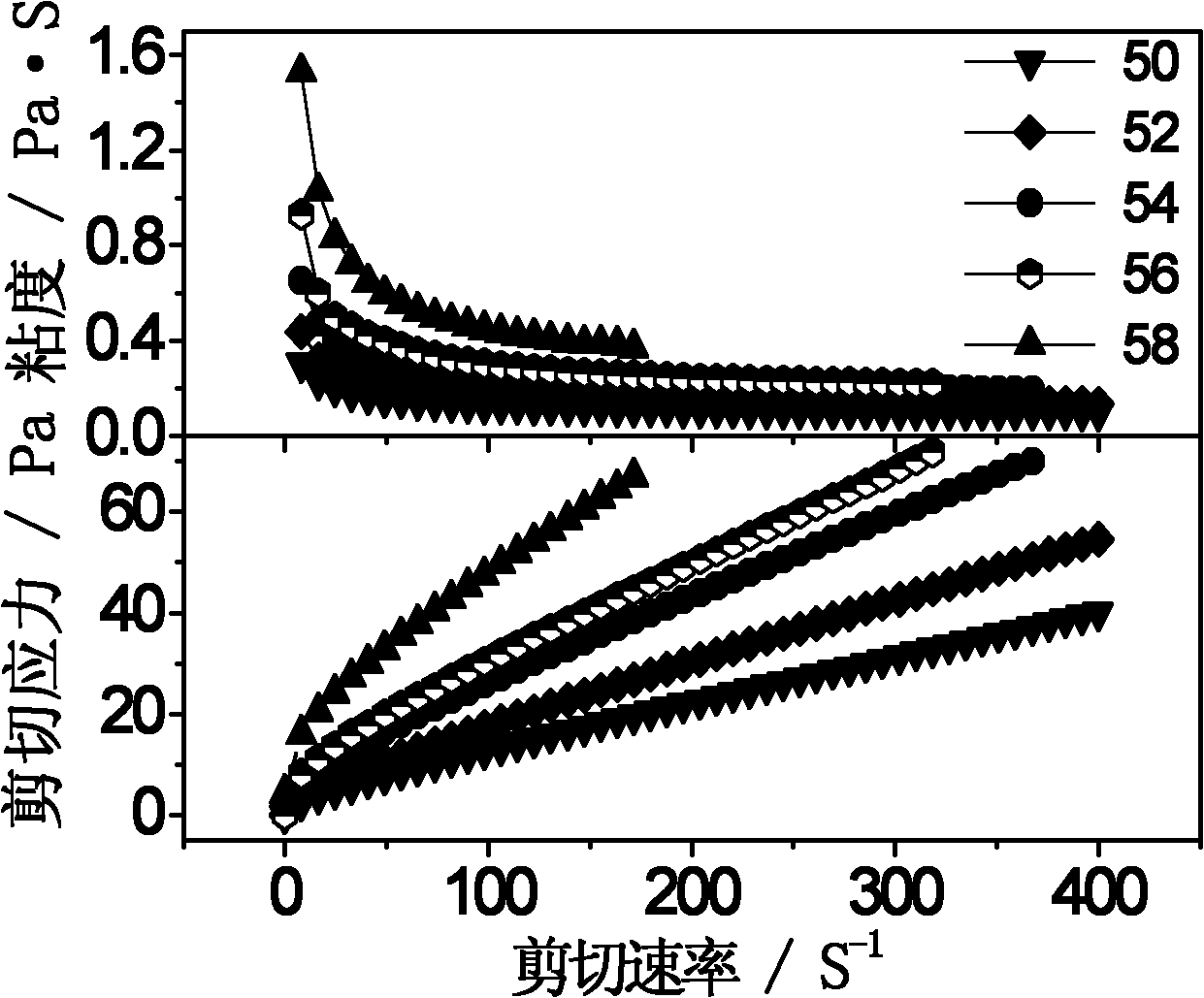

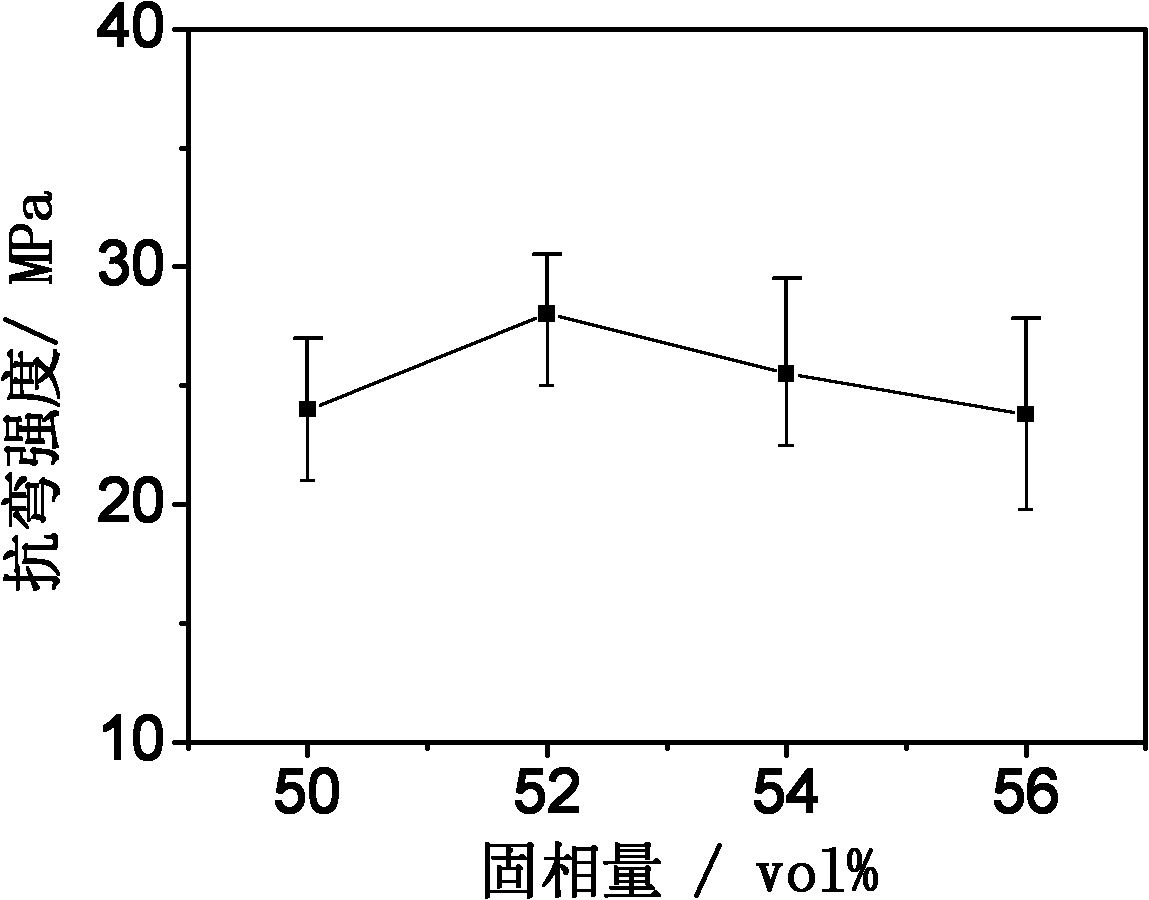

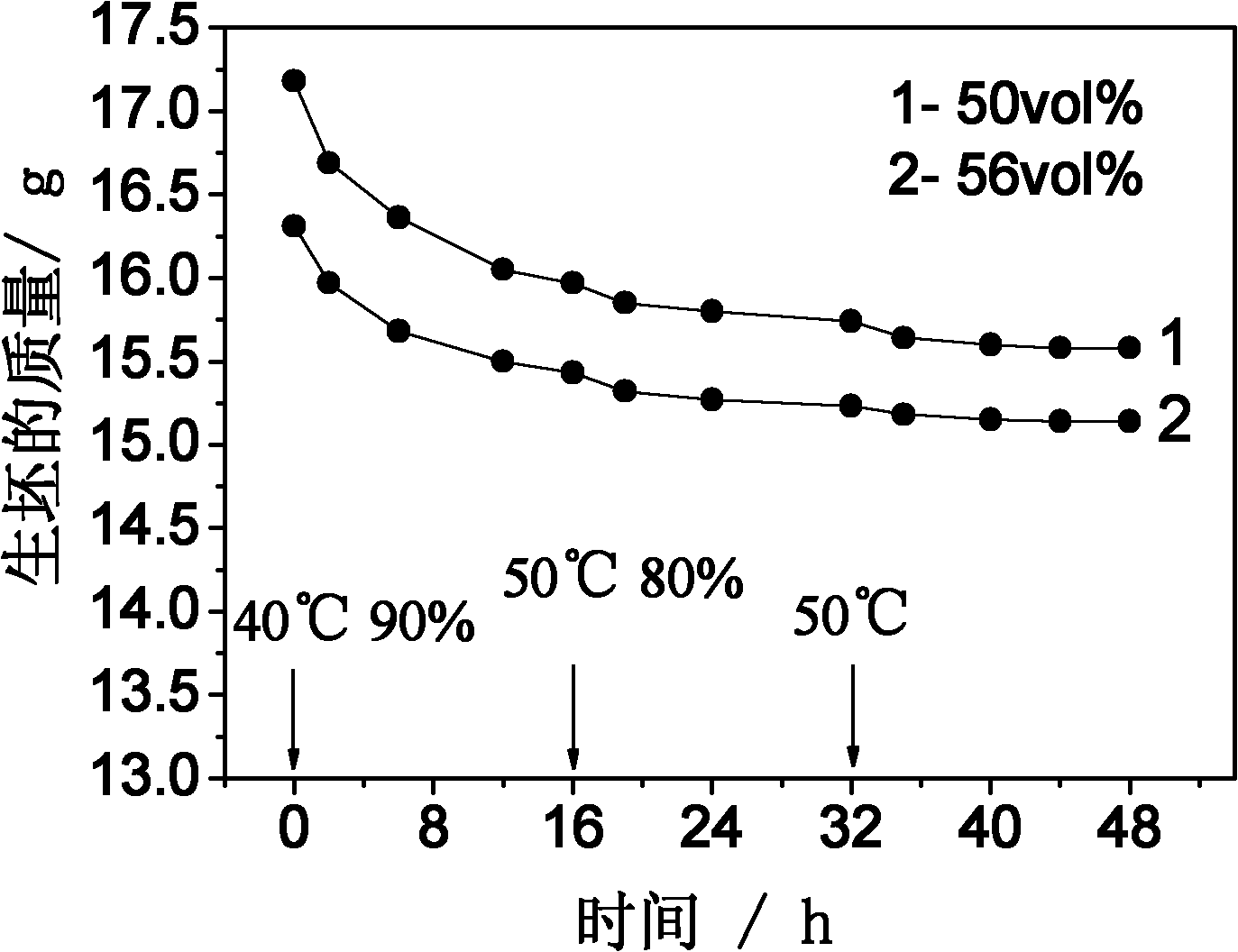

[0035] Take 5% monomer MAM (accounting for the mass fraction of the premixed solution, i.e. 5g), then add 0.01% crosslinking agent MBAM (relative to the mass of the monomer, i.e. 1g), add 94 deionized water, and dissolve to obtain 100g premixed Mixed liquid. Take 20g of the premixed solution, and prepare a solid phase amount of 48vol%, that is, add 98g of zirconia powder (primary particle size is 50-150nm), and add 0.2% ammonium polyacrylate according to the mass of zirconia powder, that is, 0.2g , adjust the pH to 7, then add 98g zirconia powder, and obtain a slurry with a solid phase content of 48vol% after ball milling. Using this slurry, 0.2% of initiator APS (relative to the mass of the monomer), ie 0.002 g, was added. Under the condition of vacuum degree of -0.07MPa, after defoaming, pour into the mold, put it in an oven, and take it out after curing at 40°C for 90 minutes. After demoulding, a wet body is obtained, and the gel curing process is completed. The body was ...

example 2

[0037] According to the steps of Example 1, get 35% monomer N-MAM (accounting for the mass fraction of the premixed solution, i.e. 35g), then add 20% crosslinking agent MBAM (relative to the quality of the monomer, i.e. 7g), add 58 to Ionized water, dissolved to obtain 100g premix. Take 20g of the premixed solution, prepare a solid phase amount of 50vol%, that is, add 120g of zirconia powder, add 0.7% sodium carboxylate according to the quality of the zirconia powder, that is, 0.84g, adjust the pH to 9, and then add 120g The zirconia powder is ball-milled to obtain a slurry with a solid phase content of 50 vol%. Using this slurry, 2% of the initiator AIBA (relative to the mass of the monomer), ie 0.14 g, was added. After degassing under the condition of vacuum degree of -0.1MPa, pour it into the mold, put it in an oven, and take it out after curing at 80°C for 25 minutes. After demoulding, a wet body is obtained, and the gel curing process is completed. Place in a humid heat...

example 3

[0039] According to the steps of Example 1, get 20% monomer DMAA (accounting for the mass fraction of the premixed solution, i.e. 20g), then add 10% crosslinking agent MBAM (relative to the quality of the monomer, i.e. 2g), add 78 g of deionized water , dissolved to obtain 100g premix. Take 20g of the premixed solution, and prepare a solid phase amount of 54vol%, that is, add 140g of zirconia powder, according to the quality of the zirconia powder, add 1% phosphoric acid chelate, that is, 1.4g, adjust the pH to 10, and then add 140g of zirconia powder was ball milled to obtain a slurry with a solid phase content of 54vol%. Using this slurry, 5% of the initiator AIBI (relative to the mass of the monomer), ie 0.2 g, was added. After degassing under the condition of vacuum degree of -0.2MPa, pour it into the mold, place it in an oven, and take it out after curing for 35 minutes at 70°C. After demoulding, a wet body is obtained, and the gel curing process is completed. The body wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com