Combined smelting device capable of increasing yield of alloy castings and application of combined smelting device

A technology for alloy castings and melting equipment, which is applied in the fields of vacuum induction melting and investment casting, can solve the problems of increasing material waste, shrinkage of solidified structures, and increasing the amount of material used, so as to improve the yield, reduce waste and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As shown in Figure 1, the combined smelting equipment for improving the yield of alloy castings includes a crucible 1 for primary smelting, an ingot mold 2 for primary smelting, a crucible 3 for secondary smelting and a precision casting mold shell 4 for secondary smelting; The crucible 1 and the crucible 3 for secondary melting have the same structure;

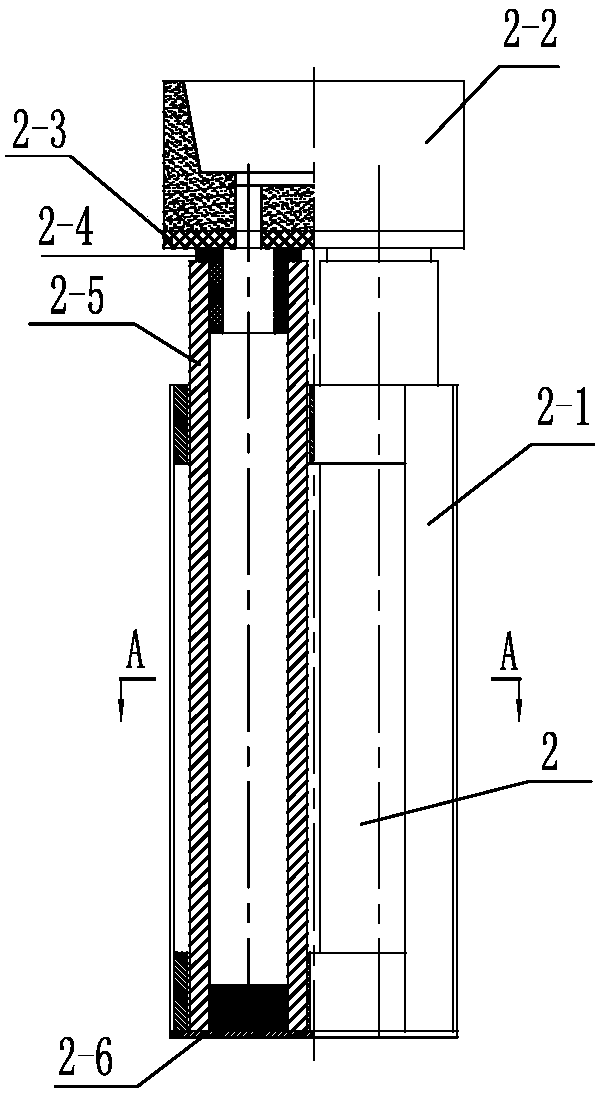

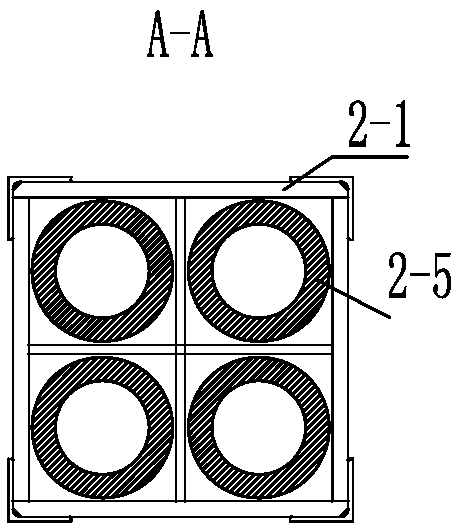

[0041] The ingot mold 2 for the primary smelting comprises a frock 2-1, a diverter plate 2-2, an insulating cotton 2-3, an insulating riser 2-4, an ingot mold body 2-5 and a graphite base plate 2-6; the diverter plate The lower end of 2-2 is provided with insulation riser 2-4, insulation cotton 2-3 is provided between diverter plate 2-2 and insulation riser 2-4, insulation riser 2-4 is arranged above ingot mold body 2-5 The outside of the ingot mold body 2-5 is provided with tooling 2-1; the bottom of the ingot mold body 2-5 is provided with a graphite base plate 2-6; the ingot mold body 2-5 can be a ductile iron ingot...

Embodiment 2

[0049] Put 50kg of prepared nickel-copper alloy raw materials into a 50kg vacuum induction furnace to melt and cast them into master alloy ingots. The 25kg vacuum induction melting furnace requires 25kg of ingot raw materials to prepare castings. According to the amount of mold shell material used for precision casting and the size of the 25kg vacuum furnace melting crucible, the size (including diameter and length) of the master alloy ingot is reversed.

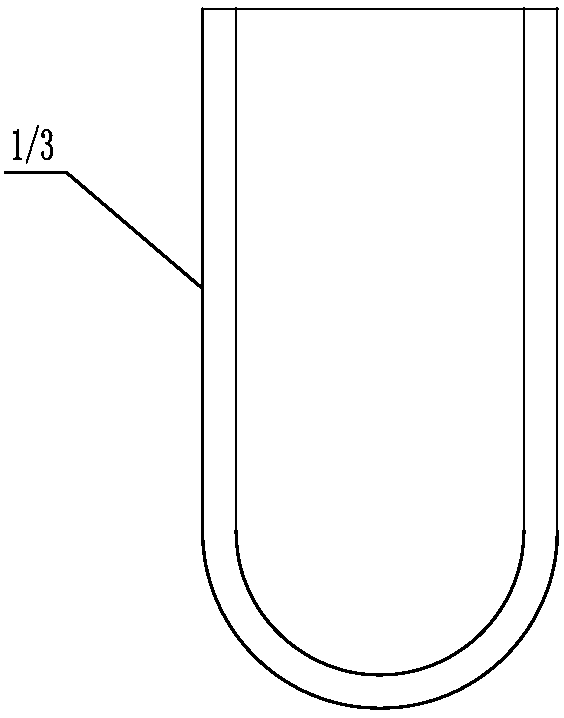

[0050] A 25kg vacuum induction furnace needs 18-20kg of materials for precision pouring. The shape of the crucible is shown in Figure 1. The diameter of the crucible is 140mm, the height is 320mm, and the radius of the arc at the bottom of the crucible is 70mm.

[0051] Taking the radius of the crucible as R and the radius of the master alloy ingot as r, then when 3 master alloy ingots are placed in a 25kg crucible, substituting n=3 into the formula, the maximum allowable radius of the master alloy is obtained as:

[0052] ...

Embodiment 3

[0057] Put 50kg of prepared nickel-copper alloy raw materials into a 50kg vacuum induction furnace to melt and cast them into ingots, and the 25kg vacuum induction melting furnace requires 25kg of ingot raw materials to prepare castings. According to the amount of mold shell material used for precision casting and the size of the 25kg vacuum furnace melting crucible, the size (including diameter and length) of the master alloy ingot is reversed.

[0058] The 25kg vacuum induction furnace needs 22-23kg of materials for precision casting, and the shape of the crucible is as follows: Figure 1-a As shown, the diameter of the crucible is 140mm, the height is 320mm, the radius of the arc at the bottom of the crucible is 70mm, the radius of the crucible is R, and the radius of the master alloy ingot is r, then when 4 master alloy ingots are placed in the 25kg crucible, Substituting n=4 into the formula, the maximum allowable master alloy radius is:

[0059]

[0060] R=70mm, r=28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com