Thermal field system suitable for large charge amount of 90t furnace

A technology of thermal field and thermal insulation cylinder, applied in the field of thermal field system, can solve the problems of low output, unsatisfactory heating effect of the system, insufficient feeding of thermal system devices, etc., so as to increase the output, improve the heating effect, increase the The effect of the feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

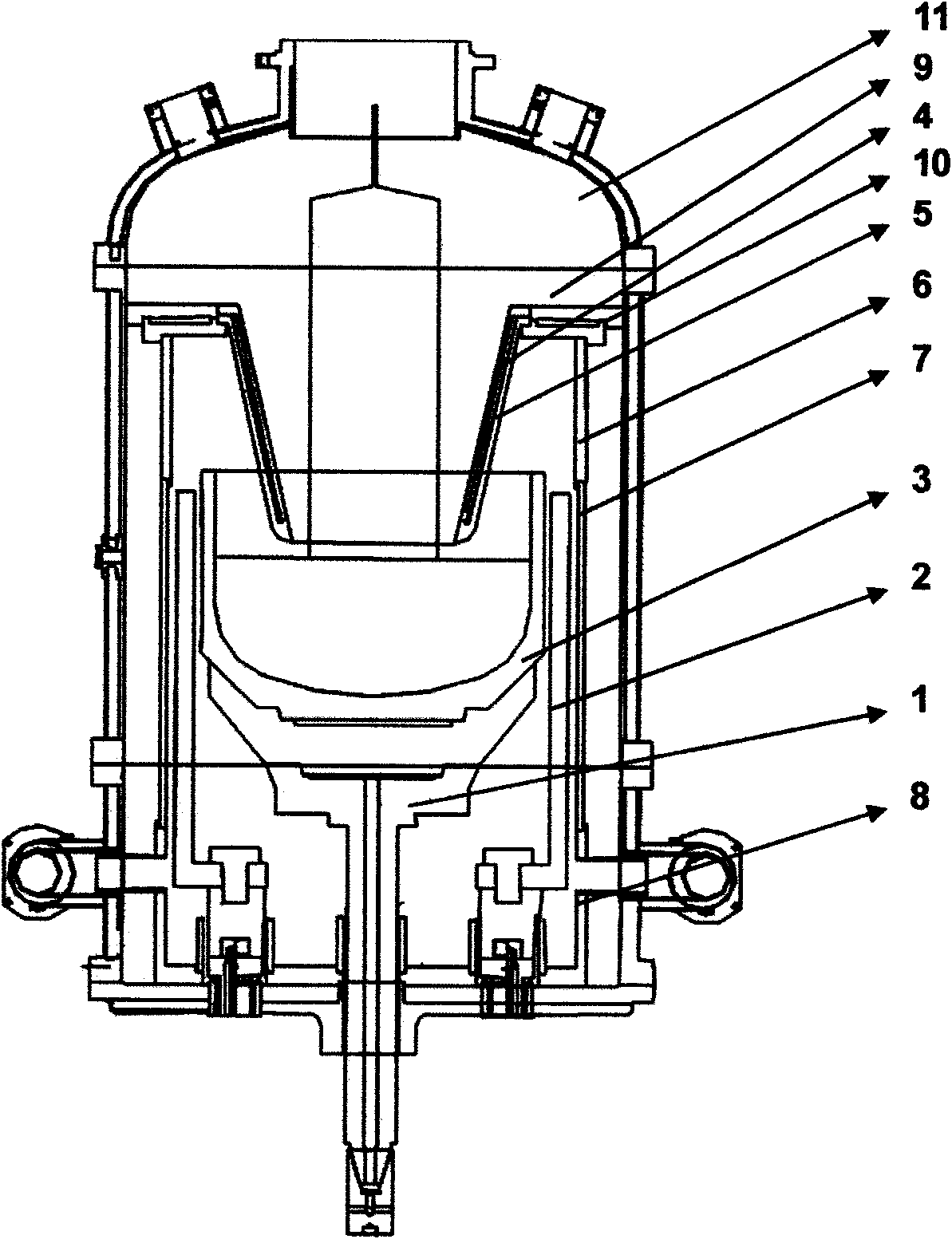

[0020] Different graphite thermal fields are installed in 90-22, and the dimensions of each component are as follows:

[0021] 1. Support rod outer diameter mm

[0022] 2. Heater: inner diameter mm, total height 655mm, heating area 500mm

[0023] 3. Three-petal crucible: outer diameter mm, inner diameter mm, height 412mm

[0024] 4. Inner layer of the guide tube: inner diameter mm, height 357mm

[0025] 5. The outer layer of the guide tube: the lower inner diameter mm, height 370mm

[0026] 6. Upper insulation barrel: inner diameter mm, total height 240mm, spigot height 10mm

[0027] 7. Medium insulation cylinder: inner diameter mm, height 560mm

[0028] 8. Lower insulation cylinder: inner diameter mm, height 320mm

[0029] 9. Upper insulation cover: inner diameter mm, outer diameter mm

[0030] 10. Lower insulation cover: inner diameter mm

specific Embodiment 2

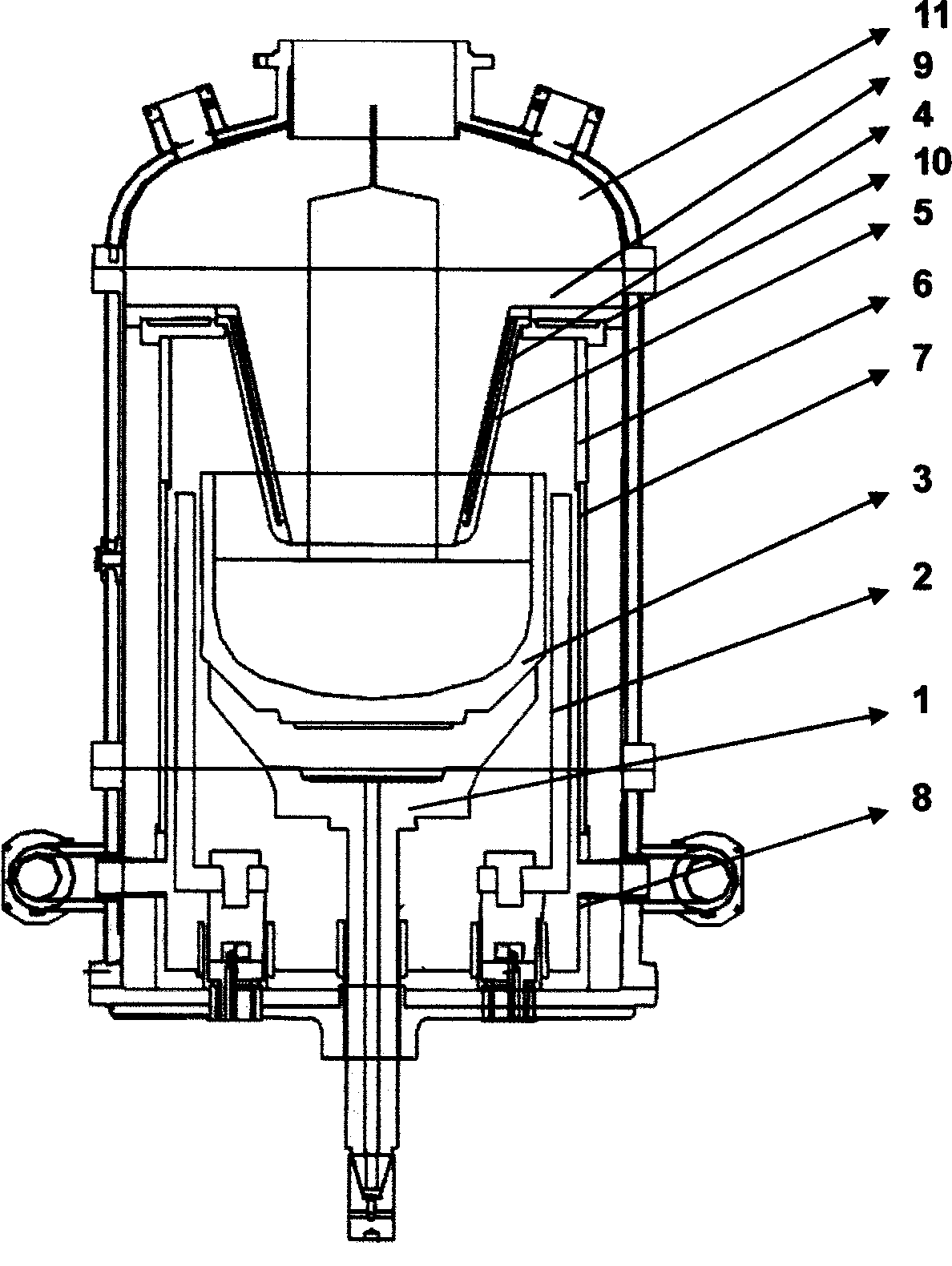

[0031] Different graphite thermal fields are installed in 90-22, and the dimensions of each component are as follows:

[0032] 1. Support rod outer diameter mm

[0033] 2. Heater: outer diameter mm, total height 655mm, heating area 500mm

[0034] 3. Three-petal crucible: outer diameter mm, inner diameter mm, height 412mm

[0035] 4. Inner layer of the guide tube: inner diameter mm, height 357mm

[0036] 5. The outer layer of the guide tube: the lower inner diameter mm, height 370mm

[0037] 6. Upper insulation barrel: inner diameter mm, total height 240mm, spigot height 10mm

[0038] 7. Medium insulation cylinder: inner diameter mm, height 560mm

[0039] 8. Lower insulation cylinder: inner diameter mm, height 320mm

[0040] 9. Upper insulation cover: inner diameter mm, outer diameter mm

[0041] 10. Lower insulation cover: inner diameter mm

specific Embodiment 3

[0042] Comparison of the price and yield of the thermal field system of specific embodiment 1 before and after improvement: after the improvement, the yield rate has obviously increased and stabilized, which has increased by 60%, indicating that the improved thermal field has greatly improved the normal production and increased output. . See Table 1 and Table 2 for details:

[0043] Table 1: Prices

[0044] Specification

Hot field price (yuan / set)

Quartz crucible price (yuan / piece)

85 furnace

(18″)

95000

1550

85 furnace

(20″)

122000

2550

90 furnace

(twenty two")

200000

4500

[0045] Table 2: Yield after improvement

[0046] Specification

Quartz Crucible Specifications

Actual feeding amount (Kg)

85 furnace

18″

60

(18″)

85 furnace

(20″)

20″

75

90 furnace

(twenty two")

22″

120

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com