Method and device for improving quality of slab tail blank

A tail blank and quality technology, applied in the field of continuous casting, can solve the problems of high scrap rate, internal quality and surface quality of slab tail blank cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

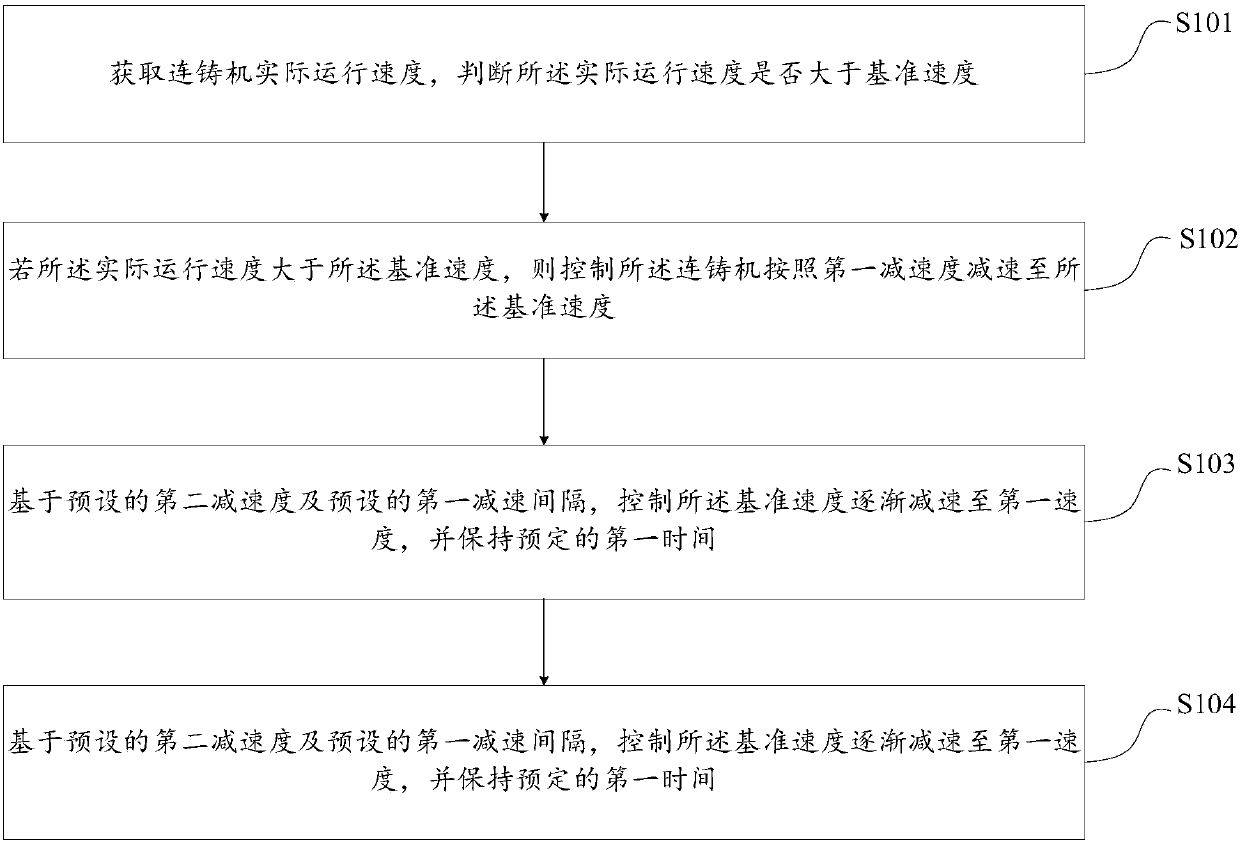

[0038] This embodiment provides a method for improving the quality of the slab tail stock, such as figure 1 As shown, the method includes:

[0039] S101, acquiring the actual running speed of the continuous casting machine, and judging whether the actual running speed is greater than the reference speed;

[0040] In this step, the required deceleration is different when the actual running speed is higher than the reference speed and when the actual running speed is lower than the reference speed. Therefore, when the last furnace stops pouring for 10 minutes, it is necessary to obtain the actual running speed of the continuous casting machine, and judge whether the actual running speed is greater than the reference speed; thereby determine the deceleration, and the reference speed is 1.2m / min.

[0041] S102. If the actual running speed is greater than the reference speed, control the continuous casting machine to decelerate to the reference speed according to a first decelerat...

Embodiment 2

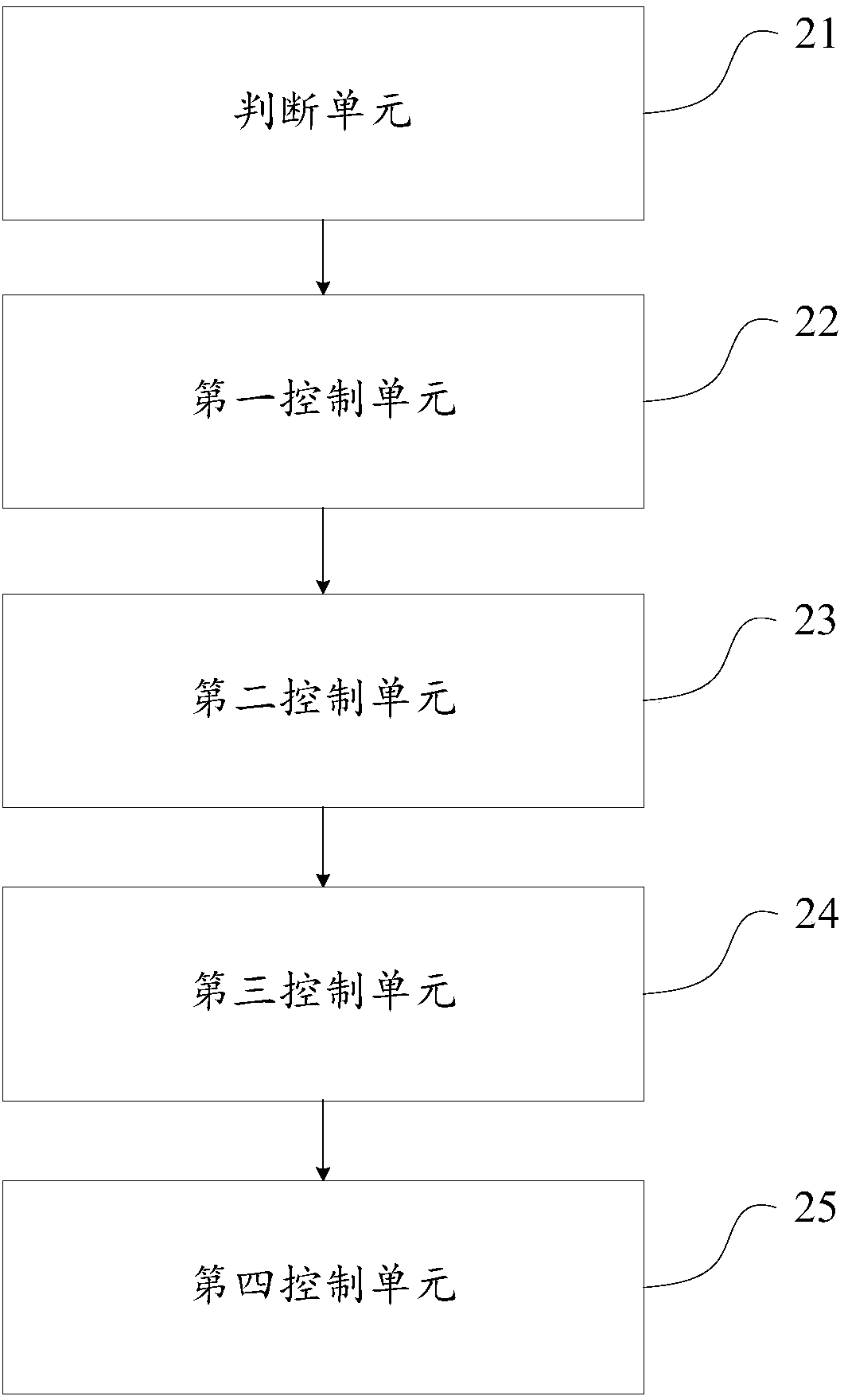

[0054] Corresponding to Embodiment 1, this embodiment provides a device for improving the quality of the slab tail, such as figure 2 As shown, the device includes: a judging unit 21, a first control unit 22, a second control unit 23, a third control unit 24 and a fourth control unit 25; wherein,

[0055] When the actual running speed is higher than the reference speed, and when the actual running speed is lower than the reference speed, the required deceleration is different. Therefore, when the last furnace stops pouring for 10 minutes, the judging unit 21 needs to obtain the actual running speed of the continuous casting machine, and judge whether the actual running speed is greater than the reference speed; thereby determine the deceleration, and the reference speed is 1.2m / min .

[0056] Correspondingly, the first control unit 22 is used to control the continuous casting machine to decelerate to the reference speed according to the first deceleration when the actual runn...

Embodiment 3

[0066] In actual application, when using the method provided in Embodiment 1 and the device provided in Embodiment 2 to cast slabs, the details are as follows:

[0067] In the continuous casting process, the required deceleration is different when the actual running speed is higher than the reference speed and when the actual running speed is lower than the reference speed. Therefore, when the last furnace stops pouring for 10 minutes, it is necessary to obtain the actual running speed of the continuous casting machine, and judge whether the actual running speed is greater than the reference speed; thereby determine the deceleration, the reference speed is 1.2m / min, and the The actual running speed is 1.4m / min.

[0068] Here, because the actual running speed is greater than the reference speed, the continuous casting machine is controlled to decelerate to the reference speed according to the first deceleration; the first deceleration is 0.05m / min 2 .

[0069] After the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com