Process method of lost-foam casting double-liquid compound crusher hammer

A technology of lost foam casting and compound crusher, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., and can solve problems such as difficulties, inability to guarantee the quality of double-liquid compounding, and inability to achieve blocking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

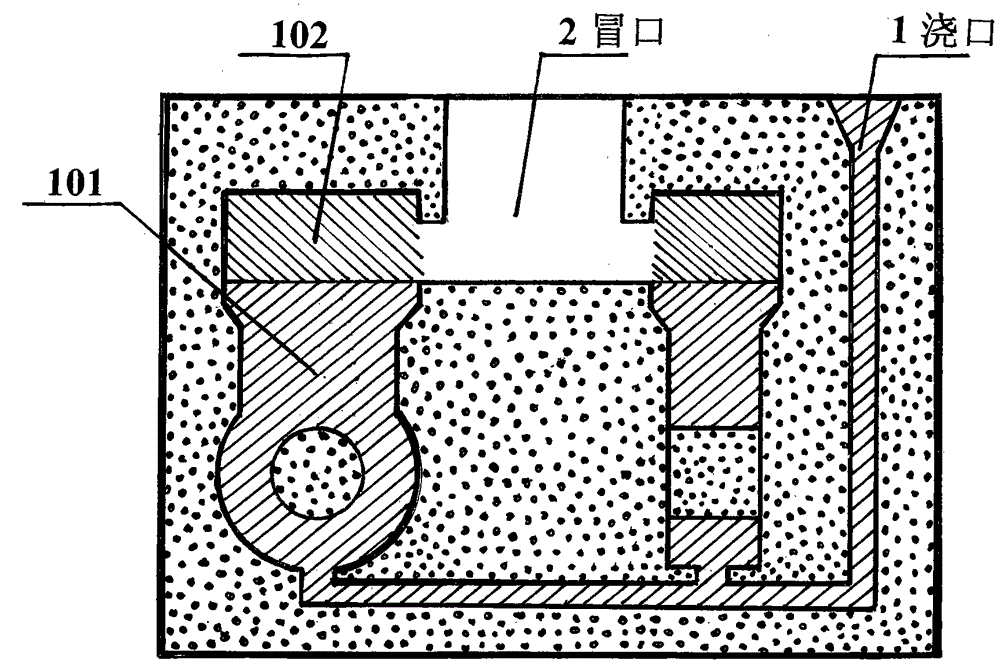

[0011] Embodiment 1: use the lost foam casting of the present invention double-fluid composite breaker hammer process: (1) form a module by the foam pattern, such as figure 1 Shown: the modules are dipped and brushed with paint, dried, boxed and filled with sand, and vibrated (multiple groups can be set in each box, and poured group by group): (2) Melting: two kinds of (101) and (102) The material is smelted by two furnaces at the same time to the temperature that should be released from the furnace; (3) pouring: according to the normal pouring temperature of the material, the hammer handle material (101) is poured quantitatively from the runner 1, and then from the riser 2 Pour the hammer end material (102) molten iron to the top of the riser; (4) Clear and cut the pouring riser after the casting is solidified and cooled.

Embodiment 2

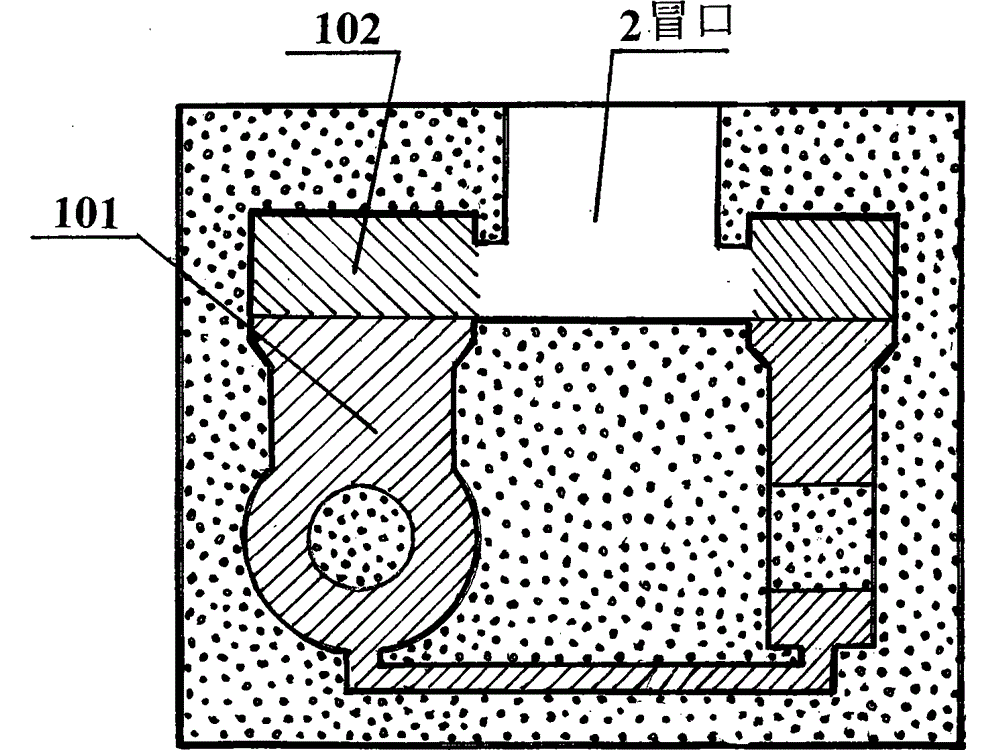

[0012] Embodiment 2: use the lost foam casting double-liquid compound breaker hammer process method of the present invention, such as figure 2 As shown: the module is dipped and brushed with paint, dried, packed with sand, vibrated, smelted, etc., as in Example 1, and will not be repeated. The pouring is: use a quantitative package to quantitatively pour the material of the hammer handle from the riser 2 After (101) molten steel, then pour hammer end material (102) molten iron into riser top from riser 2 again.

[0013] Experiments have proved that compared with the known technology, the light-duty and heavy-duty double-fluid composite crusher hammer produced by this method has the simplest process, the most stable composite quality, the production yield is greater than 99%, the production cost is reduced by 20%, and the production efficiency is improved. Improve by 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com