Large-scale casting device for aluminum-water utensil

A technology of aluminum water and containers, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of increasing production costs of enterprises, inability to effectively fill mold cavities, and high product rejection rate, and achieve convenient operation, sufficient feeding, and Strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

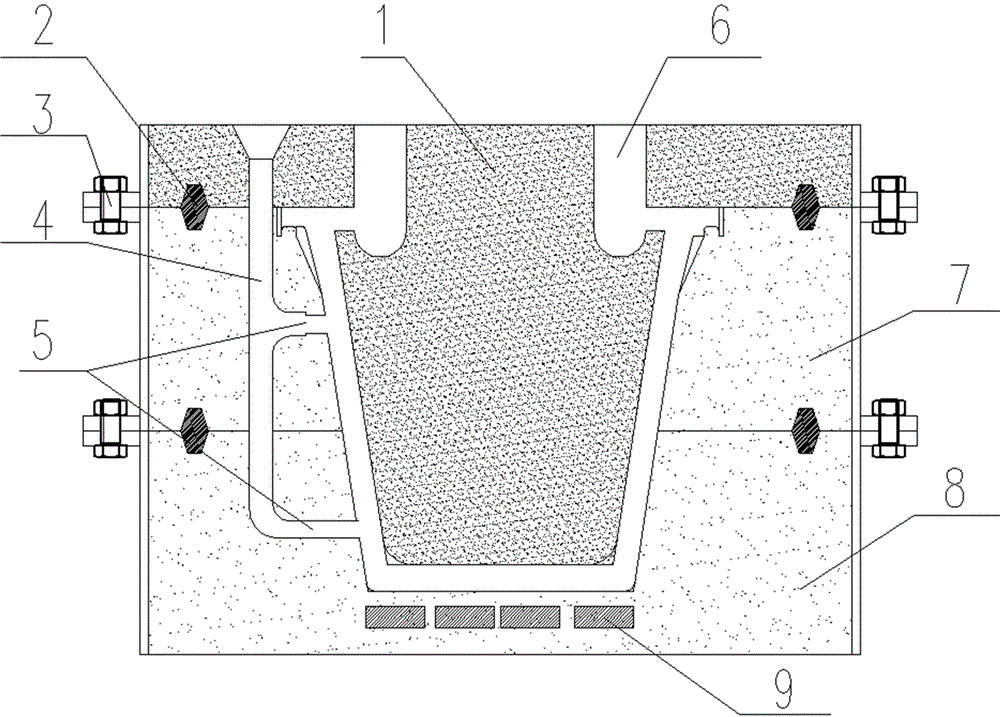

[0009] Such as figure 1 As shown, a large-scale aluminum water vessel casting device consists of an upper sand mold 1, a metal positioning cone 2, a fastening bolt 3, a sprue 4, an inner runner 5, a riser 6, an upper part of the lower sand mold 7, and a lower sand mold. Part 8, cold iron 9, composition, characterized in that: the bottom of the lower part 8 of the lower sand mold is covered with cold iron 9, and the upper sand mold 1 and the lower sand mold 7, 8 should be heated to 70 o-80 o in the oven before they are combined. After positioning the box with the metal positioning cone 2, it is connected with the fastening bolt 3. The sprue 4 and the inner runner 5 are composed of ceramic tubes with a diameter of 120mm. The height difference between the upper and lower runners 5 is 700mm, and they are designed at an angle of 135° to the casting body. The riser 6 adopts 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com