Hot cracking resistant mixed-crystal hard alloy and preparation method thereof

A cemented carbide and thermal crack resistance technology, applied in the field of cemented carbide, can solve the problems that the accuracy and stability of the twin crystal structure affect the performance, cannot accurately reflect the real grain size of WC, and cannot control the stability of the twin crystal structure. , to achieve the effect of good thermal crack resistance, high hardness and not easy to drop blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Cemented carbide includes: 76.4wt% hard phase WC, 22wt% binder phase Co and Ni and 1.6wt% Cr 3 C 2 .

[0063] The hard phase uses two kinds of WC raw materials with different Hc. The Hc value of the crude WC raw material is 3.8kA / m. 2 C, meeting the wear resistance requirements of ball milling; the Hc value of fine WC is 6.6kA / m, and the mass ratio of coarse and fine WC is 2.6:1. The mass ratio of Co and Ni is 1:1.

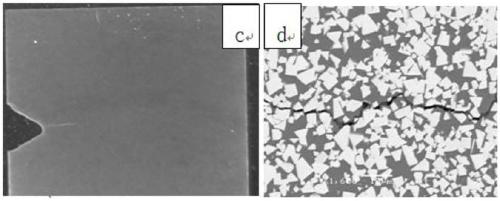

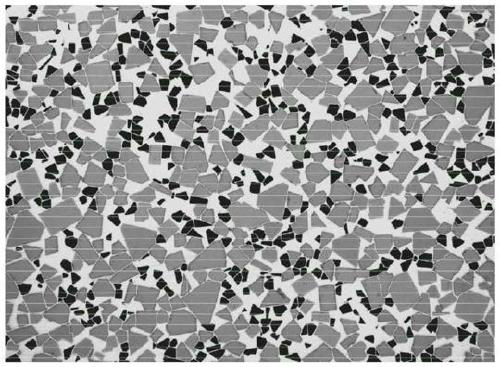

[0064] The hard phase, binder phase and Cr 3 C 2 Mix to obtain the raw material mixture, put the raw material mixture into the ball mill, the ratio of ball to material is 3:1, add alcohol, the ratio of the amount of alcohol added to the raw material mixture is 0.28L / 1kg, the molding agent is paraffin, and the amount of paraffin wax is the mass of the raw material mixture 2.0%, ball milling time 18 hours, through drying, pressing, low-pressure sintering to produce cemented carbide with mixed crystal grain size, the metallographic photo of cemented carbi...

Embodiment 2

[0066] The cemented carbide includes: 74.4wt% hard phase WC, 24wt% binder phases Co and Ni and 1.6wt% TaC.

[0067] The hard phase uses two kinds of WC raw materials with different Hc. The Hc value of the crude WC raw material is 4.2kA / m. 2 C, meeting the requirements of ball milling wear resistance; the Hc value of fine WC raw material is 6.6kA / m, the mass ratio of coarse WC and fine WC is 3.07:1; the mass ratio of Co and Ni in the binder phase is 2:1.

[0068] Mix the hard phase, binder phase and TaC to obtain a raw material mixture, put the raw material mixture into a ball mill, the ball-to-material ratio is 3:1, add alcohol, the ratio of the amount of alcohol added to the raw material mixture is 0.30L / kg, the forming agent It is paraffin wax, the mass ratio of the amount of paraffin wax to the raw material mixture is 2.0%, and the ball milling time is 16 hours. After drying, pressing, and low-pressure sintering, a cemented carbide with mixed crystal diameter is produced. T...

Embodiment 3

[0070] Cemented carbide includes: 72wt% hard phase WC, 26wt% binder phase Co and Ni and 2.0wt% Cr 3 C 2 .

[0071] The hard phase uses two kinds of WC raw materials with different Hc. The Hc value of the crude WC raw material is 4.0kA / m, and it is carbonized at 2400°C. 2 C, meeting the wear resistance requirements of ball milling, the Hc value of fine WC raw materials is 7.2kA / m, the mass ratio of coarse WC and fine WC is 3.2:1, and the mass ratio of Co and Ni is 2:1.

[0072] The hard phase, binder phase and Cr 3 C 2 Mix to obtain the raw material mixture, add the raw material mixture in the ball mill, the ball-to-material ratio is 3:1, add alcohol, the ratio of the amount of alcohol added to the raw material mixture is 0.32L / 1kg, the molding agent is paraffin, the consumption of paraffin and the ratio of the raw material mixture The mass ratio is 2.0%, and the ball milling time is 17 hours. After drying, pressing, and low-pressure sintering, an alloy with mixed crystal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com