Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Dense coating structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

Composite metal carbide wear-resistant coating and preparation process thereof

The invention relates to a composite metal carbide wear-resistant coating and a preparation process thereof, and belongs to a wear-resistant coating and a preparation process thereof. The composite metal carbide wear-resistant coating consists of adhesive coated tungsten carbide and other carbides, wherein the adhesive coated tungsten carbide has the grain size of WC-Co or WC-Ni; and the other carbides comprise chromium carbide, vanadium carbide, iron carbide, titanium carbide and the like. The preparation process comprises the following steps of: mixing the adhesive coated tungsten carbide and one or more kinds of the carbide powder; and performing spray coating (welding) or plasma spray coating (welding) on the surface of a medium-carbon steel part through supersonic flame to form the wear-resistant coating, wherein the carbon content of the medium-carbon steel is 0.35 to 0.55 weight percent (wt); the medium-carbon steel is subjected to the thermal refining state of quenching and high-temperature tempering; and the supersonic flame spray coating (welding) or plasma spray coating (welding) process sequentially comprises steps of performing sand blasting and rust removal on the surface of the medium-carbon steel, spraying a Ni-5 percent Al alloy adhesive coating and spraying a composite carbide wear-resistant coating. The composite carbide wear-resistant coating has Vickers hardness (HV) of 1,200 to 1,800, bonding force of more than 60 Mpa, and high mechanical property, wear resistance and corrosion resistance.

Owner:CHINA UNIV OF MINING & TECH +1

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

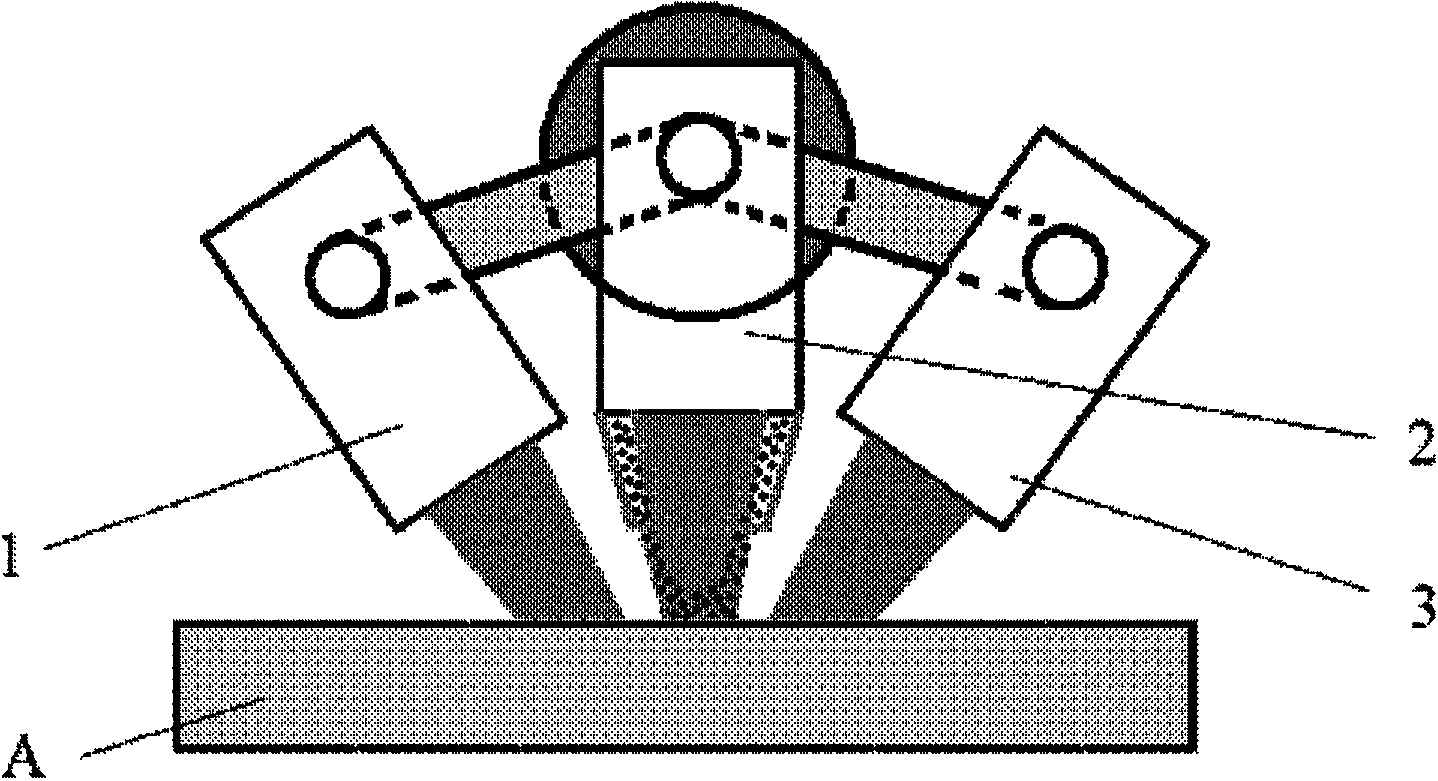

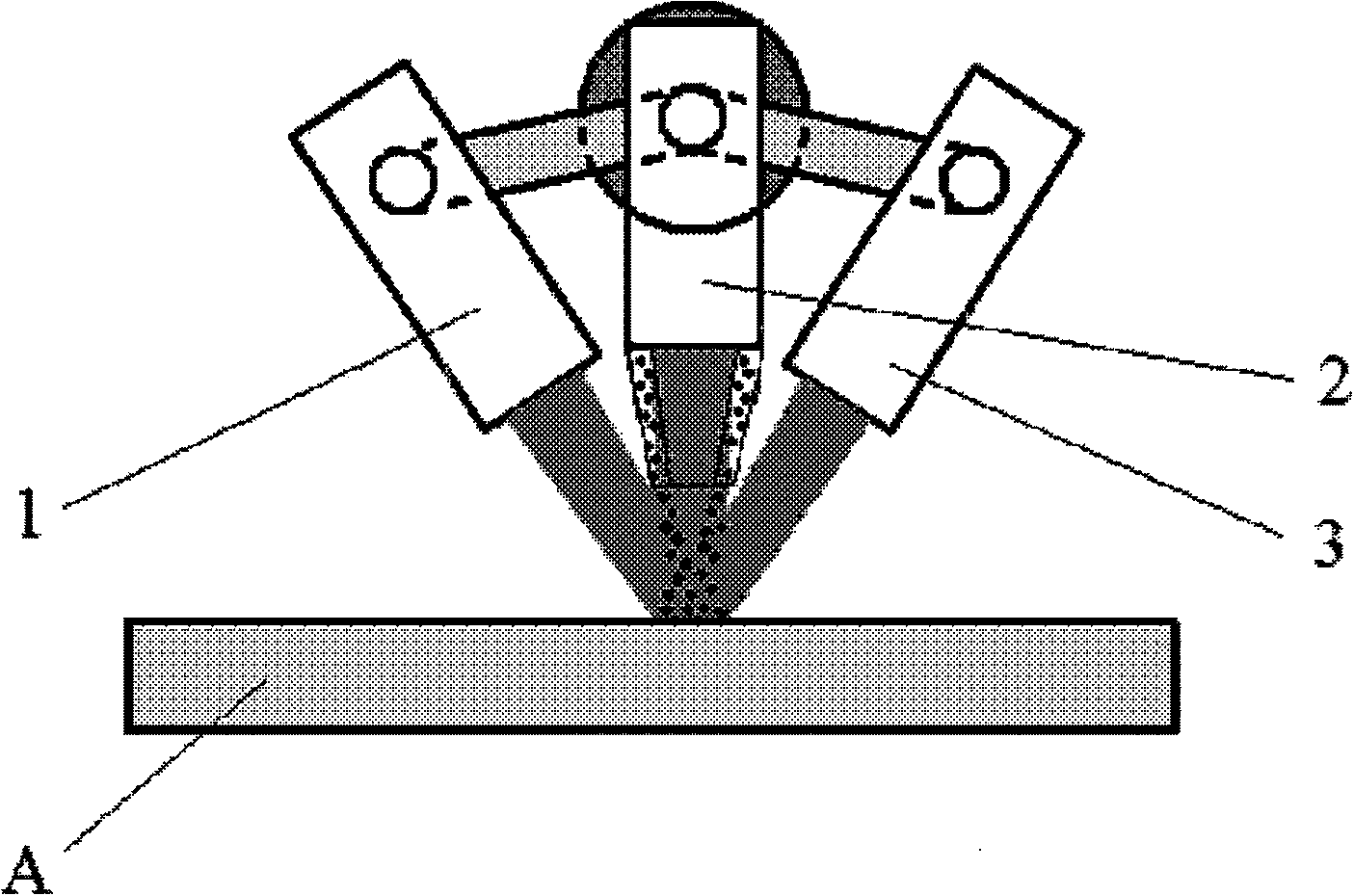

Method for performing laser cladding by using multiple lasers

InactiveCN103774137AEasy loading and unloadingEasy to operateMetallic material coating processesFree coolingOptoelectronics

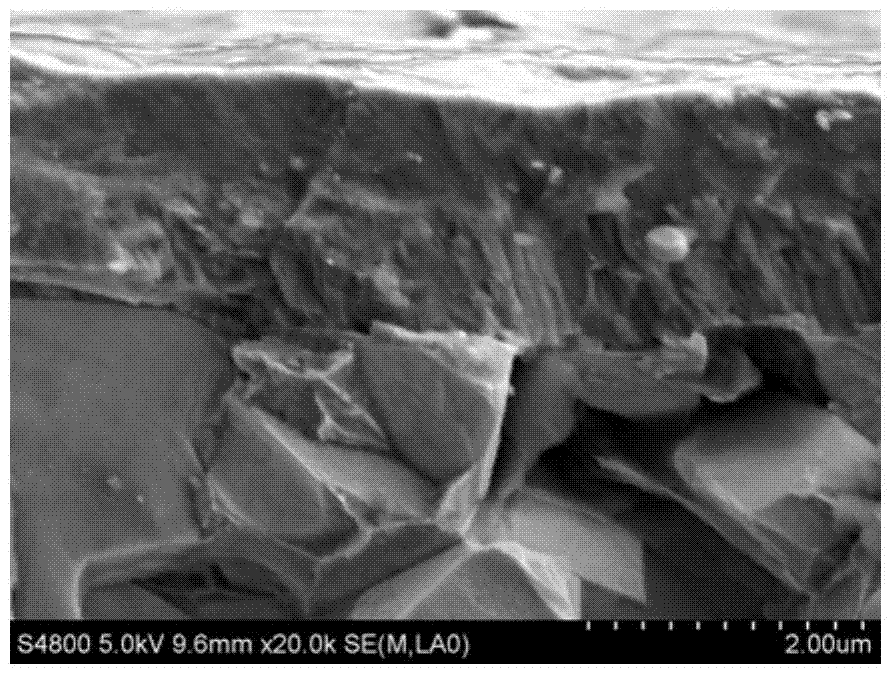

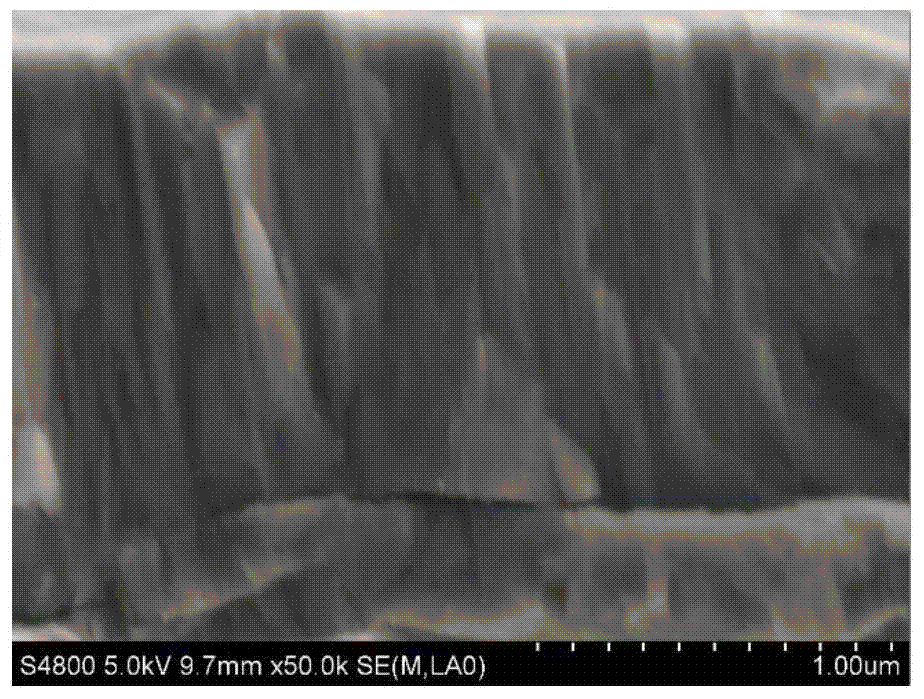

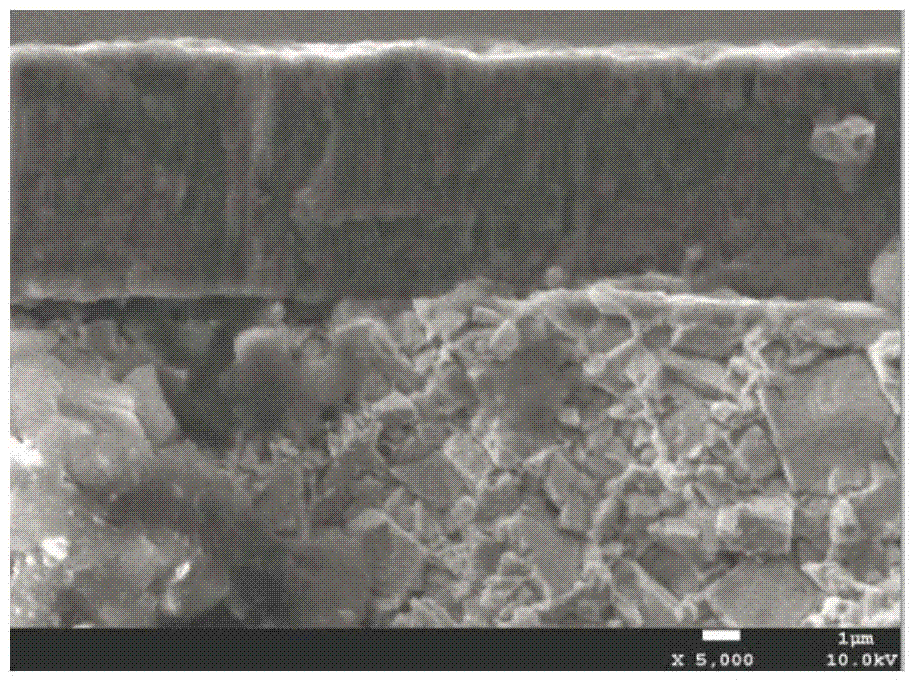

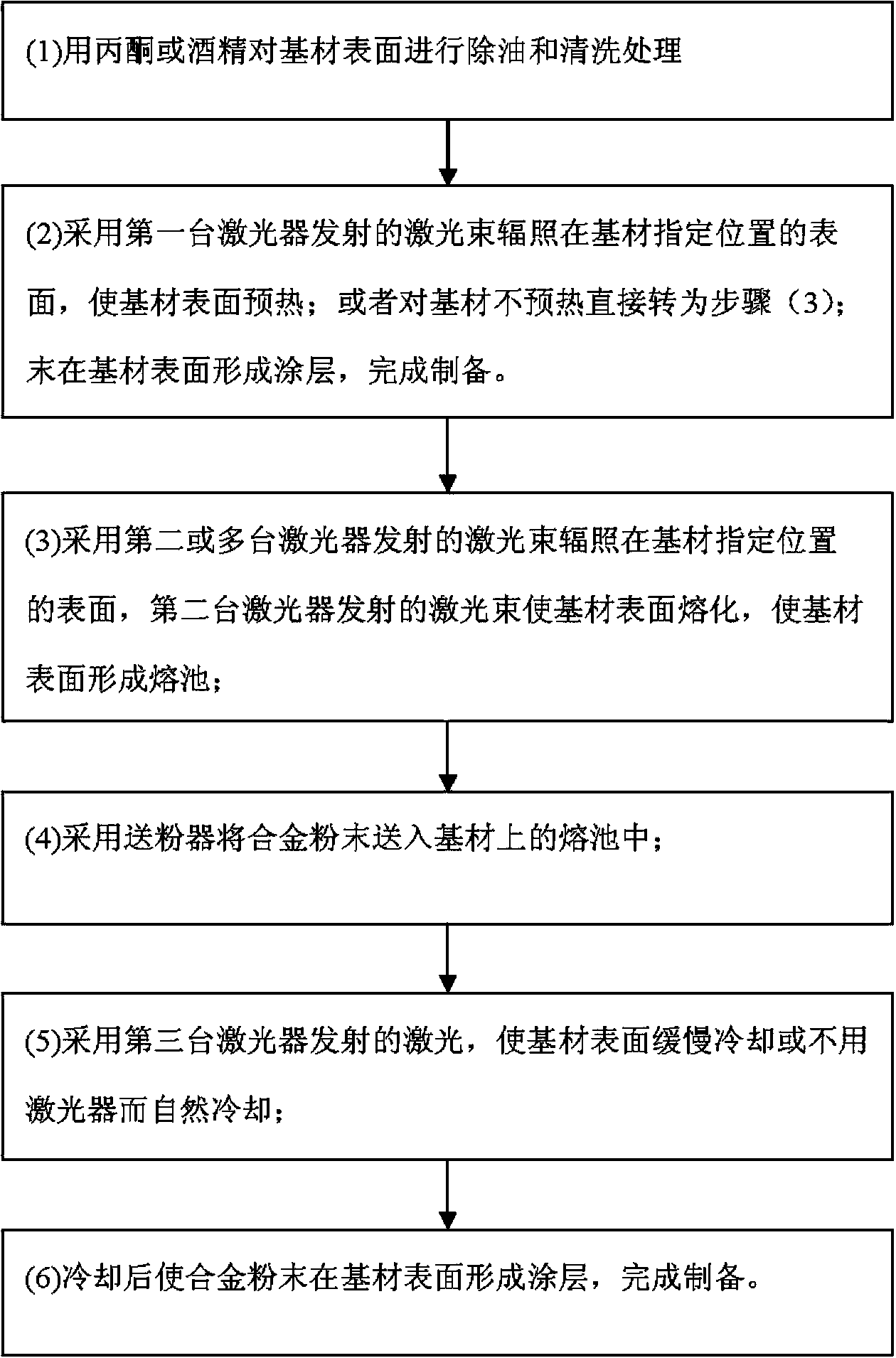

The invention discloses a method for performing laser cladding by using multiple lasers. The method comprises the following steps: performing oil-removing and cleaning treatment on the surface of a substrate by using acetone or alcohol; irradiating laser beams emitted by a first laser onto the surface of a specified position on the substrate to preheat the surface of the substrate; or directly turning to step 3 without preheating the substrate; irradiating laser beams emitted by a second or multiple lasers onto the surface of a specified position on the substrate to melt the surface of the substrate in order to form a molten pool on the surface of the substrate; feeding alloy powder into the molten pool on the substrate by using a powder feeder; and slowly cooling the surface of the substrate by using laser light emitted by a third laser or naturally cooling without using the laser to form a coating on the surface of the substrate in order to complete preparation. The method has the advantages of laser cladding efficiency, lower machining cost, good bonding of the substrate, convenience in operation and high automation degree.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

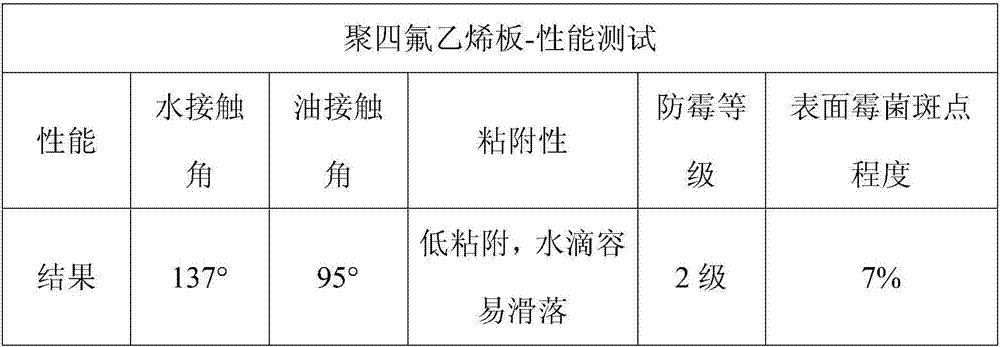

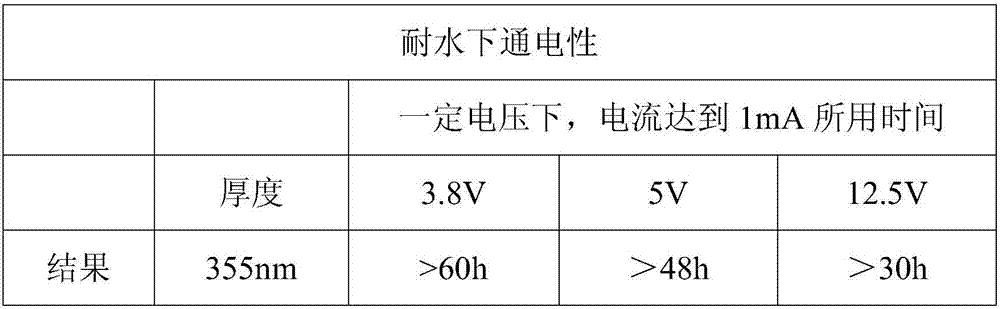

Method for preparing multifunctional nanometer protection coating through circulation small-power continuous discharge

ActiveCN107142465AImprove the protective effectCoating increaseNanotechnologyChemical vapor deposition coatingChemical vapor depositionMoisture

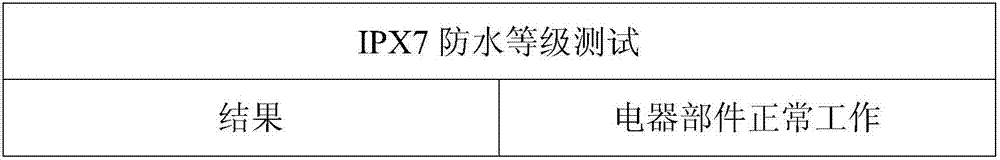

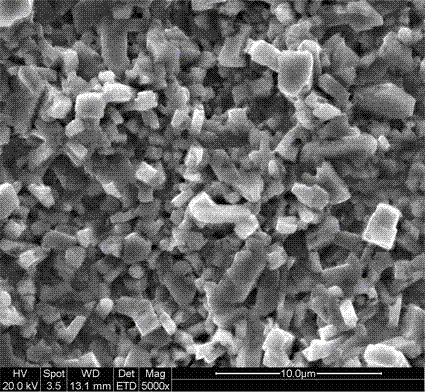

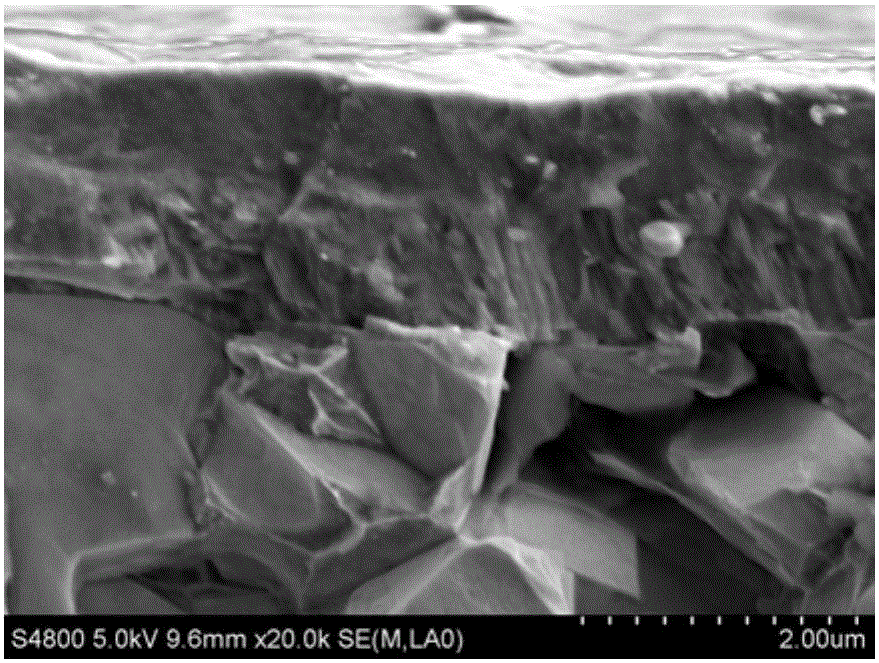

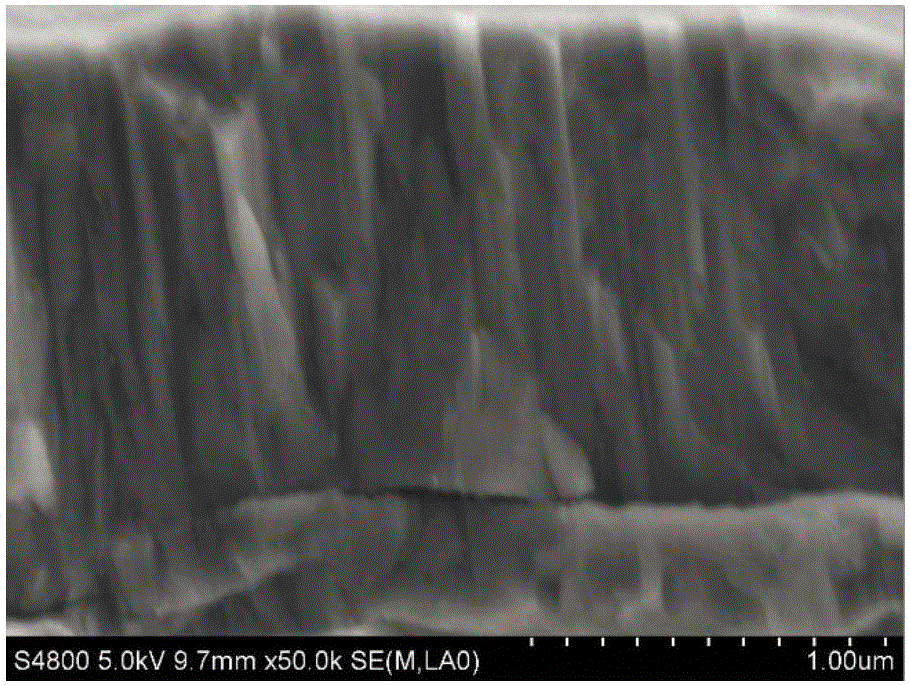

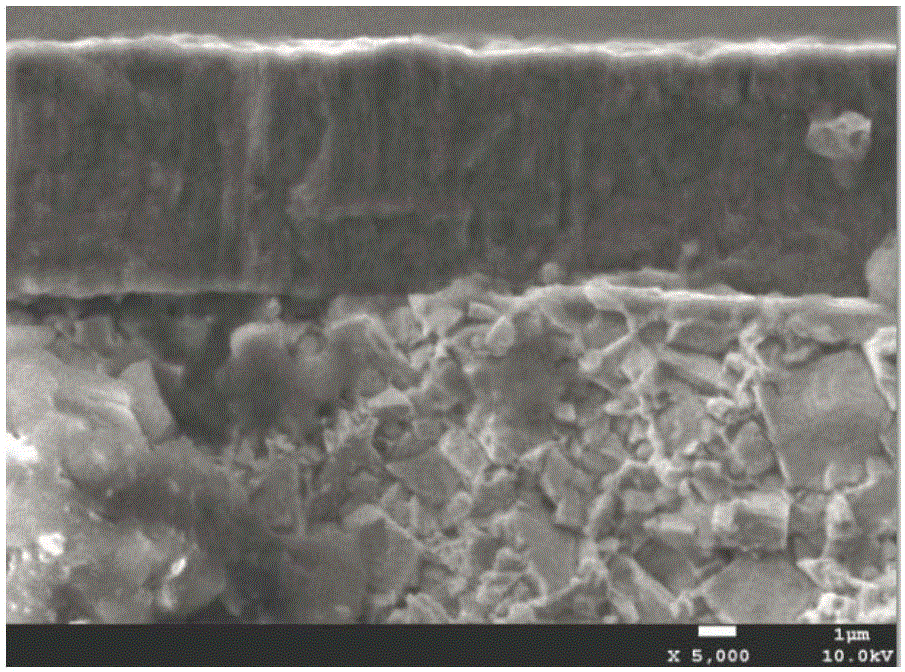

The invention discloses a method for preparing multifunctional nanometer protection coating through circulation small-power continuous discharge, and belongs to the technical field of multifunctional nanometer protection coating through circulation small-power continuous discharge. The method comprises the steps that a reaction cavity is vacuumized, inert gas is introduced into the reaction cavity, a base material moves in the reaction cavity, monomer steam is introduced into the reaction cavity, chemical vapor deposition is carried out and comprises a pretreatment stage and a film coating stage, the plasma discharge mode is large-power continuous discharge in the pretreatment stage, the plasma discharge mode is small-power continuous discharge in the film coating stage, the pretreatment stage and the film coating stage are cycle and repeated at least one time, more active sites more introduced to the surface of the base material in a circulation mode in the film coating technological process, effective film coating is added, the film structure is more compact, the nanometer coating with of the multi-layer composite structure is obtained, multiple layers of protection are provided for the product, the more compact coating structure is shown microscopically, and excellent hydrophobicity, adhesive force, acid and base resistance, mechanical performance and moisture and heat resistance are shown macroscopically.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

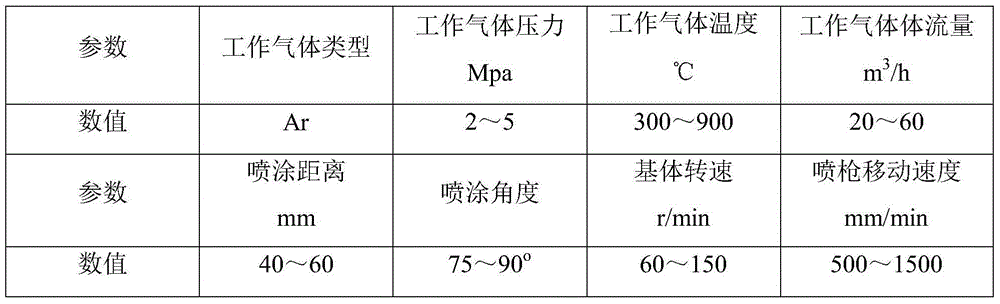

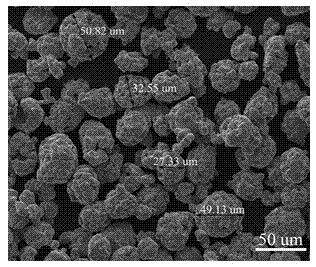

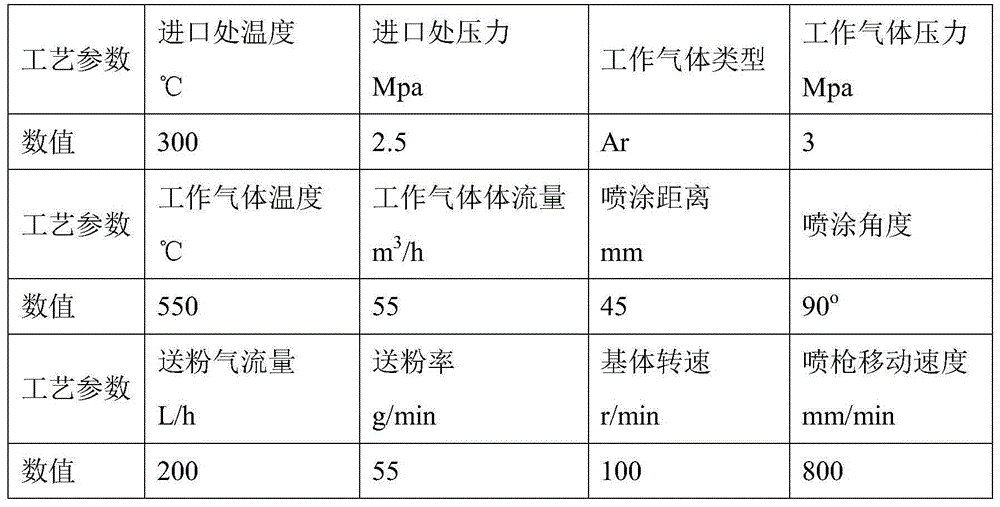

Aluminum tantalum rotating target material, and method used for preparing aluminum tantalum rotating target material via controlled atmosphere cold spraying

InactiveCN104831244ALow costHigh purityMolten spray coatingVacuum evaporation coatingControlled atmosphereRaw material

The invention discloses an aluminum tantalum rotating target material, and a method used for preparing the aluminum tantalum rotating target material via controlled atmosphere cold spraying. According to the method, aluminum tantalum powder is taken as a raw material of the aluminum tantalum rotating target material, and the aluminum tantalum rotating target material is prepared by spraying the aluminum tantalum powder via controlled atmosphere cold spraying. The method comprises following steps: the aluminum tantalum powder with a particle size ranging from 150 to 1000 meshes is prepared, wherein purity is 99.99% or higher; a stainless steel matrix is subjected to rust removing, cleaning, abrasive blasting, and the like; under protection of inert gas, spaying of an alloy transition layer is carried out via plasma spraying; and in a circulating inert gas protective atmosphere, the aluminum tantalum rotating target material is prepared by cold spraying of the aluminum tantalum powder to the matrix containing the alloy transition layer, wherein inset gas flow amount is controlled to be 200 to 1500 SCCH, the matrix is driven to rotate around a center shaft at a speed of 60 to 150r / min, and moving speed of a spray gun is controlled to be 500 to 1500mm / min. The aluminum tantalum rotating target material is high in purity (purity>=99.99%, and oxygen content <=200ppm) and density (relative density>=97%); composition is uniform; length can be as large as 4000mm; and thickness ranges from 3 to 15mm.

Owner:无锡舒玛天科新能源技术有限公司

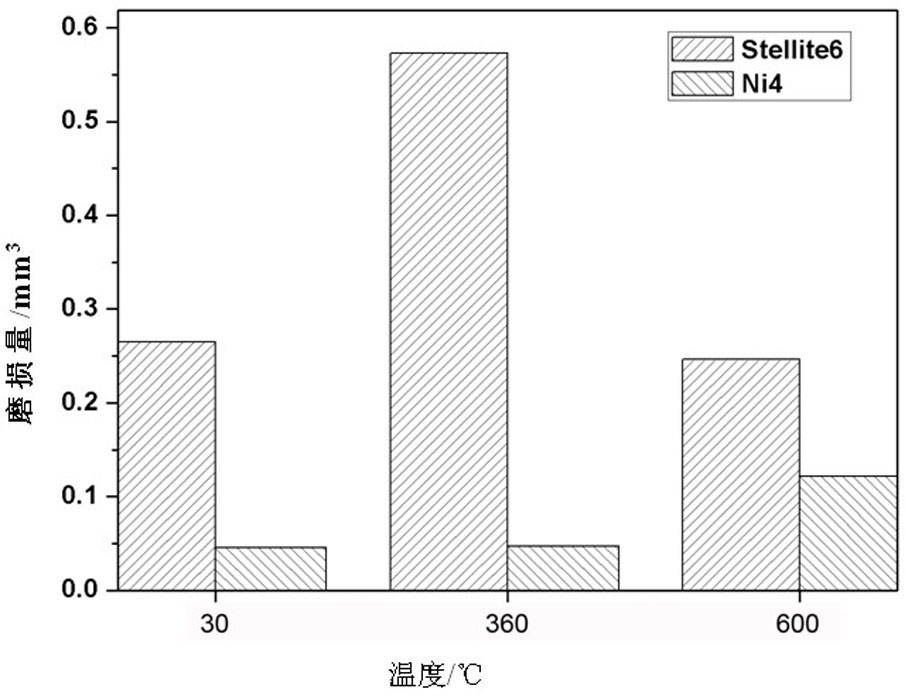

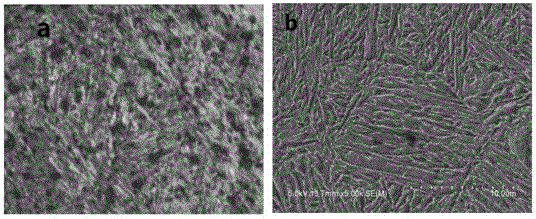

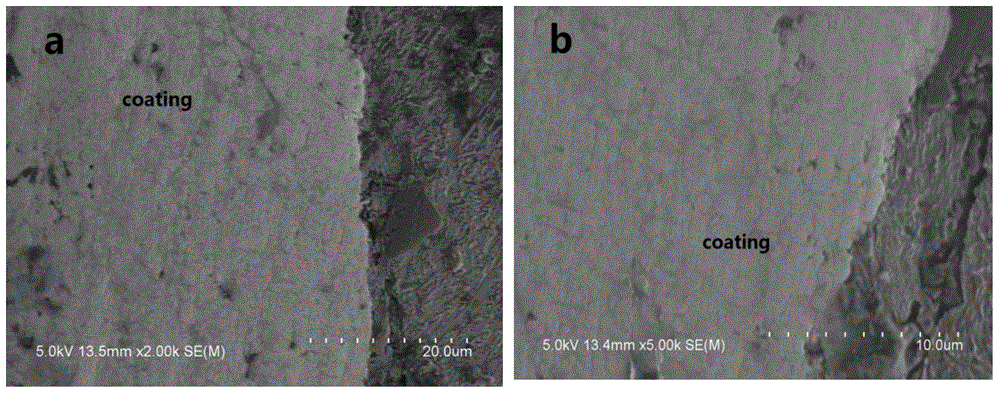

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

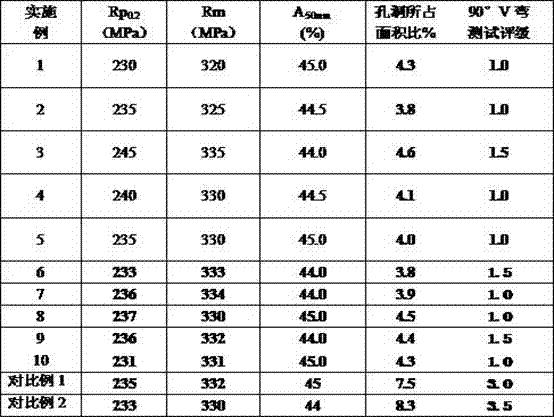

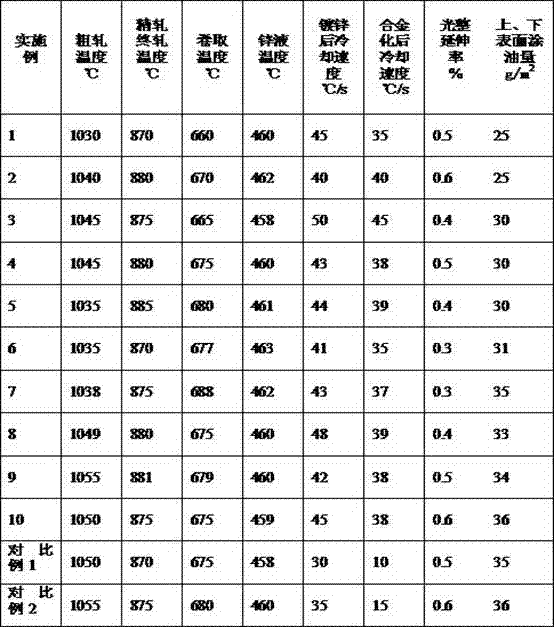

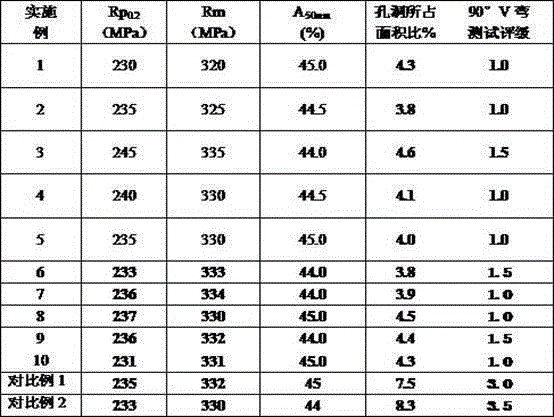

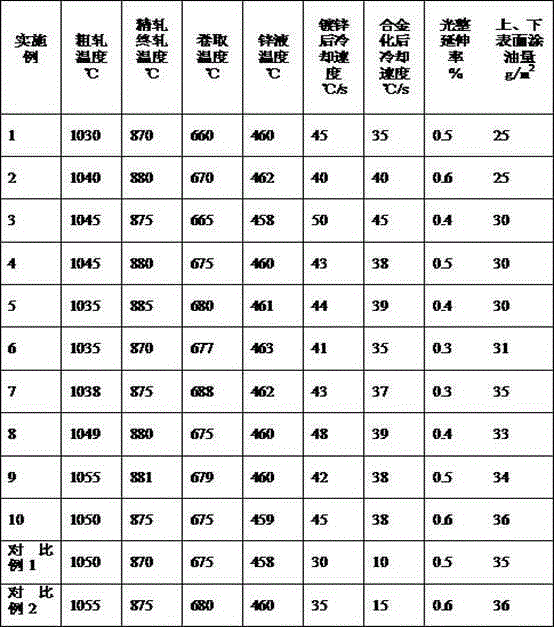

A production method of iron-zinc alloy coated steel plate with yield strength ≥ 220mpa

ActiveCN105274301BFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

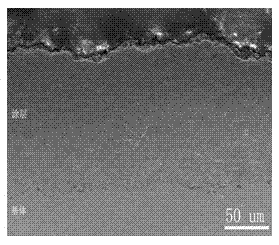

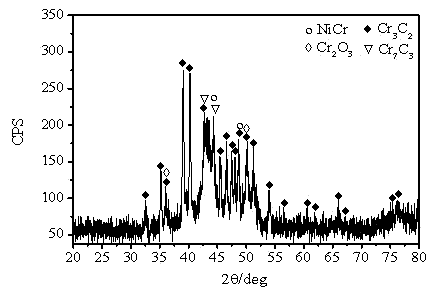

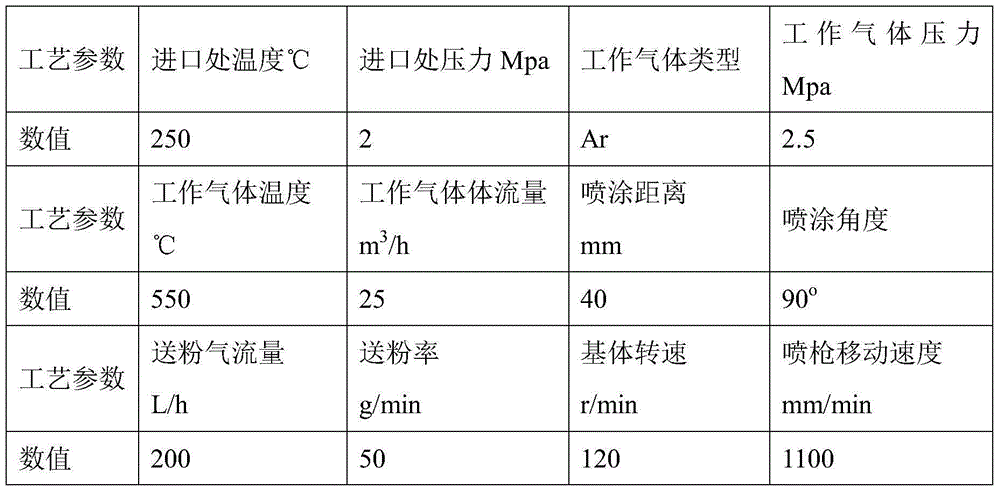

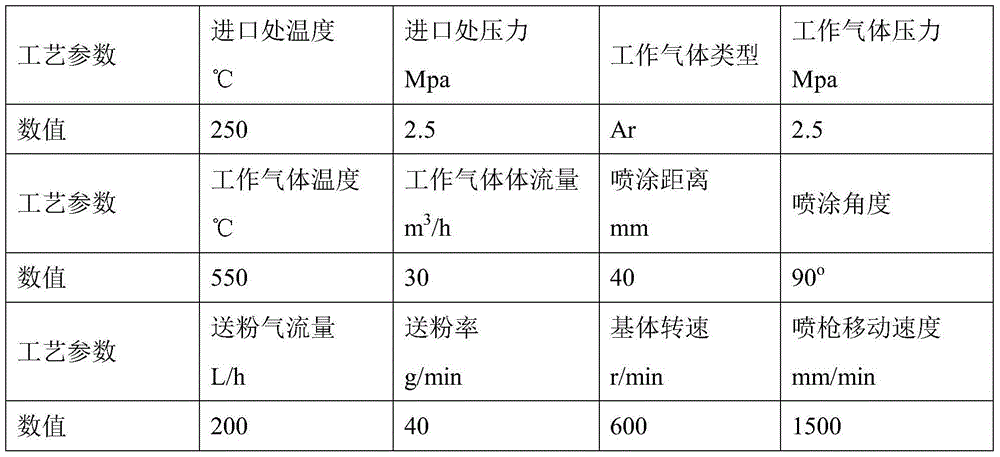

Method for spraying hypersonic flame on surface of intermediate/high-temperature furnace roller

The invention relates to a method for spraying a hypersonic flame on the surface of an intermediate / high-temperature furnace roller, belongs to the technical field of material surface treatment, and in particular relates to a spraying method of spraying restoration the surface of the intermediate / high-temperature furnace roller. The method is characterized by comprising the following steps: 1, pretreating the furnace roller to be sprayed; 2, preparing a hole sealing agent; 3, fixing the furnace roller on spraying equipment by using a clamp, determining the rotating speed according to the size of the furnace roller and controlling the moving speed of a mechanical arm of the spraying equipment according to the fact that the mechanical arm is moved by 5mm when the furnace roller turns a circle; 4, spraying, namely, starting the equipment for spraying; 5, smearing the hole sealing agent; 6, curing; 7, polishing; and 8, performing the abrasion testing. The method has the advantages that a coating layer is bonded with a basal body well, so that the coating layer has the strong bonding strength and the high peeling resistance; the coating layer is compact in tissue, so that the porosity of the coating layer is decreased below 1%; and a majority of Cr3C2 hard phases are maintained during the spraying of the coating layer, so that the high rigidity of the coating layer is realized, the abrasion resistance of the coating layer is improved and the service life of the coating layer is prolonged.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

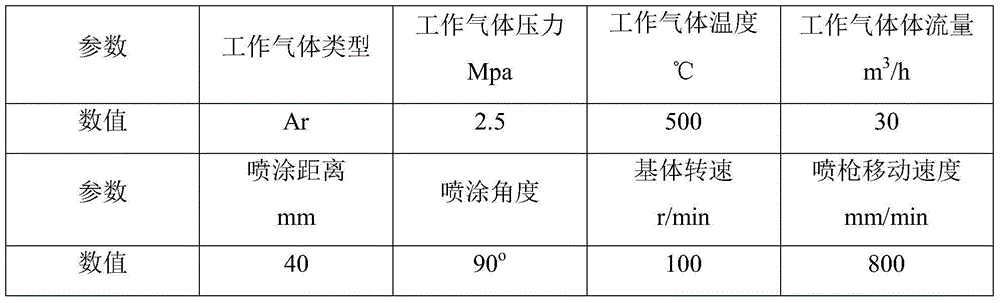

Copper/indium/gallium rotating target and method for preparing copper/indium/gallium rotating target by controllable atmosphere cold spraying

ActiveCN104818465AHigh purityHigh densityVacuum evaporation coatingSputtering coatingIndiumVolumetric Mass Density

The invention provides a copper / indium / gallium rotating target and a preparation method thereof. The preparation method comprises such steps as ultrasonic cleaning, drying and sand spraying of a basal body stainless steel pipe; preparation of the basal body stainless steel pipe including a nickel / aluminum base layer; preparation of the basal body stainless steel pipe including a copper / indium or copper / gallium translation layer; and preparation of a copper / indium / gallium target on the treated basal body pipe. The preparation method uses D50 copper / indium / gallium powder of 100 microns as a raw material, and performs the ball grinding, the screening and the protective atmosphere cold spraying to prepare the copper / indium / gallium rotating target. The method is simple in process, convenient to operate and suitable for large-scale industrial production; the prepared target has high purity (not lower than 99.99%), great relative density (not lower than 97%), unlimited size, the thickness of 3-15 mm, the length of 4000 mm and the oxygen content not higher than 200 ppm.

Owner:无锡舒玛天科新能源技术有限公司

Method for preparing multifunctional nano protective coating by circulating large-duty-ratio pulse discharging

ActiveCN107177835AImprove the protective effectCoating increaseSpecial surfacesChemical vapor deposition coatingMacro levelMoisture resistance

The invention provides a method for preparing a multifunctional nano protective coating by circulating large-duty-ratio pulse discharging and belongs to the technical field of plasma. The method is characterized in that a reaction chamber is vacuumized, inert gas is filled into the reaction chamber, a substrate can move, monomer steam is filled into the reaction chamber, and chemical vapor deposition is carried out; a deposition process comprises a pretreatment stage and a film coating stage; the plasma discharging manner in the pretreatment stage is a high-power continuous discharging manner; the plasma discharging manner in the film coating stage is a large-duty-ratio pulse discharging manner; the pretreatment stage and the film coating stage are circulated and repeated for at least one time; through circulation introduction in the film coating process, more active sites are introduced into the surface of the substrate; the effective coating of the film can be increased; the film structure is more dense; a nano coating with a multilayer composite structure is obtained; multi-level protection is provided for the product; the product shows more dense coating structure at a micro level and shows excellent hydrophobicity, adhesion, acid resistance, alkali resistance, mechanical property, moisture resistance and heat resistance at a macro level.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

InactiveCN102534606AMeet the needs of the jobGood high temperature performanceMetallic material coating processesPowder mixtureNuclear power

The invention discloses a nickel-base alloy coating for a sealing surface of a nuclear power valve, and is characterized in that the nickel-base alloy coating is prepared according to a method of conducting laser-cladding on nickel-base alloy powder. The nickel-base alloy powder comprises the following constituents by weight percent: 20.0 to 24.0 percent of Cr, 4.0 to 4.2 percent of Si, 3.0 to 3.5 percent of P, 3.0 to 3.2 percent of Mo, 8.0 to 8.5 percent of Fe, 1.0 to 1.2 percent of C, 0.8 to 1.0 percent of yttrium oxide, and Ni in balancing amount. The laser-cladding process adopts a synchronous powder feeding method and a pre-coating method. The nickel-base alloy powder mixture contains no noble metal Co, thereby particularly meeting requirements on valves under nuclear environments; and due to the formulation design of the mixture, and the advantage of the laser-cladding technology in coating preparing, the coating on the sealing surface has a favorable high-temperature property.

Owner:SUZHOU UNIV

Method for preparing wear-resistant coating of ball mill lining plate

ActiveCN105063539ABroaden your optionsHigh bonding strengthMolten spray coatingWear resistanceBall mill

The invention discloses a method for preparing a wear-resistant coating of a ball mill lining plate, and belongs to the field of remanufacturing of engineering machines. The wear-resistant coating comprises a base and a coating layer. The base comprises, by weight, 0.30%-0.44% of C, 1.50%-2.0% of Si, 0.8%-1.40% of Mn, 2.0%-2.8% of Cr, equal to or less than 0.3% of Mo, equal to or less than 0.3% of Ni, 0.02% of Re, 0.04% of P and S, and the balance Fe. The coating layer comprises, by volume fraction, 95%-98% of WC-Co powder and 2%-5% of Cr. The weight ratio of Cr to Co is 0.2-0.5. The method enables a part to have wear resistance, corrosion resistance and other special performance, the reliability of the part is improved, the service life of the part is prolonged, and especially the wear resistance of the working surface of the ball mill lining plate is improved.

Owner:ANHUI POLYTECHNIC UNIV

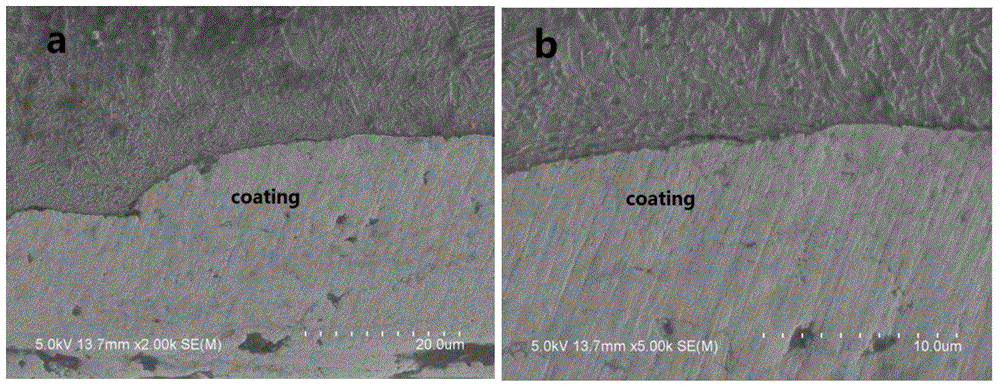

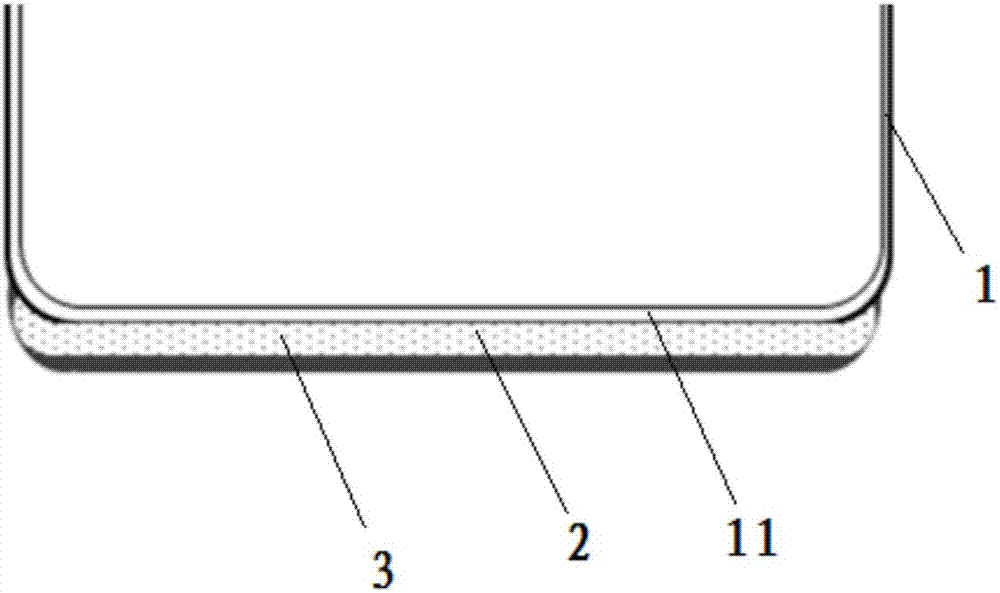

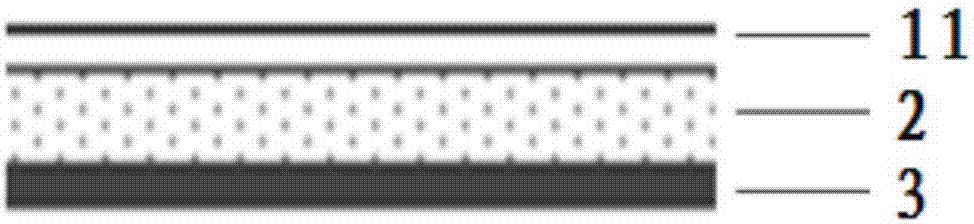

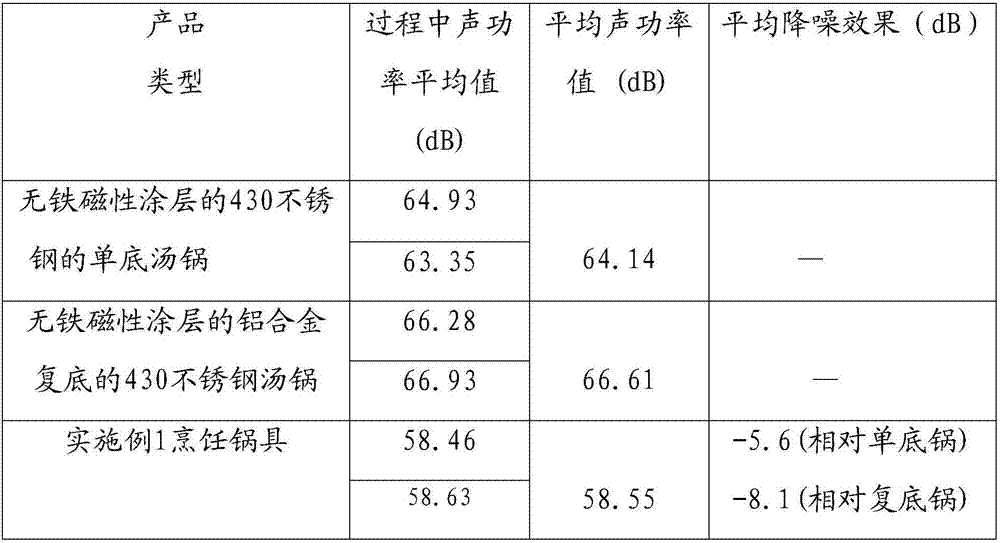

Cooking pot and manufacturing method thereof

ActiveCN107303127AProtect against rustReduce noiseCooking-vessel materialsPretreated surfacesPorosityMetallurgy

The invention relates to a cooking pot and a manufacturing method thereof. The cooking pot comprises a stainless steel pot body, a magnetic conduction coating layer and an anti-rusting wear-proof layer, wherein the magnetic conduction coating layer is located on the outer side surface of the bottom wall of the stainless steel pot body, and the porosity of the magnetic conduction coating layer is 10%-15%; and the anti-rusting wear-proof layer adheres to the magnetic conduction coating layer. According to the cooking pot, the magnetic conduction coating layer with the porosity of 10%-15% is arranged on the bottom wall of the stainless steel pot body, and energy of partial noise can be absorbed and consumed through vibration of air in internal pores of the magnetic conduction coating layer, so that the noise in an electromagnetic heating process of the pot can be remarkably reduced; and furthermore, the anti-rusting wear-proof layer is arranged outside the magnetic conduction coating layer, so that the stainless steel pot body protected by the anti-rusting wear-proof layer does not rusted for a long time (1-2 years).

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

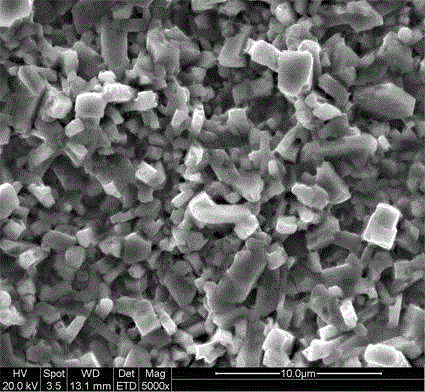

Titanium boride-based coating composite material for aluminum electrolysis, preparation method and coating method thereof

ActiveCN103194101ALower sintering temperatureReduce manufacturing costCoatingsGraphite carbonAluminium electrolysis

The invention discloses a titanium boride-based coating composite material for aluminum electrolysis, a preparation method and a coating method thereof. The composite material consists of the following raw materials in percentage by weight: 55%-70% of titanium boride-oxide composite particles, 8%-15% of a carbon additive, 15%-30% of an organic resin adhesive and 0.5%-2% of a reinforcing agent. The coating method comprises the following steps: (1) putting a graphite base material into a coating mould, and then, pouring the obtained slurry into a mould; (2) curing the base material coated with the slurry at 15 DEG C-35 DEG C for 24h-48h, and then, curing the base material at 80 DEG C-150 DEG C for 12h-24h; and (3) putting the base material coated with the slurry into a graphite crucible, filling graphite carbon powder into the graphite crucible, and carbonizing and sintering the graphite crucible in an inert gas atmosphere or in vacuum, wherein the carbonizing and sintering temperature is 850-1050 DEG C, and the carbonizing and sintering time is 80-120 hours. The titanium boride-based coating composite material for aluminum electrolysis has high combination degree with a base and good tensile strength high up to 8-10MPa; and a coating structure is dense and has strong anti-scouring property.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Surface coating part for reproduction of ball mill liner plate and manufacturing method for surface coating part

ActiveCN105063499ABroaden your optionsHigh bonding strengthMolten spray coatingGrain treatmentsBall millMaterials science

The invention discloses a surface coating part for reproduction of a ball mill liner plate and a manufacturing method for the surface coating part, and belongs to the field of reproduction of engineering machines. The surface coating part comprises a substrate and a coating layer. The substrate comprises, by weight, 0.30-0.44% of C, 1.50-2.0% of Si, 0.8-1.40% of Mn, 2.0-2.8% of Cr, 0.3% of Mo or less, 0.3% of Ni or less, 0.02% of Re, 0.04% of P and S and the balance Fe. The coating layer comprises, by volume, 95-98% of WC-Co powder and 2-5% of Cr, and the weight ratio of Cr to Co is 0.2-0.5. The surface coating part for reproduction of the ball mill liner plate and the manufacturing method for the surface coating part can give the special properties like abrasion resistance and corrosion resistance to parts, improve the reliability of the parts, prolong the service life of the parts and especially improve the abrasion resistance of a work surface of the ball mill abrasion-resistant liner plate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

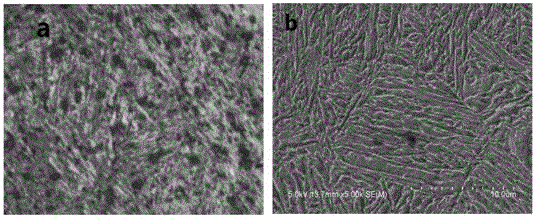

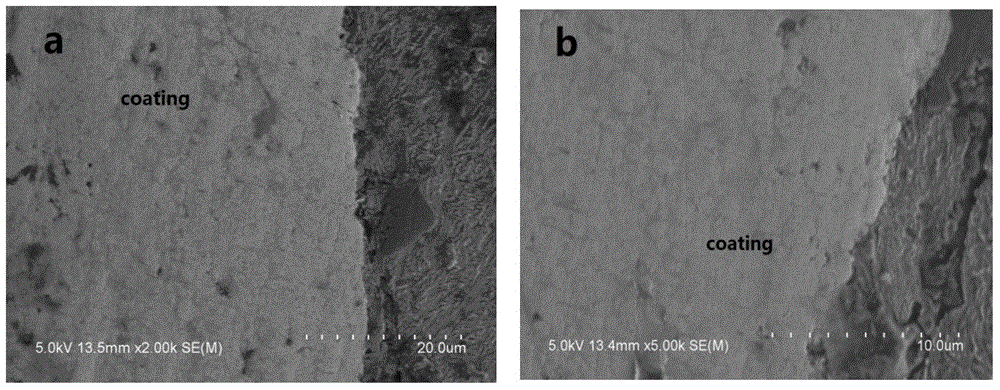

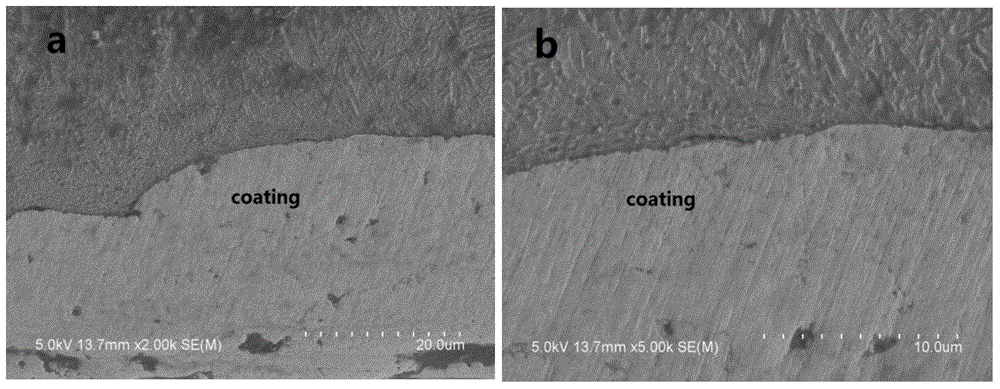

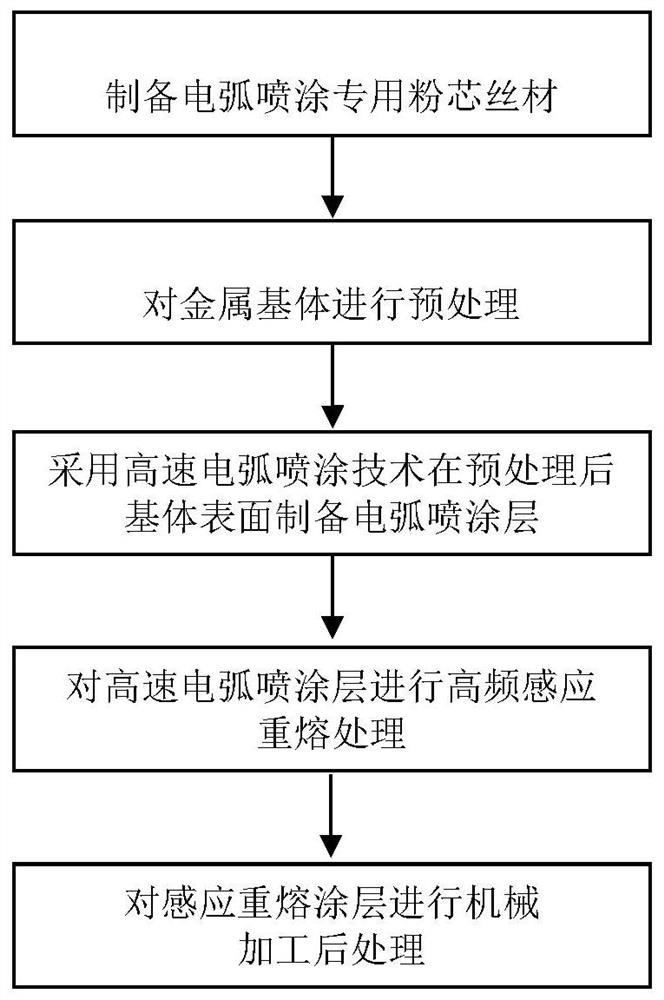

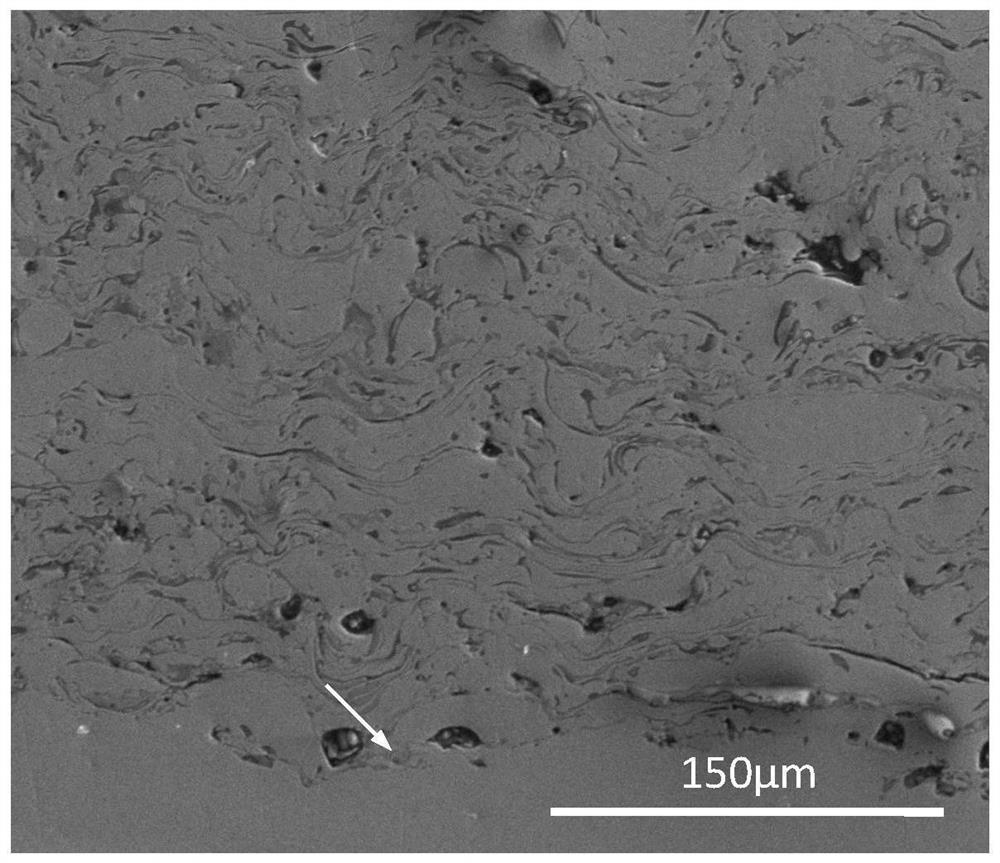

Powder core wire, preparing method thereof, corrosion preventing and abrasion resisting composite coating and preparing method of corrosion preventing and abrasion resisting composite coating

ActiveCN111763902AImprove wear resistanceImprove corrosion resistanceMolten spray coatingSurface engineeringSilicate minerals

The invention belongs to the technical field of surface engineering, and particularly relates to a powder core wire, a preparing method thereof, a corrosion preventing and abrasion resisting compositecoating and a preparing method of the corrosion preventing and abrasion resisting composite coating. The provided powder core wire comprises a skin and a powder core. The material of the skin is stainless steel. By mass percent, the powder core accounts for 30-40% of the powder core wire. By weight, the powder core comprises following components including 2.5-4.5 parts of B, 0.6-1 part of C, 3-4.5 parts of Si, 8-12 parts of Cr, 15-18 parts of Ni, 10-12 parts of Zn, 3-5 parts of Al, 0.3-0.5 part of CeO2 and 3-5 parts of silicate minerals. The powder core wire is utilized for obtaining the corrosion preventing and abrasion resisting composite coating through high-speed electric arc spraying and high-frequency induction remelting, and the obtained corrosion preventing and abrasion resistingcomposite coating combines good abrasion resistance and corrosion resistance.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +1

Boride ceramic coating prepared through electric spark deposition in-situ reaction and preparation method thereof

InactiveCN102899600AExtended service lifeImprove corrosion resistanceMolten spray coatingBorideThermal spraying

The invention relates to a boride ceramic coating in situ synthesized on the surface of a continuous casting crystallizer through electric spark deposition and a preparation method thereof. The coating is prepared through the following steps: pretreating a substrate; then with a composite material of a boron-supplying agent, an energizing agent and a filling material used as a deposition electrode, fixing the deposition electrode in a working gun of electric spark deposition equipment under the protection of argon; fixing the substrate at the cathode of the electric spark deposition equipment; starting the electric spark deposition equipment; and moving the electric spark working gun to a copper working surface of the continuous casting crystallizer for deposition of a protective coating. The coating has a compact structure, no pores and no cracks and is in metallurgical bonding with the substrate; the microhardness of the coating is about HV700; the service life of the continuous casting crystallizer is increased by more than 1 to 2 times; the preparation method provided by the invention replaces conventional surface strengthening processes for a continuous casting crystallizer like composite electroplating and thermal spraying having the disadvantages of high energy consumption, high pollution and high cost and has substantial economic and social benefits.

Owner:CHANGZHOU UNIV

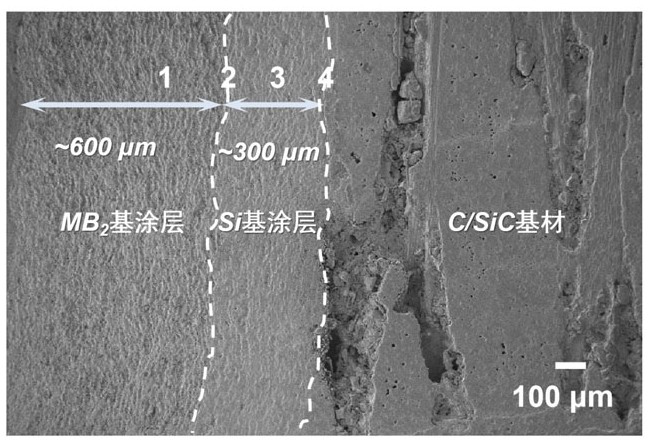

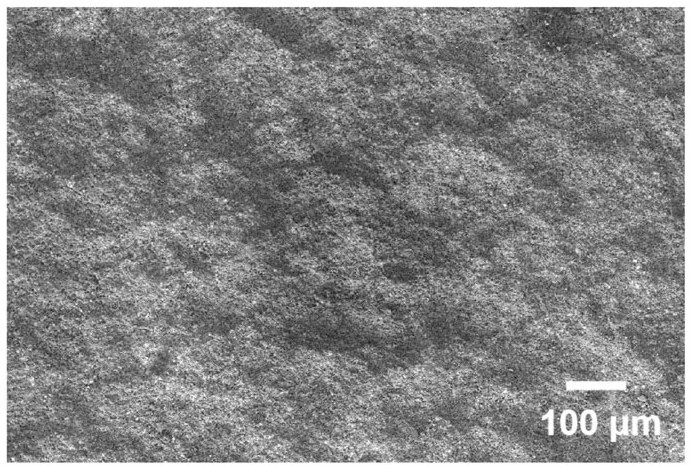

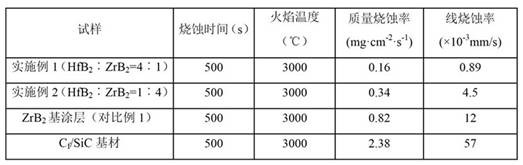

MB2-based ultrahigh-temperature ceramic coating and preparation method thereof

ActiveCN111848220AAdvanced technologyImprove antioxidant capacityEfficient propulsion technologiesOxidation resistantCeramic coating

The invention provides an MB2-based ultrahigh-temperature ceramic coating which comprises an ultrahigh temperature ceramic body coating, an ultrahigh temperature ceramic body is composed of MB2-M1Si-Mo-SiC and comprises the following components in percentage by volume: 40-60% of MB2, 20-40% of M1Si, 20-40% of Mo and 0-20% of SiC, wherein the MB2 comprises HfB2 and ZrB2, the volume ratio of the HfB2 to the ZrB2 is 4: 1-1: 4, the M1Si comprises one or more of MoSi2, CrSi2, ZrSi2 and TaSi2, and the volume ratio of the MoSi2 to the CrSi2 to the ZrSi2 to the TaSi2 is (0-4): (0-4): (1-8): (0-2). Theinvention further provides a preparation method of the MB2-based ultrahigh-temperature ceramic coating. The ceramic coating is good in ablation resistance, good in spraying manufacturability, excellent in medium-high temperature oxidation resistance, compact in structure and strong in combination with a matrix. The method is simple in process, coating components and thickness are easy to control,and production efficiency is high.

Owner:中国人民解放军火箭军工程大学

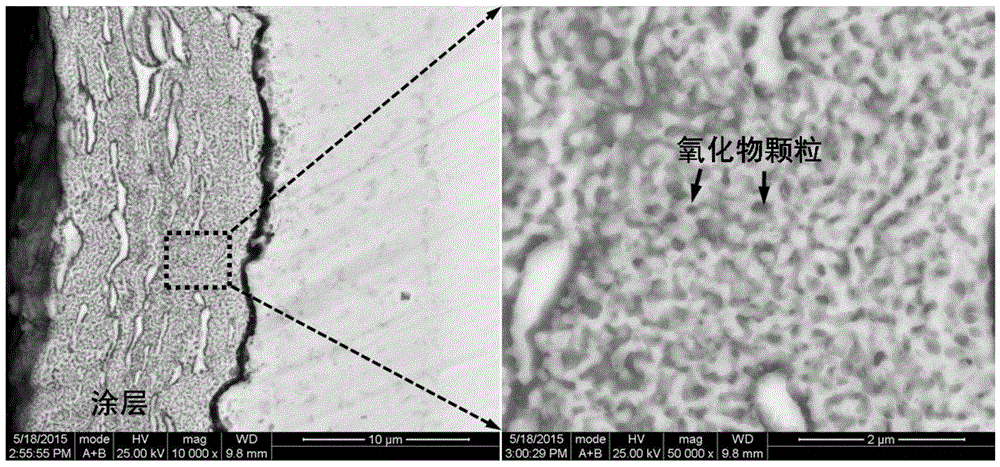

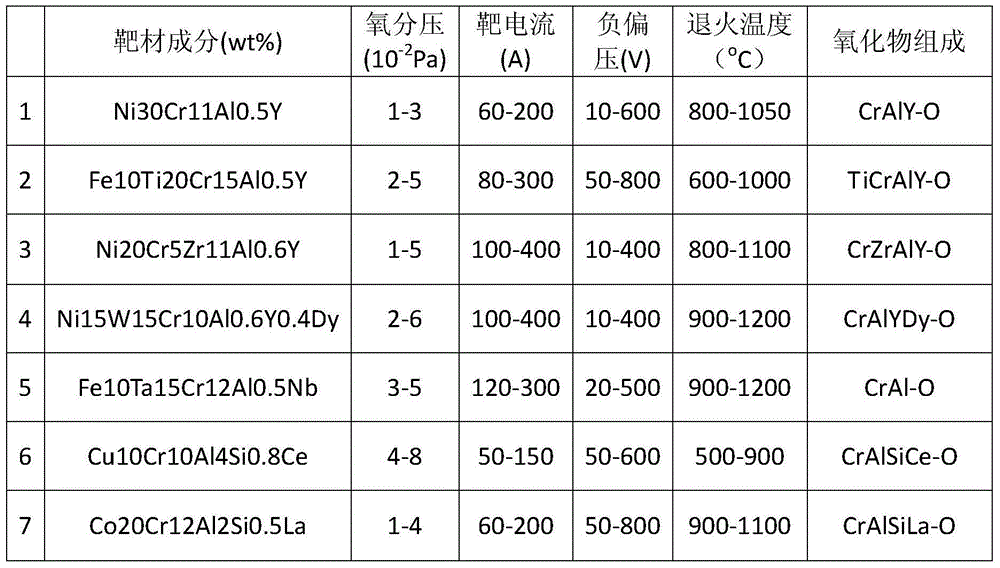

In-situ preparation method of alloy coating reinforced through dispersion of microcrystalline oxide particles

The invention relates to an in-situ preparation method of an alloy coating reinforced through dispersion of microcrystalline oxide particles, and belongs to the technical field of a coating. The method can be used for preparing an anti-corrosion wear-resistant coating and an electrical-conductive anti-ablation coating of a contact material. The alloy coating contains a low-aerobic component including copper, iron, nickel, cobalt or a combination thereof and a high-aerobic component including chromium, aluminium, zirconium, titanium, silicon and rare earth aerobic elements such as yttrium, lanthanum, dysprosium, and cerium or a combination thereof. The components are smelted or subjected to hot press sintering to prepare an arc ion plating target material, the arc ion plating target material is deposited in a low-oxygen-partial-pressure atmosphere to obtain a precursor coating; annealing is performed in a vacuum or inert atmosphere; and oxygen adsorbed and solid-dissolved in the coating and high-aerobic elements undergo an in-situ reaction to form a composite coating with nanometer / submicron oxide particles dispersed in a metal matrix. Through utilization of the advantages of arc ion plating, the prepared coating is dense in texture and the size of oxide particles is controllable. The technology is high in stability, low in cost and suitable for industrial application.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

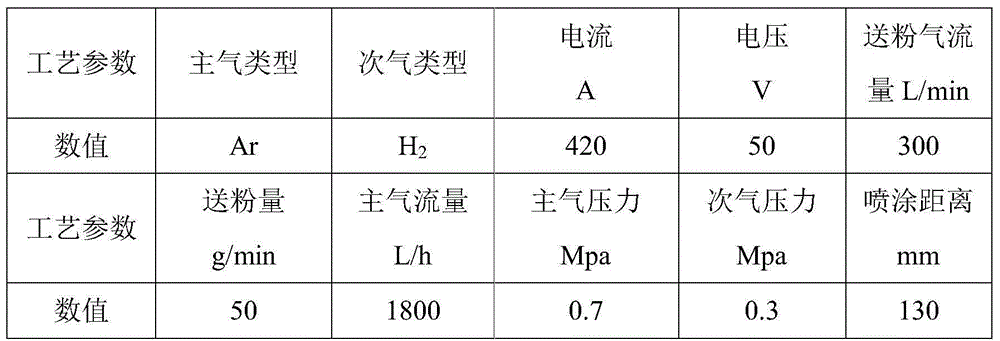

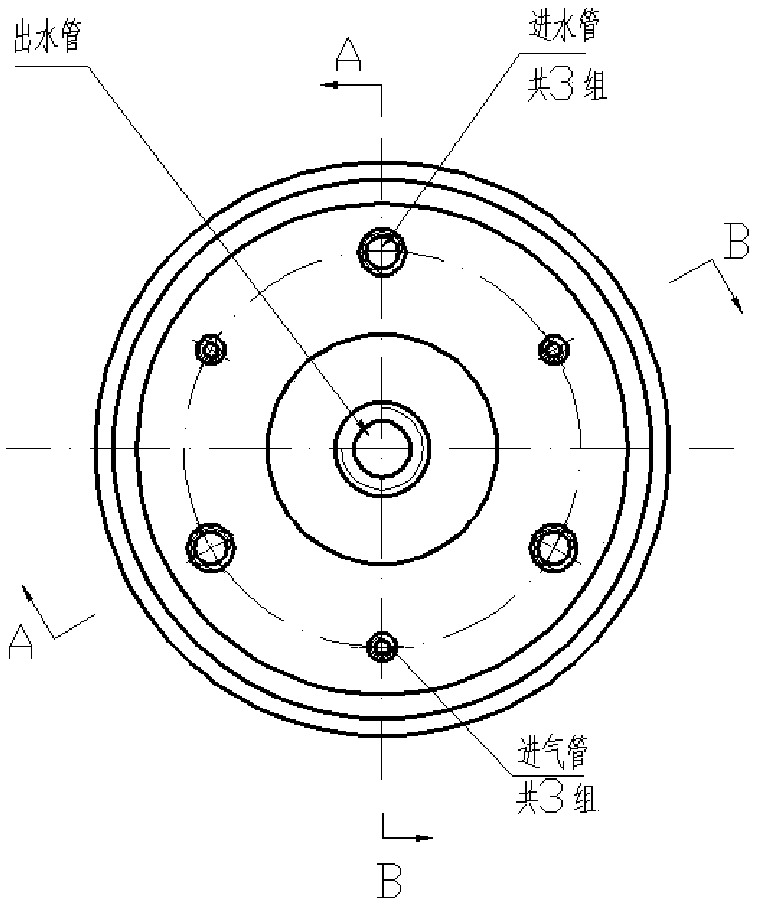

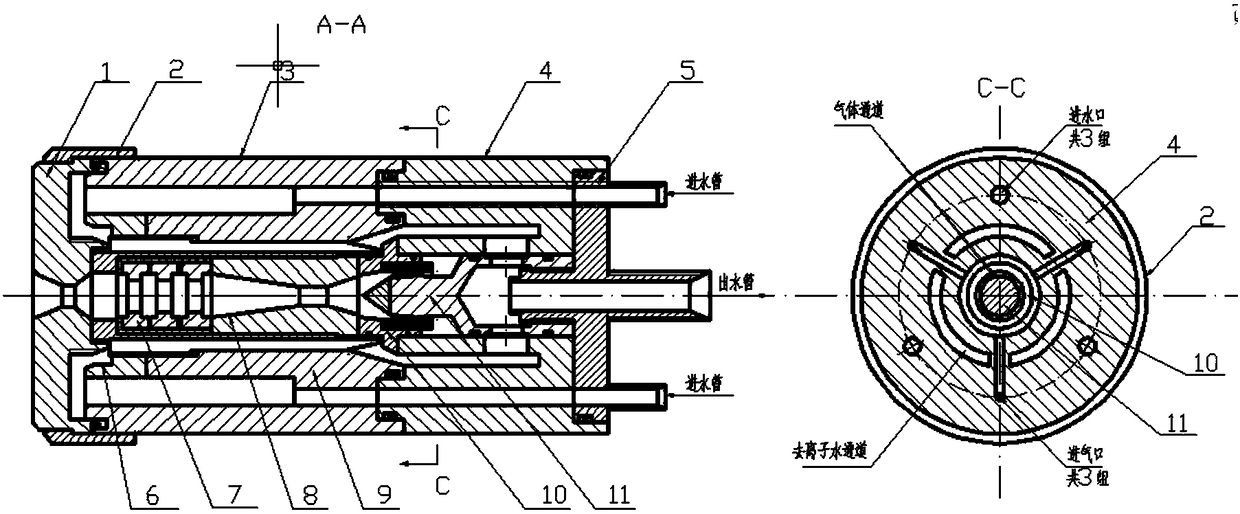

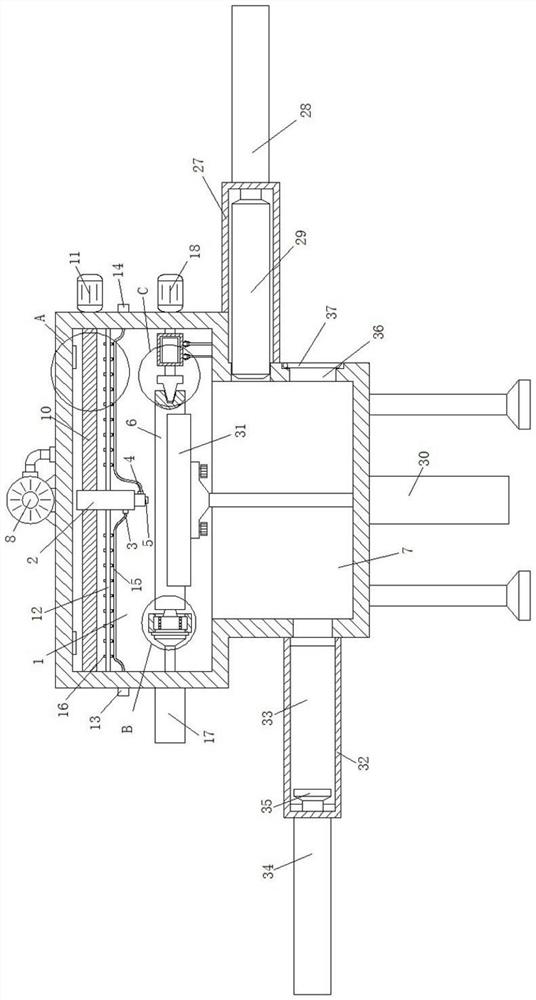

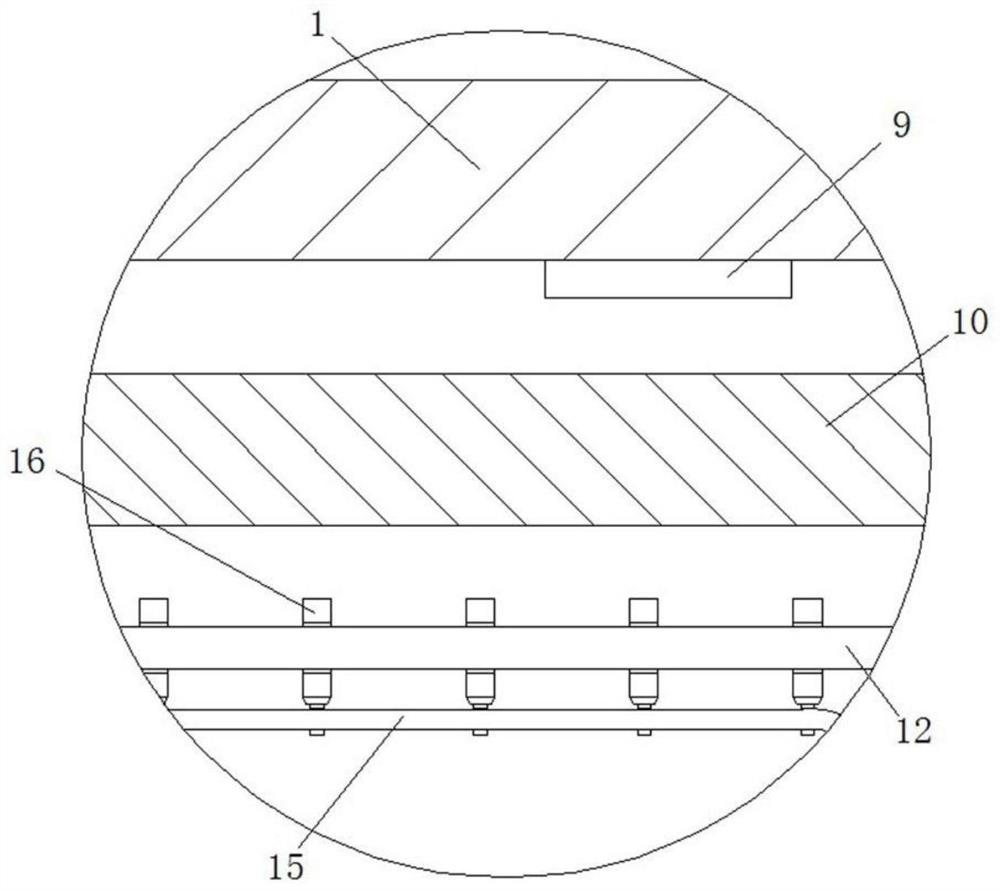

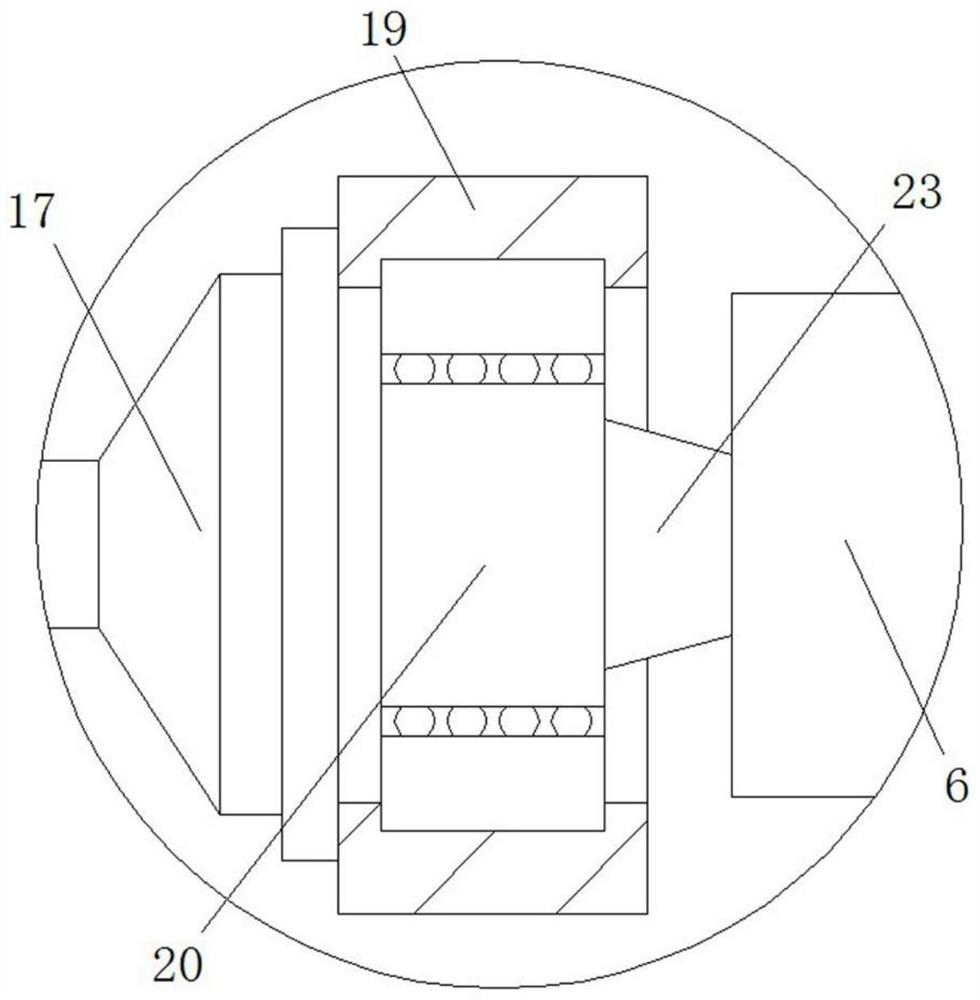

Novel hypersonic-speed high-enthalpy-value plasma gun and preparation process of WC-based composite coating layer

The invention discloses a novel hypersonic-speed high-enthalpy-value plasma gun and a preparation process of a WC-based composite coating layer. The novel hypersonic-speed high-enthalpy-value plasma gun comprises a nozzle, a fixed ring, a shell 1, a shell 2, an integrator, a water dividing sleeve, an anode, a compressor, a water cooling sleeve, a spacer sleeve and a cathode, wherein the compressoris added between the cathode and the anode to enlarge the gap between the cathode and the anode. The novel hypersonic-speed high-enthalpy-value plasma gun and the preparation process disclosed by theinvention have the beneficial effects that the arc length is prolonged, simultaneously the stability of an arc can be improved, the speed of flame flow of plasma spraying is increased, and finally, the flame-flow speed can reach 6-7 Mach (2040-2380m / s); the coating layer powder is heated to be in a molten and semi-molten state in a high-speed flame, impacts the surface of a workpiece by a high speed, and is deposited to form a dense coating layer; based on the device and process provided by the invention, the WC-based coating layer with high deposition efficiency, high bonding strength, highhardness, low porosity, high abrasion resistance, high corrosion resistance and high wear resistance can be obtained and can be applied on the surfaces of the workpieces such as a water turbine, a water pump, a ball valve, a gate and a piston rod and the like.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

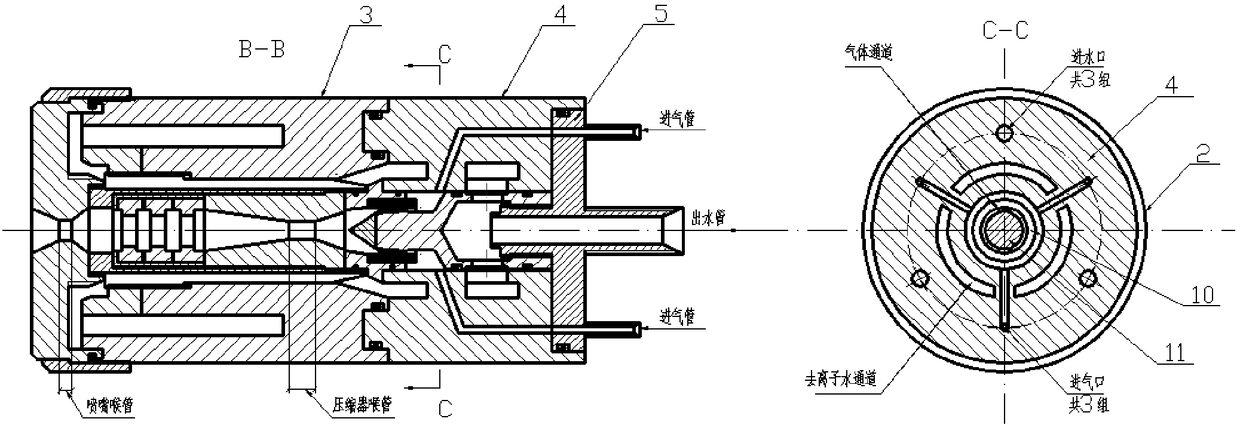

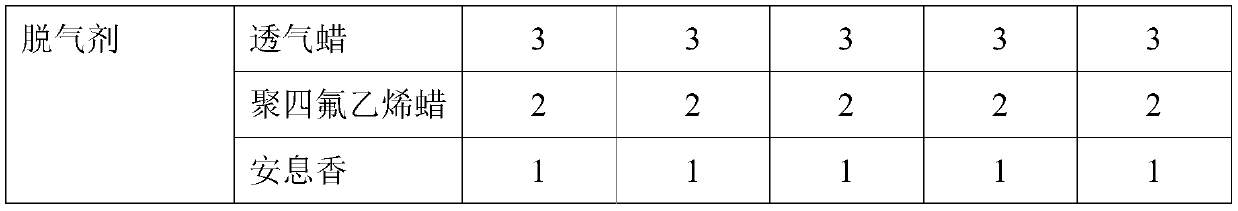

High-gloss self-cleaning powder coating and preparation method thereof

ActiveCN109762449AIncrease crosslink densityDense coating structurePowdery paintsPolyester coatingsWeather resistanceFluorocarbon

The invention discloses a high-gloss self-cleaning powder coating and a preparation method thereof. The high-gloss self-cleaning powder coating is prepared from components in parts by mass as follows:30-50 parts of hydroxyl-terminated polyester resin, 3-15 parts of fluorocarbon resin, 15-75 parts of a curing agent, 1-10 parts of modified nano-silica, 0-2 parts of pigment, 10-40 parts of filler and 0-15 parts of auxiliaries. The powder coating has excellent hydrophobic performance, further has the characteristics of good weather resistance, high gloss and high adhesion and impact resistance, and can be applied to surface coating of outdoor equipment, guardrails, advertising boards and the like and surface coating of indoor equipment, range hoods and the like.

Owner:GUANGZHOU KINTE IND

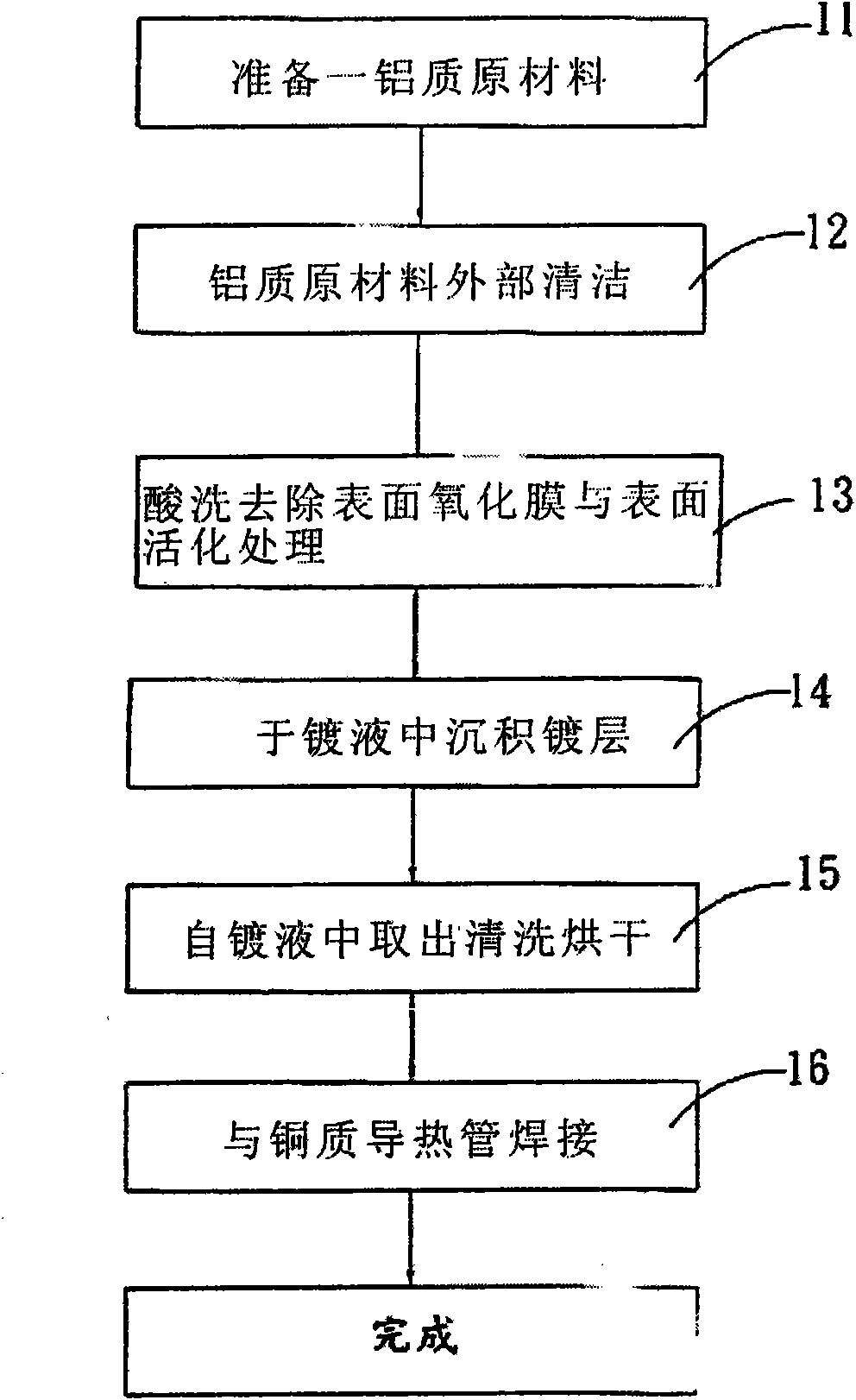

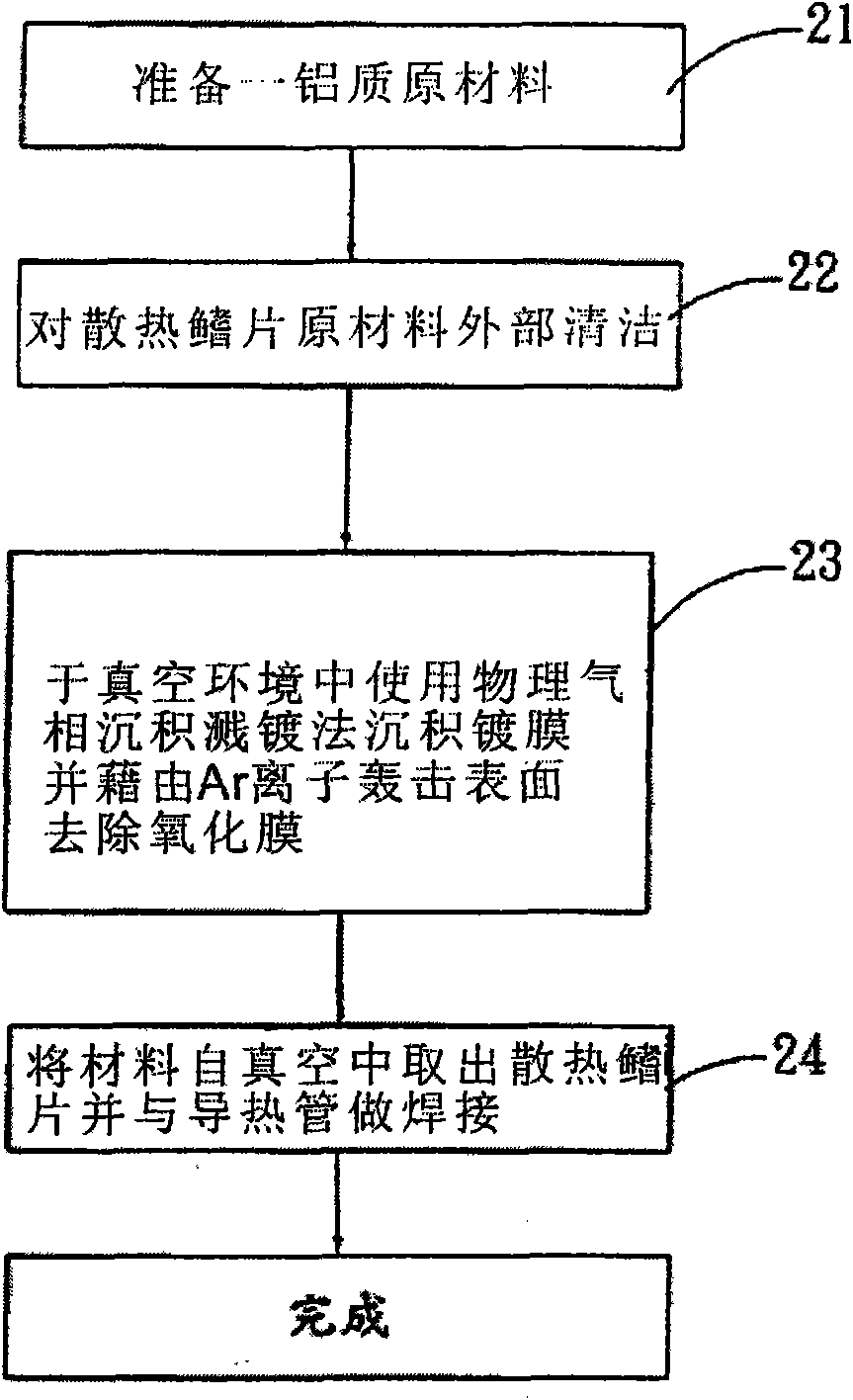

Manufacturing method of radiating module

InactiveCN101585134AIncrease productivityQuality controllableVacuum evaporation coatingSputtering coatingPhysical vapor depositionMetal

The invention discloses a manufacturing method of a radiating module, which mainly comprises the following steps: partially plating radiating fins and heat conducting tubes, which are made of two different metal materials, by a physical vapor deposition method, painting solder on the part which is partially plated, heating the solder till the solder reaches the melting point, welding the radiating fins and the heat conducting tubes so that the radiating fins and the heat conducting tubes are combined and formed into a radiating module structure. By the method for partially plating the radiating fins, the radiating fins and the heat conducting tubes can be welded even if the radiating fins and the heat conducting tubes are made of different metals so that the radiating fins and the heat conducting tubes can be firmly combined and has a superexcellent heat conducting effect.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

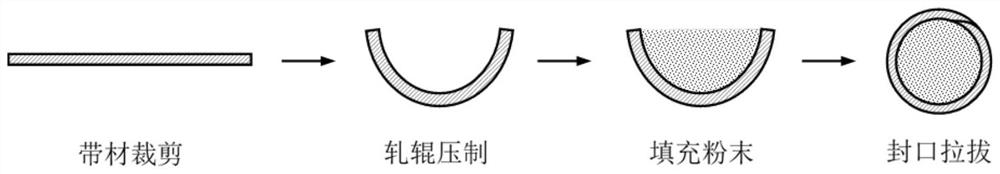

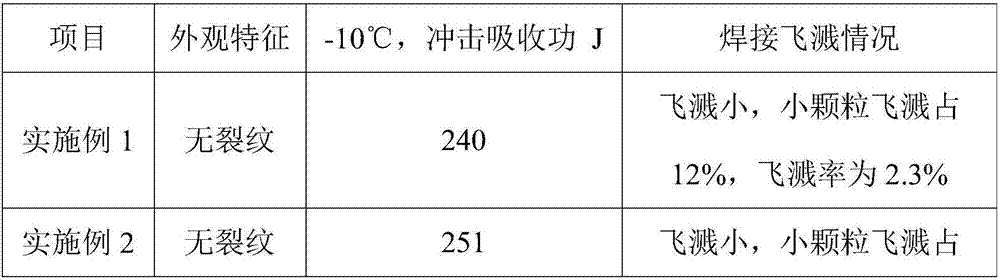

Flux-cored wire

ActiveCN107127478AAct brittleReduce porosityWelding/cutting media/materialsSoldering mediaPorositySlag

The invention discloses a flux-cored wire. The flux-cored wire comprises a low-carbon steel tape sheath and a flux core, wherein the flux core is prepared from the following raw materials according to weight percent: 1 to 2% of graphite, 15 to 17% of chromium powder, 1 to 2% of manganese powder, 4 to 6% of nickel powder, 4 to 6% of columbium powder, 1 to 3% of vanadium powder, 1 to 1.5% of titanium dioxide, 0.5 to 1% of silicon dioxide, 4 to 5% of rhenium oxide, 4 to 5% of cerium oxide, slag formers, oxidizing agents, reducing agents and the balance of iron powder. According to the flux-cored wire, all substances are matched with each other, so that the welding spatter problem can be greatly reduced, the porosity of a welding coating is low, the coating structure is compact, the toughness is good, and the strength is high.

Owner:安徽飞弧焊业股份有限公司

Process and production equipment for manufacturing rotary target material through cold spraying

ActiveCN112746260AImprove compactnessReduce oxygen contentVacuum evaporation coatingSputtering coatingSand blastingMegasonic cleaning

The invention discloses a process and production equipment for manufacturing a rotary target material through cold spraying. The process comprises the following steps of 1) sequentially carrying out ultrasonic cleaning, drying and sand blasting treatment on a base body; (2) vacuumizing the area where the base body is located; (3) introducing ITO powder into a spray gun, and meanwhile, introducing inert gas into the spray gun; and 4) driving and controlling the base body to rotate, and controlling the spray gun to move in the axial direction of the base body, so that the ITO target material is formed. According to the ITO target material prepared through the steps, due to the fact that the ITO target material is always in the helium protection atmosphere during spraying, the oxygen content and mixing of other impurities are reduced, in addition, when the target material is subjected to cold spraying, particles collide with the base body at a high speed and sufficiently deform to form a coating, the coating structure is compact, the relative density of the target material can reach 99.9% or above, the grain structure in the target material is uniform and fine, no defect structure exists, meanwhile, the deposition efficiency is high, and the production cost is reduced.

Owner:HUNAN KOSEN NEW MATERIAL

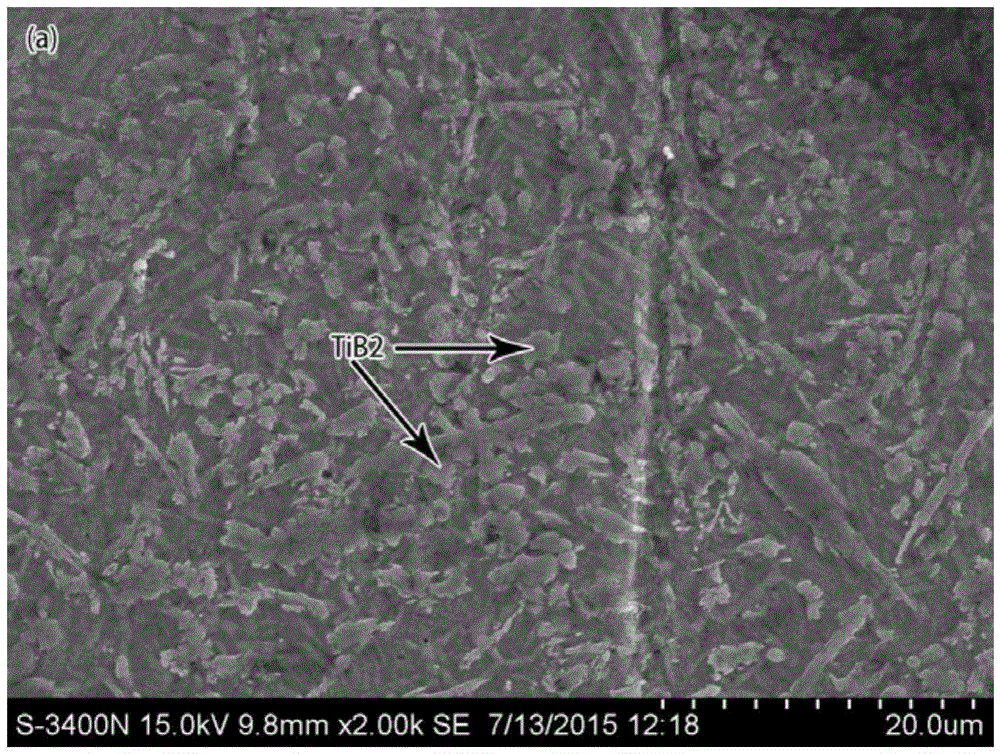

Energy-saving high-temperature radiating spray coating material for silicon steel annealing furnace as well as preparation method and application thereof

ActiveCN109136488ACompact structureEasy to dryFurnace typesHeat treatment furnacesRare-earth elementSpray coating

The invention provides an energy-saving high-temperature radiating spray coating material for a silicon steel annealing furnace. The energy-saving high-temperature radiating spray coating material comprises the following raw materials: pure corundum, silicon carbide, zirconium oxide, aluminum oxide, a silicate refractory material and a rare earth element oxide. The invention further provides a preparation method of the energy-saving high-temperature radiating spray coating material. According to the invention, the blackness of a base material is improved, excellent properties such as heat resistance, high strength, corrosion resistance, wear resistance and the like are kept, and the overall strength and compactness of a coating are further improved. The activity of reactants can be improved due to the doping of the rare earth element oxide, and at the same time, the rare earth element oxide is a preferable material for doping and stabilizing a coating structure. Further, based on the characteristics of the coating material, after the coating material is sprayed for the first time, a reasonable heating curve of the silicon steel annealing furnace is established; the coating with a dense structure is formed after spraying and combined with a furnace lining well, so that the furnace lining is effectively protected, and the peeling of the refractory material is prevented.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Capsule oil seepage preventing coating for filler-capsule-type tipping paper and preparation method of capsule oil seepage preventing coating

ActiveCN110373947AIncrease the degree of cross-linkingDense coating structureSurface covering paperNon-fibrous pulp additionWaxSurface energy

The invention discloses capsule oil seepage preventing coating for filler-capsule-type tipping paper and a preparation method of the capsule oil seepage preventing coating. The capsule oil seepage preventing coating is prepared from the following raw materials in parts by weight: 15-30 parts of waterborne polyurethane emulsion, 5-15 parts of styrene-acrylic emulsion, 1-10 parts of vinyl acetate-ethylene copolymer emulsion, 1-5 parts of a waterborne closed isocyanate cross-linking agent, 0.1-1.0 part of a wetting agent, 0.01-0.5 part of a defoamer, 35-80 parts of purified water and an appropriate quantity of PH regulators. The coating is a thermosetting coating system with the additionally added cross-linking agent and without low-surface-energy substances such as waxes, a coating with a three-dimensional reticular dense structure and high surface energy is formed under the heating condition, seepage of filler capsule oil, namely grease, and essence and fragrance molecules is effectively blocked, thus the purpose of preventing seepage of the capsule oil is realized, and meanwhile, it is also ensured that the tipping paper is wetted and firmly bonded by an adhesive in the subsequentusing process.

Owner:玉溪接装纸制造有限公司

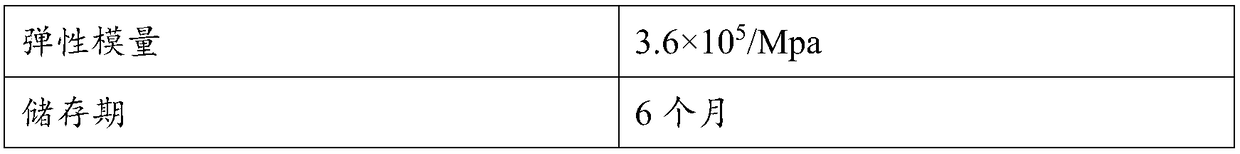

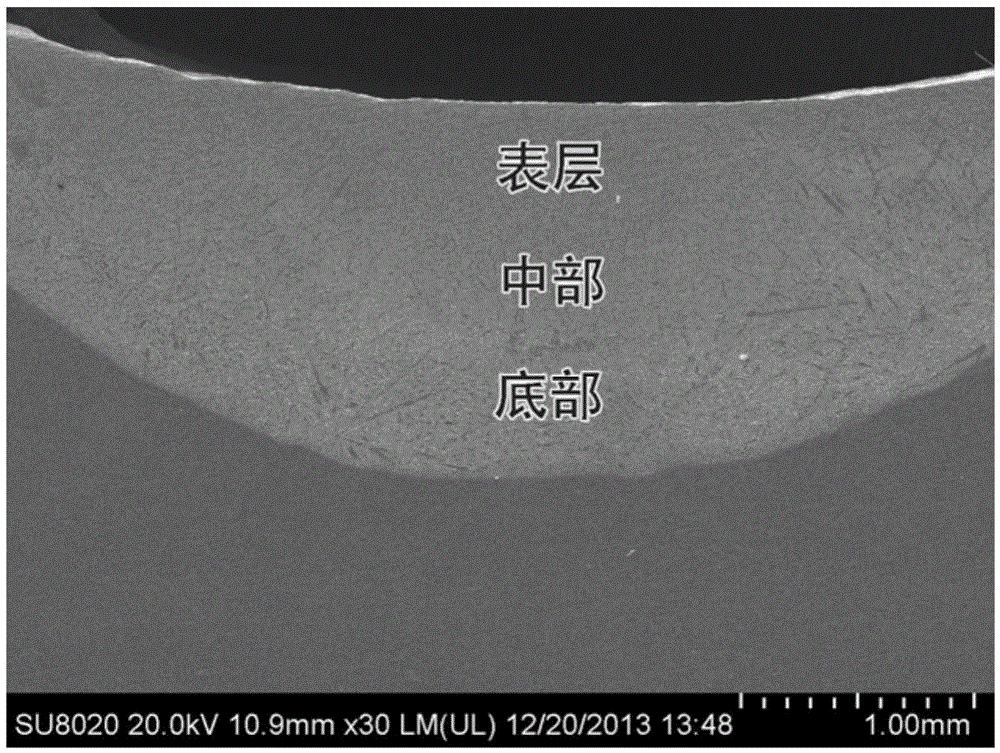

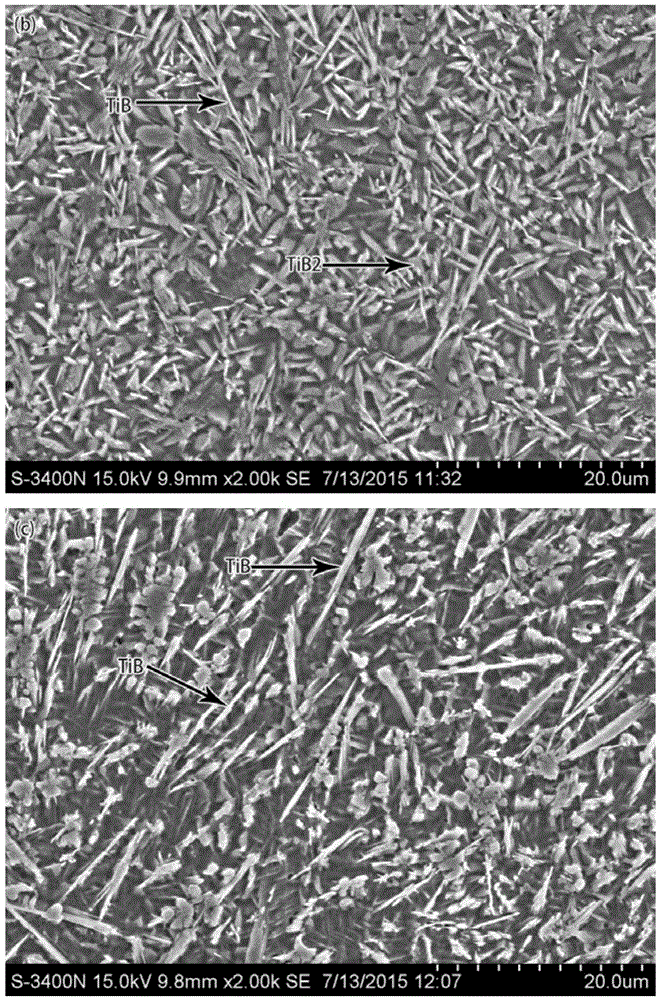

Preparation method for forming particle and short fiber gradient structure on surface of Ti-6Al-4V alloy

InactiveCN105386033AMacroscopic smoothnessDense coating structureHeat inorganic powder coatingDrawing ratioSurface layer

The invention provides a preparation method for forming a particle and short fiber gradient structure on the surface of a Ti-6Al-4V alloy. The problems that a treated surface is poor in forming, crack sensitivity is high, a surface layer is thin and prone to falling off, and a gradient structure is hard to form are solved. The preparation method comprises the steps that firstly TiB2 powder and Ti powder are evenly mixed and pre-arranged on the surface of Ti-6Al-4V; then a sample is preheated to 300-350 DEG C, and temperature is kept stable; and finally an optical fiber laser is used for preparing a composite coating on the surface of the Ti-6Al-4V alloy. The thickness of the composite coating is above 1.5 mm, the structure is dense, no air hole or crack exists, and good metallurgical bonding of the composite coating and the Ti-6Al-4V alloy is achieved. The number of particles of the composite coating is gradually lowered from outside to inside, the number of short fibers of the composite coating is gradually increased, and the draw ratio of the short fibers can be more than 10 times. The integral comprehensive performance of materials is improved by improving the structural distribution of the surface layers of the materials, and therefore the service life of the materials is prolonged.

Owner:BEIJING UNIV OF TECH

Method for producing iron-zinc alloy coated steel plate with yield strength being equal to or higher than 220 MPa

ActiveCN105274301AFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

A kind of cr/crn/(ti, al, si, cr) n composite hard coating and preparation method thereof

InactiveCN103789723BIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com