Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Improve water erosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anhydrous albany grease and preparation method thereof

ActiveCN102757847AMeet the requirements of wide temperature rangeExcellent water shear stabilityLubricant compositionChemical industryCalcium hydroxide

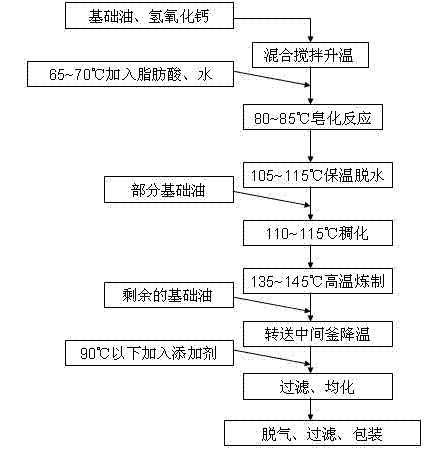

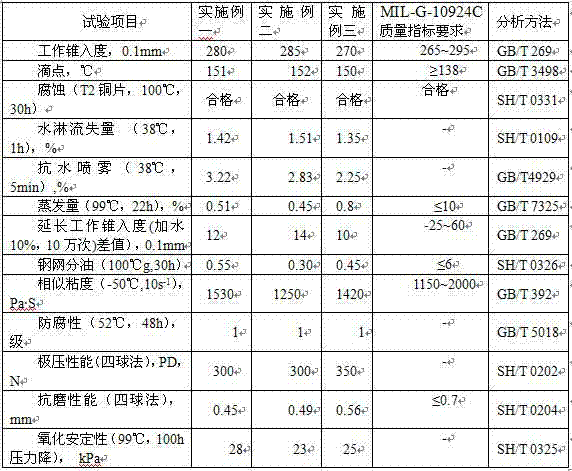

The invention belongs to the technical field of the chemical industry, and relates to grease and a preparation method thereof, in particular to anhydrous albany grease and the preparation method thereof. The anhydrous albany grease and the preparation method comprises the following components by weight: 82-90% of base oil, 1-4% of calcium hydroxide, 6-15% of fatty acid, 0.3-1% of antioxygen, 0.5-1.5% of rust inhibitor, and 0.5-3% of extreme pressure antiwear additive. The anhydrous albany grease and the preparation method have the benefits as follows: the grease is simple in preparation process and easy to control; and the prepared product has better water erosion resistance, favorable metal adhesivity and extreme pressure abrasion resistance, and can provide outstanding lubrication and abrasion resistance protection for wheel bearings and chassis.

Owner:JIANGSU LOPALTECH

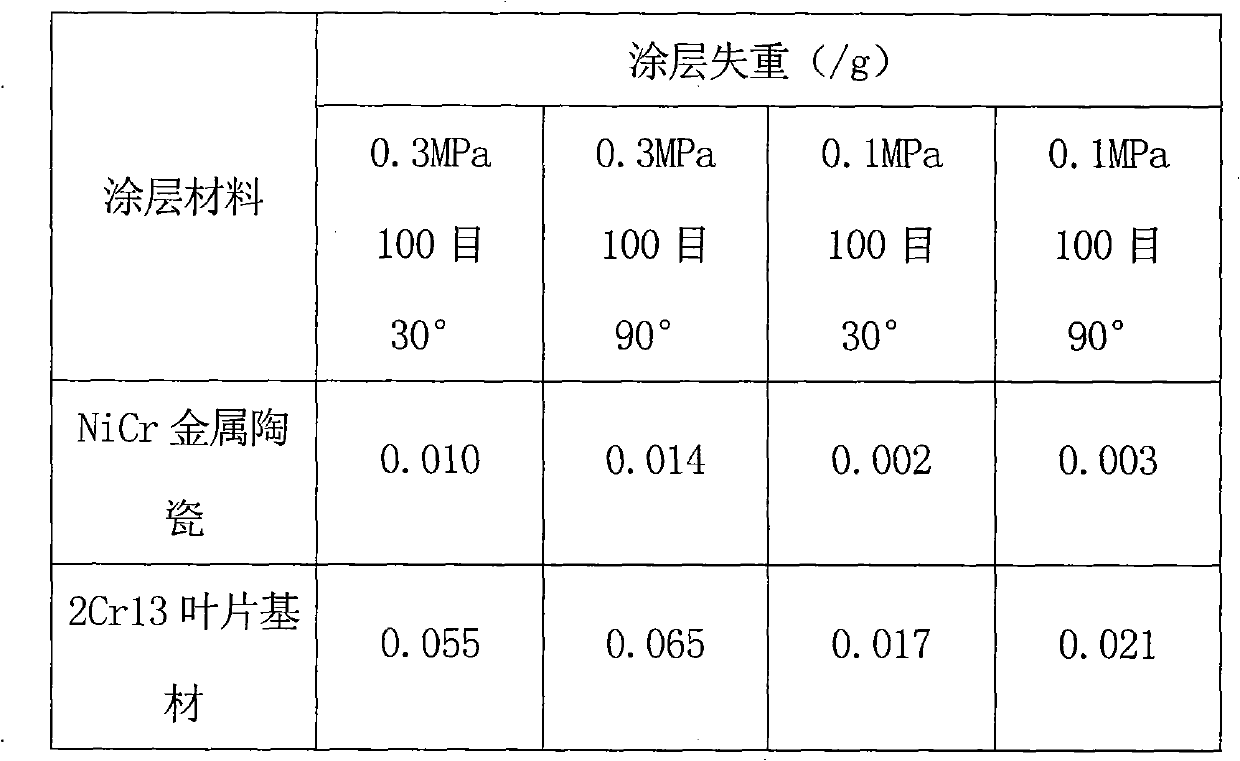

Process for repairing water erosion damage of flow passage component of steam turbine and protecting flow passage component of steam turbine

ActiveCN101767261AExtended service lifeNo change in vibration characteristicsMolten spray coatingPolishing machinesPower stationEconomic benefits

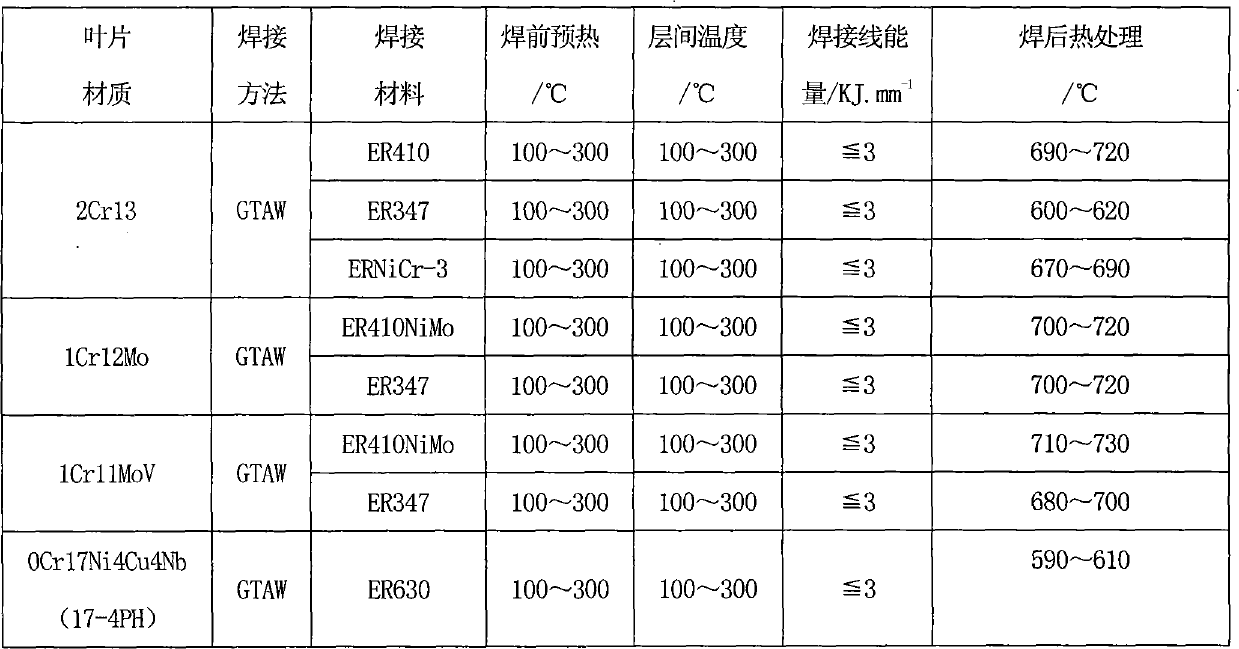

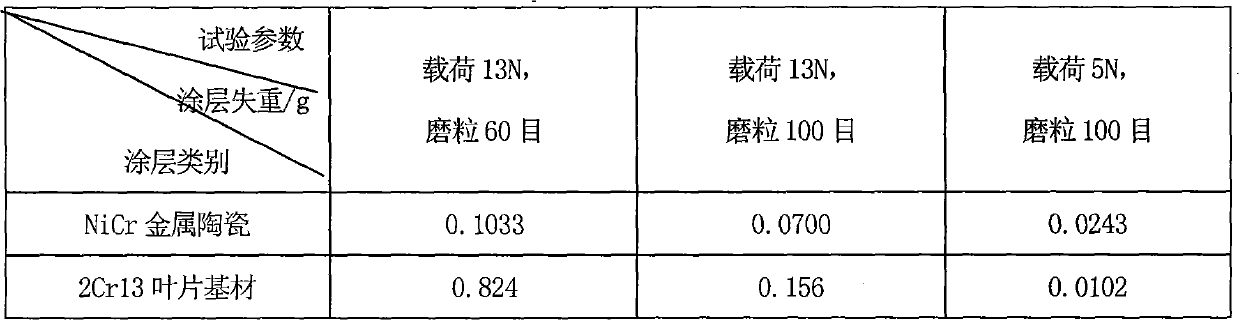

The invention discloses a process for repairing water erosion damage of a flow passage component of a steam turbine and protecting the flow passage component of the steam turbine. In the process, molded lines of the flow passage component of the steam turbine are repaired by adopting copy overlaying of manual argon tungsten arc welding aiming at the phenomenon of the water erosion damage existing in the flow passage component of the steam turbine. A water erosion resistant coating is prepared by supersonic speed flame spraying so as to achieve the purposes of repairing the molded lines of the flow passage component of the steam turbine and protecting the molded lines at large area on line and prolonging the service life of the flow passage component of the steam turbine. Through the process of the invention, the flow passage component of the steam turbine can be repaired and protected at large area on line in a short time without changing vibration characteristic, steam-driven characteristic and strength characteristic of the flow passage component of the steam turbine, so that the process has the advantages of high on-site operability, small deformation of the repaired workpiece, remarkable improvement on water erosion resistance and the like, can solve the common problem of water erosion in the flow passage component of the power station steam turbine in service on site, improves the running safety and efficiency of units and increases economic benefit of a power plant.

Owner:XIAN THERMAL POWER RES INST CO LTD

Road surface based material by sintering red mud and construction method thereof

ActiveCN1792954AImprove frost resistanceImprove water erosion resistanceRoadwaysSolid waste managementCoalSubgrade

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

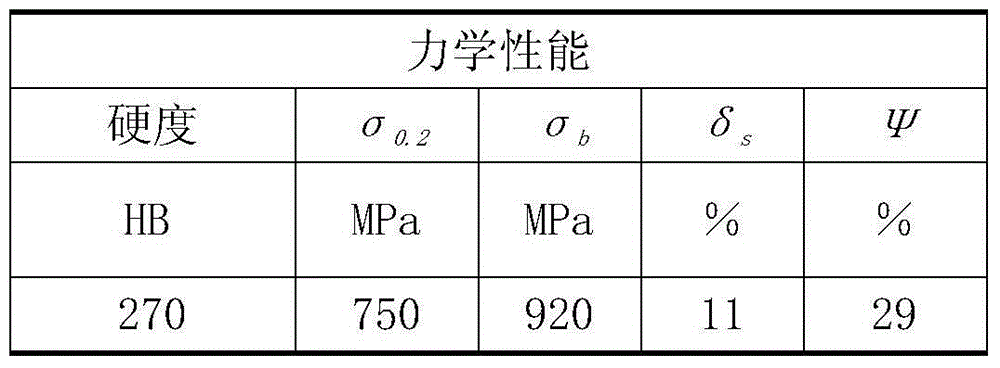

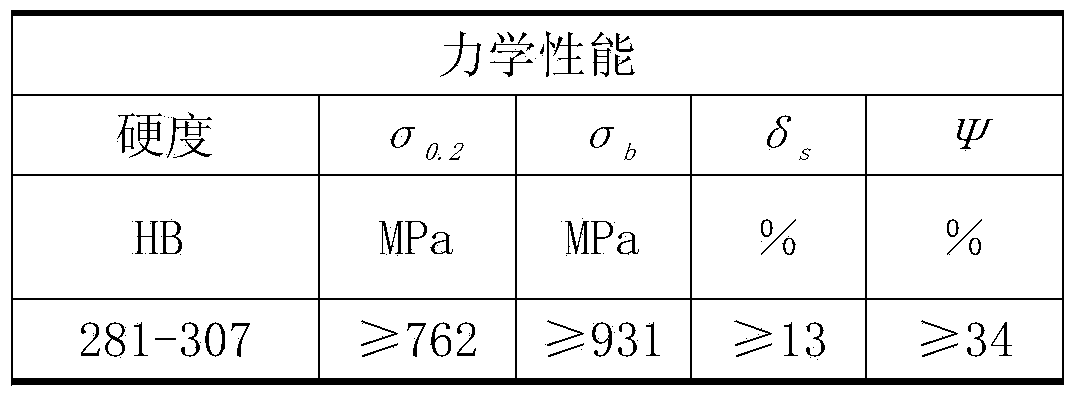

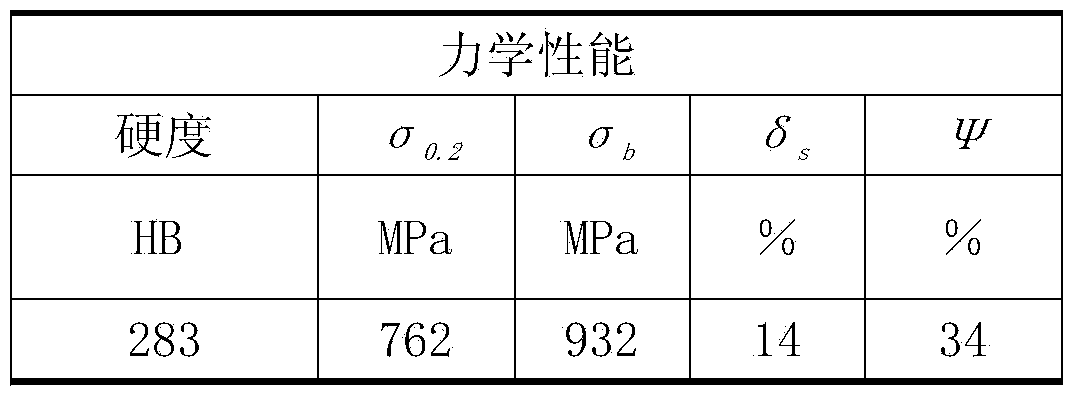

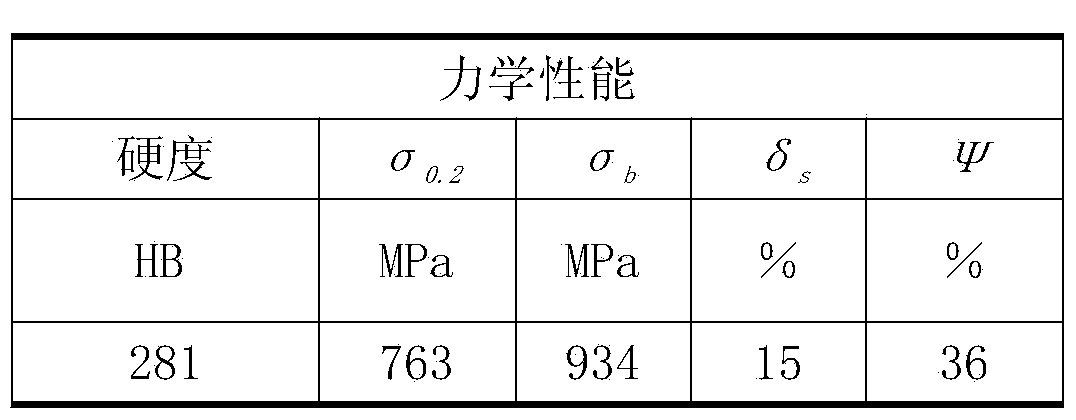

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

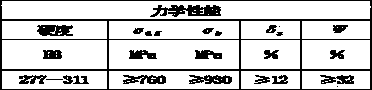

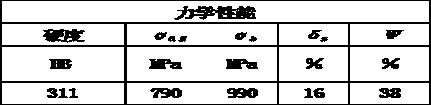

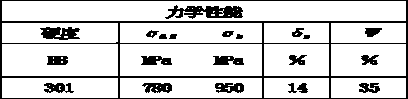

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

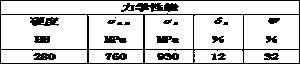

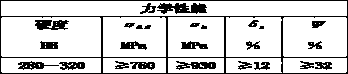

Steel ring billet casting technique based on casting and rolling combined forming

ActiveCN104439219AReduce heating timesSave blankingMolten metal pouring equipmentsFurnace typesTemperingCasting mold

The invention discloses a steel ring billet casting technique based on casting and rolling combined forming. The steel ring billet casting technique based on casting and rolling combined forming comprises the steps that firstly, a casting mold is manufactured by means of water glass sand, the casting mold is dried and sprayed with painting, casting raw materials of a steel ring are smelted and are poured into the casting mold, and normalizing, tempering and quenching-tempering heat treatment are conducted on a steel ring billet formed through pouring; secondly, the steel ring billet is cooled to the room temperature, and polishing and machining are conducted on the cooled steel ring billet; finally, the steel ring billet which can be directly used for casting and rolling combined forming is obtained. According to the steel ring billet cast according to the technique, the defects, such as shrinkage cavities, shrinkage porosity and segregation, appearing in the steel ring billet casting process can be reduced, grains are refined to the maximum extent, and the high-quality steel ring billet capable of meeting the requirement for the ring rolling performance is manufactured; due to the fact that the processes of the casting and rolling combined forming technique are simplified, the quality and performance of the ring rolling technique and a ring workpiece are guaranteed.

Owner:盐城市大丰区生产力促进中心

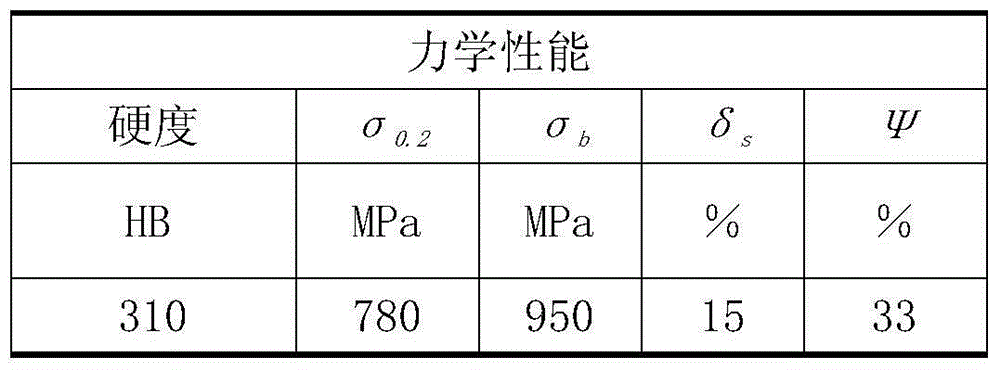

Turbine blade capable of enhancing impact toughness and production technique thereof

ActiveCN104060191AAvoid formingPrevent early brittle crackingFurnace typesHeat treatment furnacesMischmetalChemical composition

The invention provides a turbine blade capable of enhancing impact toughness, which comprises the following chemical components in percentage by mass: 0.13-0.15% of C, 0.8-0.9% of Si, 0.5-0.8% of Mn, 14-16% of Cr, 0.1-0.3% of Ni, 1.3-1.5% of Cu, 0.6-1.1% of Mo, 0.1-0.15% of W, 0.36-0.45% of V, 0.5-0.8% of Nb, 0.28-0.30% of Al, 0.16-0.18% of Ti, 0.08-0.10% of B, 0.45-0.48% of Na, at most 0.02% of S, at most 0.03% of P, 0.3-0.6% of rare-earth metal and the balance of Fe. The invention also provides a production technique of the turbine blade capable of enhancing impact toughness. The production technique can greatly enhance the impact toughness of the blade and prolong the service life of the blade.

Owner:南京赛达科技有限公司

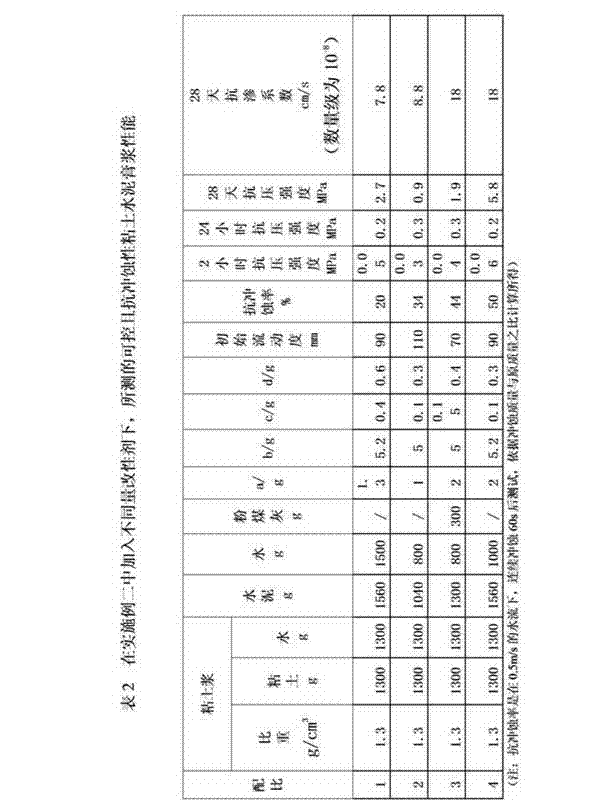

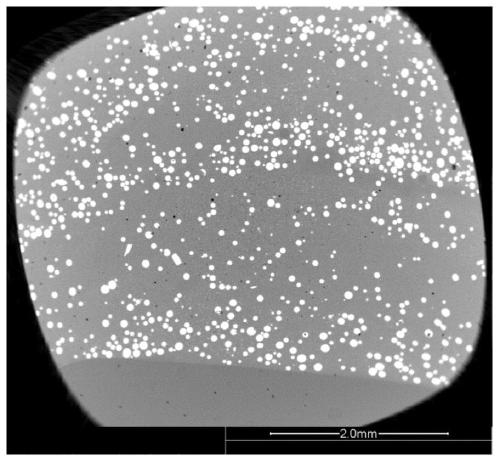

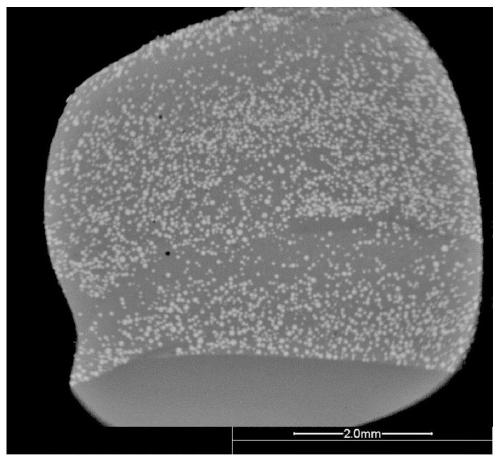

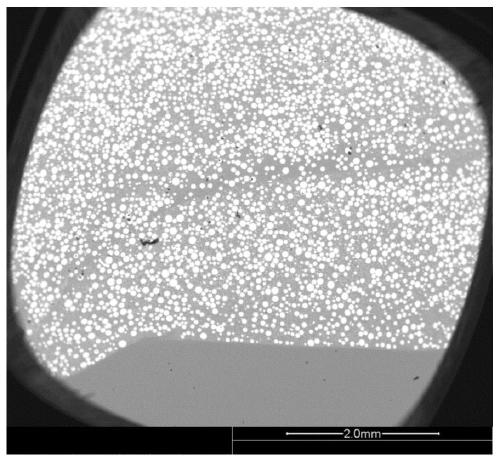

Early-strength erosion-resistant clay cement paste

ActiveCN103755275AImproved controllabilityImprove stone rate and impermeabilitySpecific gravityAluminium salts

The invention provides an early-strength erosion-resistant clay cement paste which comprises a clary cement paste and a matched modifier, wherein the clary cement paste is prepared from clay raw stock, cement and the balance of water; the clay raw stock is obtained by stirring clay with water, and the specific gravity of the obtained clary raw stock ranges from 1.15g / cm<3> to 1.40g / cm<3>; the ratio of the total mass of the clay in the clary raw stock and the cement to the mass of water ranges from 10: 7 to 10: 14; the modifier is composed of sodium metaaluminate, soluble sodium metasilicate powder, aluminum sulfate and polyacrylamide, and the content of the polyacrylamide accounts for 1-10% of the sum of the weights of the aluminum sulfate, the sodium metaaluminate and the soluble sodium metasilicate powder. The early-strength erosion-resistant clay cement paste has the advantages of good controllability, good water erosion resistance, short solidification time, high early strength, excellent anti-seepage performance, low cost, environmental protection and the like.

Owner:湖南宏禹工程集团有限公司

Hollow lightweight aggregate and preparation method thereof

InactiveCN106746813ASolve the poor buoyancy of the floating bedIncrease buoyancyMoistureConstruction aggregate

The invention discloses hollow lightweight aggregate and a preparation method thereof and belongs to the technical field of cement concrete materials. According to the aggregate preparation method, on one hand, powdered aluminum reacts with water to form a hollow inner cavity, and pumice powder, cement and solid gum are mixed to serve as a lightweight shell with ductility; on the other hand, the moisture is stored by utilizing a high-efficiency water-absorbent resin, and the foaming reaction rate of the powdered aluminum and water can be regulated by a soluble starch film, so that the prepared aggregate is low in apparent density, easy to float in water, dense in shell structure, low in crush index and high in water erosion resistance; and when the lightweight aggregate is used for making a concrete floating bed, the wind and wave resistance of the floating bed can be increased, and the polluted water is convenient to control.

Owner:UNIV OF JINAN

Open type gear lubricating oil

ActiveCN1970704AGood fluidity at low temperatureIncrease oil film thicknessBase-materialsEngineeringBase oil

Owner:辽宁海华科技股份有限公司

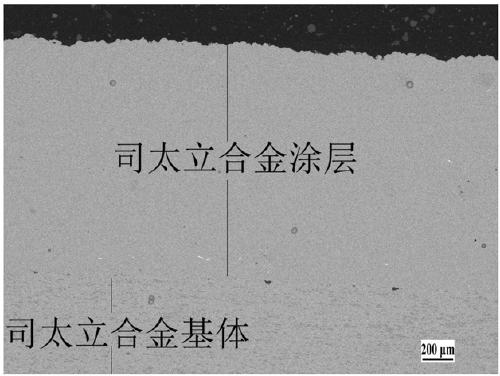

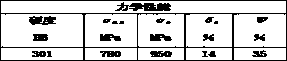

Laser cladding coating for improving water erosion resistance of brazed stellite and preparation method

ActiveCN110424010AImprove water erosion resistanceImprove service performanceMetallic material coating processesPorosityStress concentration

The invention discloses a laser cladding coating for improving the water erosion resistance of brazed stellite and a preparation method. A coating is laser-cladded on the surface of a stellite substrate brazed on a steam turbine blade, the coating is composed of a continuous phase nickel-based alloy material and dispersion strengthening phase wolfram carbide particles, the WC particles are spherical, stress concentration caused by sharp corners is effectively eliminated, the coating cannot crack, wolfram oxide with certain thickness is arranged on the surfaces of the WC particles, excessive dissolution of a WC melted nickel-based alloy is avoided, optimum dispersion strengthening of a nickel-based alloy phase is achieved, the coating is prepared through the laser cladding technology, the efficiency is high, the operation is easy, and the prepared coating is dense, free of cracks and low in porosity. The laser cladding coating for improving the water erosion resistance of the brazed stellite and the preparation method of the laser cladding coating can be used for water-erosion-resistant coatings on the surfaces of blades of large nuclear steam turbines and thermal power steam turbines and manufacturing, repairing and re-manufacturing, the service performance of parts is effectively improved, and the service life of the parts is effectively prolonged.

Owner:HAINAN NUCLEAR POWER +1

Environment-friendly type underwater non-dispersible sludge curing agent for ecological restoration

InactiveCN107445428AGood water dispersion resistanceGood underwater coagulationWater contaminantsFixation/solidifcation sludge treatmentAluminateWater dispersible

The invention discloses an environment-friendly type underwater non-dispersible sludge curing agent for ecological restoration. The environment-friendly type underwater non-dispersible sludge curing agent is prepared from the following raw materials in parts by weight: 5 to 30 parts of clinker, 2 to 8 parts of a waterproof agent, 2 to 5 parts of bentonite, 2 to 5 parts of lime, 5 to 8 parts of gypsum, 0.04 to 1 part of a water dispersion resisting agent and 0.5 to 5 parts of an exciting agent, wherein the clinker is a mixture of silicate and aluminate. The product can be used for hardening various sludge in water and improving an aggregate structure of the sludge and can be used for sealing toxic and harmful substances including heavy metal ions, cyanide, fluoride and the like; production and preparation and application processes of the product does not cause toxin and pollution and environmental hazards are not caused; the sludge treated by the product has the characteristics of relatively good whole water dispersion resisting performance and water flow scouring resisting performance, a rapid hardening speed, no need of special curing and the like; plants can grow on the sludge and caves for inhabitation can be built on the sludge, so that an ecological diversity function is met; the restoration of the ecological environment is facilitated and the utilization effect is good.

Owner:堡森(上海)新材料科技有限公司

Modified clay reinforcing paste slurry

The invention relates to modified clay reinforcing paste slurry. Existing clay reinforcing paste slurry has no good erosion-wear resistance in flowing water, and since more modifier need to be added in order to reduce to the fluidity of a material, the using cost is relatively high. The modified clay reinforcing paste slurry is characterized by being prepared from the following components in ratio by mass: 20 to 40 of bentonite, 15 to 30 of cement, 10 to 20 of silicate minerals, 3 to 10 of additive, 10 to 15 of calcium oxide and the balance of water, wherein the additive is prepared from a silane coupling anggent, sodium fluosilicate, sodium metaaluminate and calcium chloride. According to the modified clay reinforcing paste slurry disclosed by the invention, not only are controllability and water erosion-wear resistance of paste slurry improved, but also the stone rate and the impervious performance of a stone body are increased, the cost is lower, and the problems of instability in operation of the bentonite and the like of common cement bentonite paste slurry are solved.

Owner:ANJI YUHONG CLAY CHEM

Material for magnesium alloy doors and windows and production method of material

The invention discloses a material for magnesium alloy doors and windows. The material for the magnesium alloy doors and windows is composed of Mg, Al, Mn, Zn, Cu, Ni, Sc, P, Zr, Y, Ca, Sr, B, Co and a rare earth element, wherein the rare earth element is composed of Ce, Nd, Gd, Pr, Dy, Yb, La and Sm; the invention further discloses a production method of the material for the magnesium alloy doors and windows, and the method comprises the following steps: smelting, heat treatment, forging, quenching and tempering heat treatment, cooling, checking and storing, the production method is simple and easy, the manufacturing cost is low, and the produced material for the magnesium alloy doors and windows is excellent in corrosion resistance, can resist high temperature, is solderable, and has a prolonged service life.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

Turbine blade capable of improving thermal cracking resistance and production process thereof

ActiveCN104032236AReduced impact toughnessImprove impact toughnessBlade accessoriesMachines/enginesMischmetalChemical composition

The invention discloses a turbine blade capable of improving the thermal cracking resistance. The turbine blade comprises the following chemical components in percentage by mass: 0.31-0.35% of C, 0.10-0.12% of Si, 0.75-0.77% of Mn, 0.63-0.65% of Ni, 11.2-11.7% of Cr, 0.65-0.68% of Mo, 0.16-0.18% of V, 0.85-0.88% of Sr, 0.15-0.17% of Nb, 0.05-0.07% of Cu, 0.27-0.29% of Al, 0.13-0.15% of Ti, 0.06-0.08% of B, less than or equal to 0.02% of S, 0.21-0.35% of rare earth metal and the balance of Fe. By adopting the turbine blade, the impact toughness of a blade is greatly improved, the thermal cracking resistance of the blade is improved, and the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

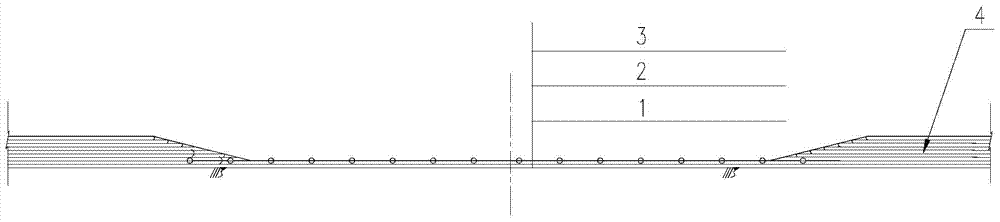

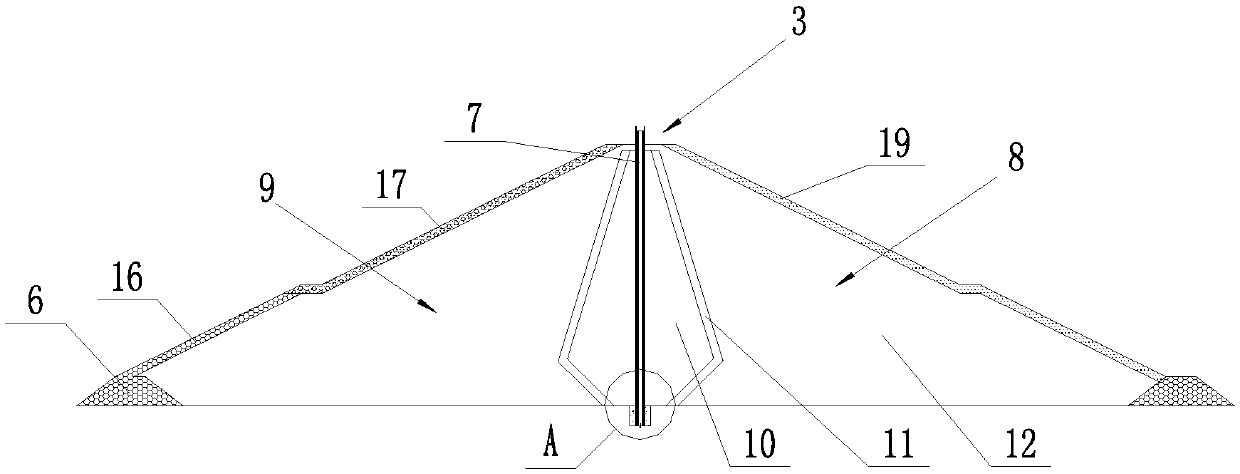

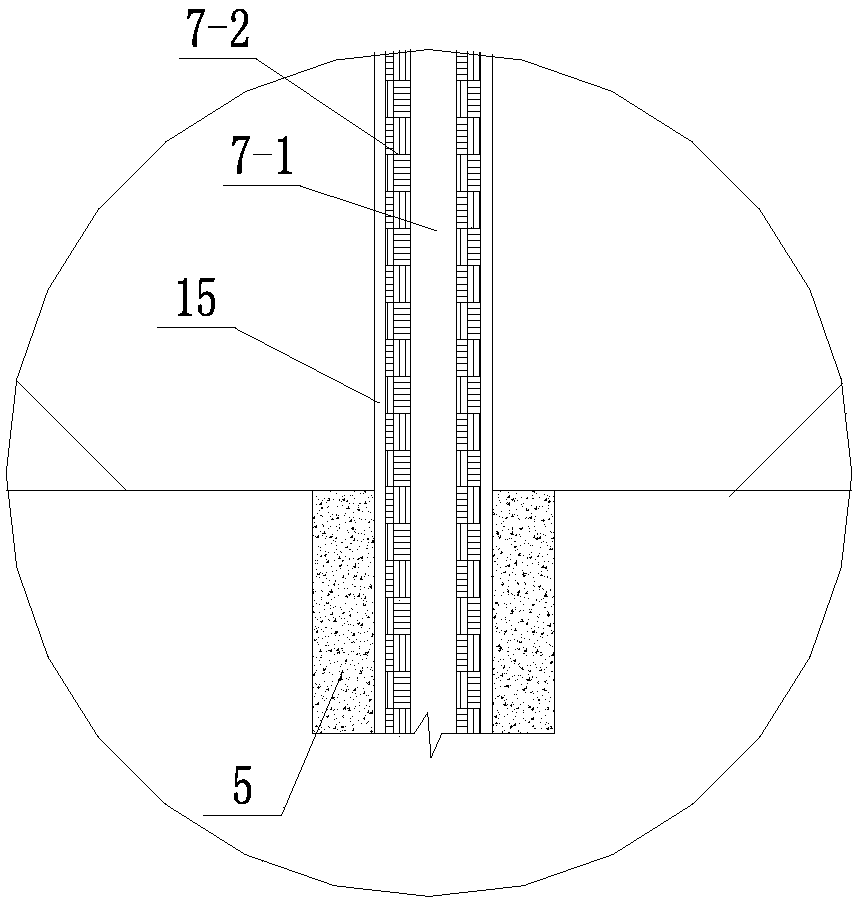

Closure gap protection structure applied to deep beach enclosure and closure method for closure gap protection structure

InactiveCN104711952AHigh abrasion resistanceGood sand retention performanceMarine site engineeringSurface layerWater flow

The invention provides a closure gap protection structure applied to a deep beach enclosure. The closure gap protection structure is formed by three layers in a stacking manner, the bottom layer is a through-length filling sand bag layer, the middle layer is coping through-length sand bag layer and the surface layer is a sand rib soft mattress layer. According to the invention, a closure gap bottom sill and a mouth are constructed by filling the filling bags with sand, the geotextile with scouring resistance, high abrasion resistance and good sand protection performance is applied to parts, which are scoured by water flow, and the soft mattress is applied to the bottom sill and other parts, which are severely scoured by water flow for protection on the basis of above protection, so that erosion protection is improved through the closure gap protection structure, the sand bags are prevented from being damaged, filling sandy soil is protected from loss under the high flow speed, closure gap safety of the common enclosure engineering is guaranteed, and a relatively good operating condition is provided for closure of the closure gap. The whole closure gap protection structure is high in current scour resistance, convenient to construct, less in investment, safe and reliable.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

High-strength titanium alloy steam turbine blade

InactiveCN108624783ALow costDoes not affect the chemical compositionAntifouling/underwater paintsBlade accessoriesEpoxyTitanium alloy

The invention discloses a high-strength titanium alloy steam turbine blade. The surface of the steam turbine blade is further provided with a protection layer, and the protection layer is prepared from, by mass, 10-15 parts of modified ethylene-propylene-diene monomer rubber, 15-20 parts of methyl phenyl silicone resin, 8-11 parts of organosilicon-modified epoxy resin, 5-7 parts of nanometer SiC powder, 13-15 parts of filler and pigment, 3-5 parts of dispersing agent, 10-15 parts of coupling agent, 13-15 parts of curing agent, 7-9 parts of defoaming agent and 1-3 parts of anti-mildew bactericide. The high-strength titanium alloy steam turbine blade has good strength, and is good in corrosion resistance, simple in preparation process, low in cost and long in service life.

Owner:南京赛达科技有限公司

Atmozing agent capable of being used to replace farm mulching and its prepn

InactiveCN1362469AAntifreezeWith insulationOrganic fertilisersSoil conditioning compositionsCellulosePlastic mulch

The present invention relates to an atomization agent instead of agricultural plastic mulch film, which is characterized by that it uses vermiculite, diatomaceous earth, ban soil, microcrystal cellulose, yellow clay, cotton pump residue, pregelatinized starch, PVA and water as raw material, respectively adopts the processes of pulverizing, drying and hydrolysis treatment to make them into suspended emulsified liquor, and adopts atomization method to spay it on the soil surface to form protecting shell layer with the actios of antifreezing, raising temp., temp.-insulating, drought-resisting, preserving soil moisture and increasing fertilizer effect, and good air permeability and antiscouring property.

Owner:高克

Silicate plugging agent for oil-well water plugging and application method thereof

ActiveCN103571445AHigh water-cement ratioImprove pumping performanceDrilling compositionSealing/packingPhysical propertyMaterials science

The invention discloses a silicate plugging agent for oil-well water plugging and an application method thereof, wherein the silicate plugging agent comprises the following components by weight percentage: 8-12% of general purpose portland cement, 1-3% of silica fume, 0.3-0.7% of water glass, 0.01-0.03% of sodium lignin sulfonate and the balance of water. The application method of the silicate plugging agent for oil-well water plugging comprises the following steps: in the stirring process, orderly adding the water glass, the sodium lignin sulfonate and the silica fume in a stirring pot with water proportionally, and stirring evenly to obtain a mixed solution; next, adding the general purpose portland cement to the mixed solution while stirring to form the base solution of the silicate plugging agent; and pouring the base solution of the silicate plugging agent into formation fractures. The silicate plugging agent provided by the invention has the advantages of high water cement ratio, good pumping performance, long initial setting time, high after-final-setting strength, good water scouring resistance, all of which are similar to the own physical properties of the formation; the silicate plugging agent is capable of achieving the construction requirements of oil-well water plugging; and the properties of the silicate plugging agent are suitable for nonhomogeneous fractured reservoirs.

Owner:PETROCHINA CO LTD

Underwater dispersion-resistant concrete additive for building

The invention discloses an underwater dispersion-resistant concrete additive for a building. The underwater dispersion-resistant concrete additive is prepared from the following components in parts byweight: 1 to 2 parts of methylcellulose, 1 to 2 parts of hydroxypropyl methyl starch, 2 to 5 parts of zeolite powder, 10 to 15 parts of stearic acid, 10 to 12 parts of naphthalene-based superplasticizer, 1 to 2 parts of sepiolite fibers, 3 to 5 parts of polyacrylamide, 1 to 3 parts of polyvinyl alcohol, 3 to 5 parts of sodium aluminate, 20 to 22 parts of polycarboxylate superplasticizer, 63 to 73parts of water, and 10 to 12 parts of polyacrylamide. By adopting the underwater dispersion-resistant concrete additive, the cohesiveness, the mobility, the dispersion resistance and the self-compacting performance of the concrete can be comprehensively improved, so that a mixture is not isolated and dispersed, is self-leveled and self-compacted without being vibrated, the water on the original poured surface can be extruded, after the mixture is cured, and the mixture has good adhesion with the surface of the original concrete surface; and the methylcellulose and the polyacrylamide are usedas the anti-scattering agent, so that the concrete has good cohesiveness and water scouring resistance.

Owner:徐州巨龙新材料科技有限公司

In-situ layered utilization of building solid wastes and application to reduction of salt and alkali in soil

ActiveCN108273833ARealize the rational use in situWithout destroying the basic structureSolid waste disposalContaminated soil reclamationEnvironmental resistanceSurface layer

The invention provides in-situ layered utilization of building solid wastes. The in-situ layered utilization of the building solid wastes comprises the following steps: two types of rough solid wastesand fine solid wastes in field building solid wastes are crushed and screened; two types of rough green plant waste and fine green plant wastes, comprising plant residues, weeds, falling leaves and battens, are crushed; foreign soil, organic and inorganic improved materials and microbial agents are added to the original field soil to form prepared soil for future use; rough solid waste layers, fine solid waste layers, rough green plant waste layers, fine solid waste layers, fine green plant waste layers and prepared soil layers are put in fields without excavated original soil from bottom layers to surface layers; and finally, planting oil layers cover for compaction in layered filling. The cost of improving engineering project field soil physical structures is reduced; the recycling andenvironmental protection effects are prominent; and soil capillary pipe holes are cut off in solid waste layers to prevent the problem of returning salt and alkali.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

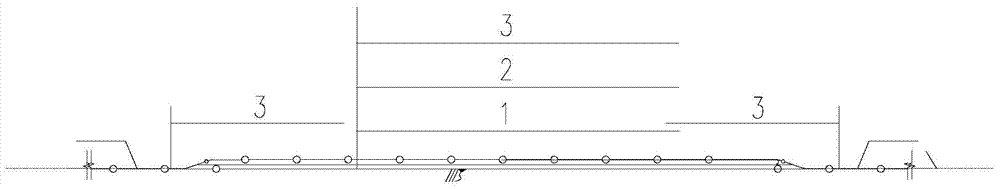

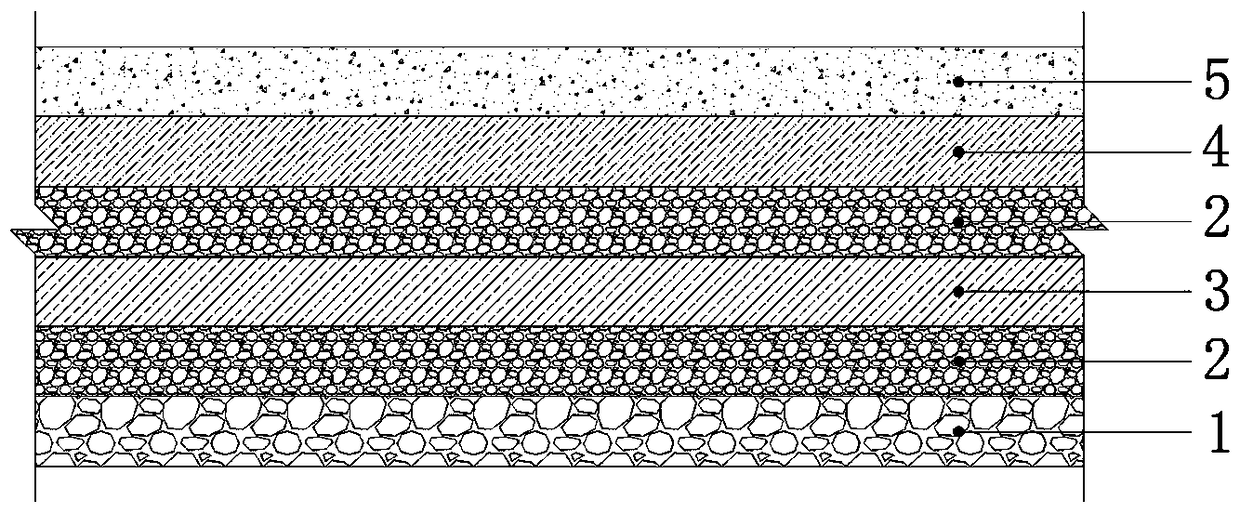

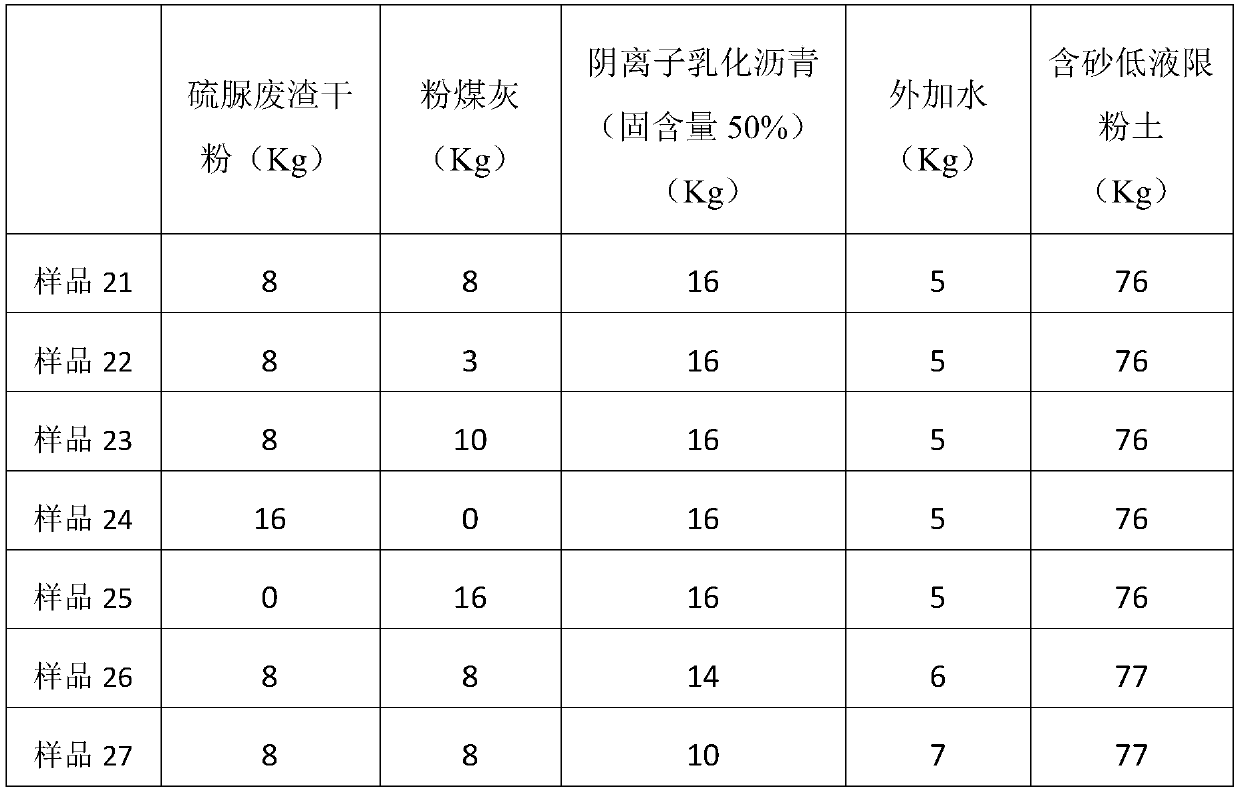

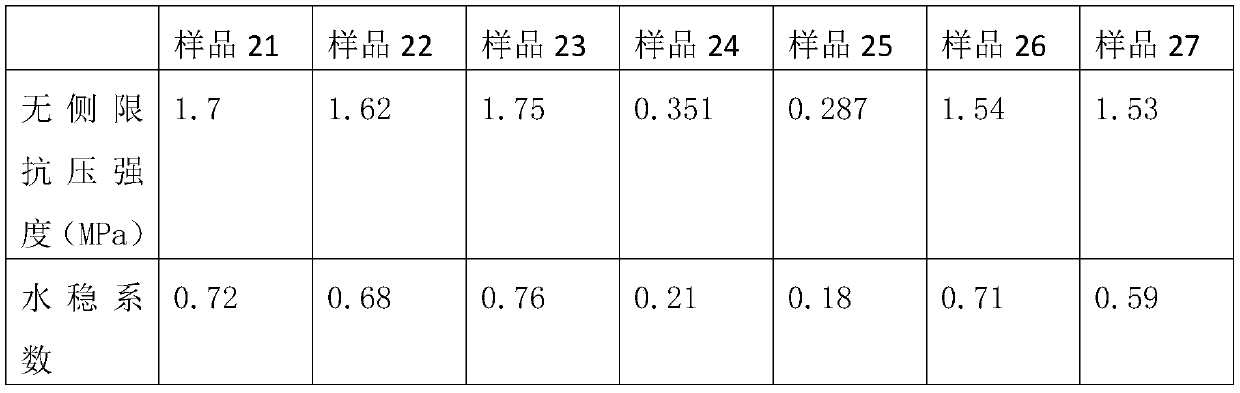

Soil composite curing agent and soil curing method

PendingCN111088053AMeet strength requirementsLow priceBuilding constructionsOrganic fertilisersSoil scienceRoad engineering

The invention discloses a soil composite curing agent and a soil curing method, and belongs to the field of road engineering. The curing agent is mainly prepared by mixing thiourea waste residue dry powder, fly ash and emulsified asphalt according to a certain ratio. Compared with the prior art, the curing agent has the advantages that thiourea waste residues, fly ash and emulsified asphalt are combined for composite curing of soil, a cured soil body with good strength and high water resistance can be formed, the technical requirement for soil curing in the field of road engineering is met, and the curing agent has good application and popularization value.

Owner:SHANDONG TRANSPORTATION INST

Corrosion-resistant turbine blade and production process thereof

ActiveCN104032239AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesTurbine bladeRare earth

The invention discloses a corrosion-resistant turbine blade which comprises the following chemical components in percentage by mass: 0.29-0.31 percent of C, 0.11-0.13 percent of Si, 0.69-0.73 percent of Mn, 0.60-0.62 percent of Ni, 9.5-9.7 percent of Cr, 0.15-0.17 percent of V, 0.16-0.18 percent of Nb, 0.05-0.07 percent of Cu, 0.21-0.23 percent of Al, 0.13-0.15 percent of Ti, 0.75-0.77 percent of Sb, 0.82-0.88 percent of Co, less than or equal to 0.03 percent of S, less than or equal to 0.02 percent of P, 0.09-0.12 percent of rare earth metals and the balance of Fe. The water erosion resistance and corrosion resistance of the blade can be improved, so that the service life of the blade is prolonged.

Owner:南京赛达科技有限公司

Explosion-proof type fixed ammonia gas detection probe and manufacturing method thereof

InactiveCN105039787AHigh elastic limitIncrease yield pointMaterial analysisRare-earth elementPhysical chemistry

The invention discloses an explosion-proof type fixed ammonia gas detection probe used on an ammonia gas detector. The explosion-proof type fixed ammonia gas detection probe comprises a displayer and a probe tube extending out of the displayer. The probe tube comprises the following components of C, Mn, P, S, Mo, Ni, Cu, Si, Ti, Cr, Mn, Fe, Pb, Nb, V, rare earth elements and the balance Al. The rare earth elements comprise La, Y, Sc, Gd, Sm, Ho, Tb and the balance lanthanide. The invention further provides a manufacturing method for the explosion-proof type fixed ammonia gas detection probe. The manufacturing method is simple and easy to implement, manufacturing cost is low, pollutants cannot be generated in the manufacturing process, the corrosion resistance of the manufactured fixed ammonia gas detection probe is good, the explosion-proof performance is good, service life is prolonged, and cost is reduced.

Owner:JIANGSU JINDI ELECTRONICS TECH

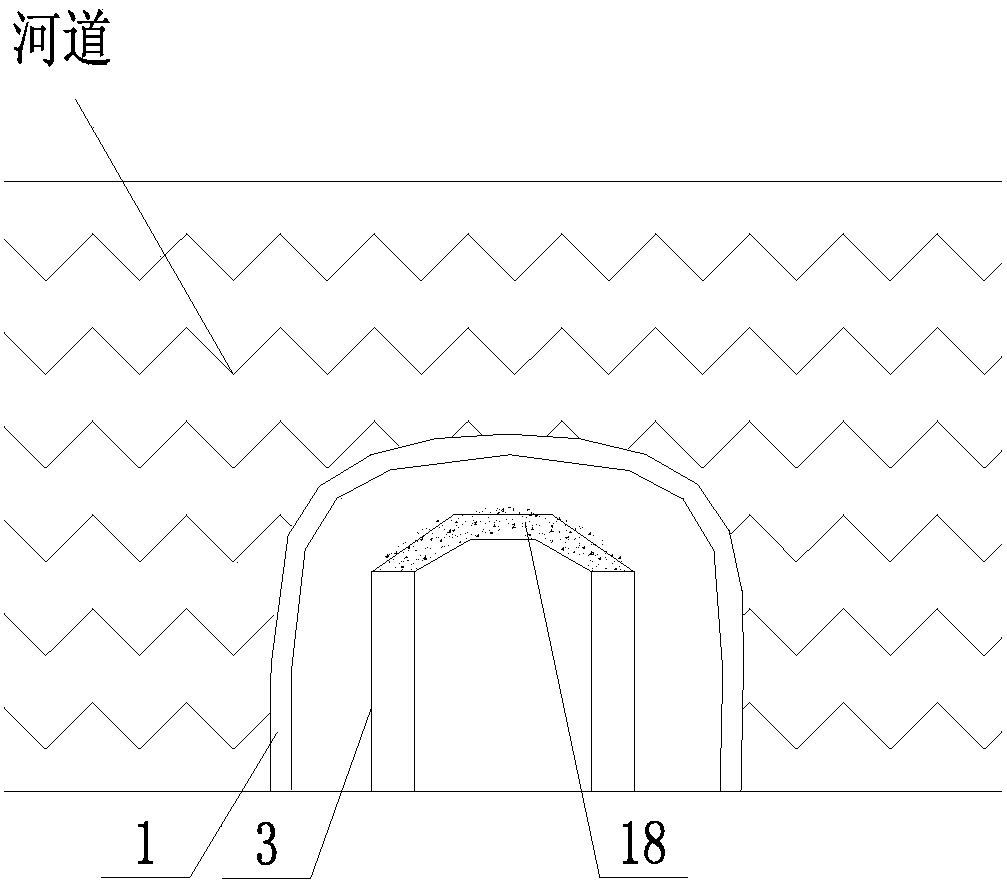

Combined cofferdam for sludge river bed and construction method of combined cofferdam

The invention discloses a combined cofferdam for a sludge river bed and a construction method of the combined cofferdam. The combined cofferdam comprises a longitudinal concrete cofferdam body and twotransverse soil-rock cofferdam bodies, wherein the two transverse soil-rock cofferdam bodies are arranged between the two ends of the longitudinal concrete cofferdam body and a river bank. The construction method comprises the steps of construction of a temporary cofferdam, construction of the longitudinal concrete cofferdam body and construction of the transverse soil-rock cofferdam bodies. According to the construction method, a gabion facing layer and a stone facing layer are arranged on the upstream face of each transverse soil-rock cofferdam body, the water flow scouring resistance of the upstream faces of the transverse soil-rock cofferdam bodies is improved, and the phenomenon that a water body is polluted by muddy water because of scouring of rainwater and water flow is avoided. In the construction method, a bottom blocking structure and a vertical water-proof structure are directly constructed at a time, and due to the construction of a first seepage-prevention wall, the impermeability of the concrete cofferdam body itself is effectively increased; the first seepage-prevention wall and a second seepage-prevention wall are constructed by using a high-pressure chemical churning pile device so that setting of mixed cement grout can be rapid, it is avoided that the mixed cement grout goes away with the water flow before setting, and therefore, the aims of solidification and seepage prevention are achieved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Hydrolysis resistant glass for vacuum bottle liner and preparation method thereof

The invention discloses hydrolysis resistant glass for a vacuum bottle liner and a preparation method thereof. The hydrolysis resistant glass is prepared from the following raw materials, by weight, 40-50 parts of river sand, 20-30 parts of efflorescent sand, 10-15 parts of potash feldspar, 5-10 parts of barite, 15-20 parts of cullet, 10-15 parts of zircon, 10-15 parts of obsidian, 5-10 parts of fibrolite, 4-8 parts of calcium carbonate, 2-5 parts of sodium nitrate, 1-2 parts of nickel oxide, 0.5-1 part of graphene and 3-6 parts of cryolite powder. The vacuum bottle glass provided by the invention has excellent hydrolysis resistance, good chemical stability and high water erosion resistance. By the use of the vacuum bottle glass, the problem that the vacuum bottle liner is easy to separate out flakes can be solved effectively, and quality safety of the vacuum bottle liner is guaranteed.

Owner:FENGYANG JINXING IND

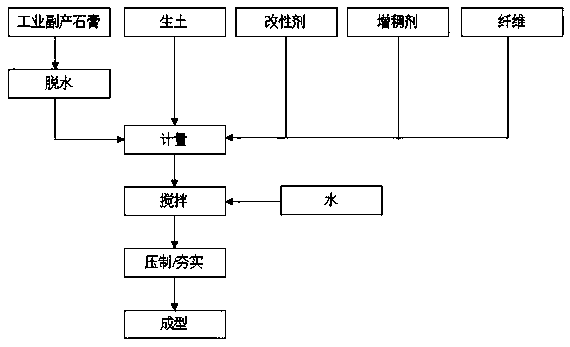

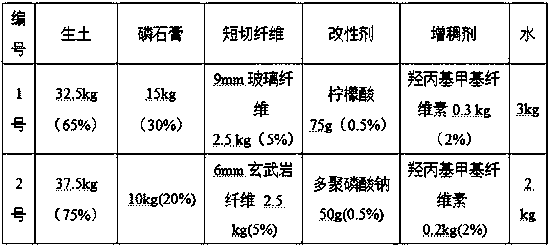

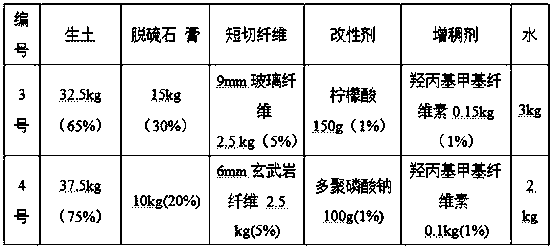

Gypsum modified rammed earth material and preparation method thereof

The invention discloses a gypsum modified rammed earth material and a preparation method thereof. According to the material, an industrial by-product gypsum is used for modifying an ordinary immaturesoil material, and the gypsum modified rammed earth material is prepared from 65%-75% of immature soil, 20%-30% of the by-product gypsum and 0%-5% of fibers; 0.5%-1% of modifier is added according tothe mass of the by-product gypsum; 1%-2% of a thickener is added according to the mass of the by-product gypsum. The industrial by-product gypsum and the other components are stirred and mixed after the industrial by-product gypsum is dehydrated, and an appropriate amount of water is added, so that the gypsum modified rammed earth material can be used. The material not only can be directly used for rammed earth wall production, but also can be used for producing a rammed earth brick. The gypsum modified rammed earth material has the advantages of being light in self weight, high in strength, good in heat insulation performance, environmentally friendly, recyclable and the like and achieving simple preparation and construction. The gypsum modified rammed earth material is a wall material suitable for low-rise buildings of villages and small towns, and can replace traditional materials, adobe bricks and the like.

Owner:KUNMING UNIV OF SCI & TECH

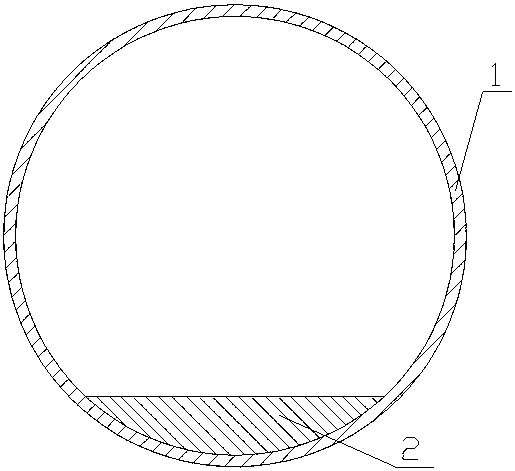

Turbine blade water erosion damage remanufacturing method

ActiveCN109653803AAvoid clogged nozzlesImprove water erosion resistanceMolten spray coatingBlade accessoriesStellite alloySteam turbine blade

Turbine stellite water erosion is the inevitable phenomenon for a steam generator set. The invention provides a turbine blade water erosion damage remanufacturing method. Naturally, the multi-mode structure powder self-strengthening effect is used for improving the density and bonding strength of the stellite repaired through supersonic speed flame spraying, pressure stress is introduced into a coating, and the service life of the coating is prolonged. The method solves the problem that through the traditional technology, the service life of a re-manufactured layer is short after stellite water erosion, and the turbine blade water erosion damage remanufacturing method can be implemented on the site under the situation that a blade is not detached.

Owner:XIAN THERMAL POWER RES INST CO LTD

A kind of floating ball for preventing the evaporation of the water surface of plain reservoirs and flood dams in arid areas

ActiveCN105905247BSimple structurePracticalHydraulic engineering apparatusVessel stability improvementWater savingPolyolefin

The invention relates to a capping anti-evaporation technology and especially relates to a floating ball capable of preventing water surface evaporation of a plain reservoir and a logging dam in an arid area. The floating ball is characterized in that the sealed hollow floating ball is made of plastic, wherein the plastic is composed of polyolefin with an added inhibitor, the inhibitor occupies a weight percentage of 2.5%-3.7% in the weight of a floating ball shell, and the rest part is made of the polyolefin; a balance weight is firmly connected to the bottom of an inner shell of the hollow floating ball; the radius of the hollow floating ball is 40-60 mm; the ball shell thickness of the hollow floating ball is 1.2-1.8 mm; and the hollow floating ball is light grey. The floating ball has the advantages that the structure is simple; the floating ball floats on a water surface and does not require connection and fixation; the floating ball has high strength and a low gravity center; under external force of winds and waves, the floating ball does not turn over vertically easily; anti-evaporation and water-saving effects are good; the floating ball is highly resistant to the winds and waves, collision, freezing and thawing, leakage, ultraviolet light and water erosion; the manufacture cost is low; and practicability is high.

Owner:XINJIANG AGRI UNIV +1

Long-life steam turbine blade and production process thereof

ActiveCN104046919AReduced impact toughnessImprove impact toughnessBlade accessoriesFurnace typesMaterials scienceIndustrial engineering

The invention discloses a long-life steam turbine blade. The long-life steam turbine blade consists of the following chemical components in percentage by weight: 0.29-0.31% of C, 0.16-0.19% of Si, 0.75-0.77% of Mn, 0.73-0.85% of Ni, 9.5-10.1% of Cr, 0.55-0.64% of Mo, 0.15-0.17% of Sn, 0.11-0.15% of V, 0.82-0.84% of Sr, 0.15-0.17% of Nb, 0.02%-0.03% of Cu, 0.13%-0.15% of T, 0.06-0.08% of B, not greater than 0.01% of Ca, not greater than 0.03% of S, not greater than 0.03% of P, 0.16%-0.18% of rear-earth metal, and the balance of Fe. The production process disclosed by the invention is carried out by hot-forging, annealing, blade mechanical machining, distressing thermal treatment, tempering thermal treatment, cooling, surface-enhanced thermal treatment, physical and chemical inspecting, ultrasonic-wave flaw detecting, and cleaning-packaging. The production process disclosed by the invention can greatly improve impact toughness of the blade, can improve water erosion resistance and corrosion resistance of the blade, and can prolong the service life of the blade.

Owner:南京赛达科技有限公司

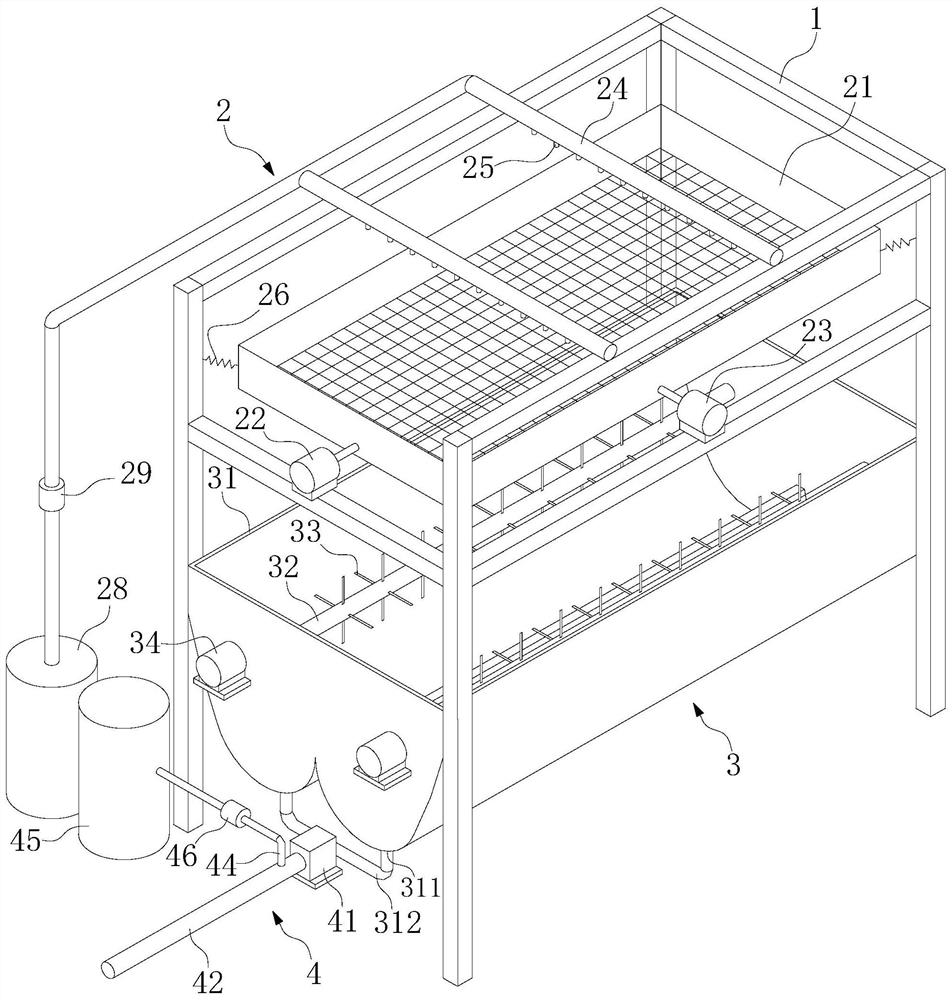

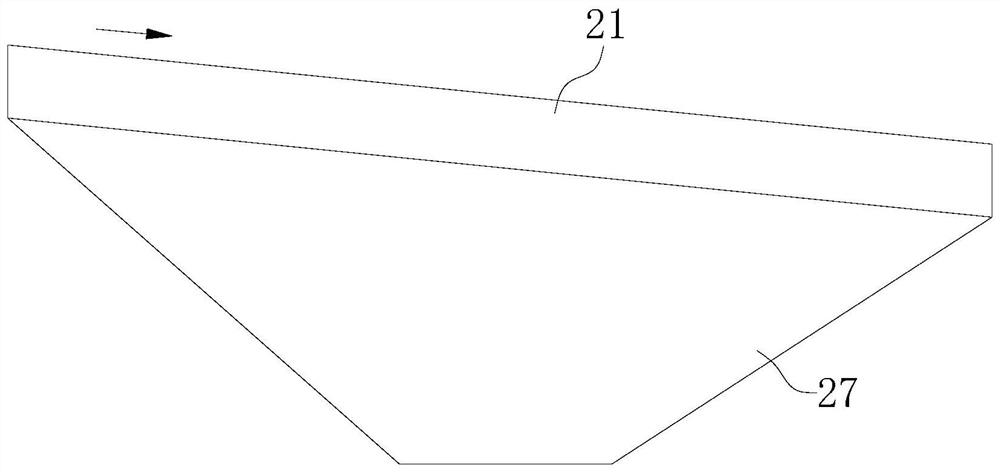

Integrated screening, curing and stirring system for shield tunneling muck and slurry

PendingCN112807816AEasy to eliminateReduce contentTransportation and packagingRotary stirring mixersElectric machineryProcess engineering

The invention discloses an integrated screening, curing and stirring system for shield tunneling muck and slurry. The system comprises a supporting frame, a screening and separating module, a collecting and stirring module and a curing agent adding and homogenizing module, wherein the screening and separating module comprises a square hole screen, a transverse vibration motor, a longitudinal vibration motor and one or more than one spraying pipe; the collecting and stirring module comprises a collecting box and a horizontal stirring device installed in the collecting box, and the collecting box is located below the square hole screen; and the curing agent adding and homogenizing module comprises a slurry pump, a conveying pipe and an automatic curing agent metering and adding device. The integrated screening, curing and stirring system of the invention realizes continuous line production of separation, homogenization, curing and stirring of coarse particles of the shield tunneling muck and the slurry; a curing agent and the slurry are uniformly mixed in the conveying pipe by virtue of the turbulent flow effect formed by the division bars in the conveying pipe, a slurry homogenization pool and a curing and stirring pool do not need to be arranged, and the system is small in occupied space and high in automation degree and provides equipment support for efficient and environment-friendly treatment of the shield tunneling muck.

Owner:中铁十局集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com