Turbine blade water erosion damage remanufacturing method

A steam turbine blade and remanufacturing technology, which is applied to the supporting elements of blades, mechanical equipment, engine elements, etc., can solve the problems of low coating life and difficult construction in narrow spaces, and achieve the effect of avoiding the phenomenon of powder blocking the nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

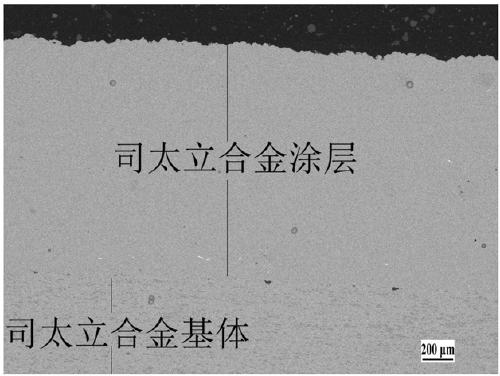

[0015] Example: Aiming at the phenomenon of water erosion of the Stellite alloy of a steam turbine blade of a 600MW unit, firstly, the jagged damage is polished to form a smooth surface, and the periphery of the area to be remanufactured is protected by a 0.5mm thin iron sheet, using 24-mesh brown The corundum is sandblasted, and after the sandblasting is completed, the sandblasting part is cleaned with high-pressure dry air. Stellite 6 powder with a particle size of 10-30 microns is used as the repair material, and Stellite 6 spherical powder material with a particle size of 100-200 microns is used as the shot blasting material, which is mechanically mixed by a powder mixer at a mass ratio of 1:1.5 and Put it into a powder mixer with a stirring device, and use air-assisted combustion supersonic flame spraying equipment for spraying, and the diameter of the throat of the spray gun is 10mm. The first propane pressure is 90psi, the second propane pressure is 98psi, the air press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com