Long-life steam turbine blade and production process thereof

A steam turbine blade and production process technology, which is applied in the direction of blade support components, mechanical equipment, manufacturing tools, etc., can solve the problems of rotor imbalance, blade failure and fracture, and failure to work, so as to prevent early brittle cracking and improve impact toughness , the effect of uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

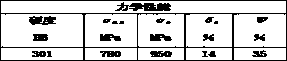

Embodiment 1

[0050] This embodiment provides a long-life steam turbine blade, the mass percentage of its chemical composition is: C: 0.29%, Si: 0.16%, Mn: 0.75%, Ni: 0.73%, Cr: 9.5%, Mo: 0.55%, V : 0.11%, Sr: 0.82%, Nb: 0.17%, Sn: 0.15%, Cu: 0.02%, Ti: 0.13%, B: 0.06%, Ca: 0.01%, S: 0.03%, P: 0.01%, rare earth Metal: 0.16%, the balance is Fe; the chemical composition mass percentage of the rare earth metal is: cerium: 6%, praseodymium: 7%, neodymium: 10%, promethium: 10%, gadolinium: 6%, lutetium: 5% , dysprosium: 4%, terbium: 13%, and the balance is lanthanum.

[0051] The production process of the high-life steam turbine blade in this embodiment is carried out according to the following procedures: hot forging→annealing→blade mechanical processing→stress relief heat treatment→quenching and tempering heat treatment→cooling→surface strengthening heat treatment→physical and chemical inspection→ultrasonic flaw detection→clean packaging; :

[0052] The annealing process: after hot forging, ...

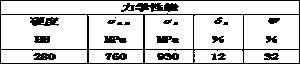

Embodiment 2

[0062] This embodiment provides a long-life steam turbine blade, the mass percent of its chemical composition is C: 0.31%, Si: 0.19%, Mn: 0.77%, Ni: 0.85%, Cr: 10.1%, Mo: 0.64%, Sn: 0.17%, V: 0.15%, Sr: 0.84%, Nb: 0.16%, Cu: 0.06%, Ti: 0.14%, B: 0.08%, Ca: 0.008%, S: 0.01%, P: 0.03%, rare earth metal : 0.18, the balance is Fe; the chemical composition mass percentage of the rare earth metal is: cerium: 8%, praseodymium: 8%, neodymium: 11%, promethium: 10%, gadolinium: 7%, lutetium: 6%, dysprosium : 6%, terbium: 14%, and the balance is lanthanum.

[0063] The production process of the high-life steam turbine blade in this embodiment is carried out according to the following procedures: hot forging→annealing→blade mechanical processing→stress relief heat treatment→quenching and tempering heat treatment→cooling→surface strengthening heat treatment→physical and chemical inspection→ultrasonic flaw detection→clean packaging; :

[0064] The annealing process: after hot forging, kee...

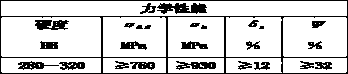

Embodiment 3

[0074] This embodiment provides a long-life steam turbine blade, the mass percentage of its chemical composition is: C: 0.31%, Si: 0.19%, Mn: 0.77%, Ni: 0.85%, Cr: 10.1%, Mo: 0.64%, Sn : 0.17%, V: 0.15%, Sr: 0.84%, Nb: 0.16%, Cu: 0.06%, Ti: 0.14%, B: 0.08%, Ca: 0.008%, S: 0.01%, P: 0.03%, rare earth Metal: 0.18, the balance is Fe; the chemical composition mass percentage of the rare earth metal is: cerium: 10%, praseodymium: 9%, neodymium: 12%, promethium: 11%, gadolinium: 8%, lutetium: 7%, Dysprosium: 8%, terbium: 15%, and the balance is lanthanum.

[0075] The production process of the high-life steam turbine blade in this embodiment is carried out according to the following procedures: hot forging→annealing→blade mechanical processing→stress relief heat treatment→quenching and tempering heat treatment→cooling→surface strengthening heat treatment→physical and chemical inspection→ultrasonic flaw detection→clean packaging; :

[0076] The annealing process: after hot forging,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com