ASA resin suitable for automobile millimeter-wave radar and preparation method thereof

An ASA resin and millimeter wave radar technology, which is applied in the field of polymer molding and polymer blending, can solve the problems of ASA toughness, millimeter wave radar signal interference, and the inability to meet the toughness requirements of automotive exterior materials. The effect of maintaining weather resistance and impact toughness, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

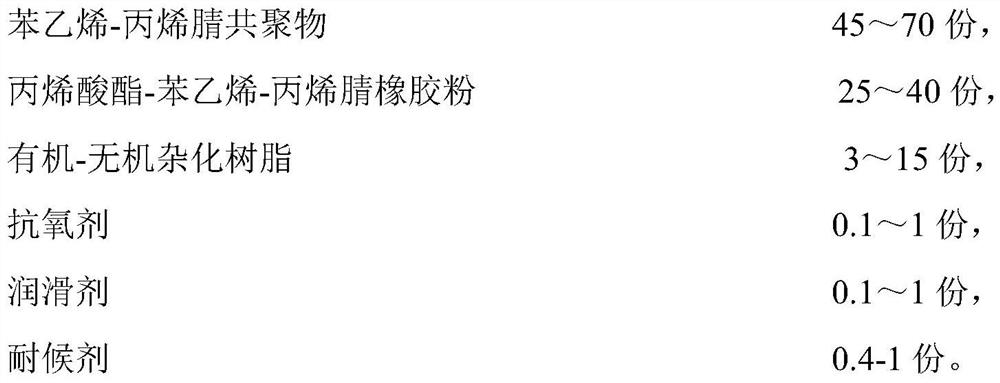

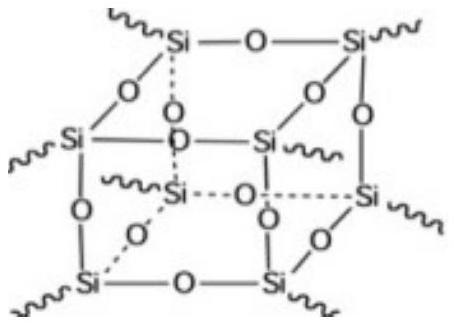

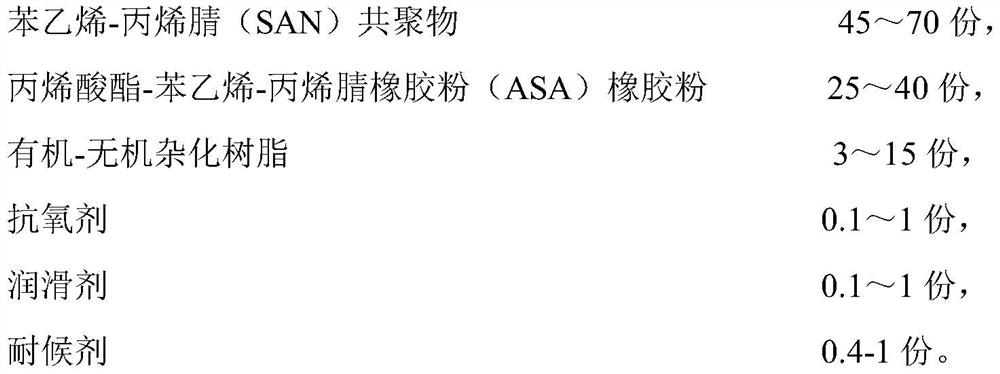

[0029] Embodiments 1 to 5 relate to ASA resins suitable for automotive millimeter-wave radars. The components and contents of the ASA resin materials are shown in Table 1; the SAN resin is Chimei PN128 from Taiwan, and the ASA rubber powder is Kumho XC500 from South Korea. The inorganic hybrid resin is POSS, wherein the top segment of the POSS cage molecule is a methyl acrylate polymer segment (Wang Wenping, ATRP preparation and characterization of POSS / PMMA composite materials, Polymer Materials Science and Engineering [J], 2007 , 23 (4): 247-249), antioxidant is the Irganox 168 of Ciba Company; Lubricant is commercially available N, N-ethylene bisstearic acid amide, and weathering agent is hindered amine antioxidant (Ciba , 770DF).

[0030] Table 1 Components and parts by weight

[0031] Example 1 Example 2 Example 3 Example 4 Example 5 SAN resin 62 62 62 62 62 ASA rubber powder 35 33 31 28 23 Organic-inorganic hybrid resin 3 5...

Embodiment 6

[0037] This embodiment relates to an ASA suitable for automobile millimeter-wave radar, and its preparation method is as follows:

[0038] a. Take the corresponding raw materials according to the following components and weight:

[0039]

[0040] b. Then first mix SAN resin, ASA rubber powder, organic-inorganic hybrid resin, antioxidant, lubricant, and weather resistance agent in a mixing mixer;

[0041] c. Blend and granulate the mixture obtained in step b through a twin-screw extruder to obtain ASA resin particles suitable for automotive millimeter-wave radar. The barrel temperature of the extruder is 190° C., and the screw speed is 700 rpm.

[0042] The SAN resin has a weight-average molecular weight of 120,000 and a glass transition temperature of 104°C;

[0043] The ASA rubber powder, the acrylate rubber content is 55%, and the rubber particle size is 200nm;

[0044] Described organic-inorganic hybrid particle is POSS, and wherein, POSS cage molecule top segment is p...

Embodiment 7

[0049] This embodiment relates to an ASA suitable for automobile millimeter-wave radar, and its preparation method is the same as that of Embodiment 6, except that:

[0050]a. Prepare materials according to the following components and parts by weight:

[0051]

[0052] b. Then first mix SAN resin, ASA rubber powder, organic-inorganic hybrid resin, antioxidant, lubricant, and weather resistance agent in a mixing mixer;

[0053] c. Blend and granulate the mixture obtained in step b through a twin-screw extruder to obtain ASA resin particles suitable for automotive millimeter-wave radar. The barrel temperature of the extruder is 250° C., and the screw speed is 300 rpm.

[0054] The SAN resin has a molecular weight of 150,000 and a glass transition temperature of 105.5°C;

[0055] The ASA rubber powder, the acrylate rubber content is 53%, and the rubber particle size is 300nm;

[0056] Described organic-inorganic hybrid particle is POSS, and R is styrene-acrylonitrile copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com