Multi-component alloy casting ball

A multi-element alloy and casting ball technology, which is applied in the field of multi-element alloy casting balls, can solve the problems of unsatisfactory mechanical properties of low-chromium balls and high cost of high-chromium balls, and achieve the effects of reducing broken rate, reducing chromium content, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

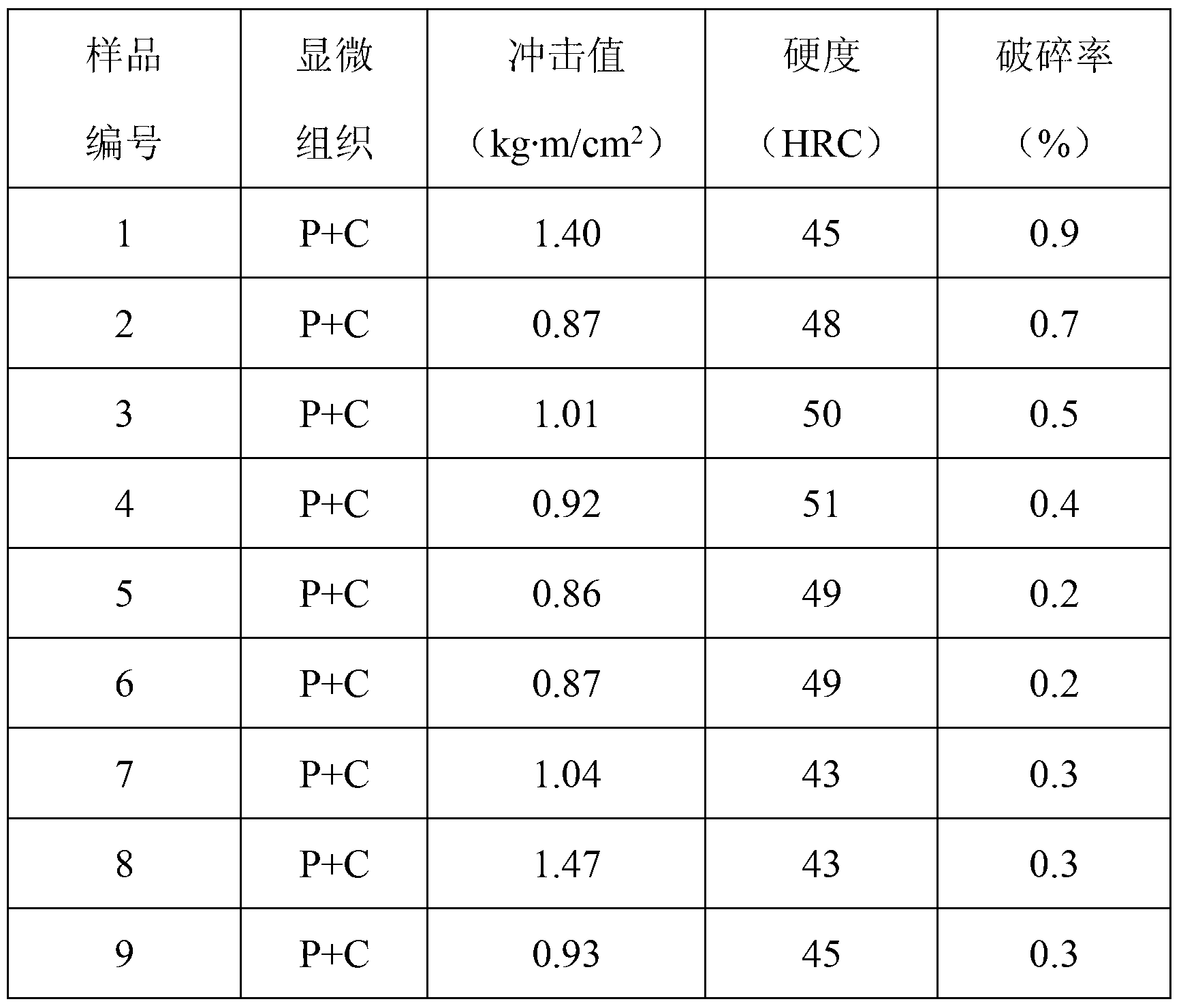

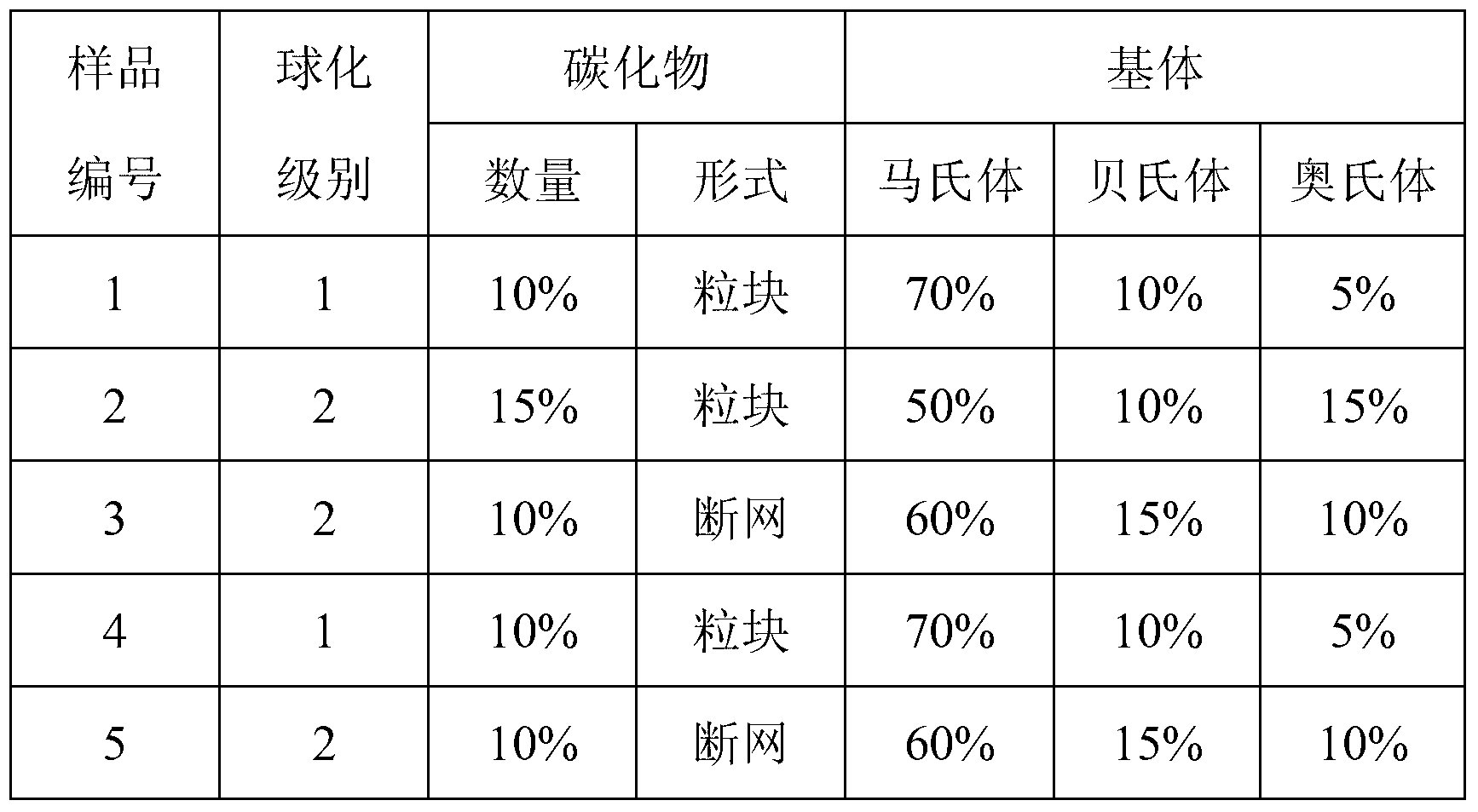

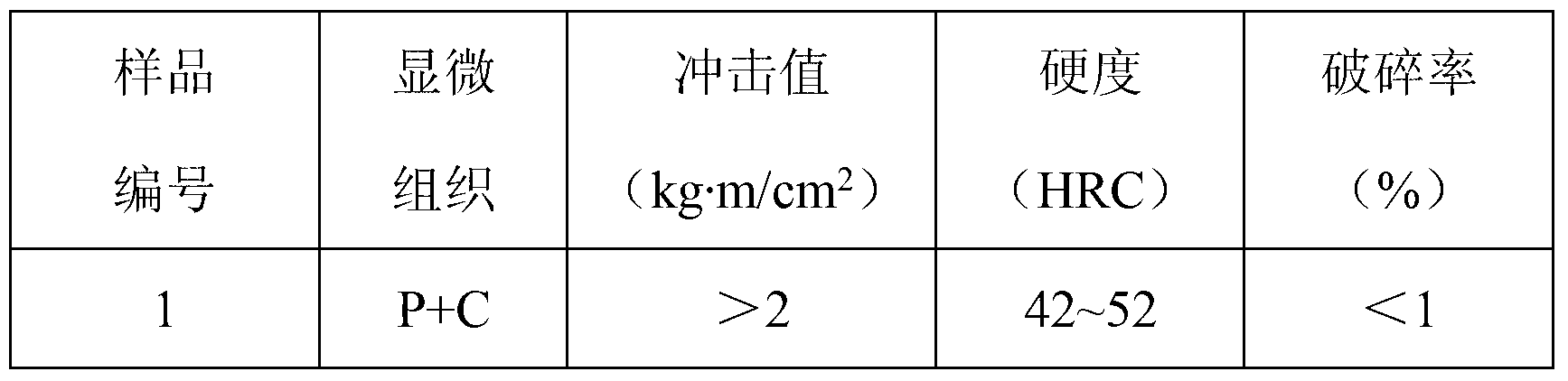

Examples

Embodiment Construction

[0012] The present invention is further explained below with specific embodiments, but the following description does not constitute a limitation to the scope of claims of the present invention.

[0013] In order to make the grinding ball have a certain hardness and ensure good hardenability, in addition to a certain amount of carbon, a certain amount of hardenability-enhancing elements are usually added to the grinding ball, such as chromium, nickel, copper, molybdenum, etc. . In the chemical composition of the grinding ball, the higher the carbon content, the more beneficial it is to improve the wear resistance, but the impact toughness will decrease. In order to ensure that the grinding ball has both a certain hardness and a certain toughness, the carbon content in the grinding ball It is best to control it at 2.5% to 2.7%. Silicon is a non-carbide forming element, too high a content will have an adverse effect on hardenability, so its content is best controlled below 1.0%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com