Method for improving interface characteristics of SiC device

A device surface and device technology, which is applied in the field of improving the interface characteristics of SiC devices, can solve the problems of single improvement surface, improvement of non-transition area, improvement of surface roughness of SiC devices, etc., to achieve the effect of improving work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

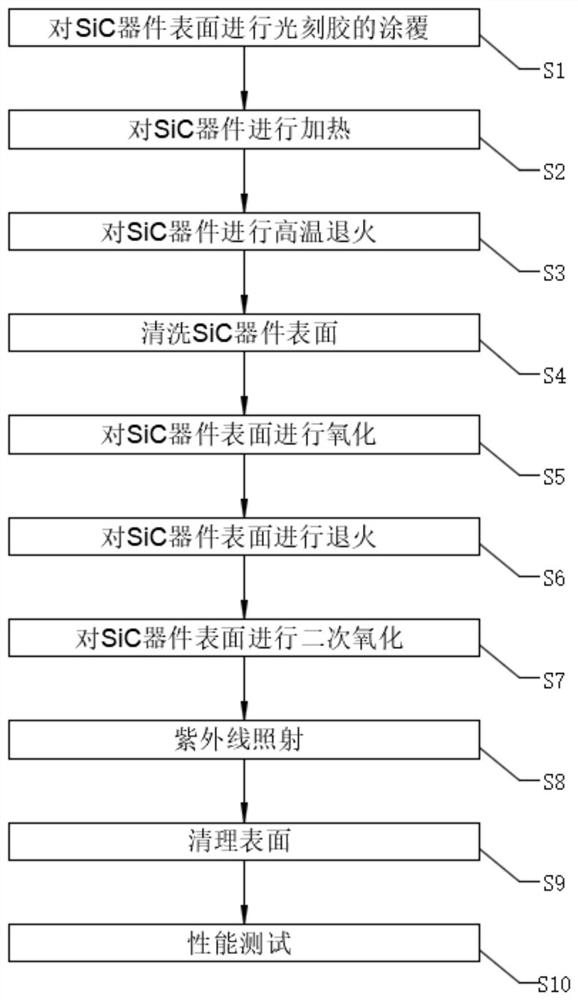

[0032] see figure 1 , the present invention provides a technical solution: a method for improving the interface characteristics of SiC devices, comprising the following steps:

[0033] S1. Coating photoresist on the surface of the SiC device, coating the photoresist on the surface of the SiC device, and drying it naturally for 30 minutes after coating, and controlling the room temperature at 25°C during air drying;

[0034] S2. Heat the SiC device, place the SiC device in a heating device, and heat it to 550°C to form a carbide film on the surface of the SiC device, and the heating time is 30 minutes;

[0035] S3. Perform high-temperature annealing on the SiC device, cool the heated SiC device to room temperature, and put it into an annealing device for high-temperature annealing activation;

[0036] S4. Cleaning the surface of the SiC device, cleaning the surface of the SiC device, removing impurities, and air-drying the SiC device after cleaning, the air-drying time is 15 m...

Embodiment 2

[0051] see figure 1 , the present invention also provides a technical solution, which is different from the first embodiment: a method for improving the interface characteristics of SiC devices, comprising the following steps:

[0052] S1. Coating photoresist on the surface of the SiC device, coating the photoresist on the surface of the SiC device, and drying it naturally for 35 minutes after coating, and controlling the room temperature at 28°C during air drying;

[0053] S2. Heat the SiC device, place the SiC device in a heating device, and heat it to 600°C to form a carbide film on the surface of the SiC device, and the heating time is 33 minutes;

[0054] S3. Perform high-temperature annealing on the SiC device, cool the heated SiC device to room temperature, and put it into an annealing device for high-temperature annealing activation;

[0055] S4. Cleaning the surface of the SiC device, cleaning the surface of the SiC device, removing impurities, and air-drying the SiC...

Embodiment 3

[0070] see figure 1 , the present invention also provides a technical solution, which is different from the first embodiment: a method for improving the interface characteristics of SiC devices, comprising the following steps:

[0071] S1. Coating photoresist on the surface of the SiC device, coating the photoresist on the surface of the SiC device, and drying it naturally for 45 minutes after coating, and controlling the room temperature at 30°C during air drying;

[0072] S2. Heat the SiC device, place the SiC device in a heating device, and heat it to 650°C to form a carbide film on the surface of the SiC device, and the heating time is 35 minutes;

[0073] S3. Perform high-temperature annealing on the SiC device, cool the heated SiC device to room temperature, and put it into an annealing device for high-temperature annealing activation;

[0074] S4. Cleaning the surface of the SiC device, cleaning the surface of the SiC device, removing impurities, and air-drying the SiC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com