Method for removing volatile organic malodorous substances from biogas slurry by using extraction method

A volatile organic and extraction technology, which is applied in the field of waste resource utilization, can solve the problems of loss of nutrient elements, non-specific adsorption of porous solid substances, slow chemical reaction speed, etc., and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

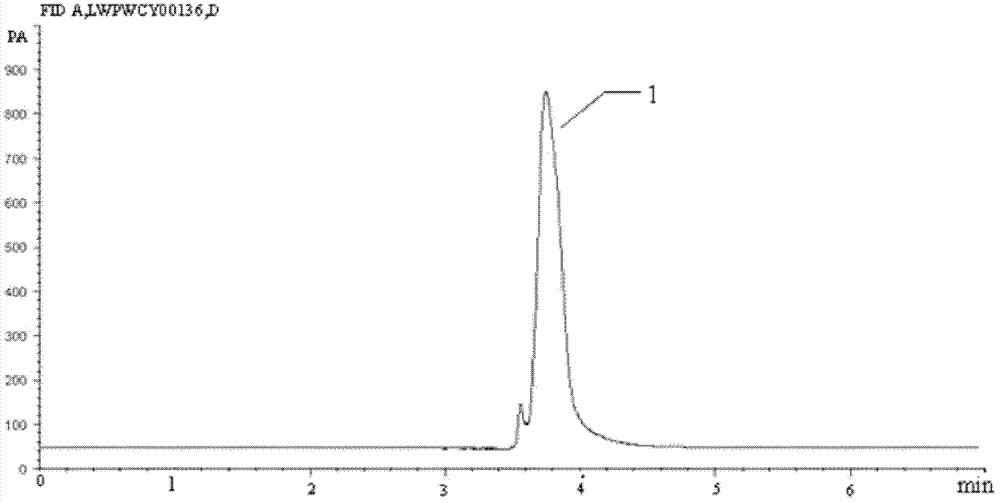

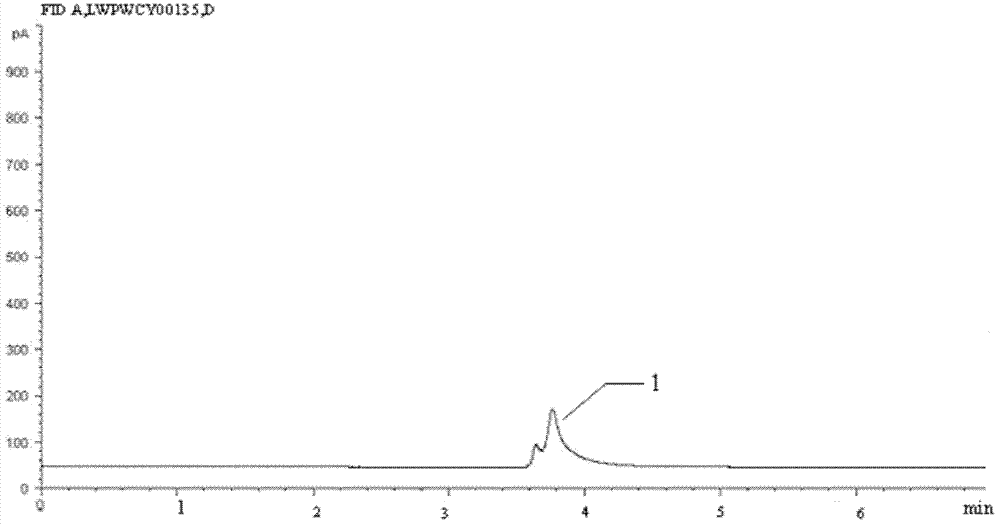

[0024] Specific implementation mode one: the specific implementation mode of the method of the present invention is as follows: figure 1 , figure 2 This embodiment will be described.

[0025] The biogas slurry was obtained from the biogas station in Jiutai City, Jilin Province, and the main fermentation raw material was cow dung.

[0026] a. Chloroform extraction: Mix the biogas slurry and chloroform with a volume ratio of 12:1 from which the slag-like substances have been removed, and then put it into a closed container (in order to ensure sufficient oscillation space, the volume of the container should be equal to that of the biogas slurry and chloroform. 2-3 times the total volume, preferably glass material), vibrate the container for 30 minutes in a reciprocating or revolving manner, transfer the liquid in the container to the liquid separator, and let it rest for 2 hours to make it layered and complete The first extraction; after the liquid is static and separated, the...

specific Embodiment approach 2

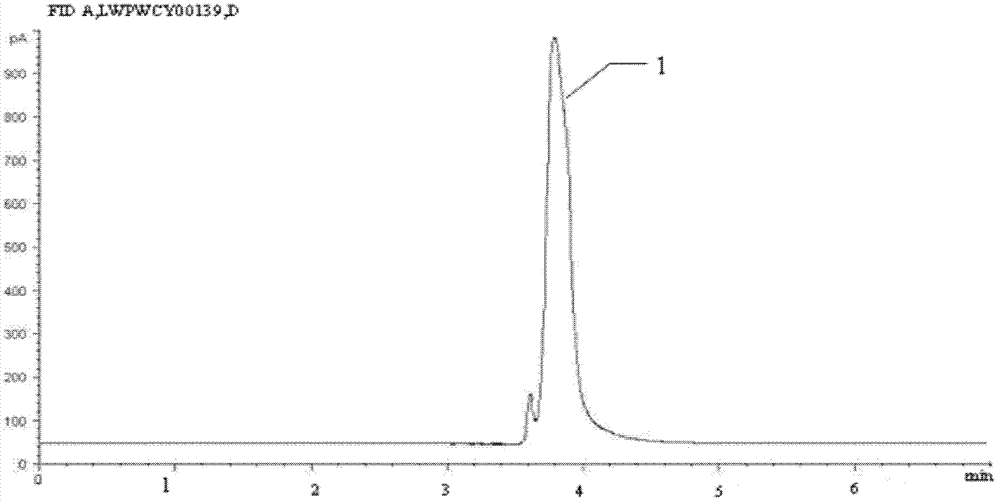

[0038] The specific implementation method of the method of the present invention is as follows: image 3 , Figure 4 This embodiment will be described.

[0039] The biogas slurry was taken from No. 13 Village, Gongpeng Town, Yushu City, Jilin Province, and the main fermentation raw material was chicken manure.

[0040] a. Chloroform extraction: Mix the biogas slurry and chloroform with a volume ratio of 15:1 after removing the slag-like substances, and then put it into a closed container (in order to ensure sufficient oscillation space, the volume of the container should be equal to that of the biogas slurry and chloroform. 2-3 times the total volume, preferably glass material), vibrate the container for 30 minutes in a reciprocating or revolving manner, transfer the liquid in the container to the liquid separator, and let it rest for 2 hours to make it layered and complete The first extraction; after the liquid is static and separated, the lower liquid is discarded, and the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com