Plant ecological interior wall coating and preparation method thereof

An interior wall coating and ecological technology, which is applied in the field of plant ecological interior wall coating and its preparation, can solve the problem of no fully biodegradable water-based interior wall coating, etc., achieves good deodorization and sterilization, strong adhesion, and maintains air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

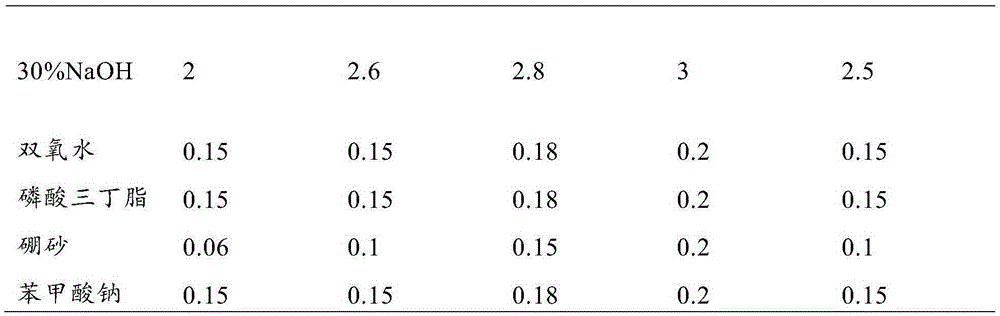

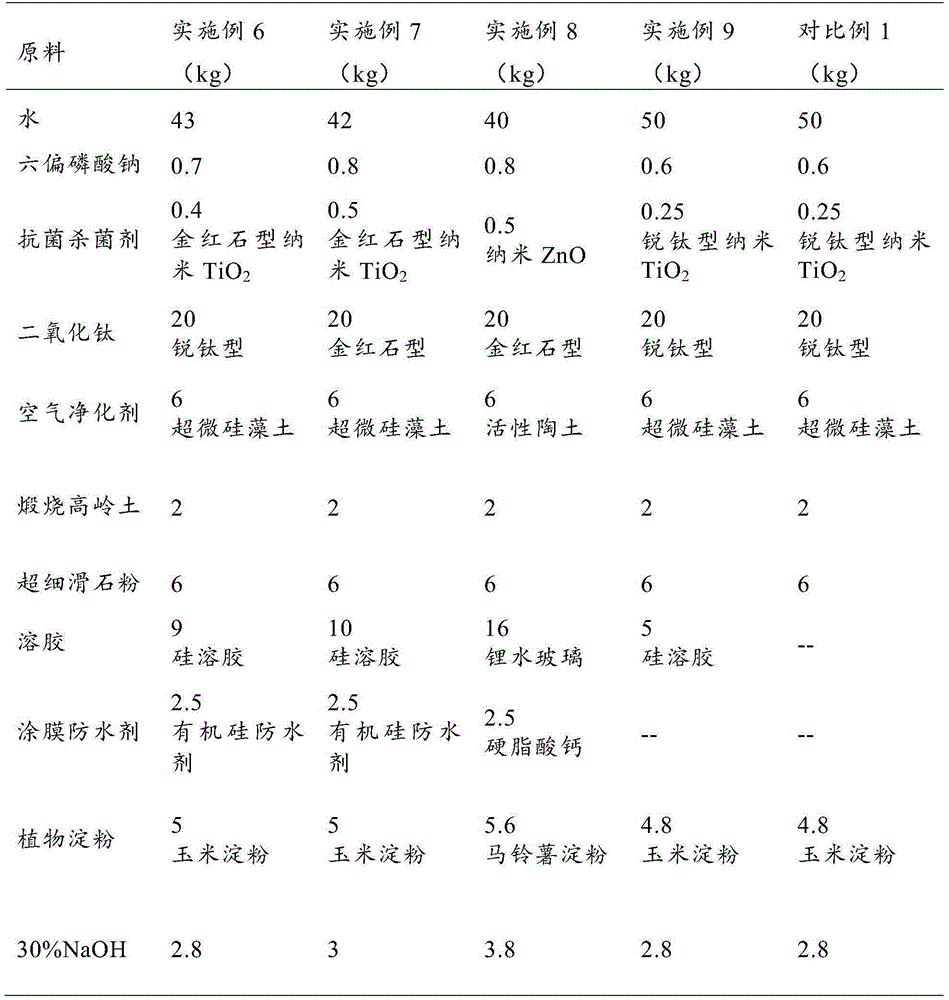

[0051] The preparation of embodiment 1~9 and comparative example 1 interior wall paint

[0052] Prepare the plant ecological interior wall coating with the raw material ratio of each embodiment in Table 1 respectively, and the preparation steps are as follows:

[0053] a. Add the water of formula quantity into the mixing tank, under stirring at 400rpm, completely dissolve the sodium hexametaphosphate dispersant in the water;

[0054] b. Add antibacterial and bactericide, stir and disperse at 2200rpm for 15min;

[0055] c. adding tributyl phosphate accounting for 50% of the formula amount;

[0056] d. Under stirring at 600rpm, add titanium dioxide, air purifier, calcined kaolin, superfine talcum powder, and plant starch in sequence; adjust to 800rpm and continue stirring and dispersing for 15 minutes;

[0057] e. Add 30% NaOH solution and hydrogen peroxide in turn, after gelatinization and thickening, adjust to 1200rpm and continue stirring for 60min;

[0058] f. Slowly add ...

Embodiment 9

[0070] The difference between Example 9 and Example 3 is that no film waterproofing agent is added, and the difference between Comparative Example 1 and Example 3 is that no sol and film waterproofing agent are added. The performance of embodiment 3, 9 and comparative example 1 in terms of adhesion and water resistance is tested, and the test results are shown in table 2. The adhesion of embodiment 3 and embodiment 9 is better than that of comparative example 1 and can reach the water-soluble wall Topcoat technical requirements. The water resistance test is detected after soaking for 48 hours. The water resistance of Example 3 is qualified without shedding, blistering and wrinkling. In Example 9, 80% of the unit area has no shedding, blistering and wrinkling. In Comparative Example 1, 70% of the unit area has no Shedding, foaming and wrinkled skin, although partial shedding, blistering and wrinkled skin also occur in Example 9, it is better than Comparative Example 1 without a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com