Austenitic, lightweight, high-strength steel sheet of which the yield ratio and flexibility are outstanding and a production method therefor

By adjusting the alloy element concentration and process technology, austenitic lightweight high-strength steel plates with high yield strength ratio and ductility are prepared, which solves the shortcomings of existing steel plates in terms of yield strength and specific gravity, and achieves high strength, low specific gravity and Low-cost automotive component materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

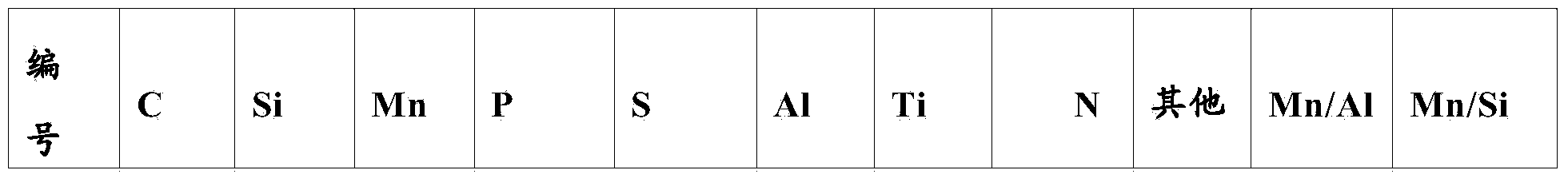

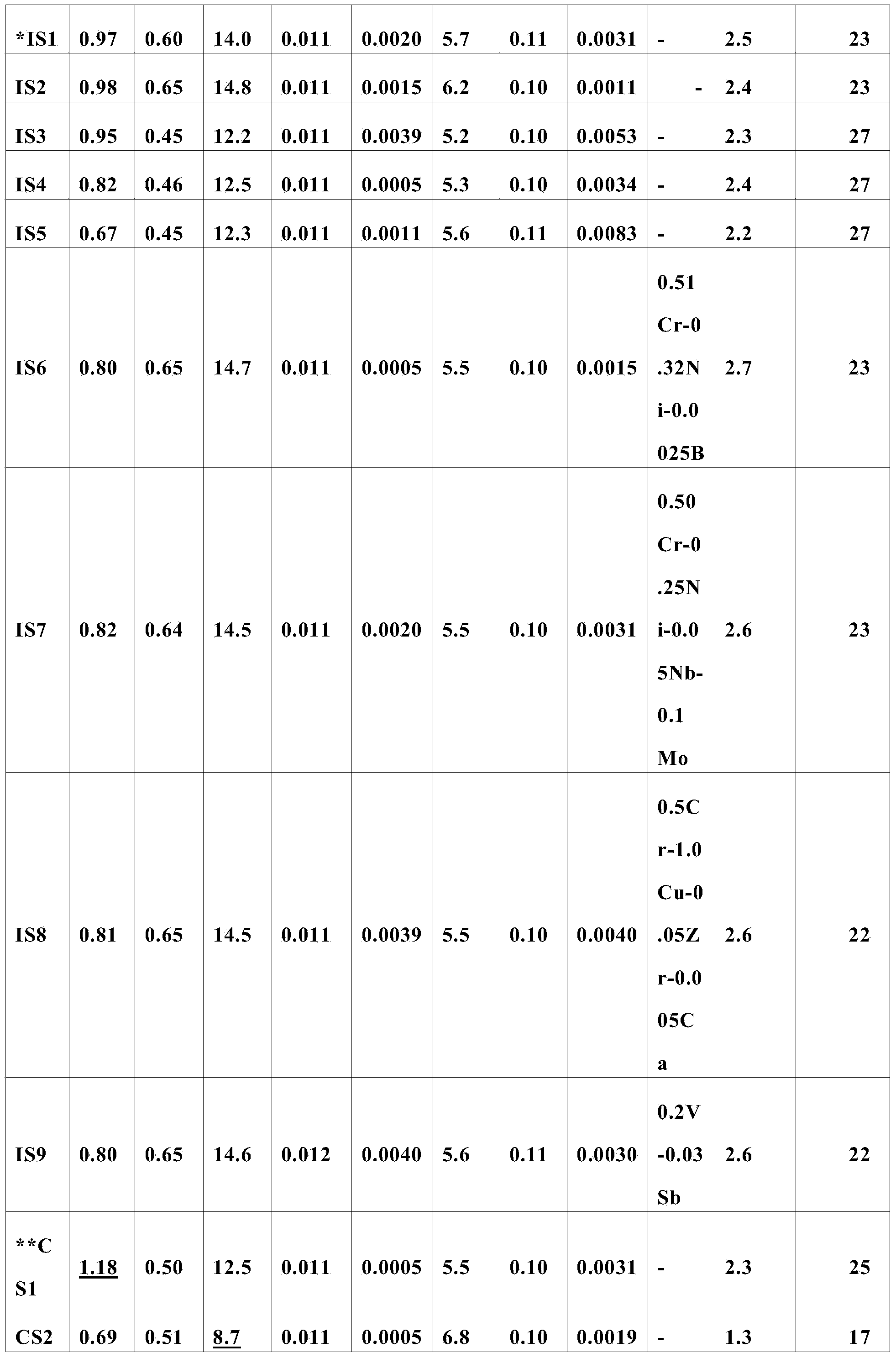

[0067] Steel sheets were produced under the conditions shown in Table 2 by using steel ingots having the compositions shown in Table 1. During the manufacturing process, the starting temperature of hot rolling was 1150° C., the heating rate during cold rolling was 5° C. / second, and the annealing time was 45 seconds. Then, the properties and microstructures of the hot-rolled and cold-rolled steel sheets were measured as shown in Table 3.

[0068] Table 1

[0069]

[0070]

[0071]

[0072] *IS: inventive steel, **CS: comparative steel

[0073] Table 2

[0074]

[0075]

[0076] *IS: Inventive steel, **ISP: Inventive sample, ***CSP: Comparative sample, ****CS: Comparative steel

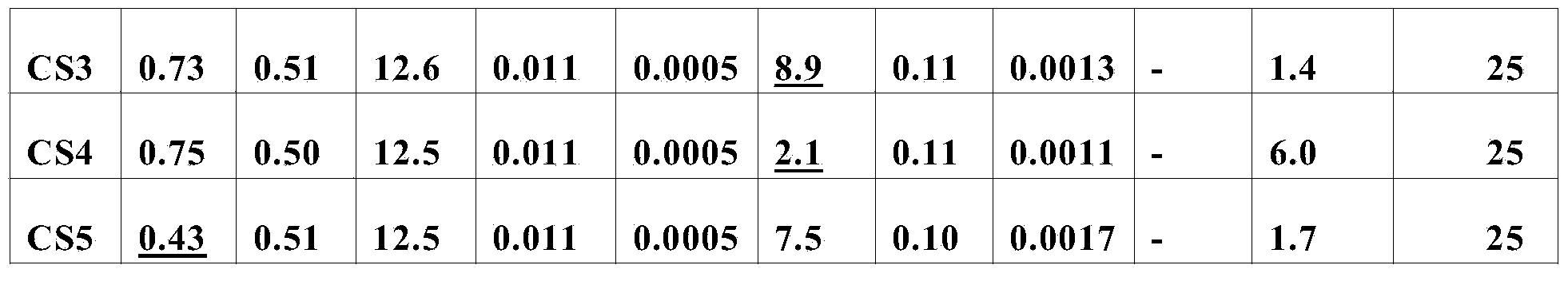

[0077] table 3

[0078]

[0079]

[0080] *IS: Inventive steel, **ISP: Inventive sample, ***CSP: Comparative sample, ****CS: Comparative steel

[0081] As shown in Tables 1 to 3, samples 1 to 9 of the present invention prepared according to the composition and manufacturing con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com