Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Reduce sheet thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

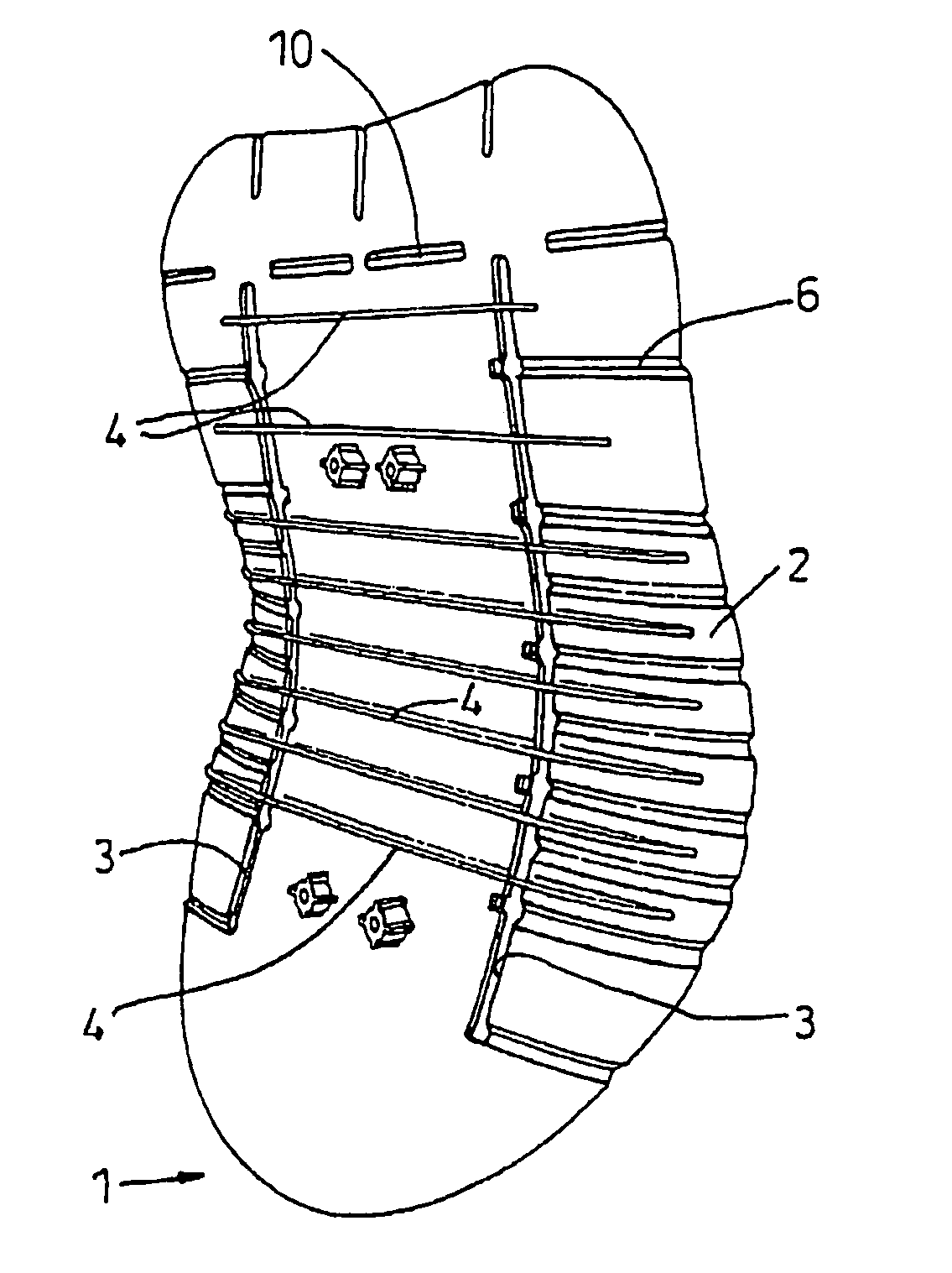

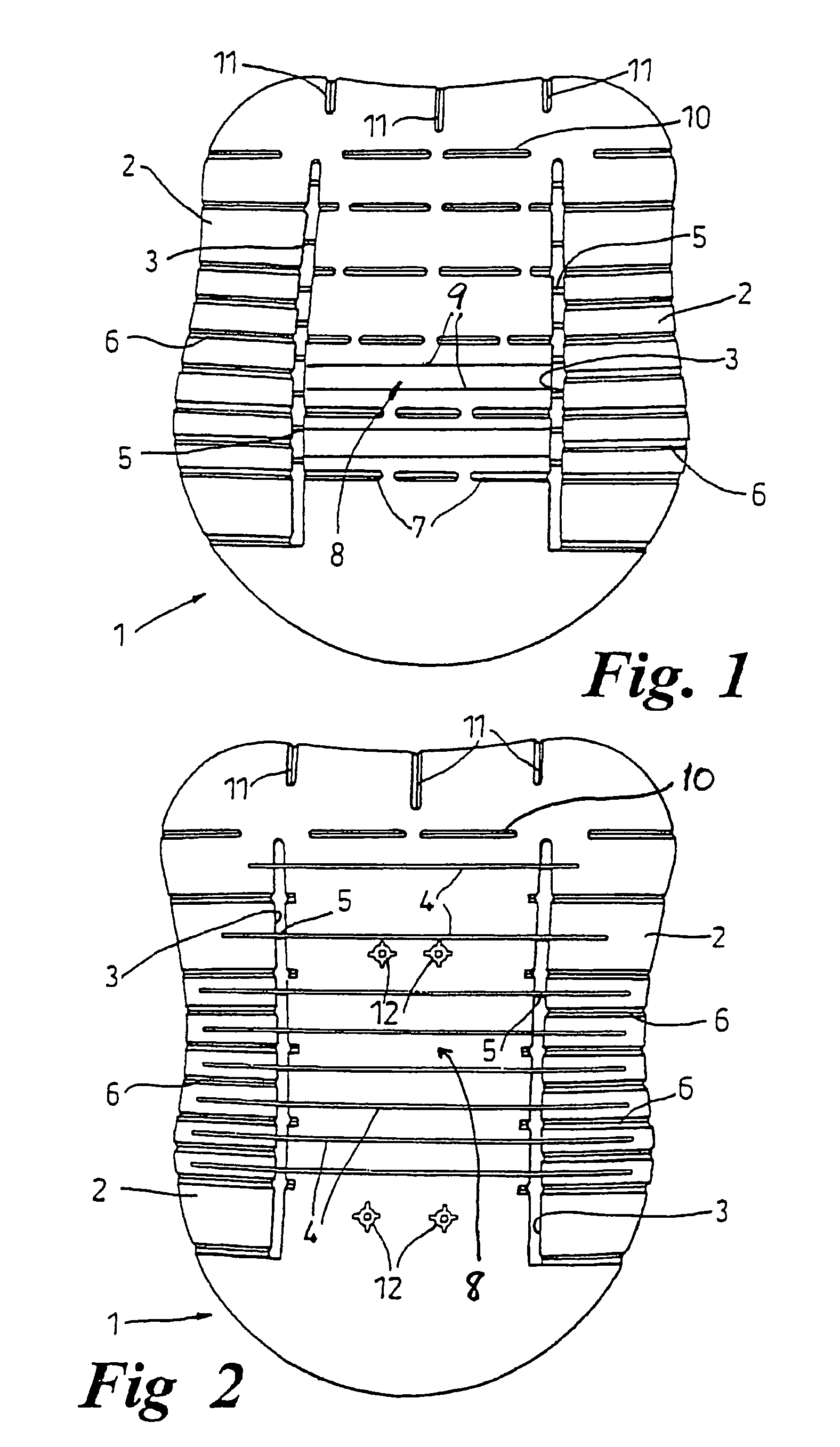

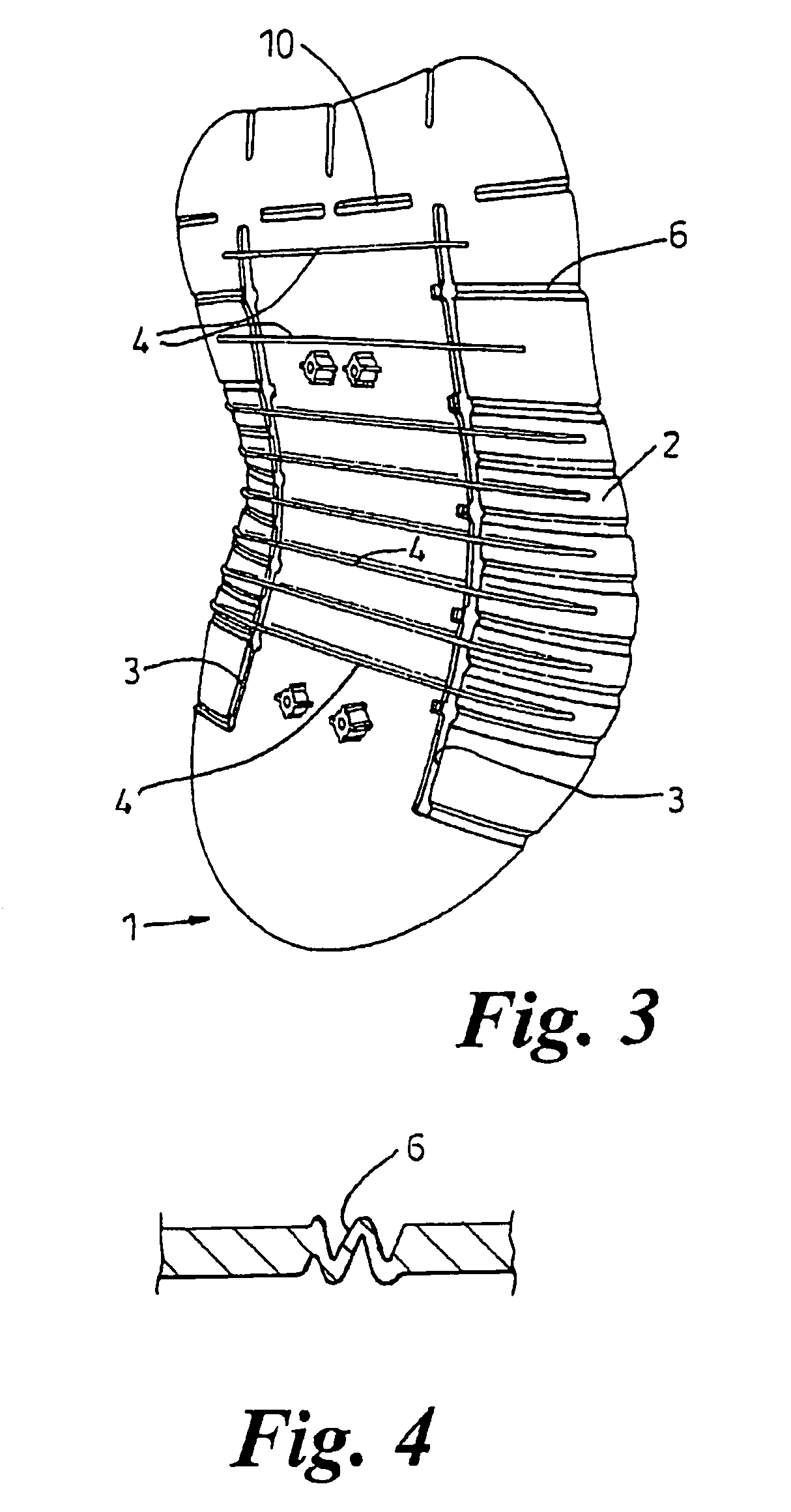

Seat backs

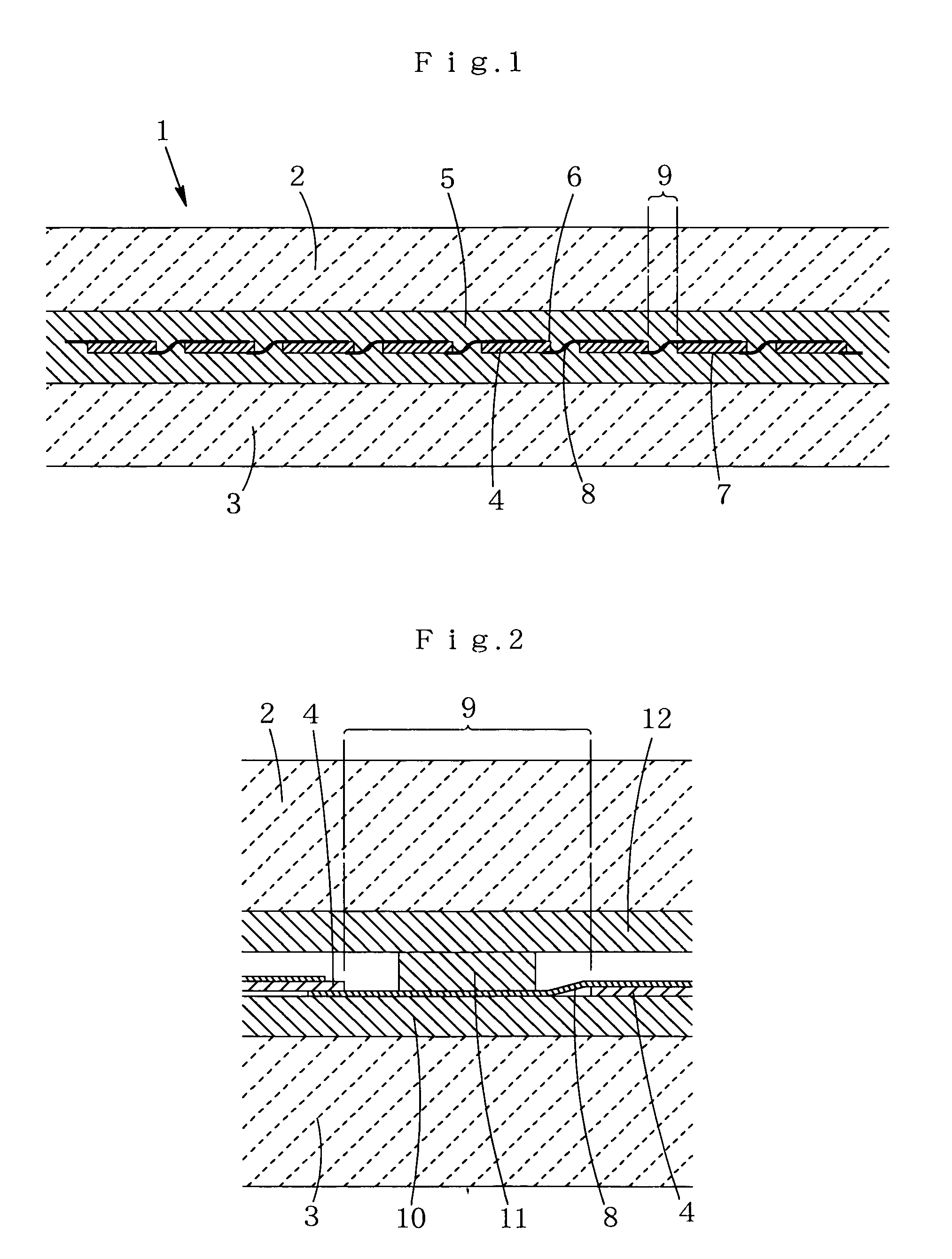

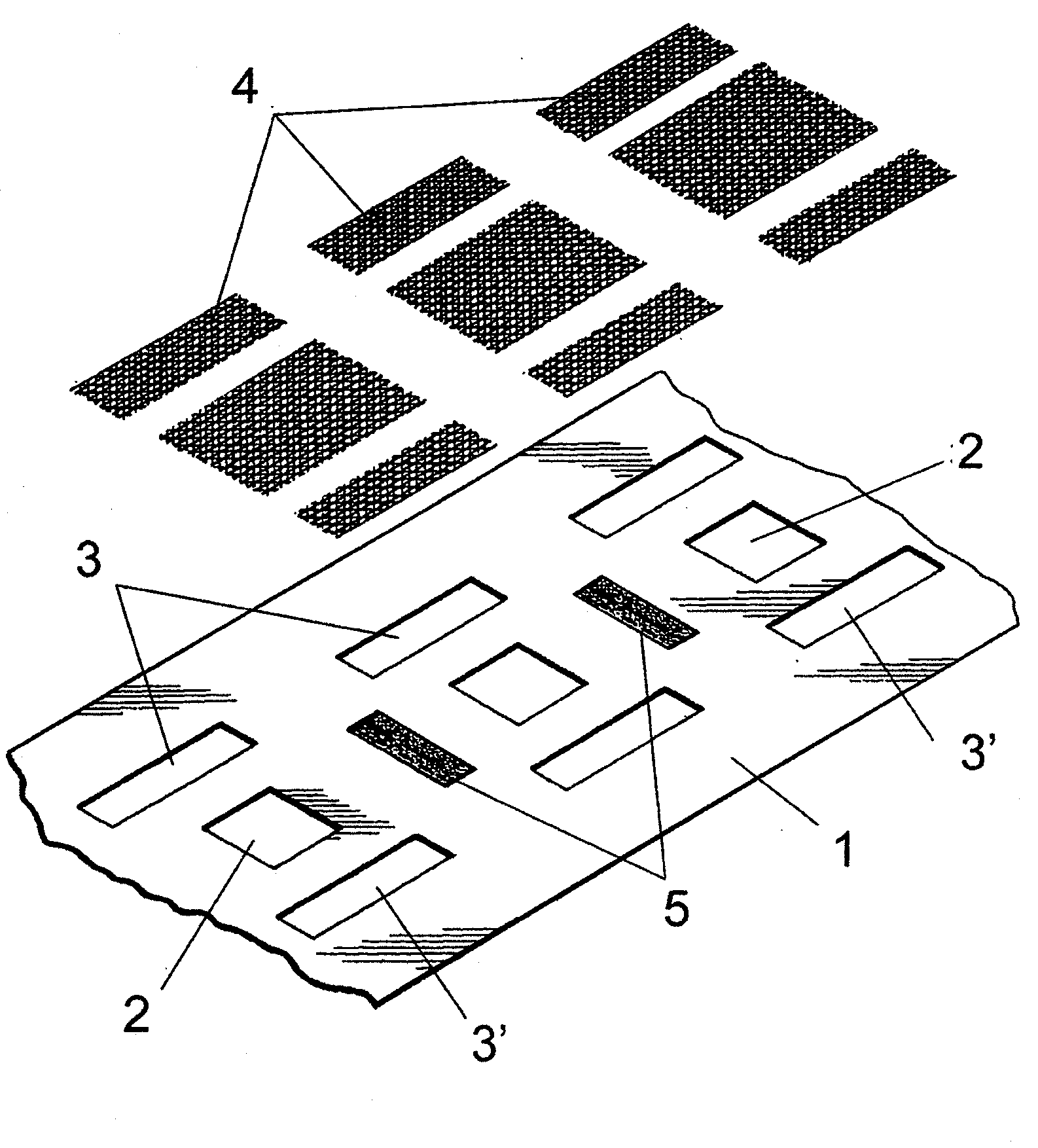

The core (1) of a seat back, which will be upholstered to form the complete back, is a moulded plastics sheet bowed forwardly and with attachment points (12) near top and bottom for securing to a rigid support. The sheet is constructed to be stiffer over its upper portion then over the lower and, when secured, to be able to ripple or alter its curvature between the attachment points. It may have wings (2) inclining forwardly at each side with closed end slots (3) between the wings (2) and the central zone (8) of the core. The wings can be divided into generally horizontal sections carried by integrally moulded transverse ribs (4) spanning the slots (3), the division between sections being by slots (13) or narrow membranes (6). The top of the core may also be divided into side-by-sections, the division being by slots (14) or narrow membranes (11).

Owner:WILLIAMS DAVID NICHOLAS LEWIS

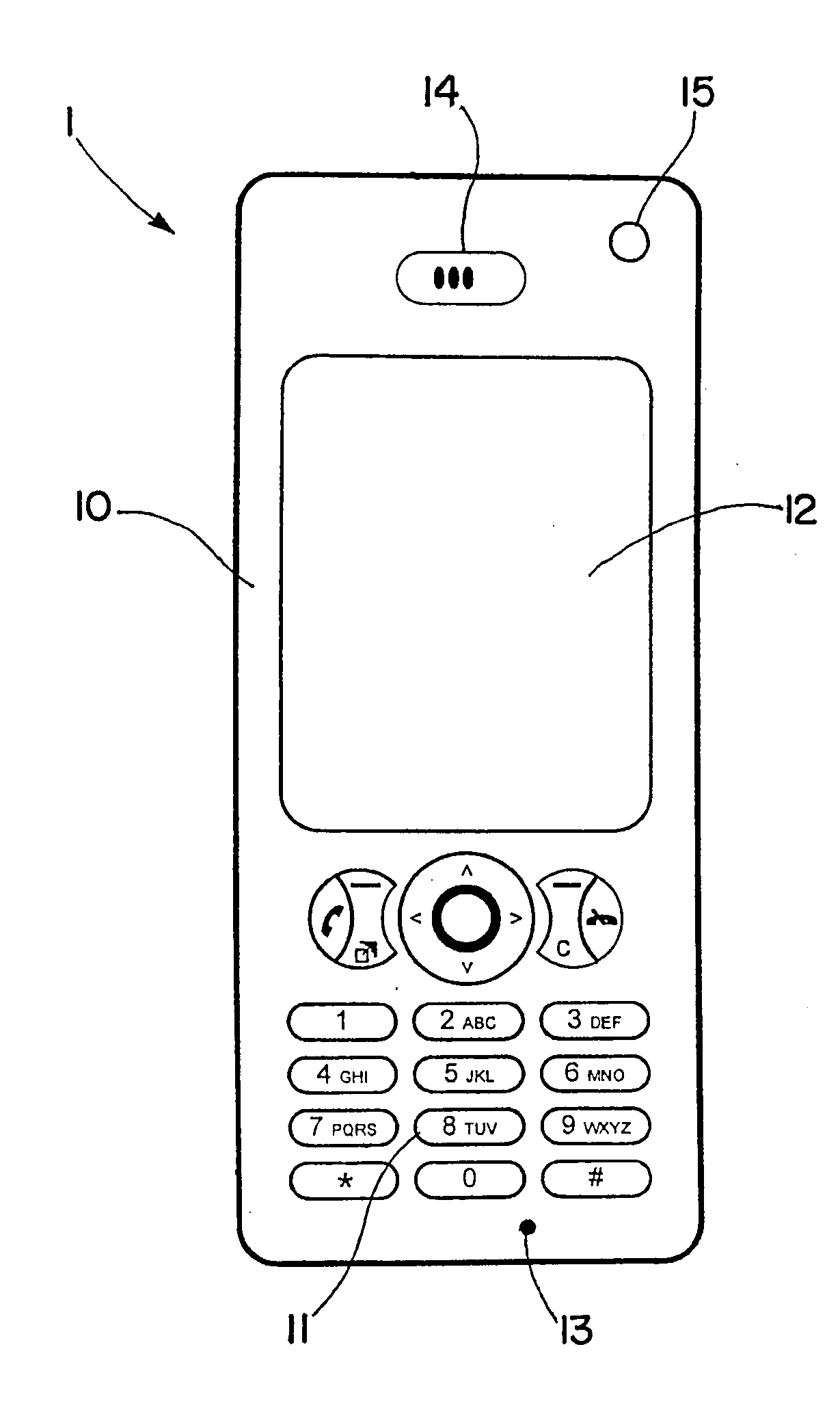

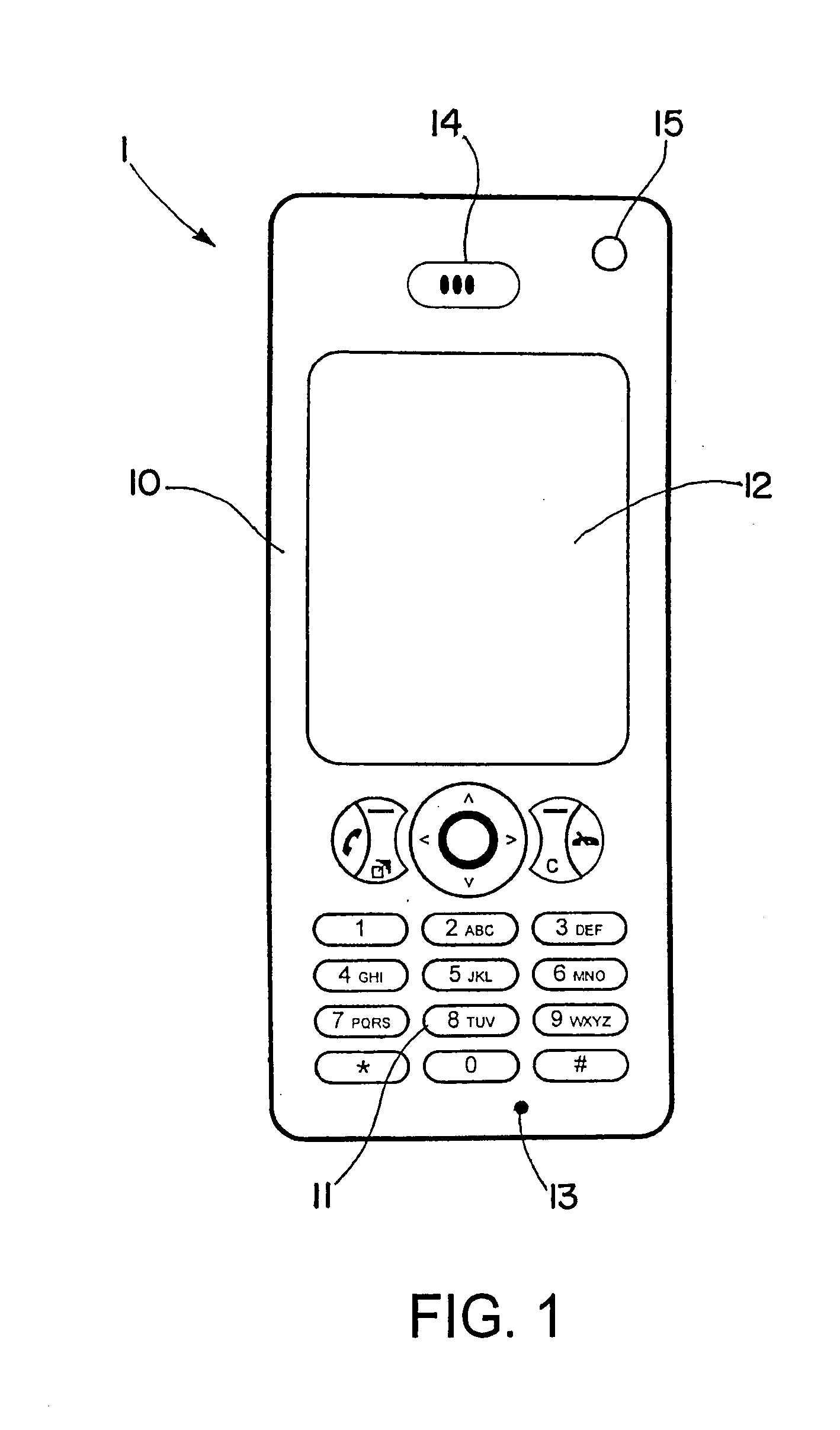

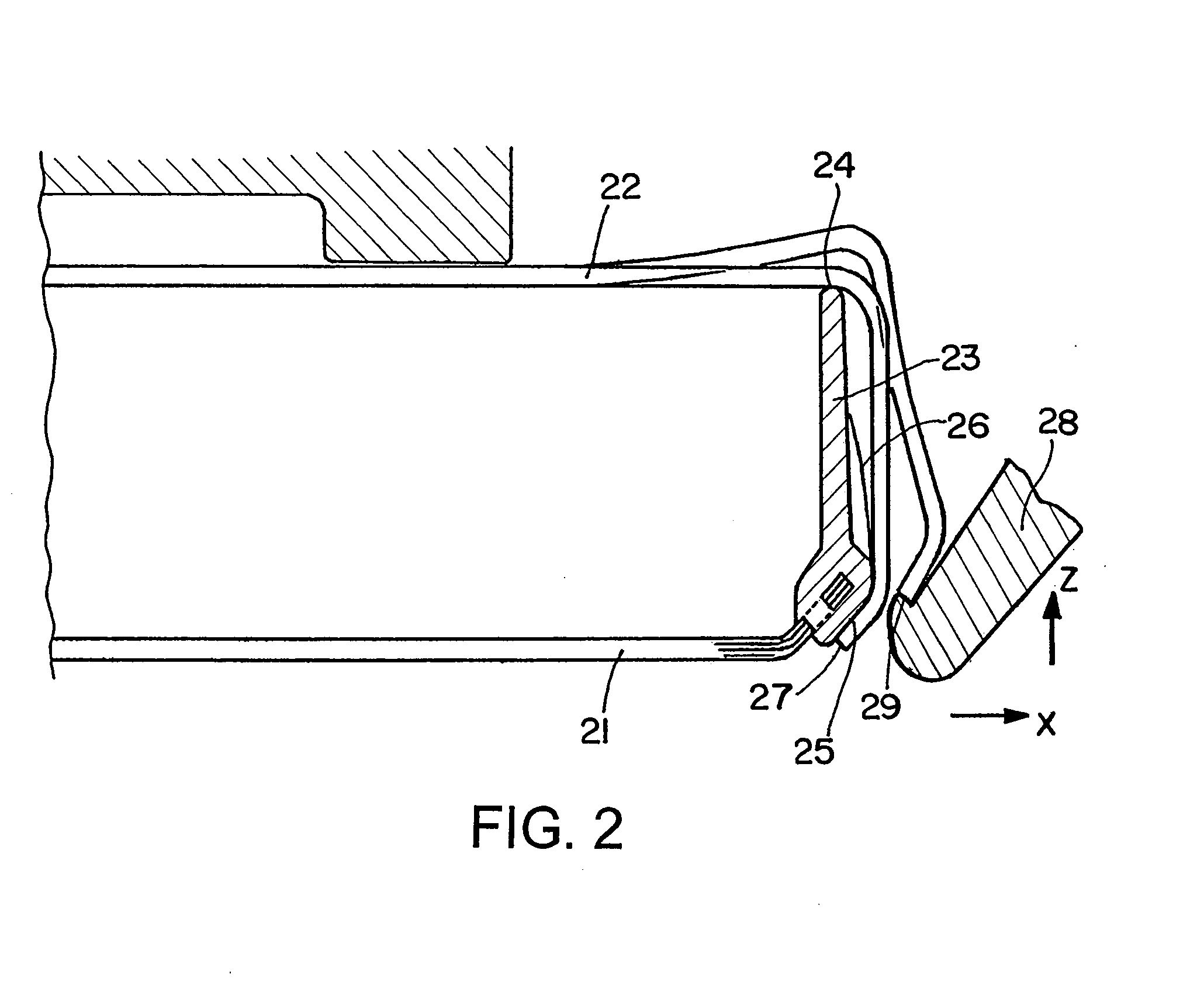

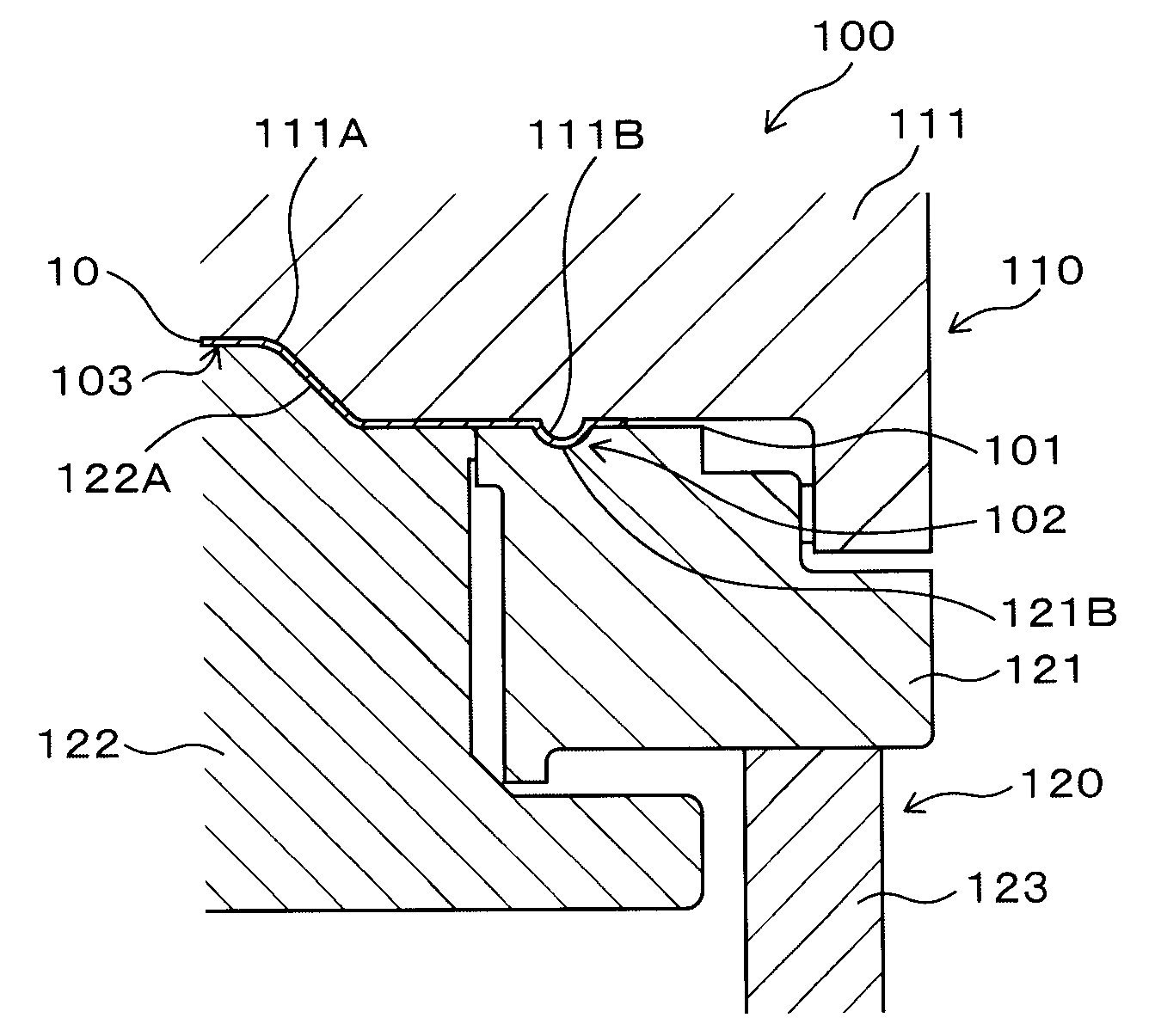

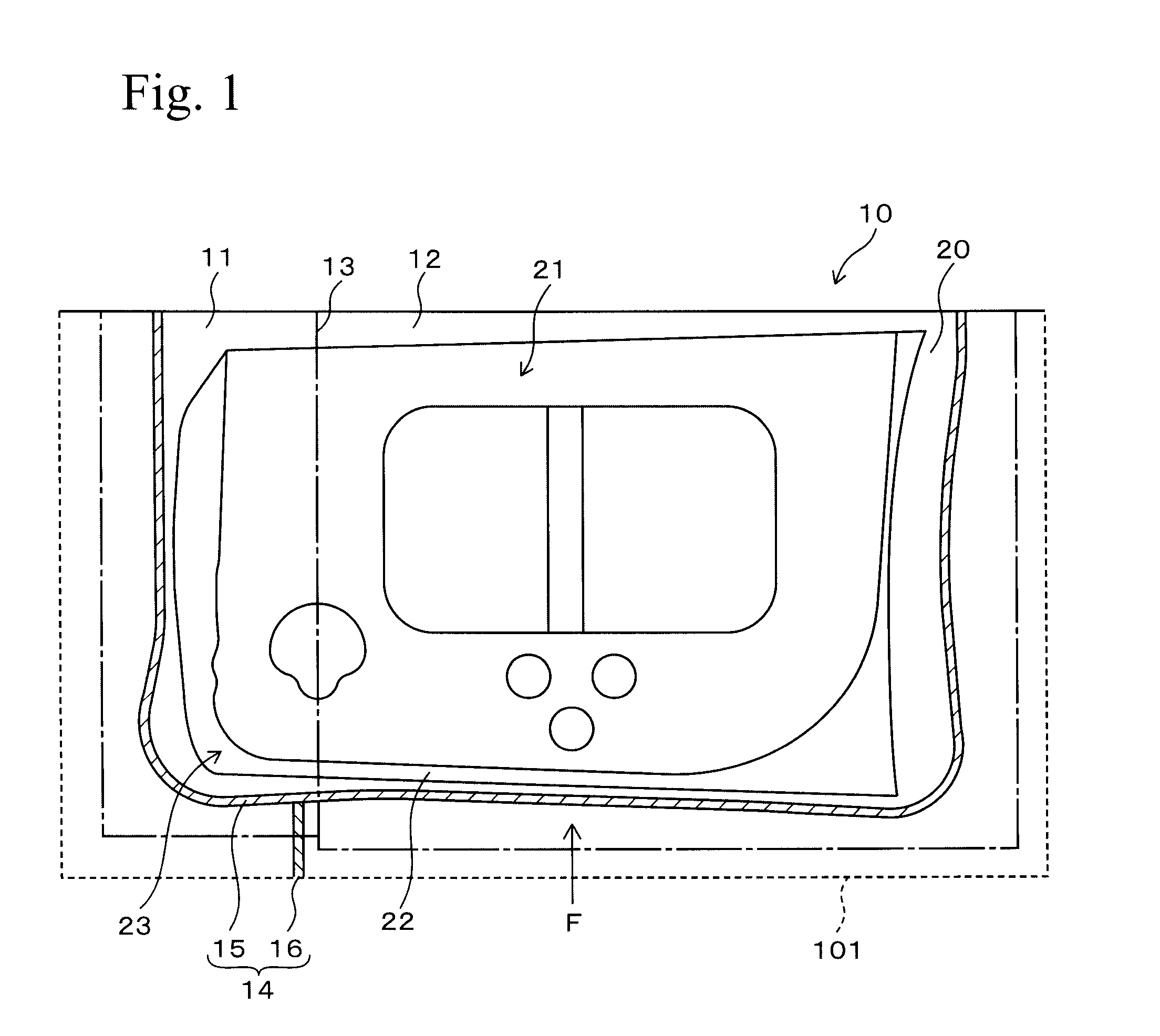

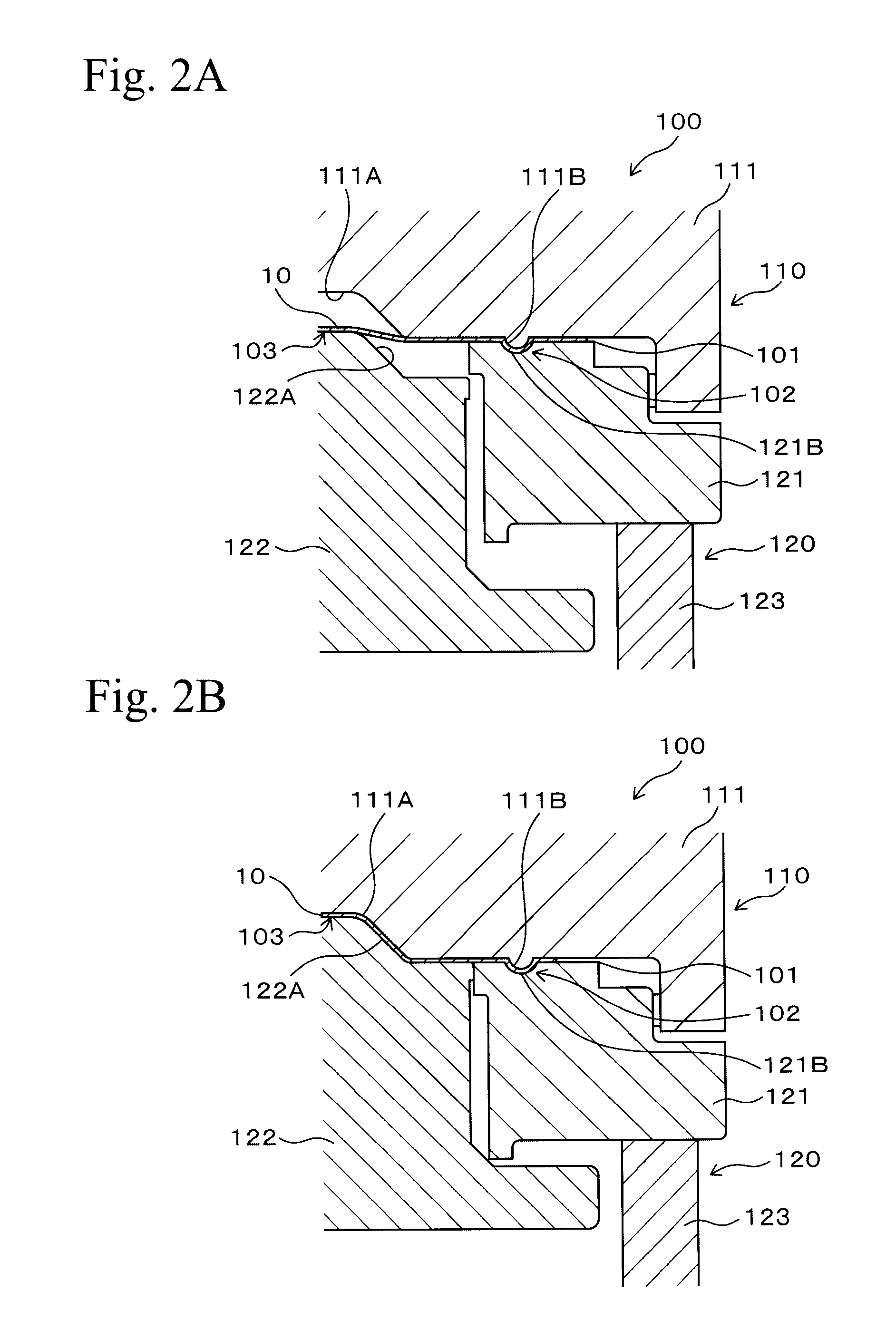

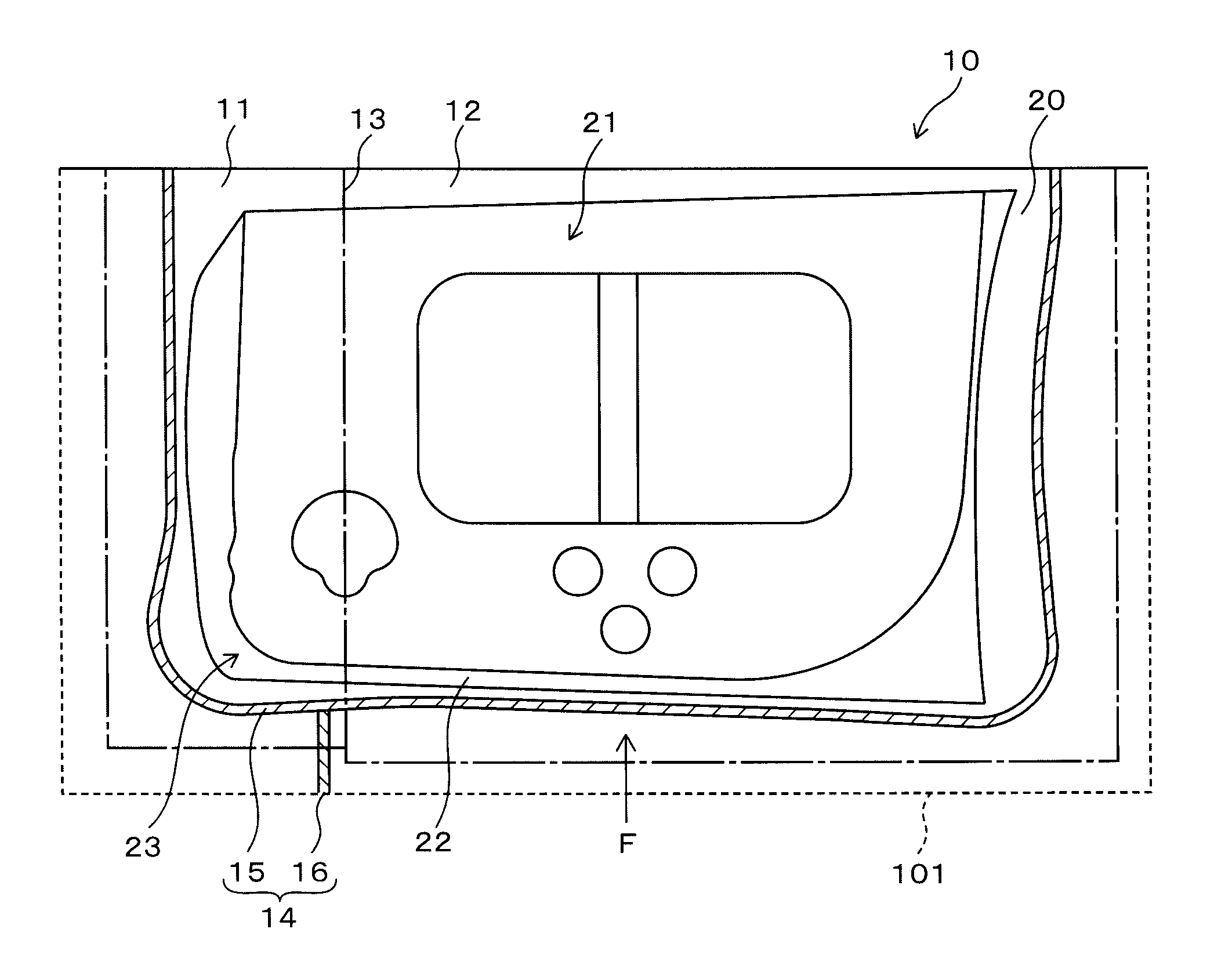

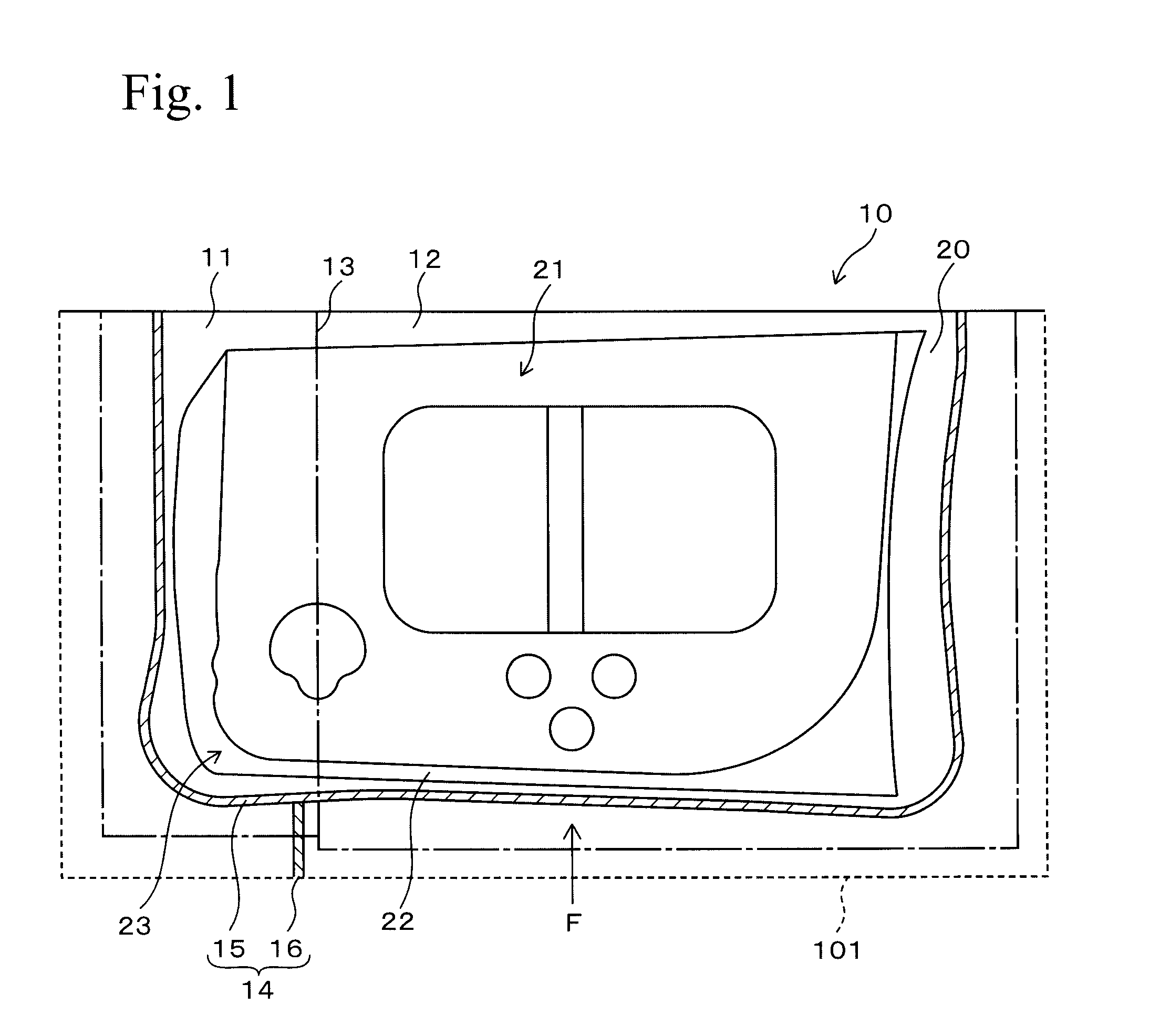

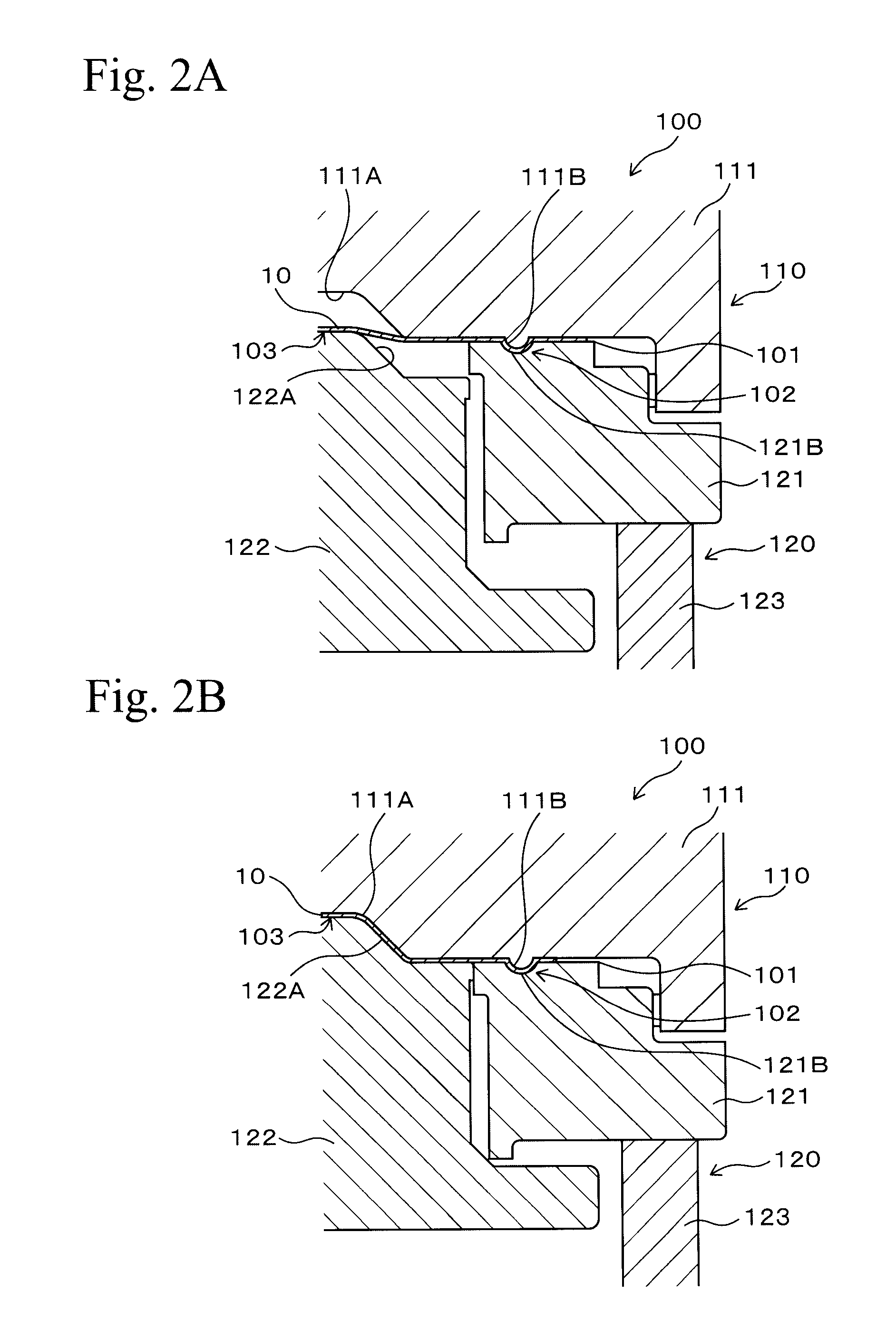

Metal cover for portable electronic device

InactiveUS20090205983A1Reduce eliminateReduce sheet thicknessOther accessoriesContainer/bottle contructionEngineeringElectronic equipment

Owner:SONY ERICSSON MOBILE COMM AB

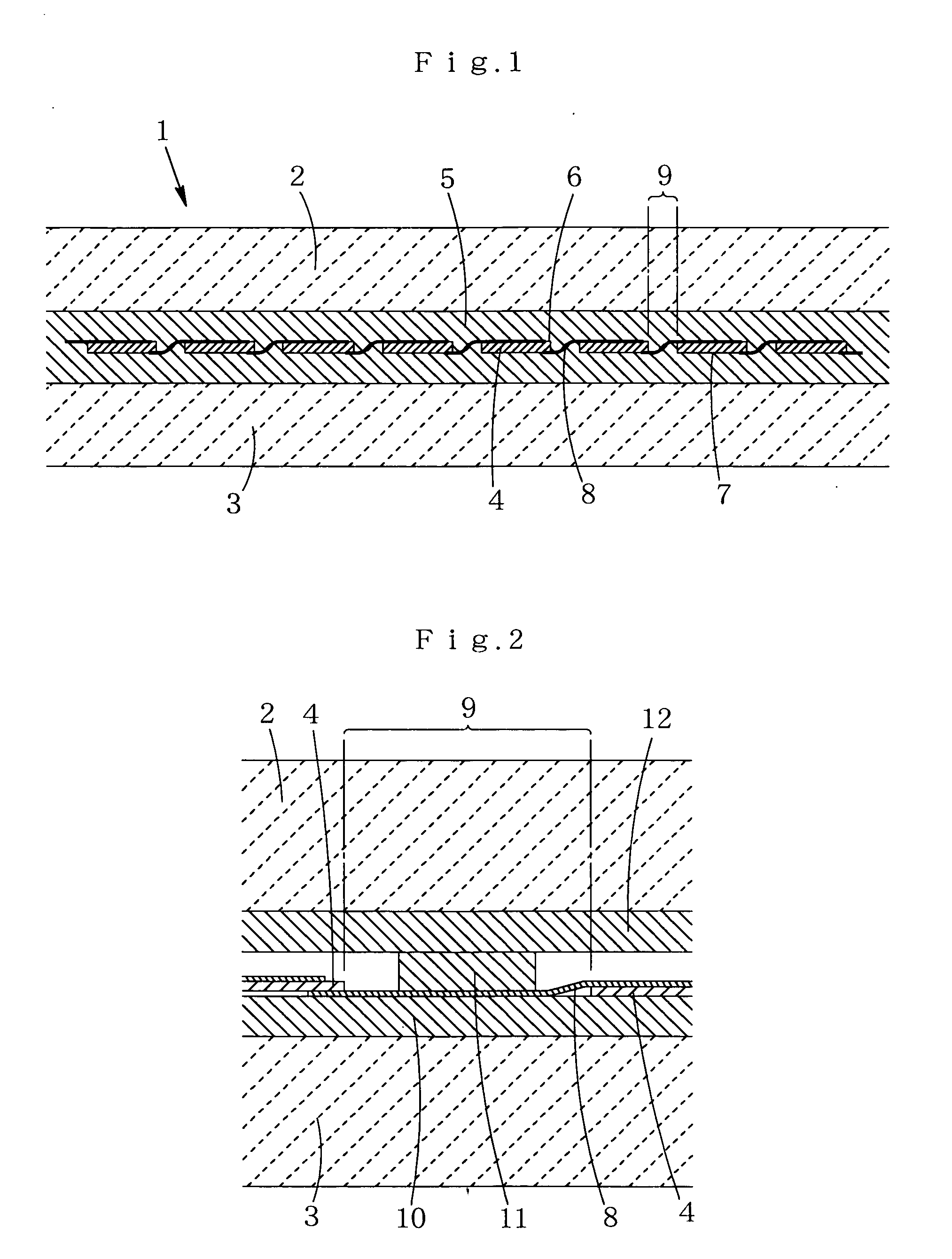

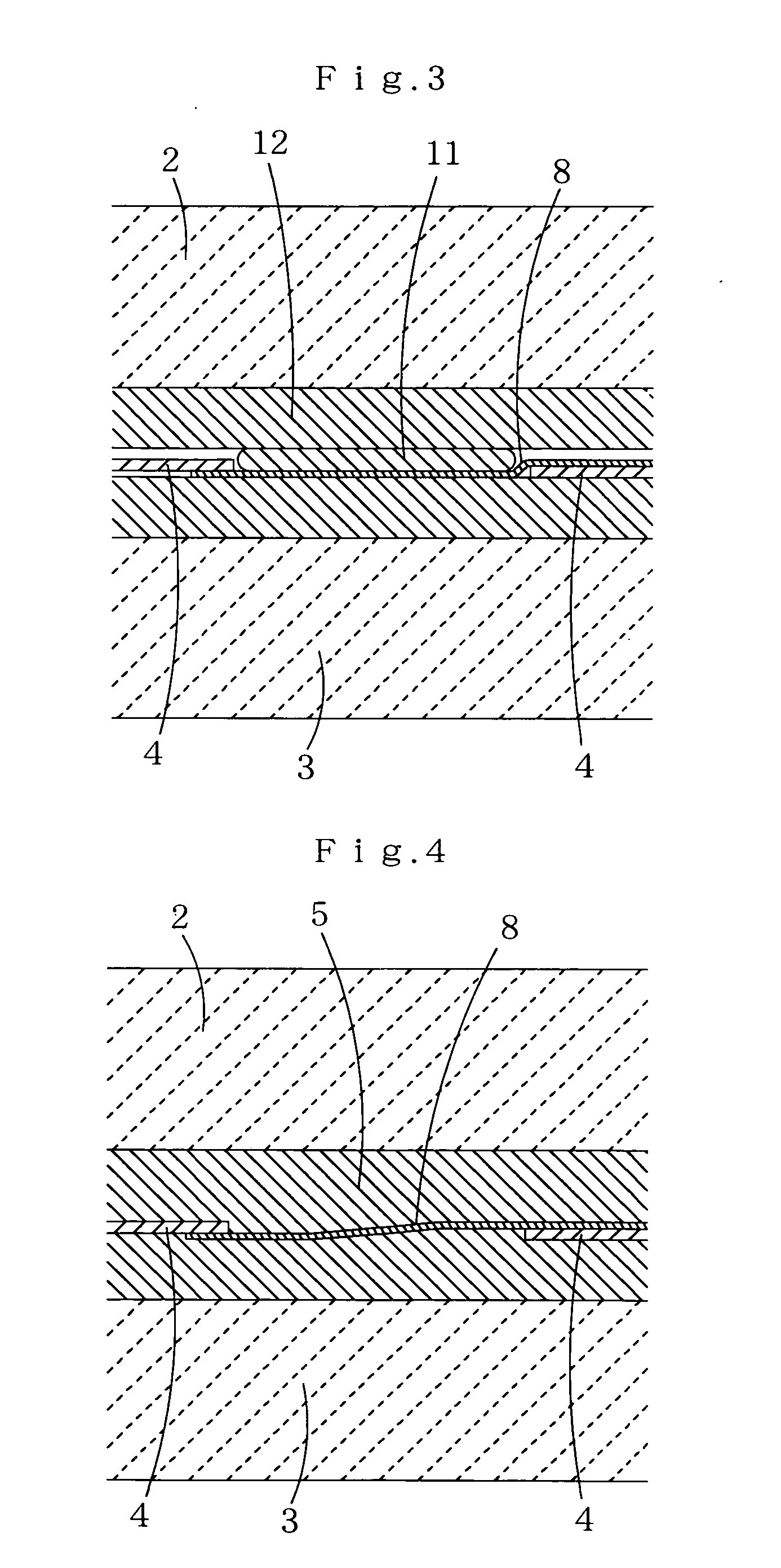

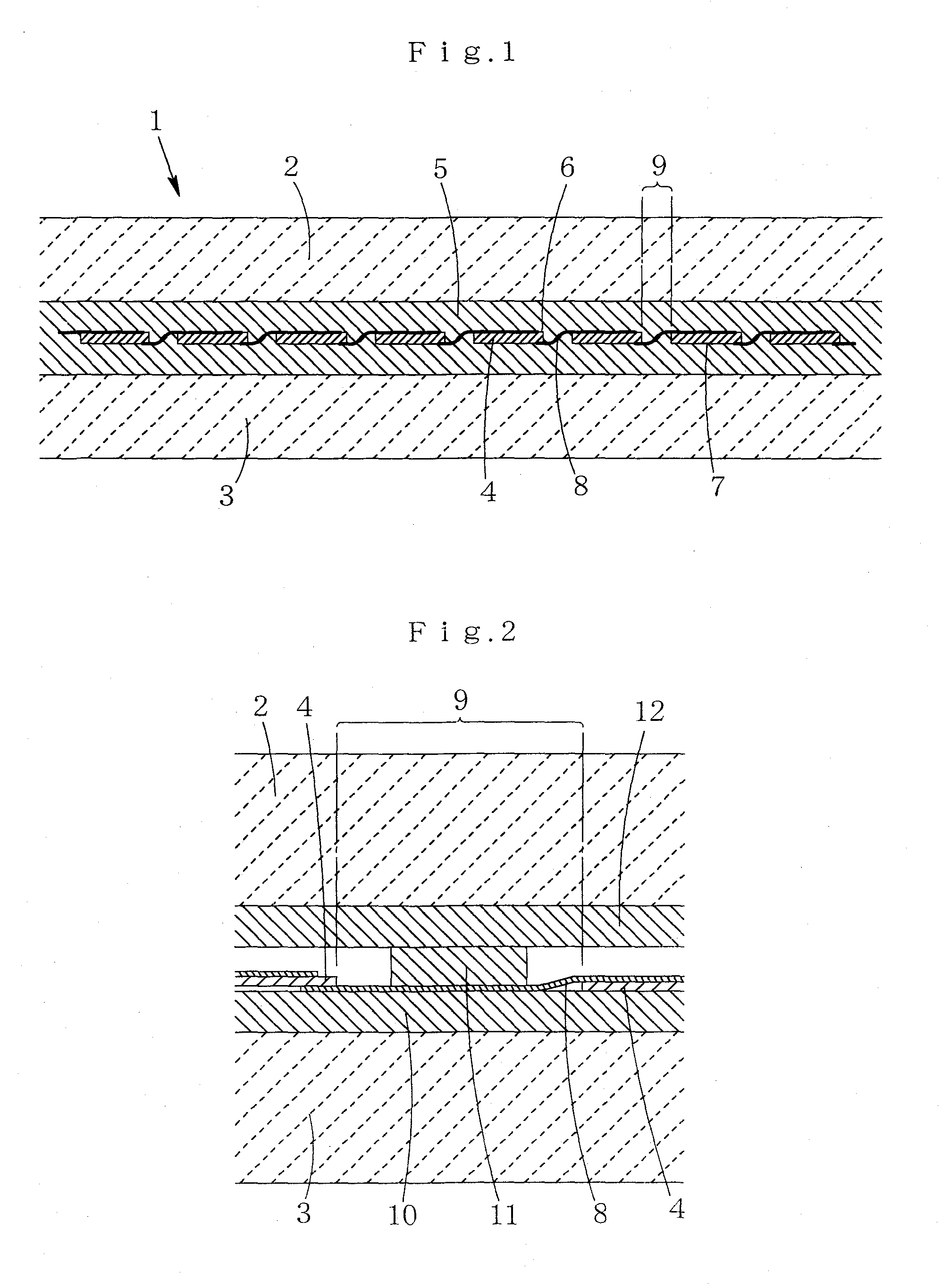

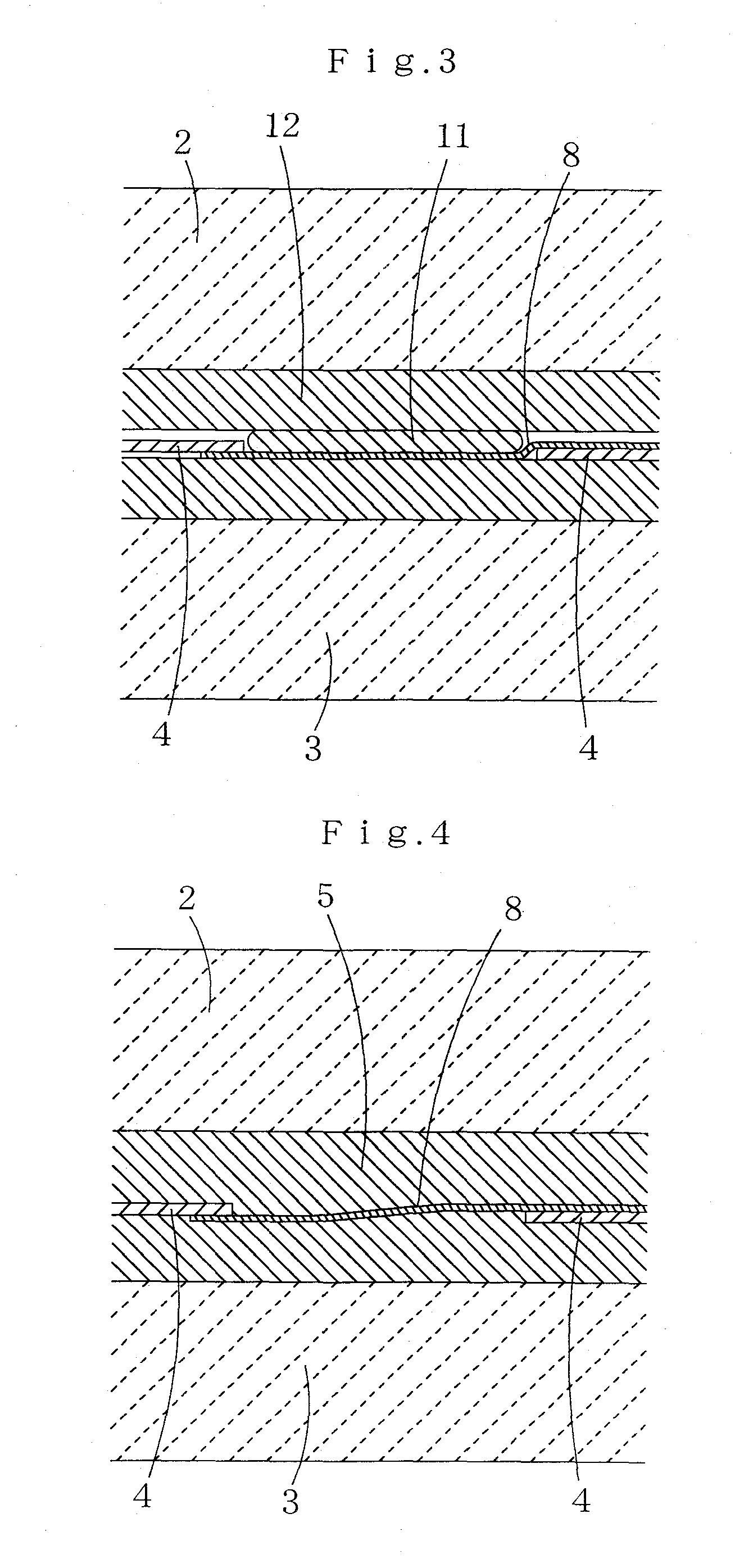

Solar battery module manufacturing method

ActiveUS20050274410A1Control generationEffectively inhibit flowingPV power plantsSolid-state devicesEngineeringCooling down

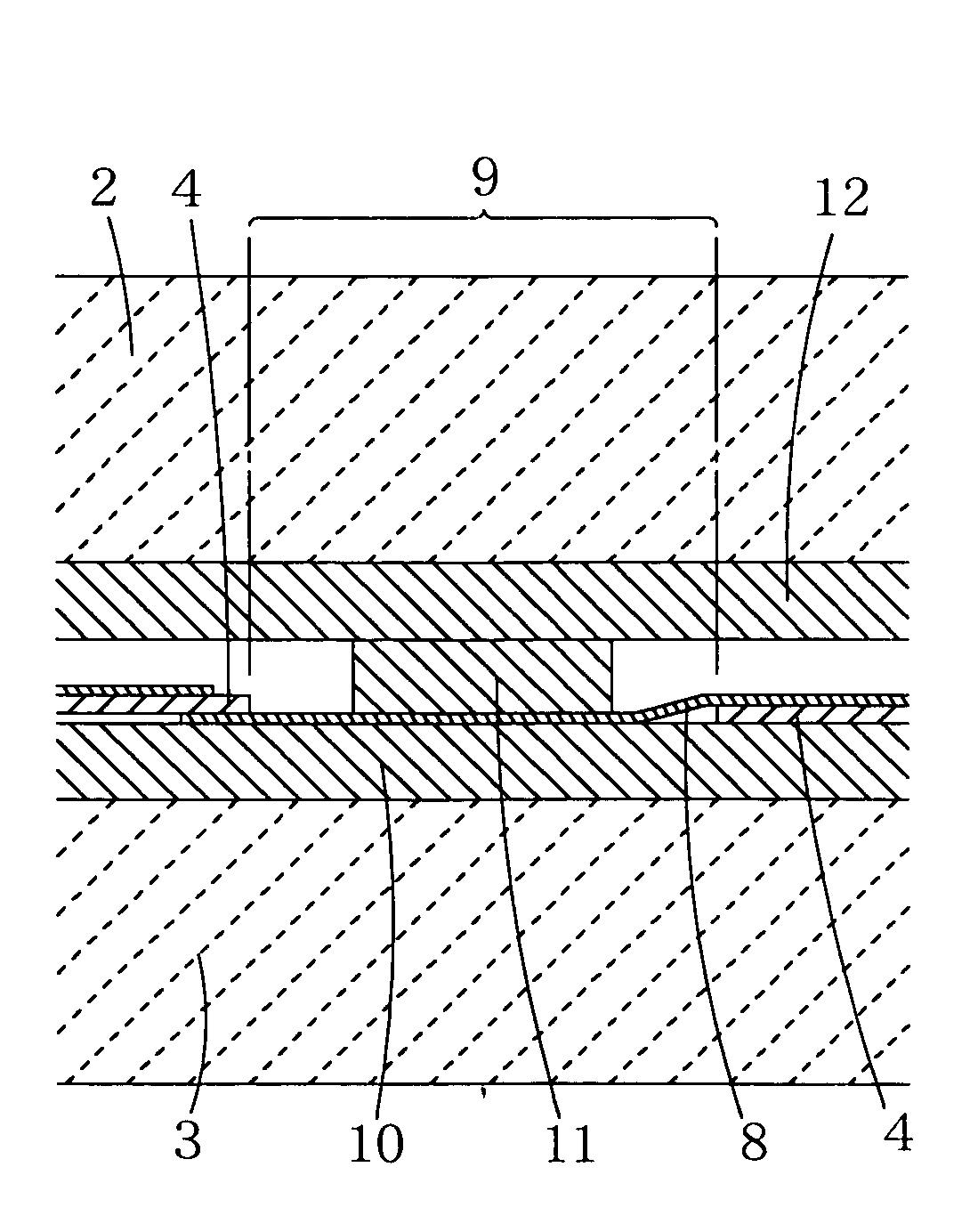

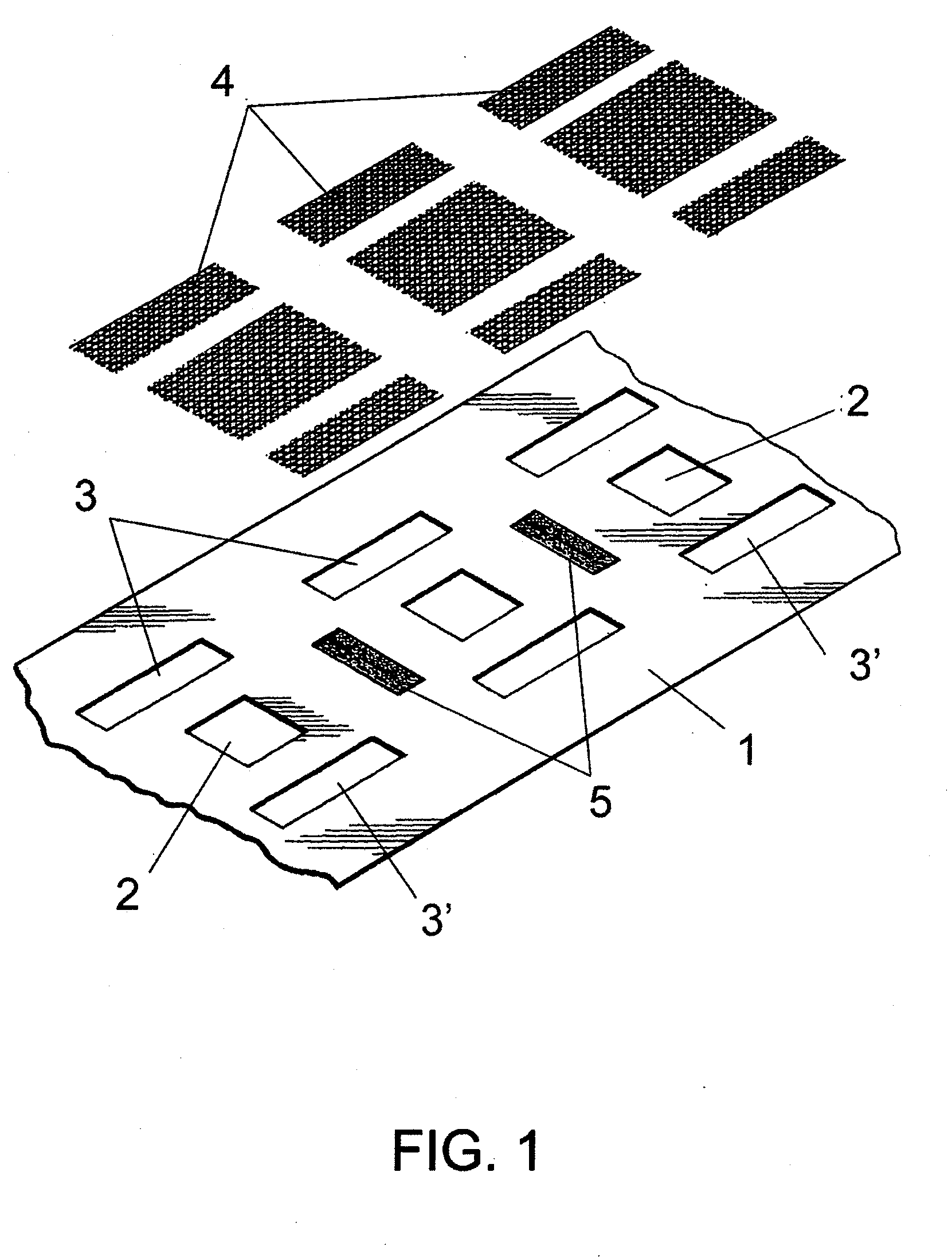

Provided is a process of producing a solar battery module 1 including plural solar battery cells 4 sealed by a resin 5 between a transparent panel 2 of the light reception surface side and a back face panel 3, which is characterized by arranging plural solar battery cells 4 at a prescribed interval and mutually connecting them to each other by a conductor 8; arranging a first sealing resin sheet 12 substantially covering the entire surface of the transparent panel 2 of the light reception surface side between the transparent panel 2 of the light reception surface side and the solar battery cells 4; arranging a second sealing resin sheet 10 substantially covering the entire surface of the back face panel 3 between the back face panel 3 and the solar battery cells 4; arranging sealing resin sheet pieces 18, 19 which are thicker than the solar battery cells 4 at a space 9 between the solar battery cells 4 so as to be sandwiched by the first sealing resin sheet 12 and the second sealing resin sheet 10; discharging air between the transparent panel 2 of the light reception surface side and the back face panel 3; and heating the resin 5 for melting and then cooling down it for sealing. According to this, when the plural solar battery cells 4 are arranged and sealed by the resin 5, breakage of the solar battery cells 4 can be prevented from occurring.

Owner:NAKAJIMA GLASS

B-shaped beam with integrally-formed rib in face

InactiveUS20080093867A1Reduce “ offset ”Weight increaseBumpersMetal rolling arrangementsShaped beamEngineering

Owner:SHAPE CORP

Toughening color master batch for high impact polystyrene, composite board and liner of refrigeration equipment

InactiveCN102153829AHigh strengthReduce sheet thicknessDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigeration

The invention discloses a toughening color master batch for high impact polystyrene, a composite board and a liner of refrigeration equipment. The toughening color master batch for the high impact polystyrene comprises the following components in part by weight: 25 to 85 parts of toughening agent, 10 to 50 parts of softener, 10 to 50 parts of base material and 5 to 35 parts of toner. According to the toughening color master batch for the high impact polystyrene, a carrier in a conventional color batch is replaced by the toughening agent, so that the toughening color master batch has the effect of toughening the high impact polystyrene in the process of dying the high impact polystyrene. According to the high impact polystyrene composite board, the strength is obviously improved, so that the thickness of the board can be reduced and the using amount of materials can be reduced; return material proportion in an extruded board material can be obviously improved, even the composite board can totally adopt a return material; by controlling the addition ratio of the toughening color master batch, the performance of the board can be regulated so as to meet different requirements; due to low density of the toughening color master batch, the weight of the liner formed by the composite board with the same size can be reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

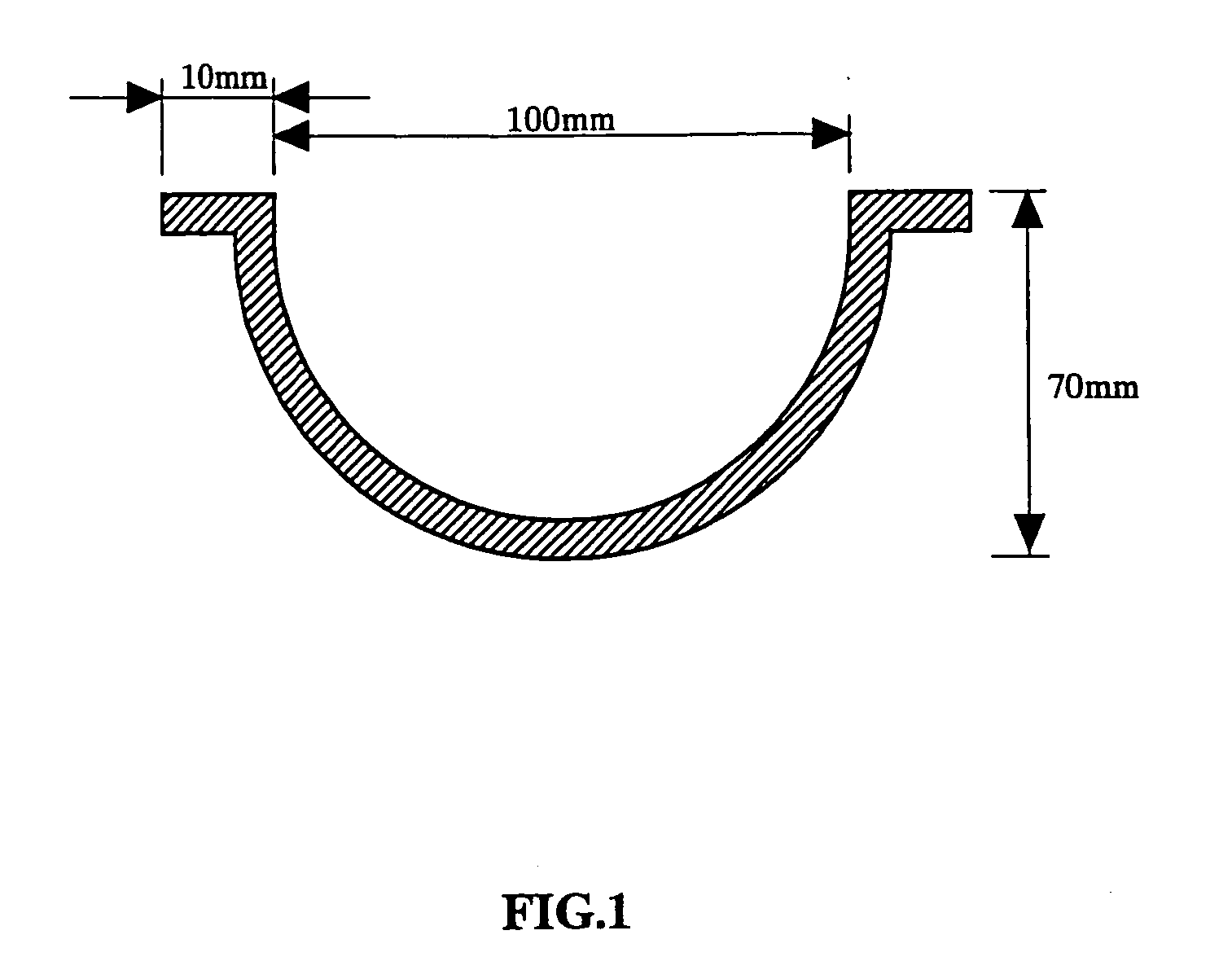

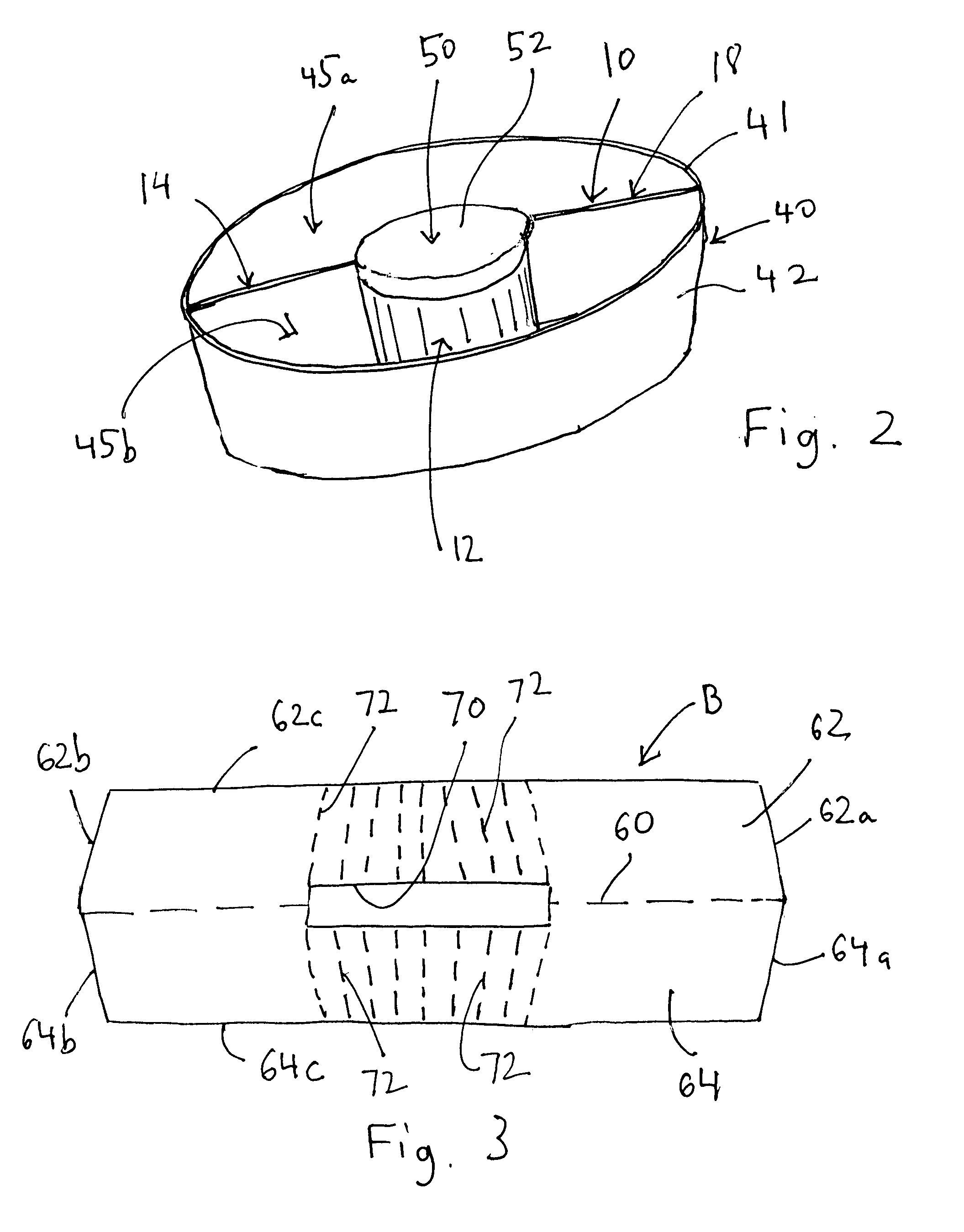

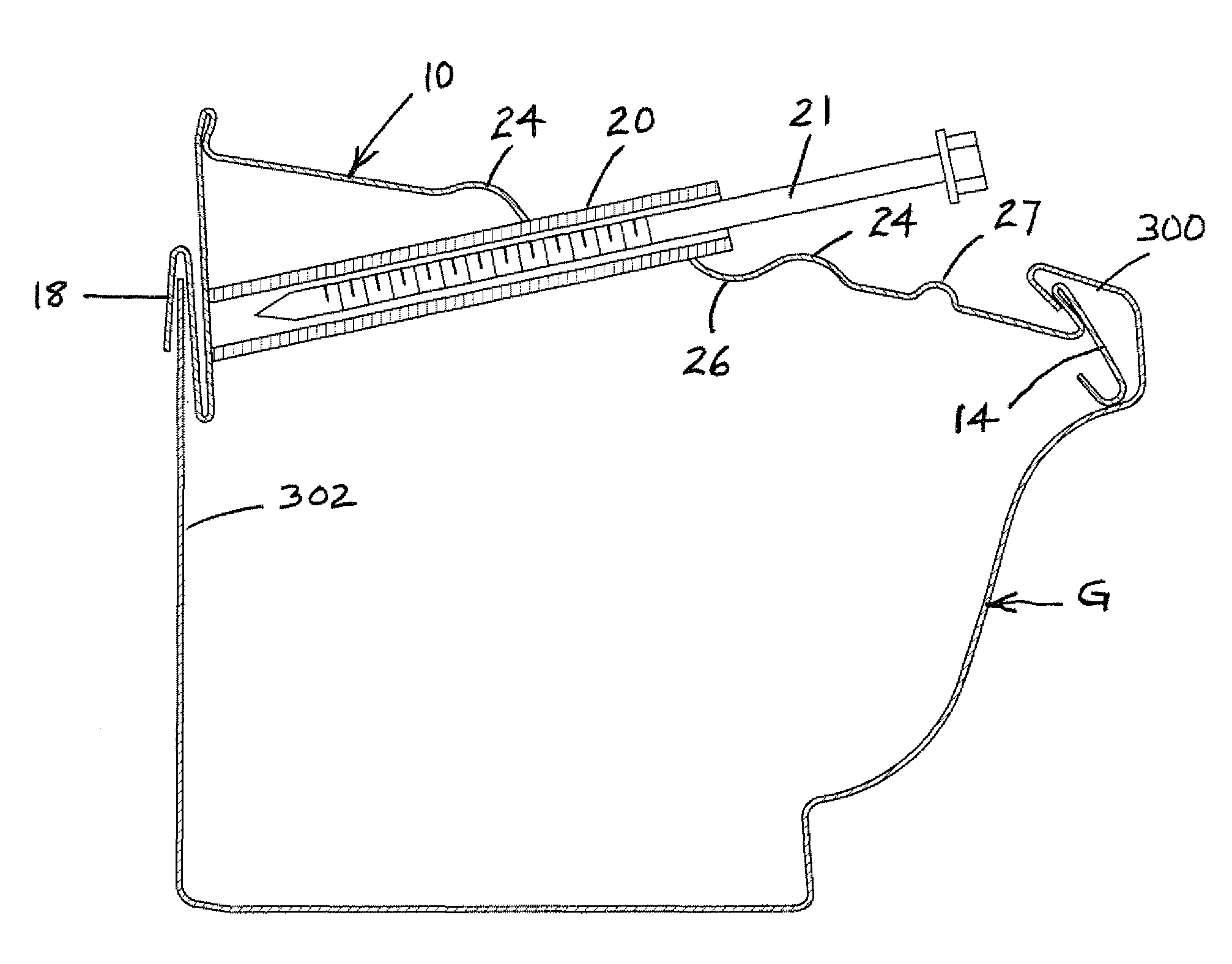

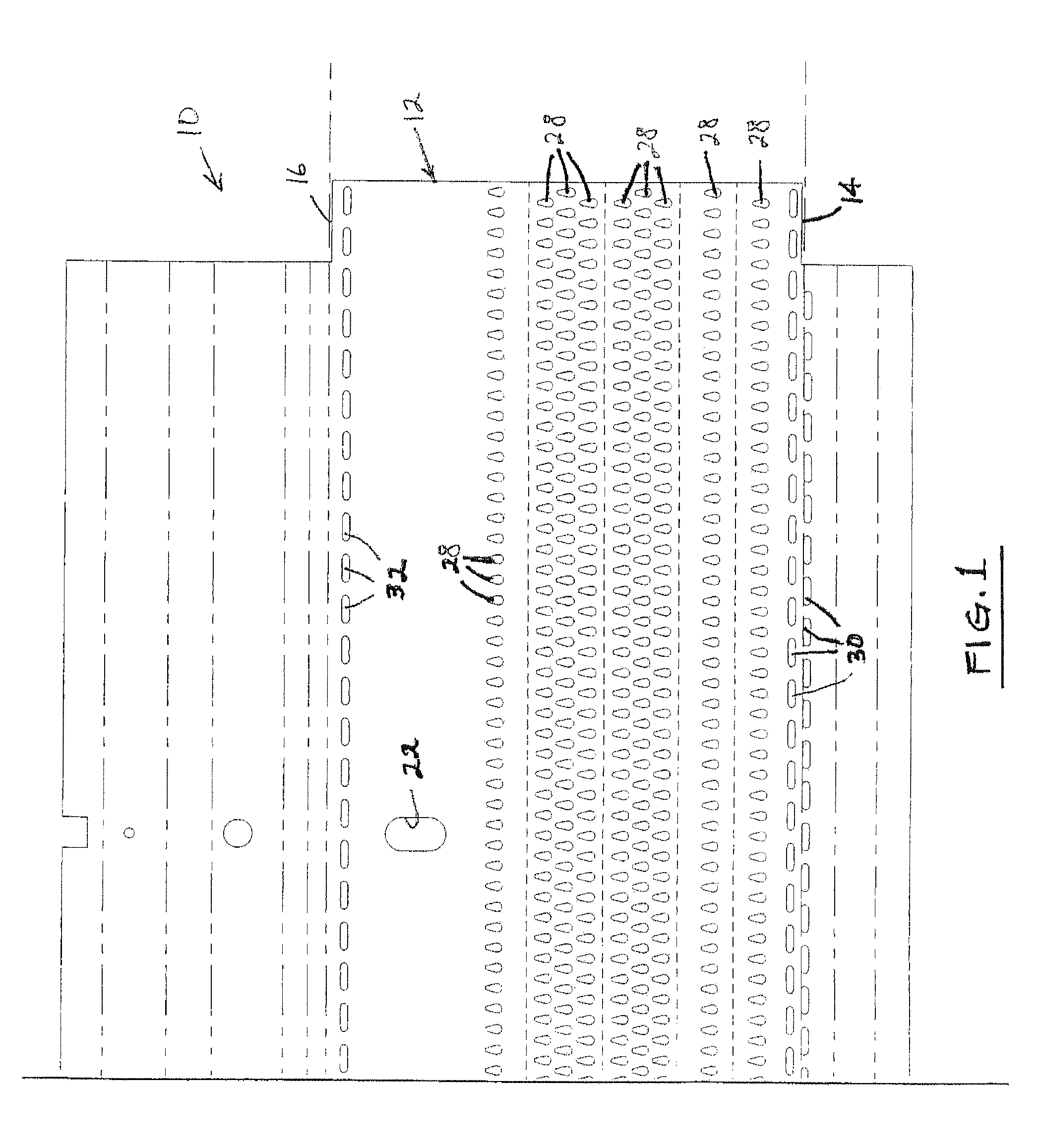

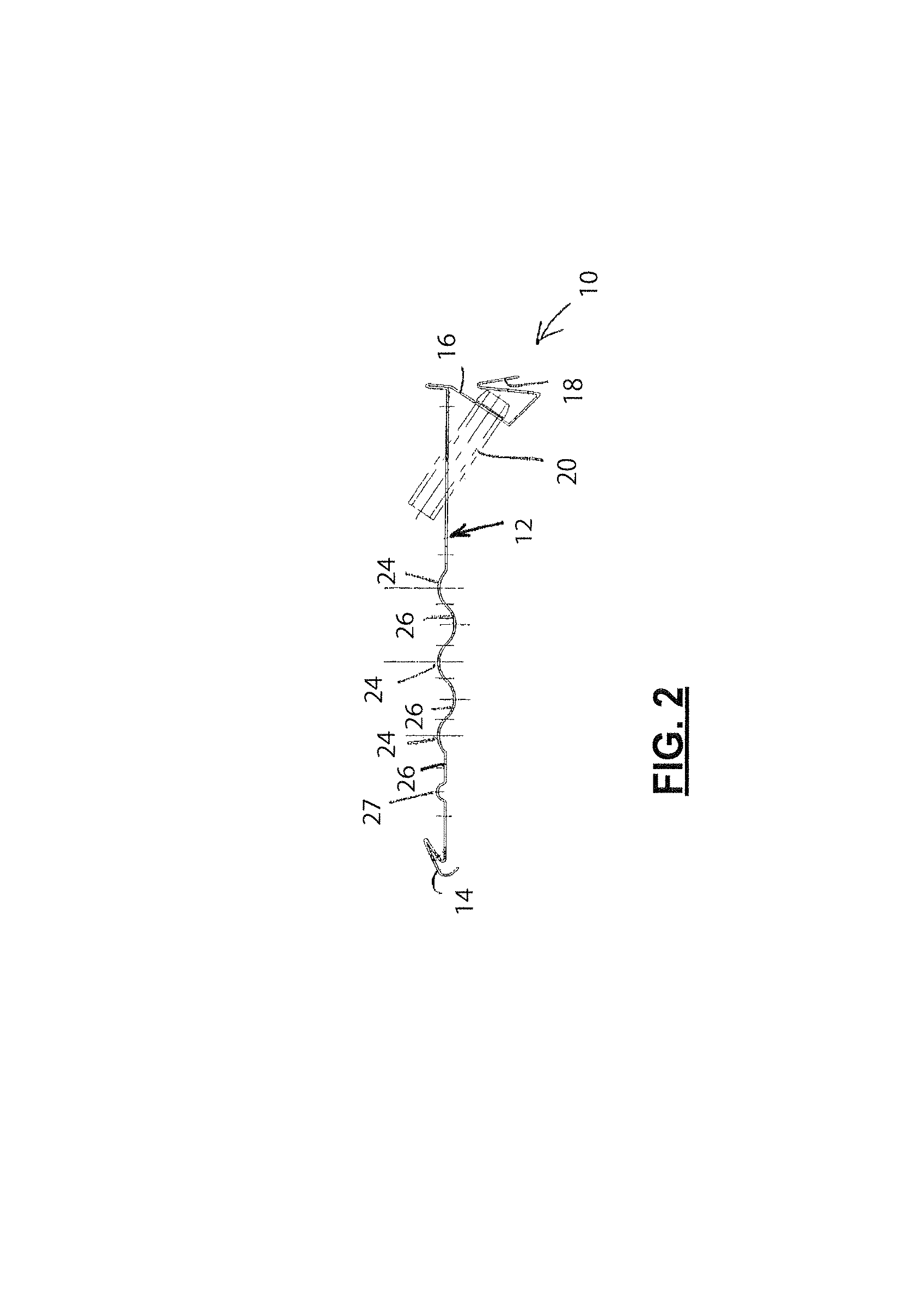

Gutter guard

ActiveUS20110265391A1Easy to assembleConveniently mountedRoof coveringStands/trestlesWater flowEngineering

Owner:PROD INNOVATION GRP

Thermoplastic Resin Foam

A thermoplastic resin sheet which has both a high reflectance ratio and excellent shape-holding property suitable for backlights and illumination boxes for use in illumination signboards, illumination fixtures and displays and illumination boxes. The thermoplastic resin foam is manufactured by a manufacturing method including a process for containing inert gas by holding thermoplastic resin sheet containing metallic oxide in a pressurized inert gas atmosphere and a process for heating the thermoplastic resin sheet in which the inert gas is contained at a temperature higher than the softening temperature of the thermoplastic resin, under normal pressure, and foaming the resin.

Owner:FURUKAWA ELECTRIC CO LTD

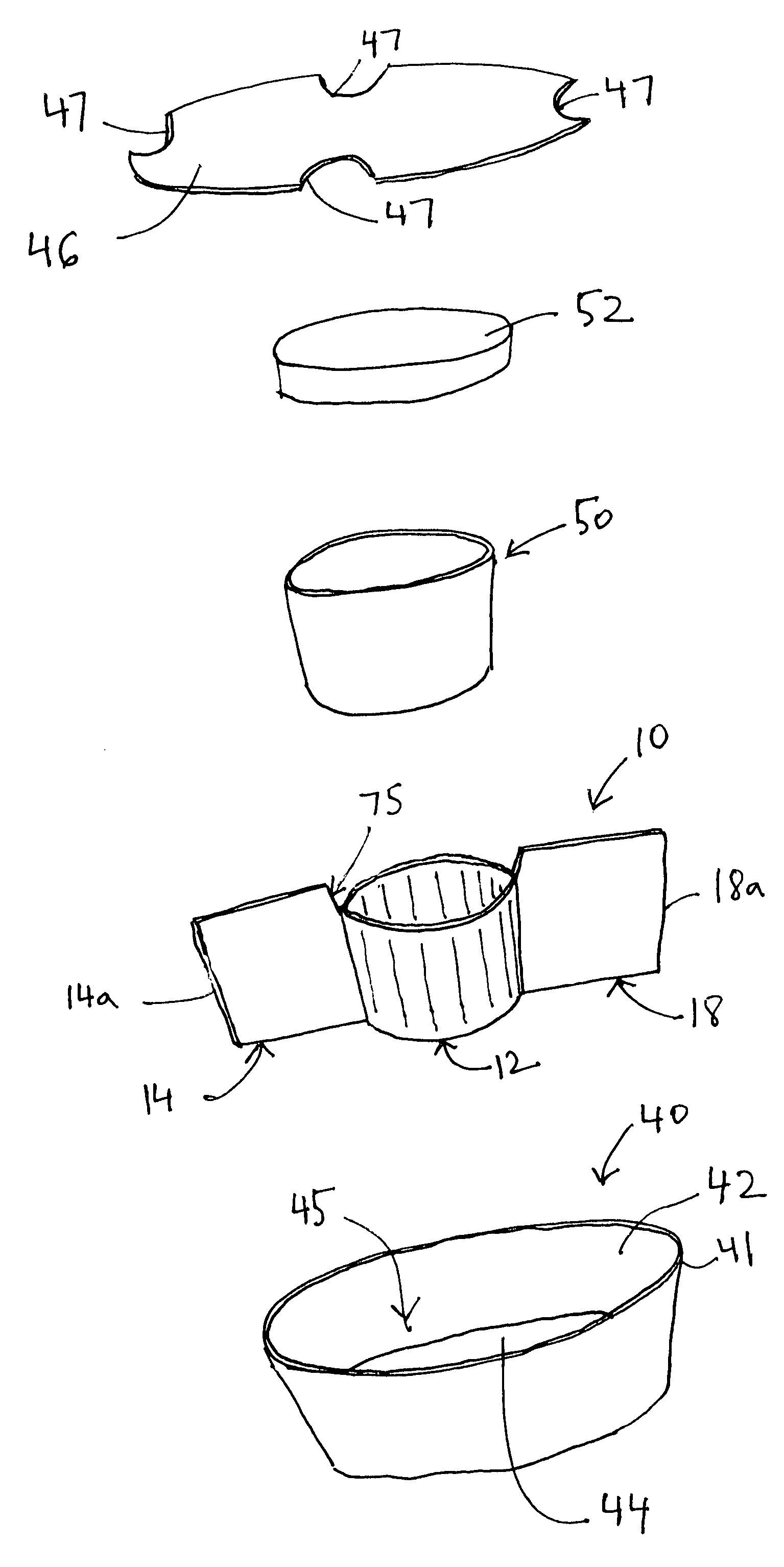

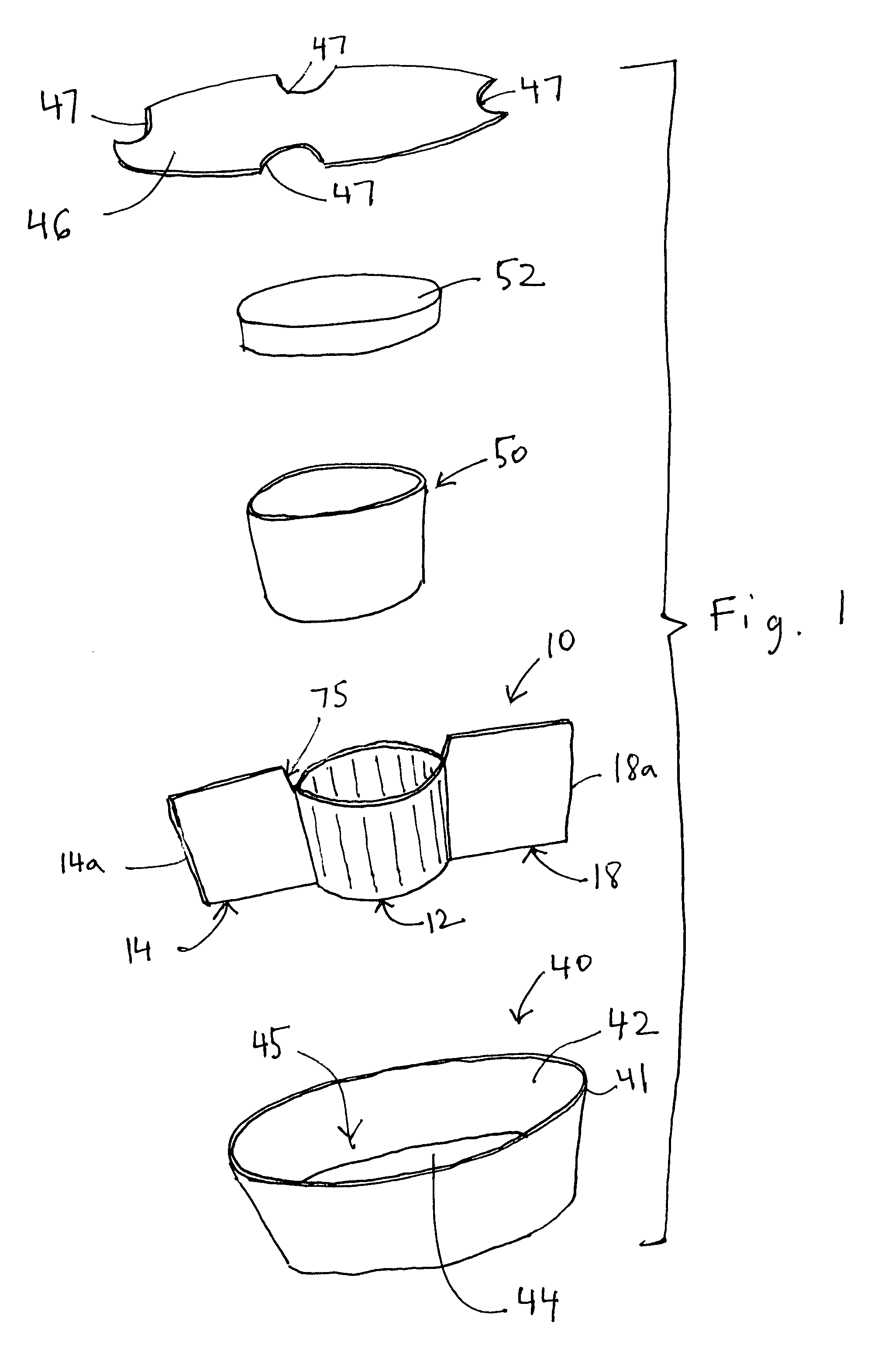

Removable divider for food container

InactiveUS20080105736A1Reduce and eliminate tendencyThickness of base can be reducedInternal framesLarge containersPaperboardEngineering

The present invention is for a divider for use with a food package, wherein the divider is manufactured from inexpensive coated paperboard and is of a simple one-piece construction. More particularly, a divider according to a preferred embodiment of the present invention is formed from a one-piece, foldable blank of paperboard material, which is folded in half and secured onto itself so as to form a two-ply, reasonably stiff construction. The divider is shaped and dimensioned to fit within a food container, which may preferably have a circular cylindrical shape, so as to bisect same and define two separate interior regions thereof. In addition, the divider includes a center portion wherein the paperboard material is not adhered onto itself, so as to allow the formation of a ring-shaped, cup-holding portion suitable for positioning and retaining a separate container within the package.

Owner:INT PAPER CO

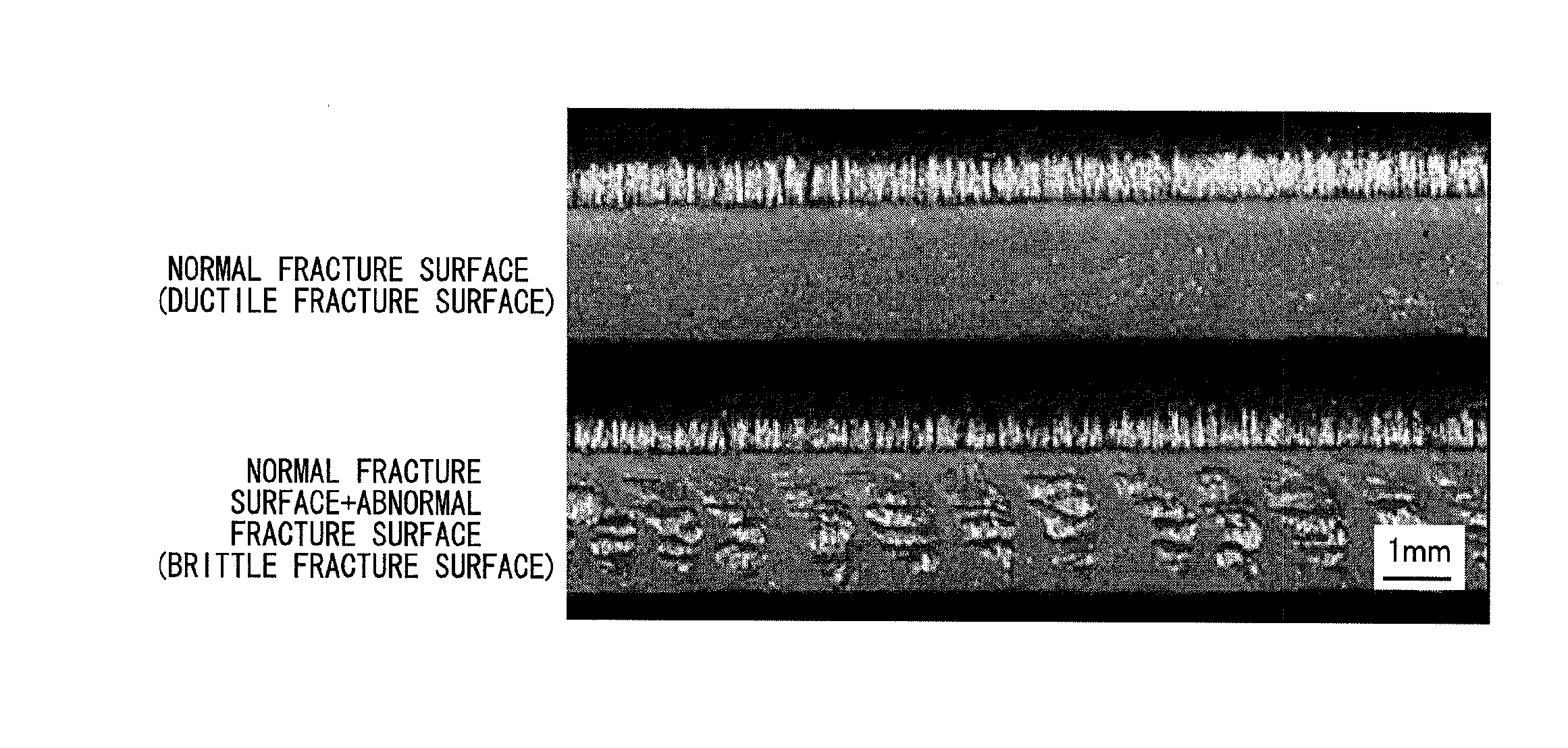

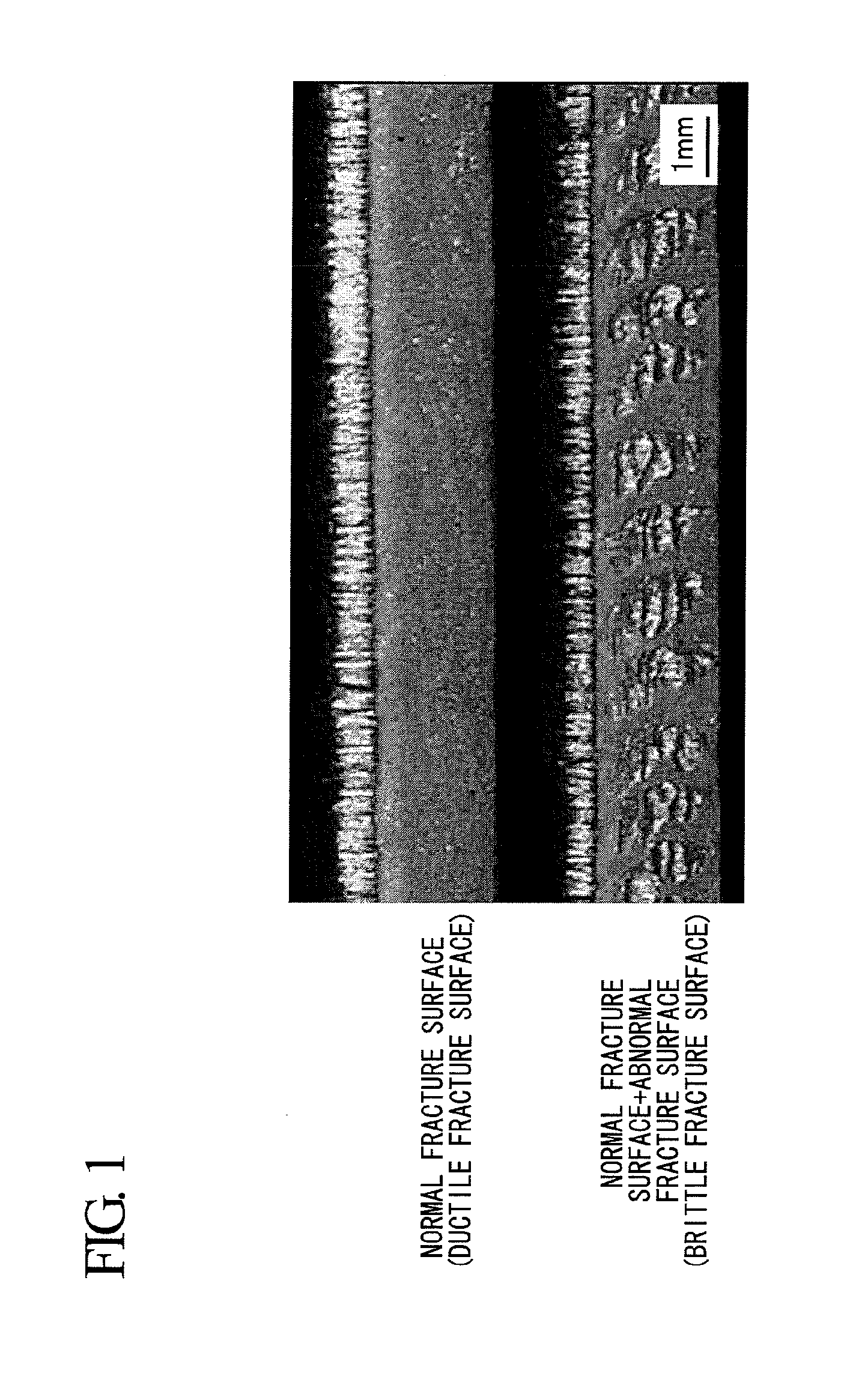

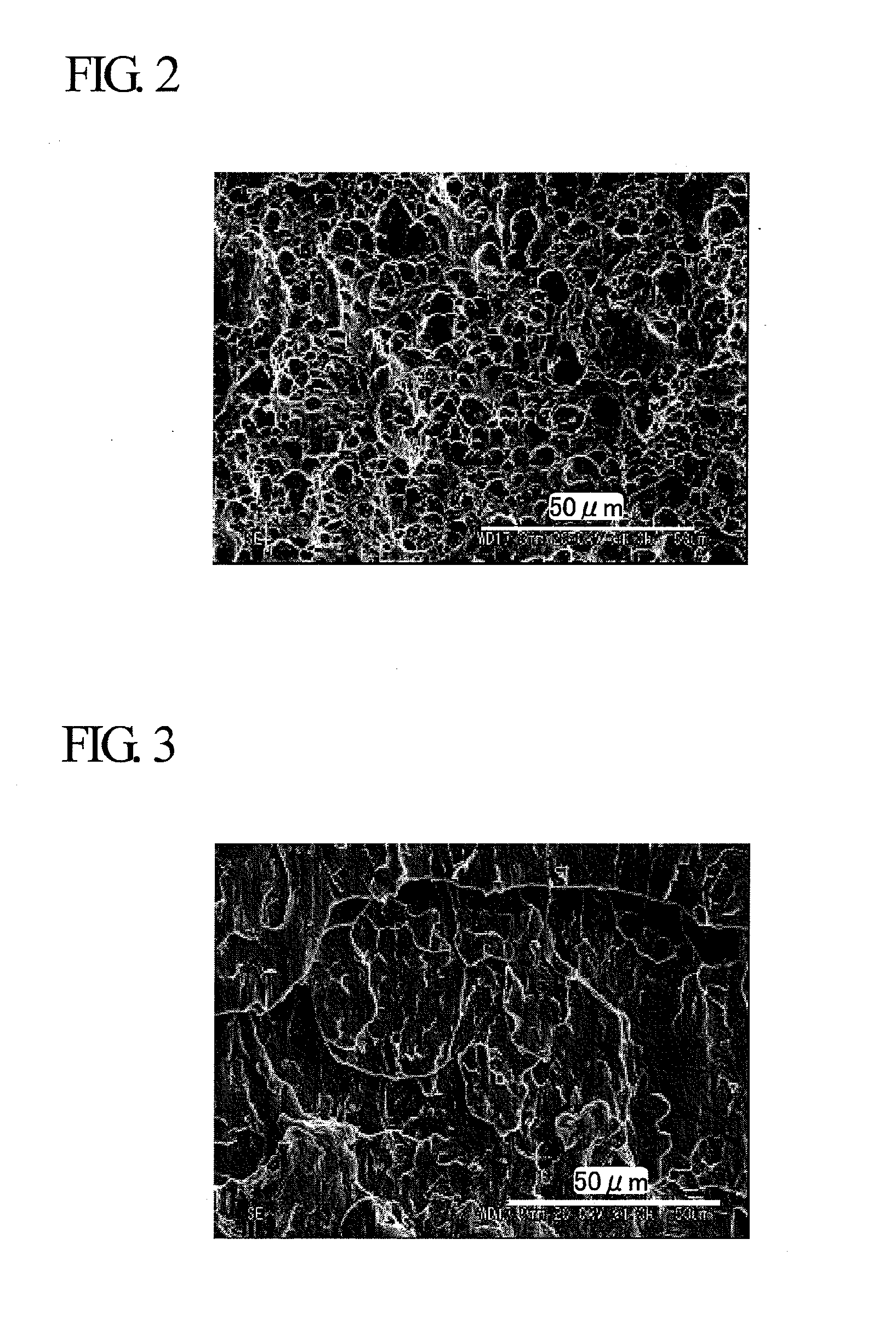

Hot-rolled steel sheet excellent in fatigue properties and stretch-flange formability and method for manufacturing the same

InactiveUS20110017360A1Excellent stretch-flange formabilitySuitable for processingHot-dipping/immersion processesFurnace typesFatigue limitMicrostructure

This hot-rolled steel sheet contains, in terms of mass%, C: 0.015% or more to less than 0.040%; Si: less than 0.05%; Mn: 0.9% or more to 1.8% or less; P: less than 0.02%; S: less than 0.01%; Al: less than 0.1%; N: less than 0.006%; and Ti: 0.05% or more to less than 0.11%, with the remainder being Fe and inevitable impurities, wherein Ti / C is in a range of 2.5 or more to less than 3.5, Nb, Zr, V, Cr, Mo, B and W are not included, a microstructure includes a mixed microstructure of polygonal ferrite and quasi-polygonal ferrite in a proportion of greater than 96%, a maximum tensile strength is 520 MPa or more and less than 720 MPa, an aging index AI is more than 15 MPa, a product of a hole expansion ratio (A) % and a total elongation (El) % is 2350 or more, and a fatigue limit is 200 MPa or more.

Owner:NIPPON STEEL CORP

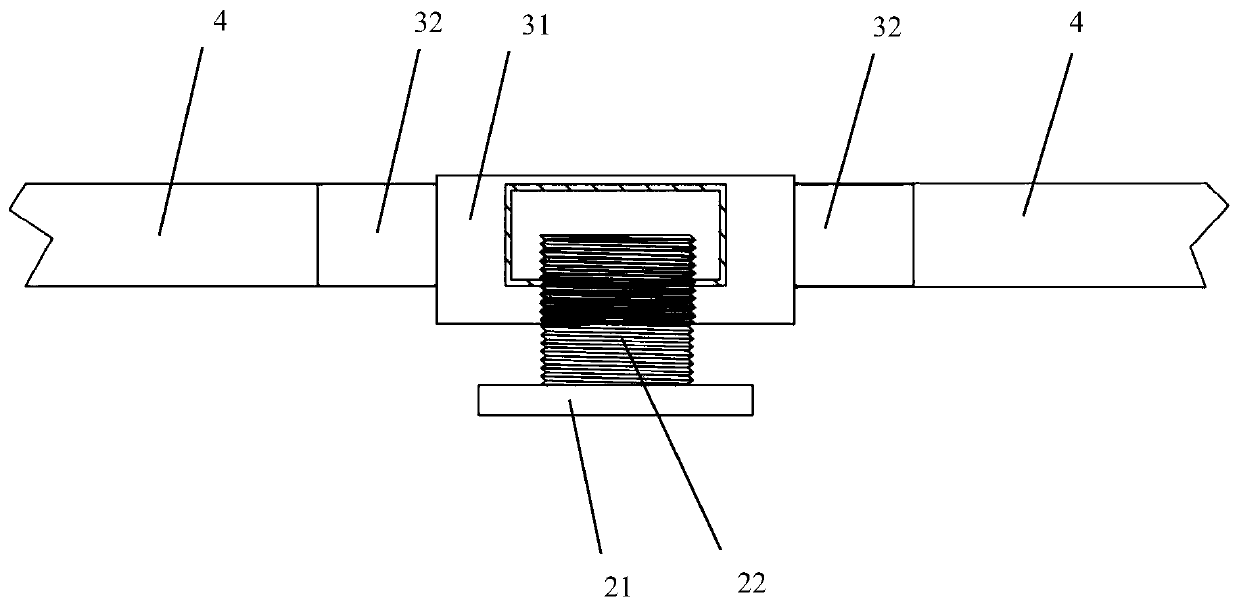

Press forming die assembly

A press forming die assembly for press forming a blank material includes a draw forming portion that the blank material flows and a draw bead for controlling the amount of the blank material flowing into the draw forming portion. A first draw bead is provided at a periphery of the draw forming portion in a direction substantially parallel to an outer peripheral shape of the draw forming portion. A second draw bead extends from the first draw bead toward the outside of the draw forming portion in a direction intersecting the first draw bead. The blank material includes a thick sheet portion having a greater thickness than the other portion or a high rigidity portion having a higher rigidity than that of the other portion. The second draw bead is provided at a portion corresponding to the thick sheet portion or the high rigidity portion of the blank material.

Owner:HONDA MOTOR CO LTD

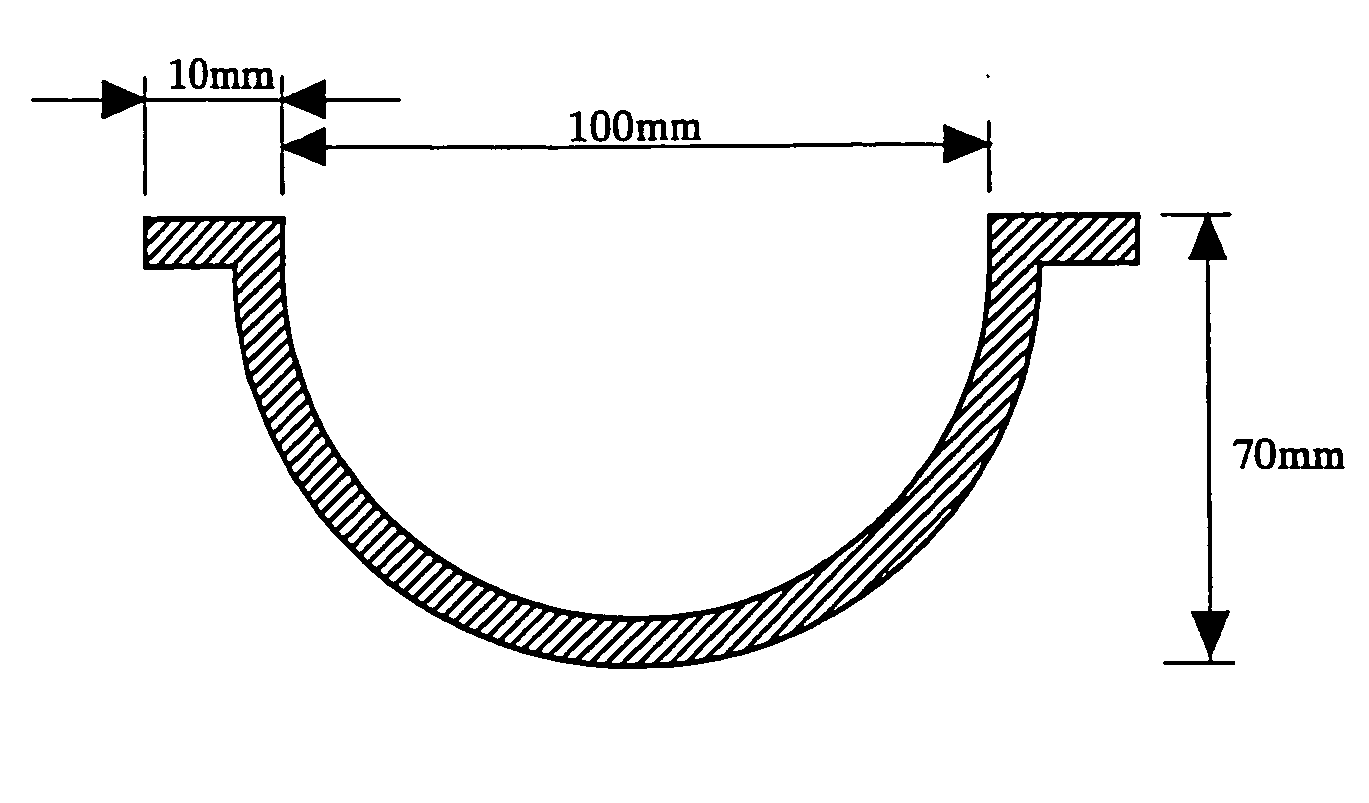

Gutter guard

ActiveUS8250813B2Reduce sheet thicknessWater to drop more readilyRoof coveringStands/trestlesWater flowEngineering

Owner:PROD INNOVATION GRP

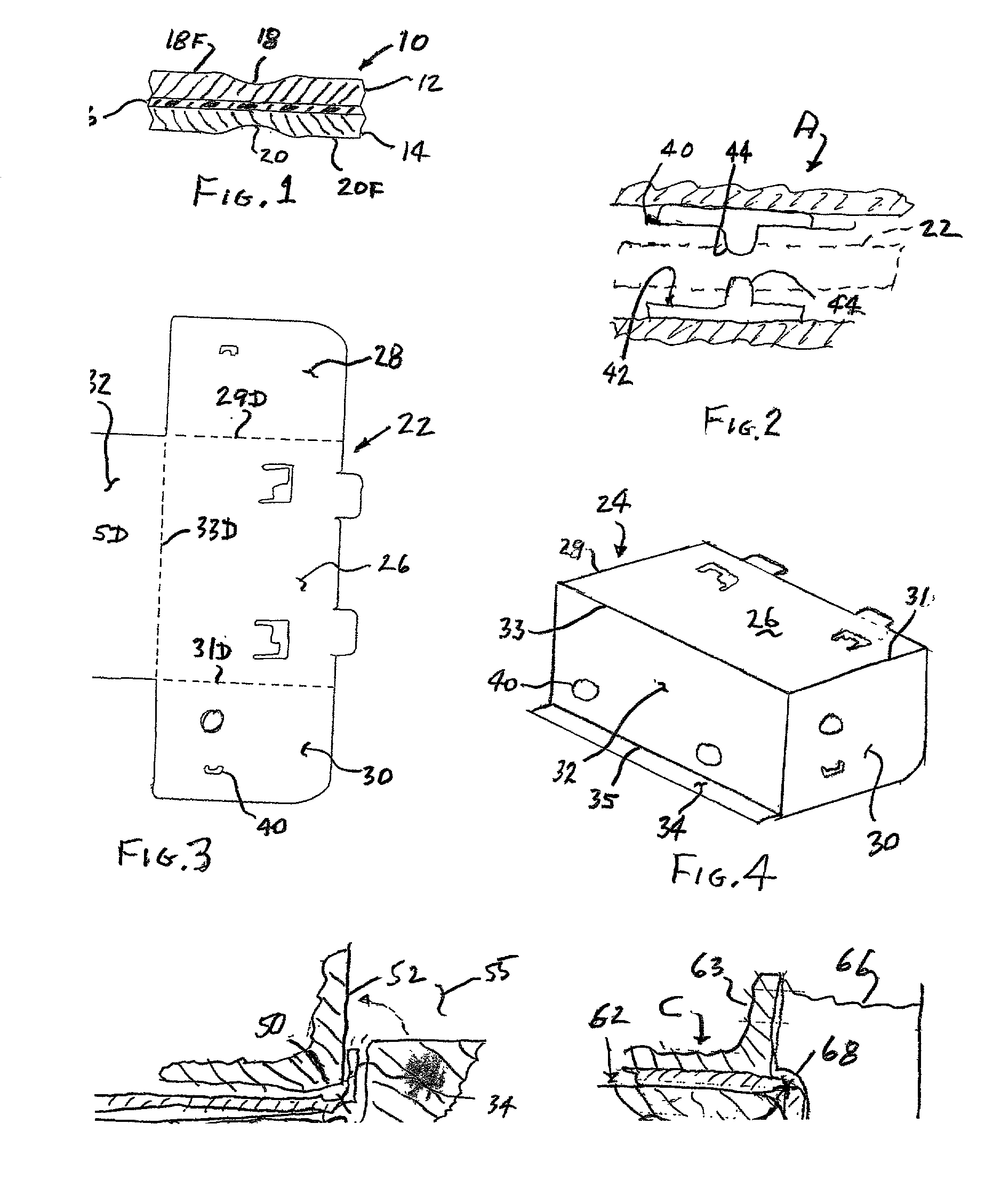

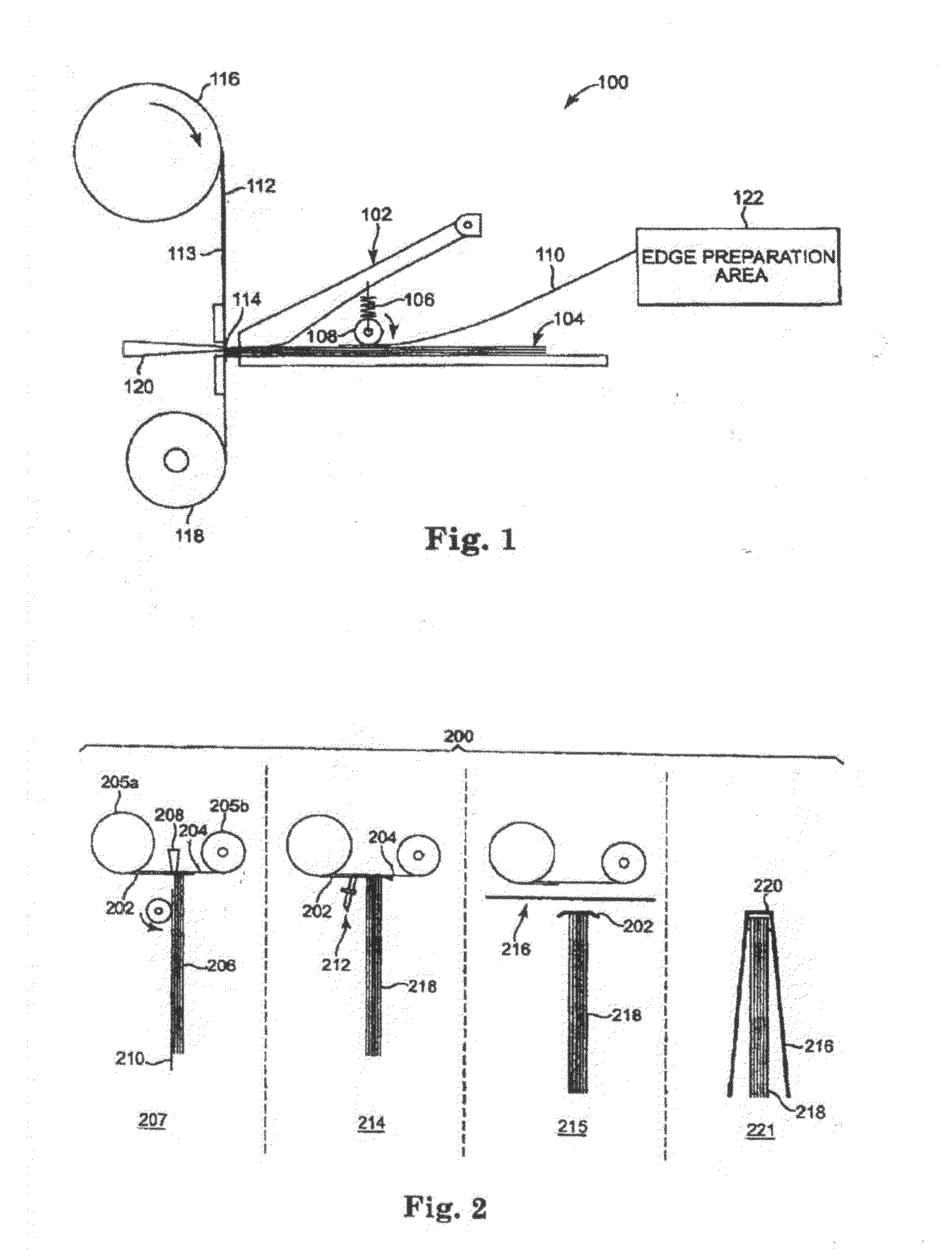

Process of bending laminated metal sheet

InactiveUS20020148273A1Reduce sheet thicknessEliminates laminate sheet slidingEngineeringMetal sheet

This invention improves on the process of bending in a conventional progressive stamping press a flat laminated metal sheet around a corner edge of a die block to form a generally straight piece-part corner, and comprises the steps of forming extended concavely rounded depressions in the opposite sheet faces at the sheet locations of the intended corner, then locating and clamping the sheet with the depressed regions aligned along a die block corner, and then mechanically bending the sheet with said depressed sheet regions aligned over the die block corner edge. The sheet depressions can be aligned essentially opposite one another, being rounded concavely and of a high width-to-depth ratio and of a depth to reduce the sheet to between 80-30% of its original thickness. The sheet depressions might occur at one stamping press station by opposing press tools each having a convex rounded working edge elongated along the length of the intended corner, with the blank bending occurring at a subsequent stamping press station.

Owner:BUHRKE IND

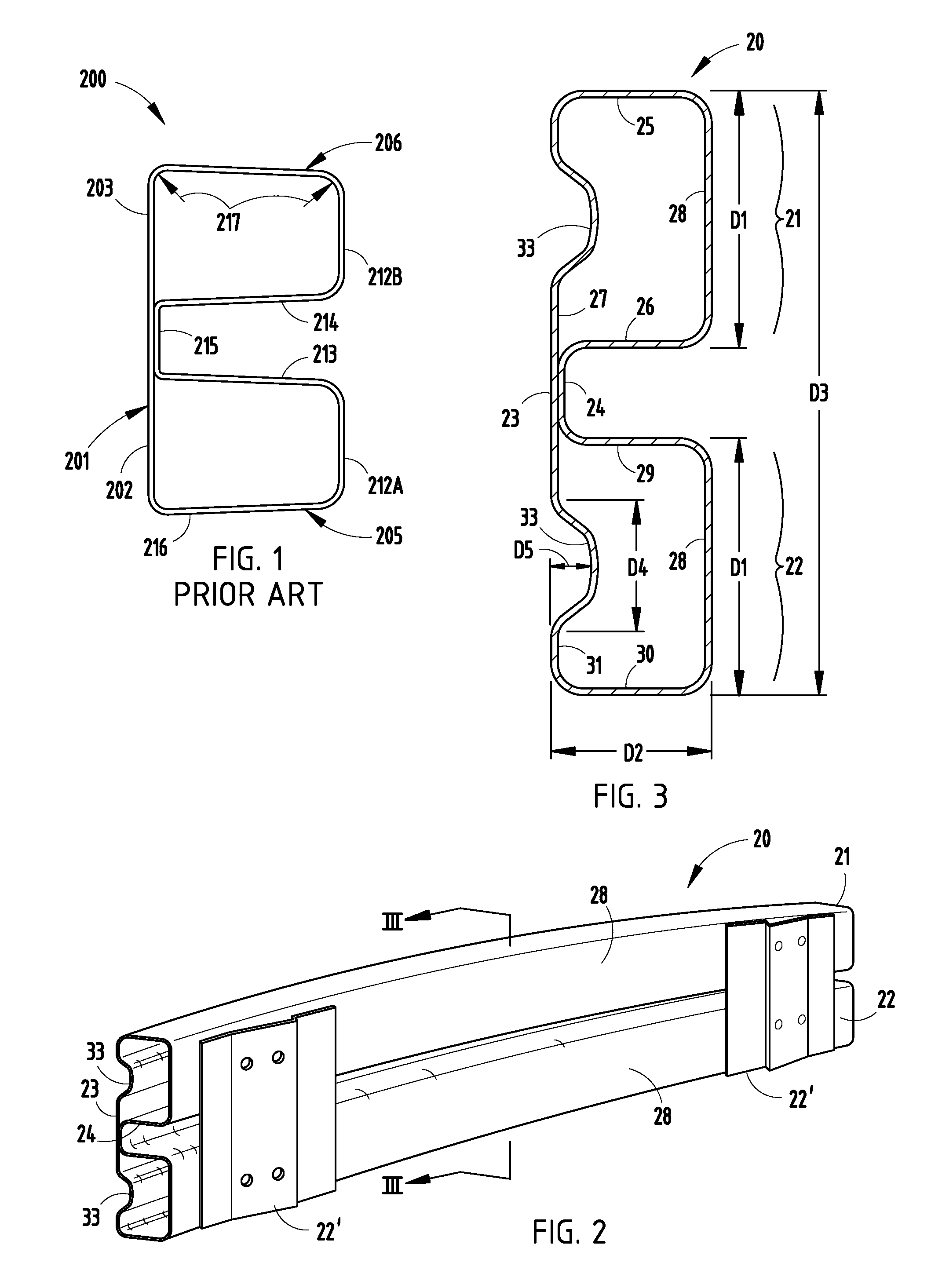

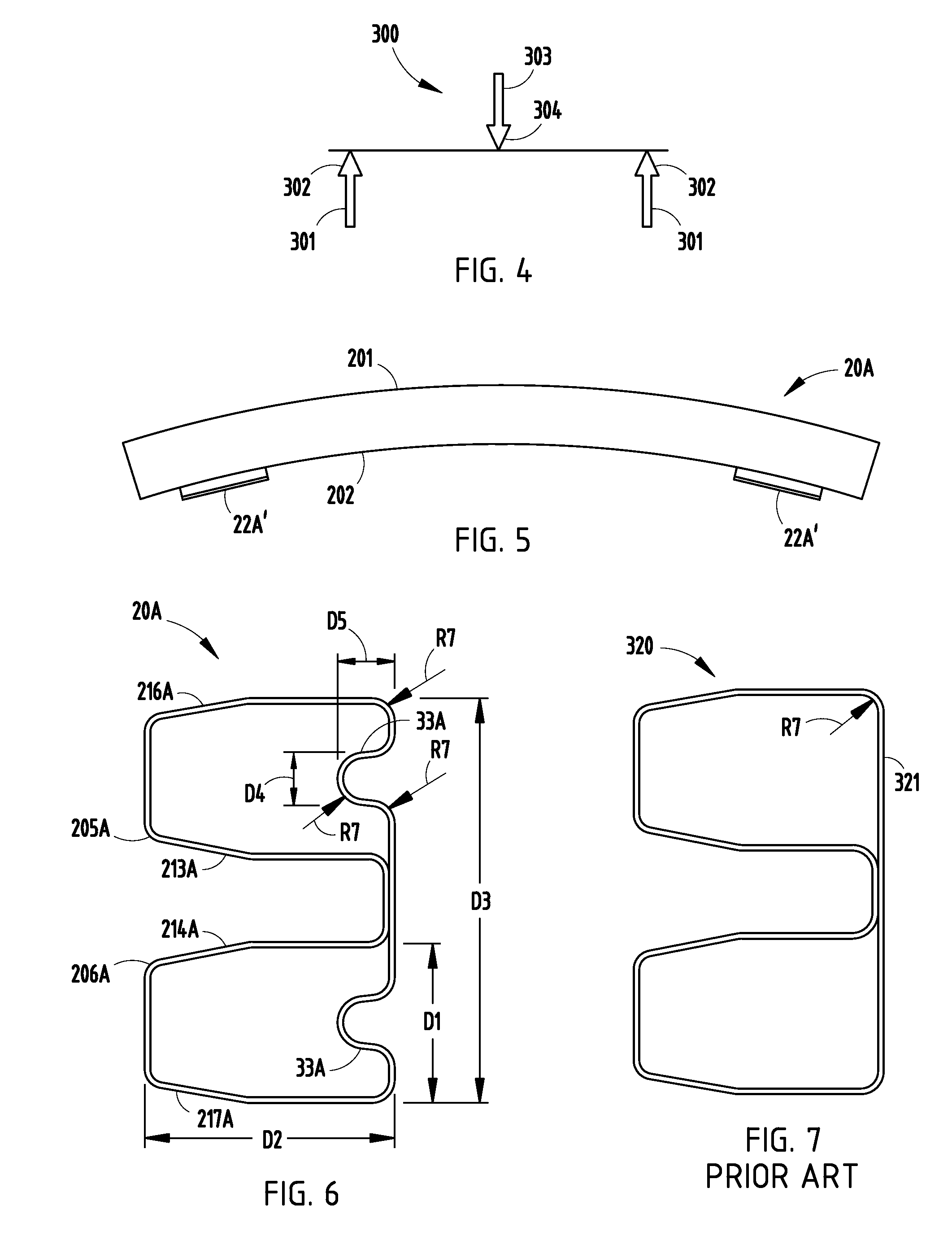

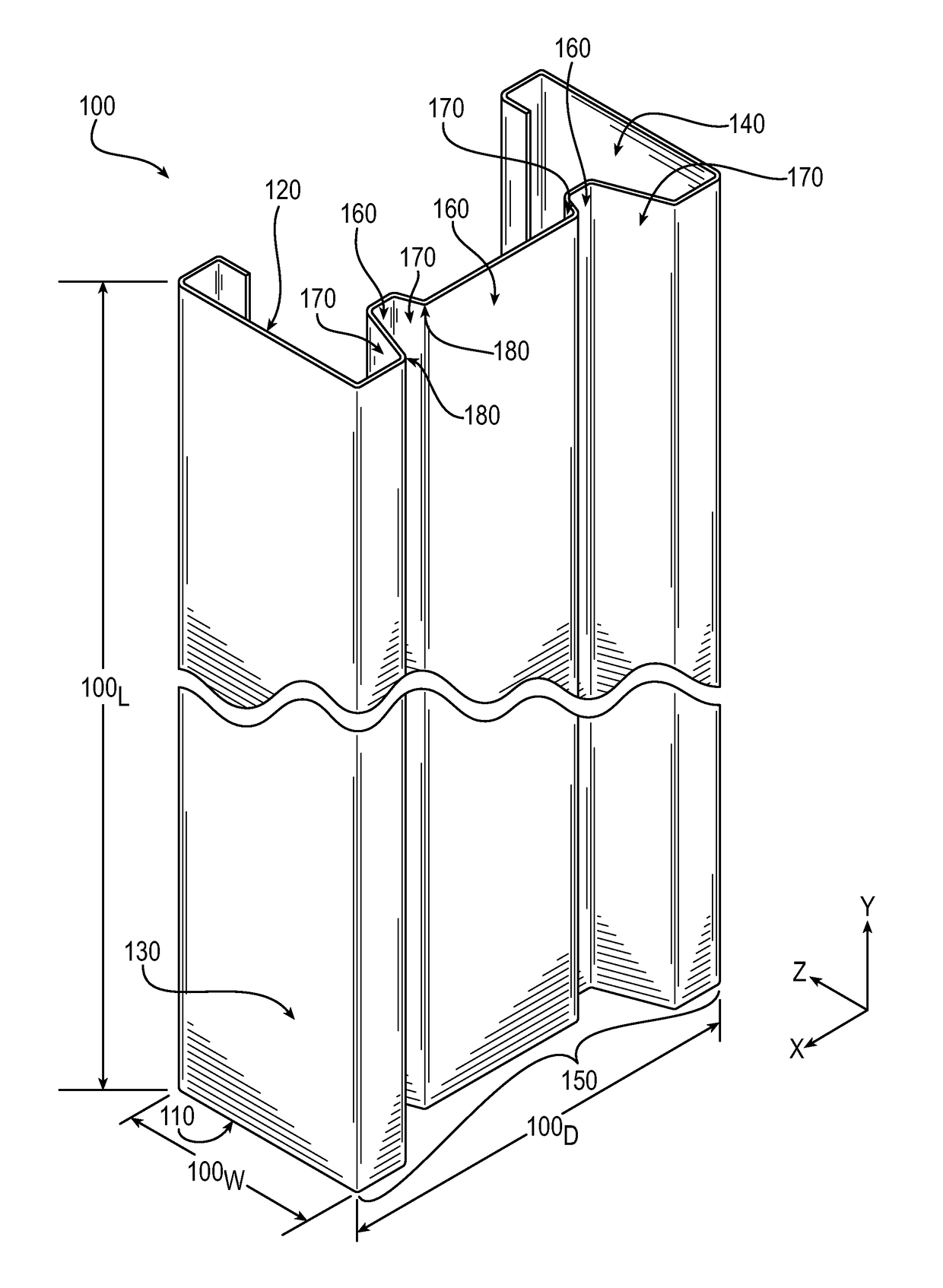

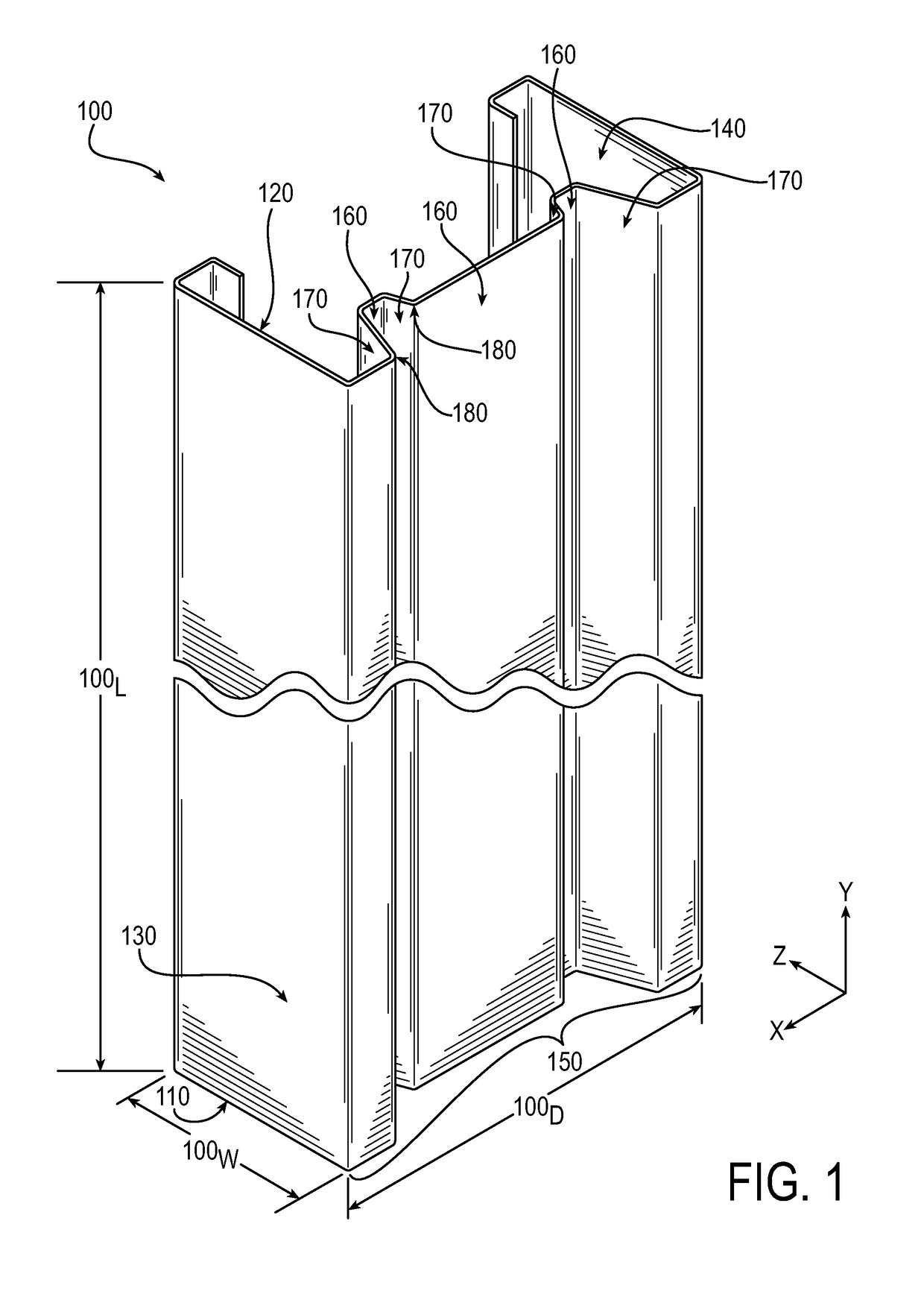

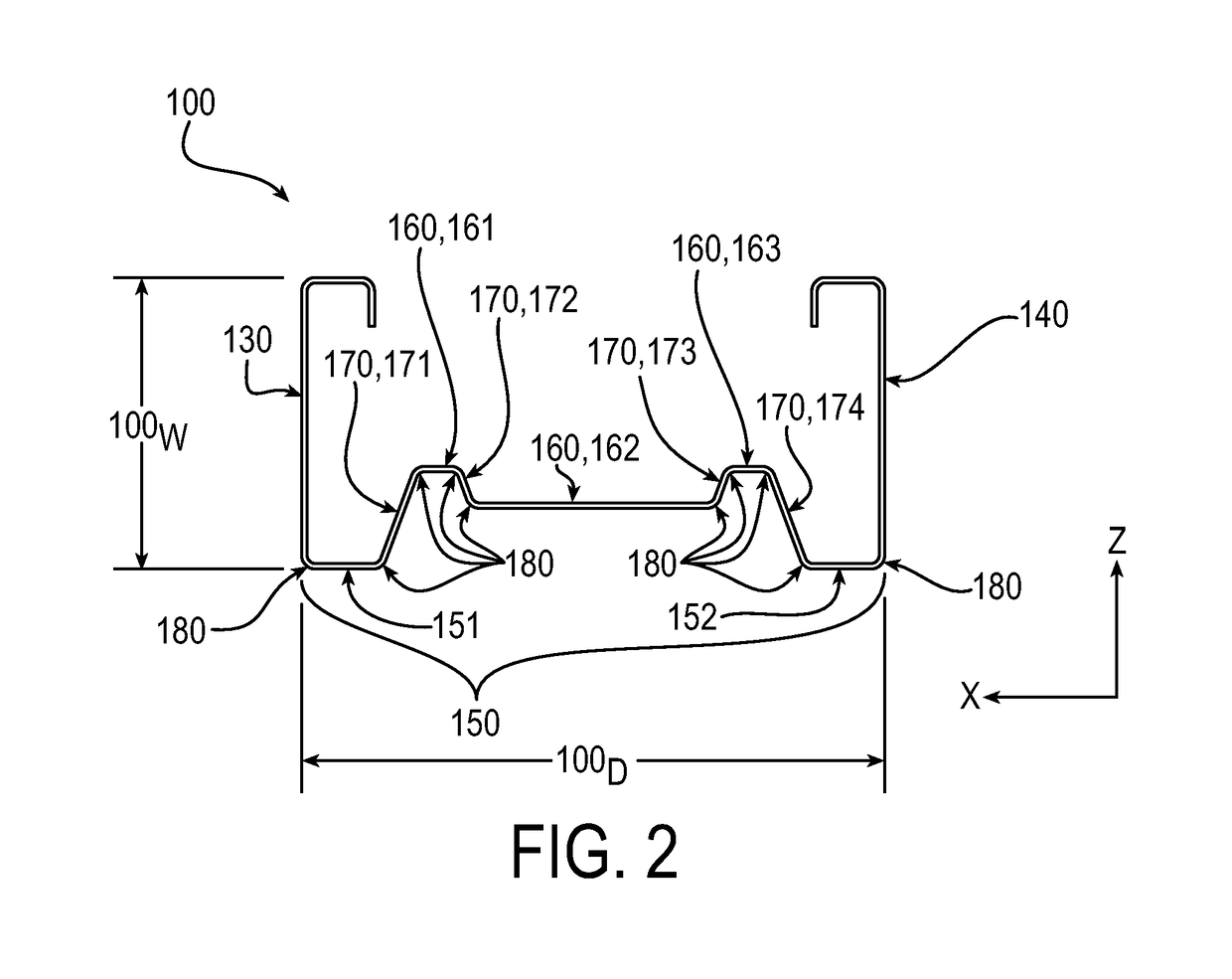

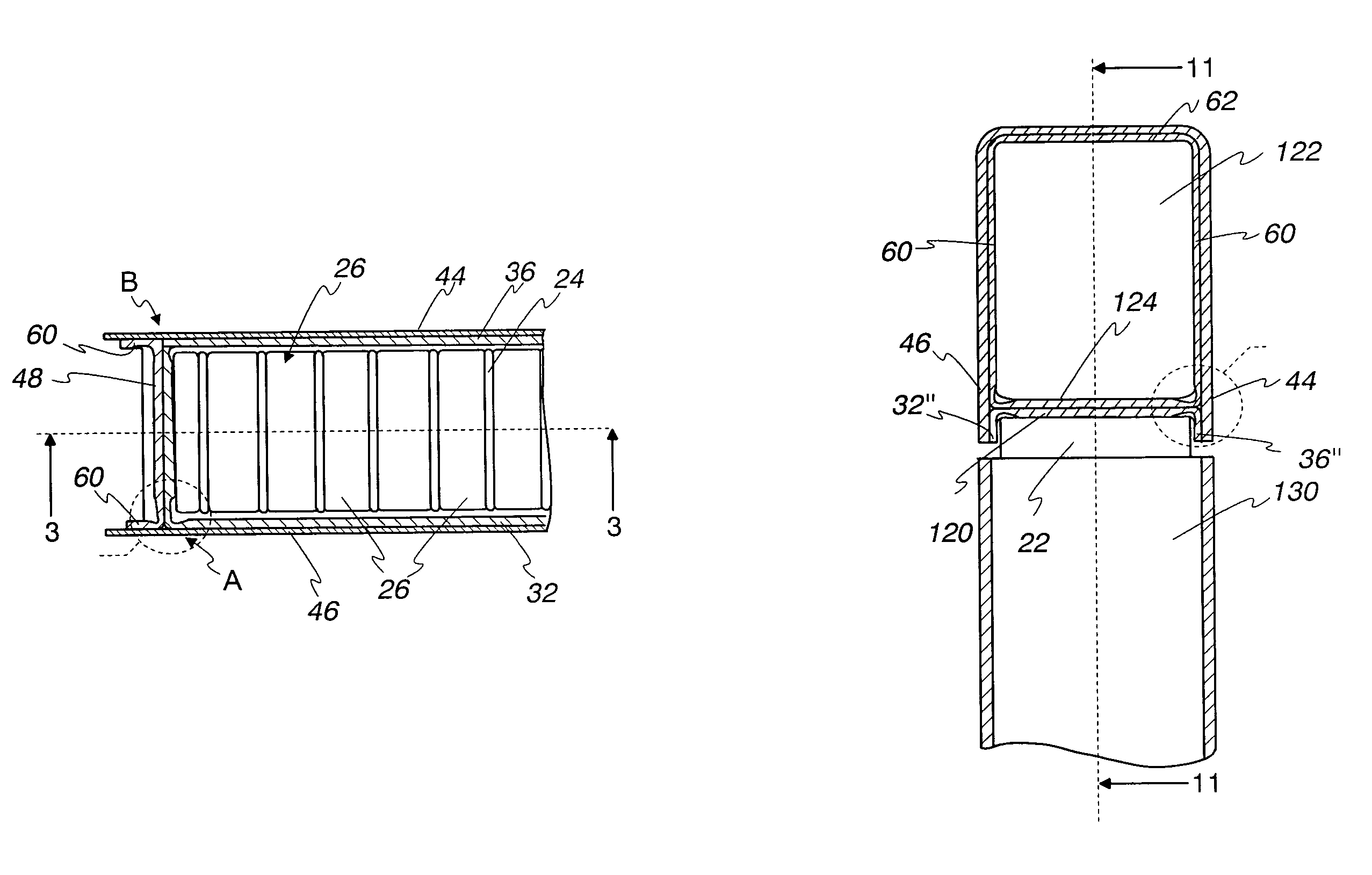

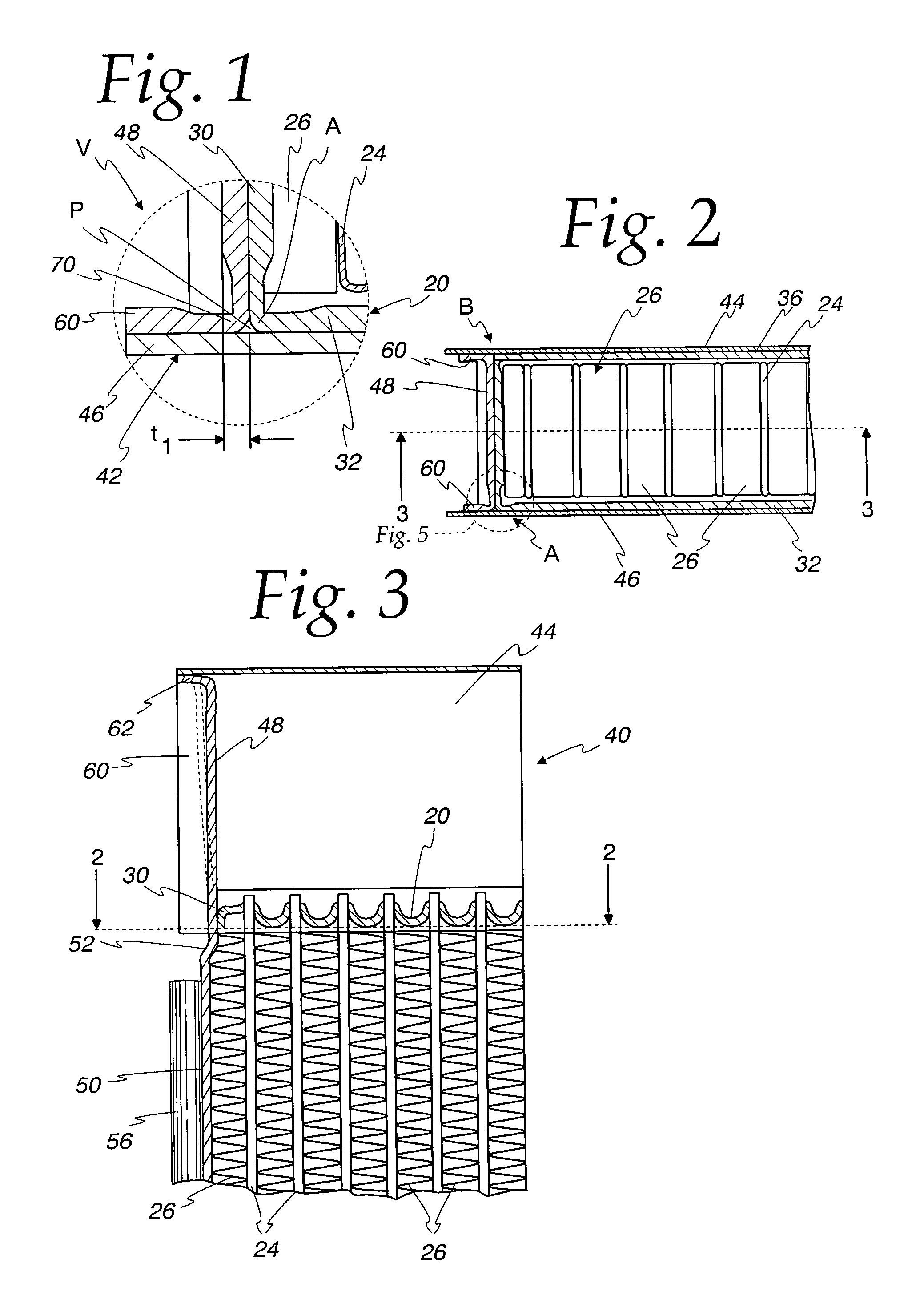

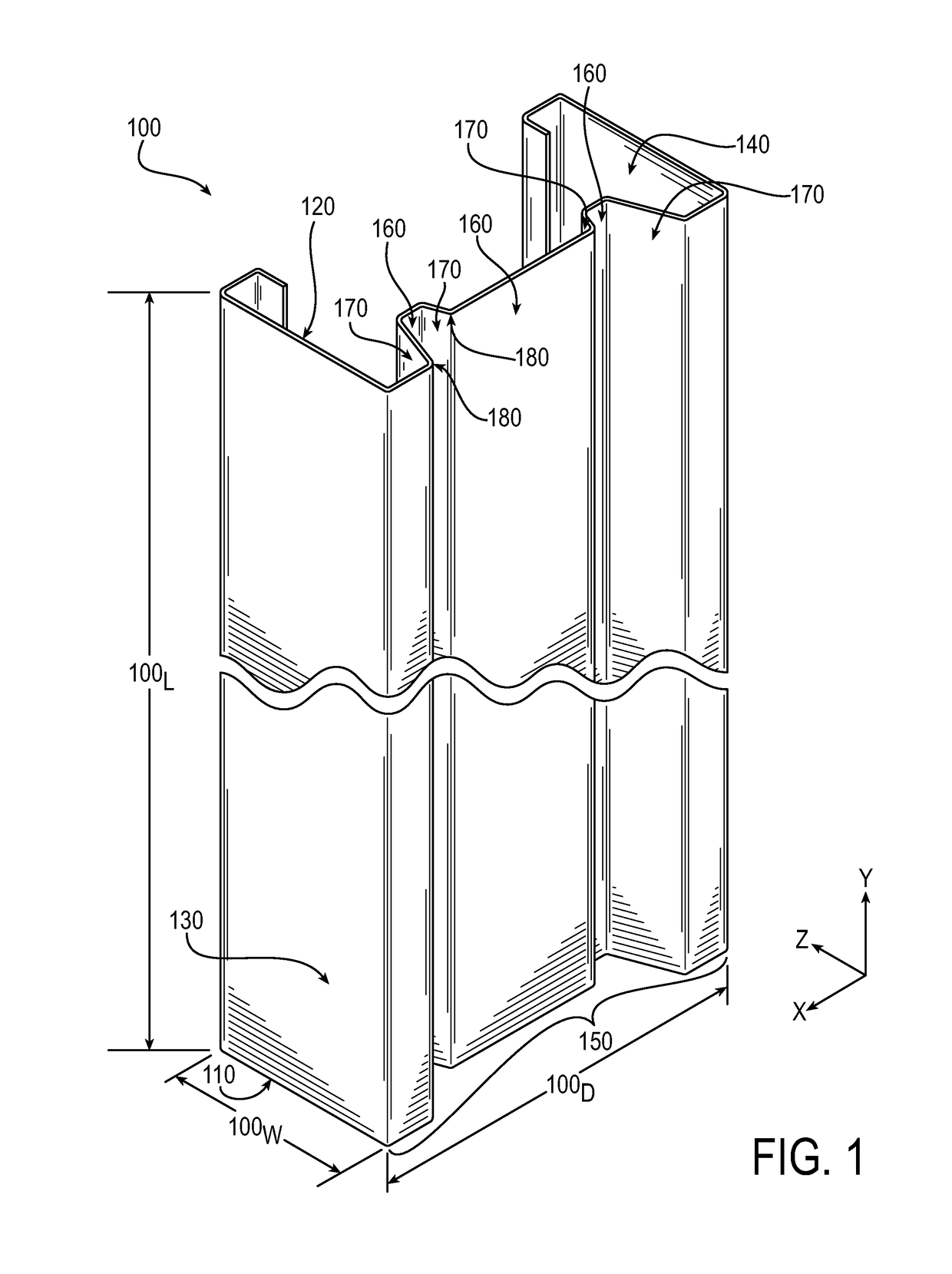

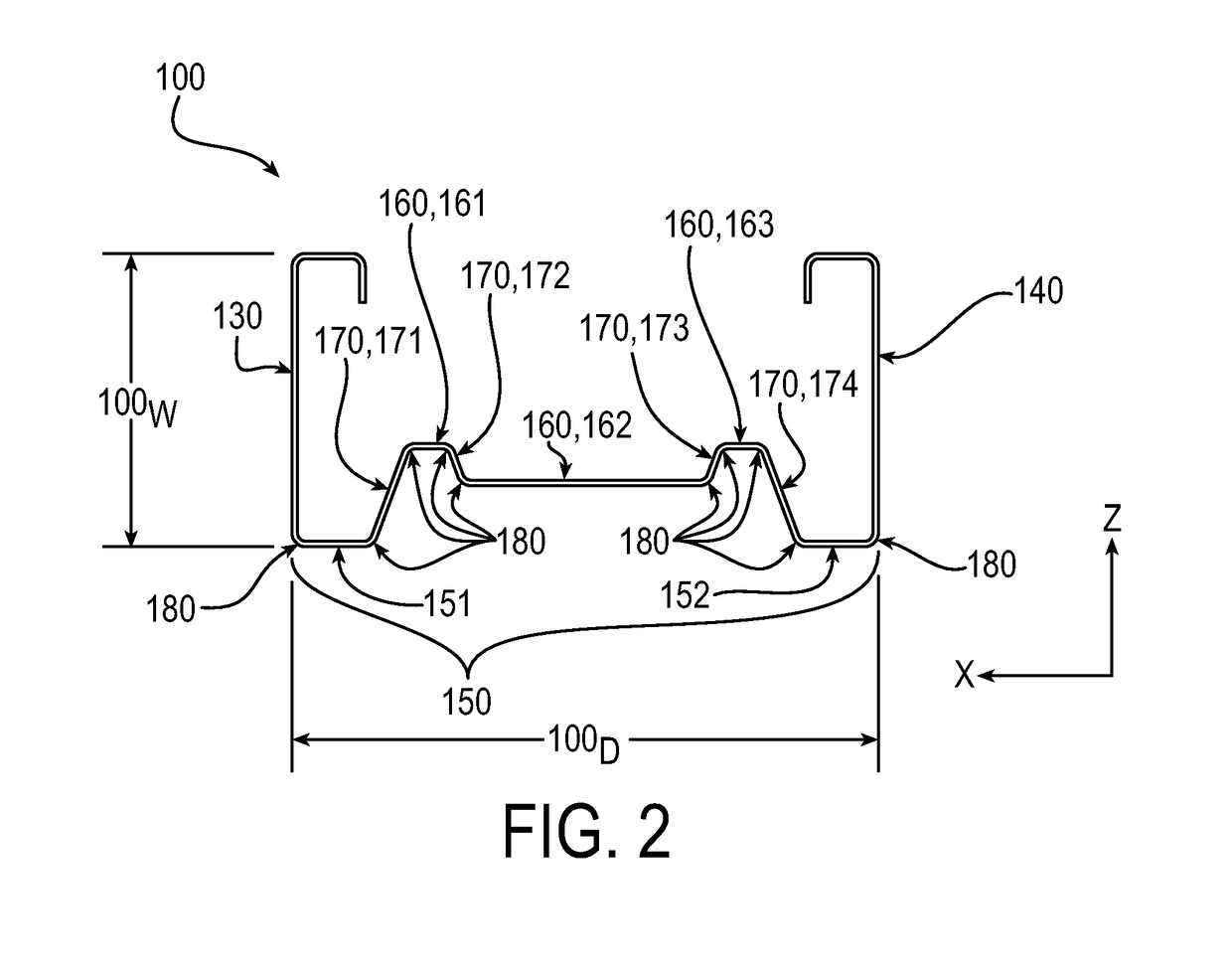

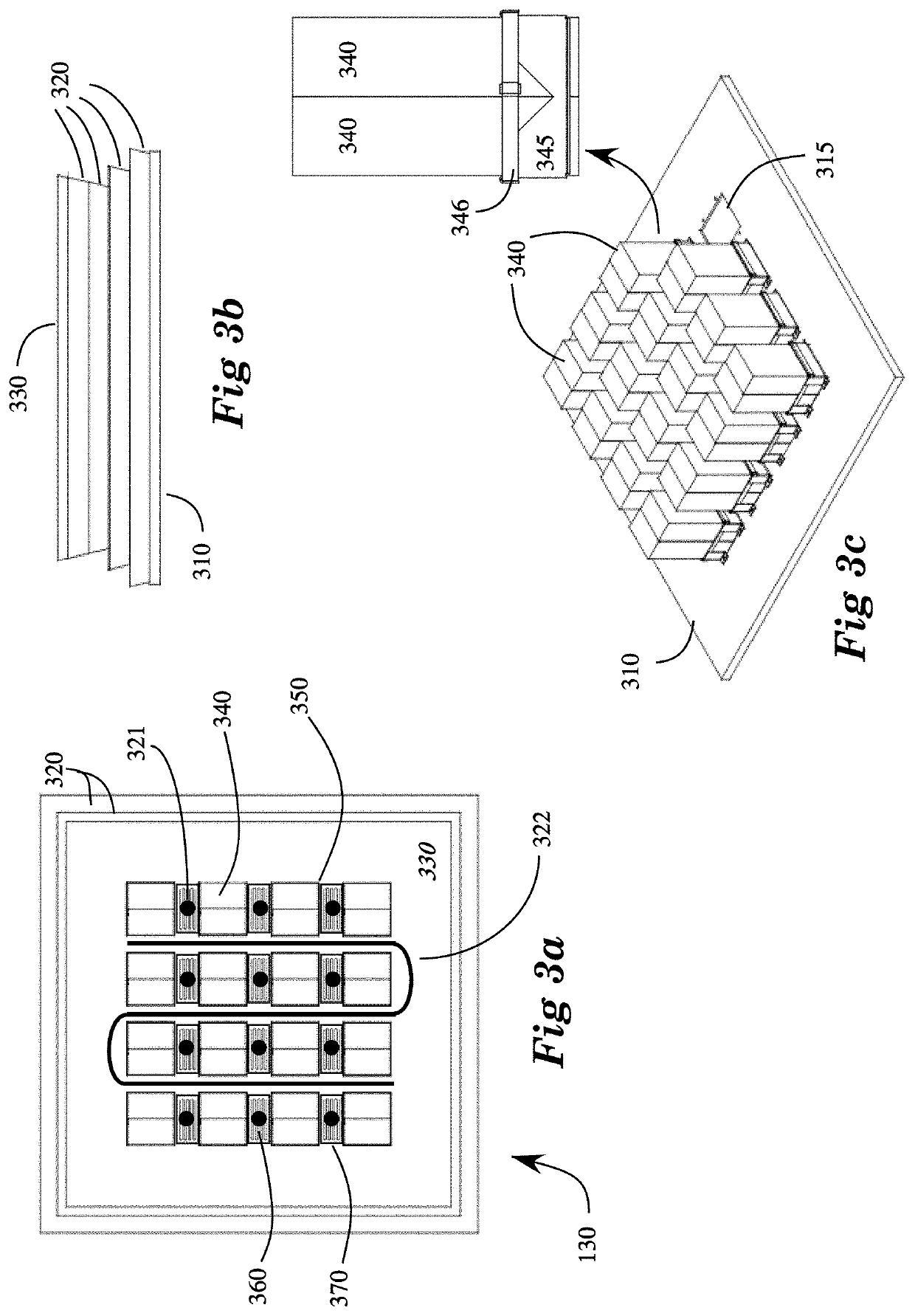

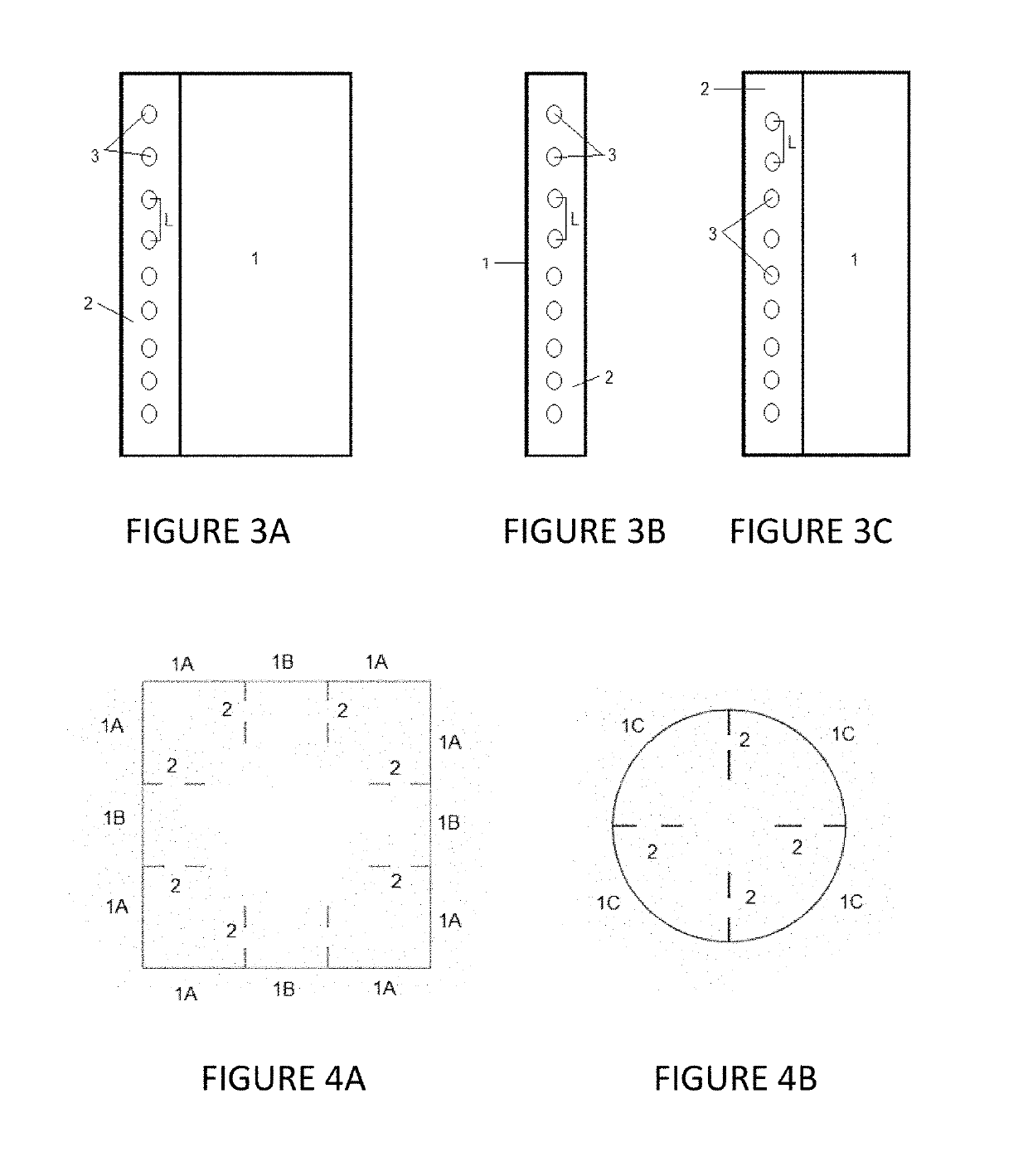

Amplified metal stud framing

Embodiments include structural metal stud framing members with an improved web design. The structural metal stud framing member with the improved web design are referred to as an amplified metal stud member. Embodiments include a bracing structure and a stiffening structure to collectively increase the axial and lateral load capacity of the stud. In other words, embodiments increase the internal strength to weight ratio for both the overall axial and lateral load.

Owner:BS CONCEPTS LLC

Crosslinked polyolefin-based resin foam sheet and process for producing the same as well as adhesive tape

InactiveUS20080057301A1Reduce sheet thicknessIncrease flexibilityFilm/foil adhesivesLayered productsPolyolefinHeat resistance

The present invention provides a crosslinked polyolefin-based resin-extruded foam sheet capable of reducing its thickness while retaining excellent flexibility and heat resistance. The crosslinked polyolefin-based resin foam sheet of the present invention is obtained by feeding a polyolefin-based resin and a thermally degradable blowing agent to an extruder, melting and kneading them, extruding the kneaded material through the extruder into a sheet to form an expandable polyolefin-based resin sheet, and expanding the sheet. Herein, a degree of crosslinking of the crosslinked polyolefin-based resin foam sheet is 5 to 60% by weight, an aspect ratio of a cell (MD average cell diameter / CD average cell diameter) is 0.25 to 1, and the polyolefin-based resin contains 40% by weight or more of a polyethylene-based resin obtained using a metallocene compound containing a tetravalent transition metal as a polymerization catalyst.

Owner:TATEO EIJI +1

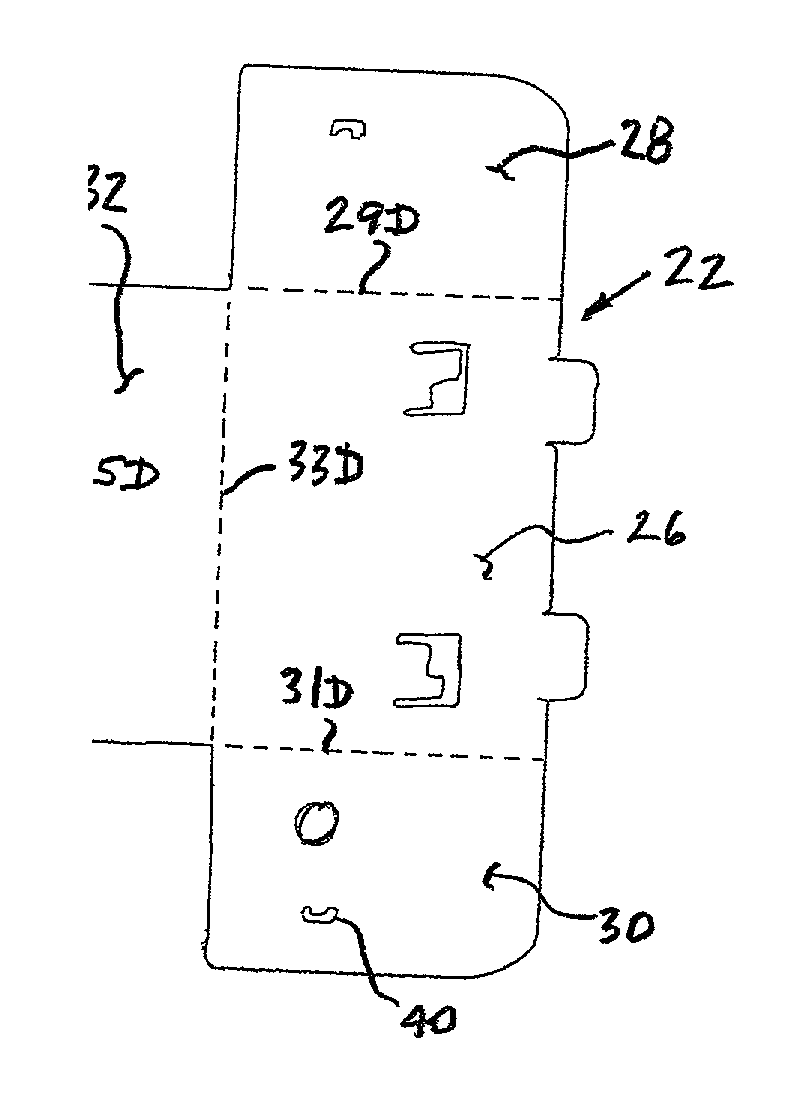

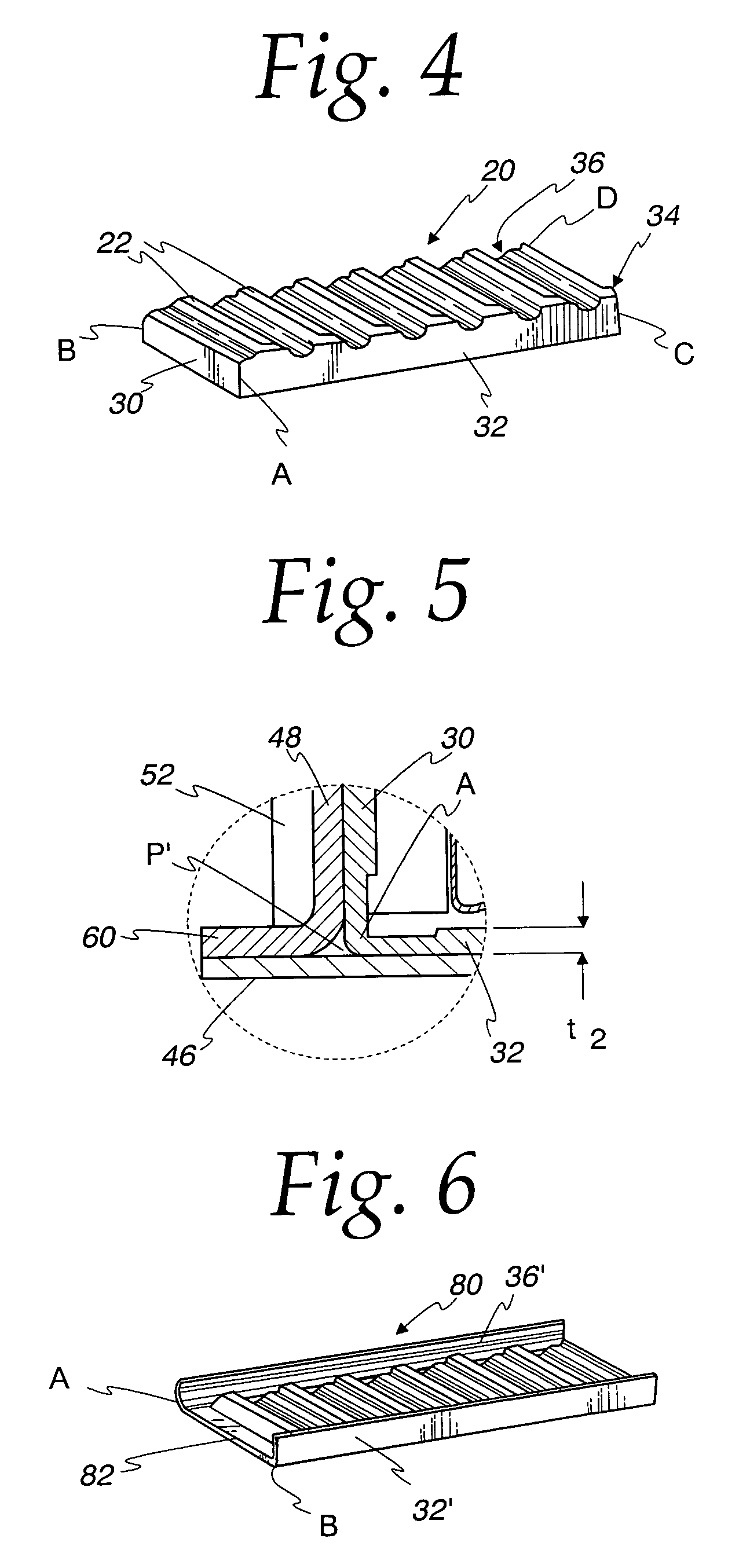

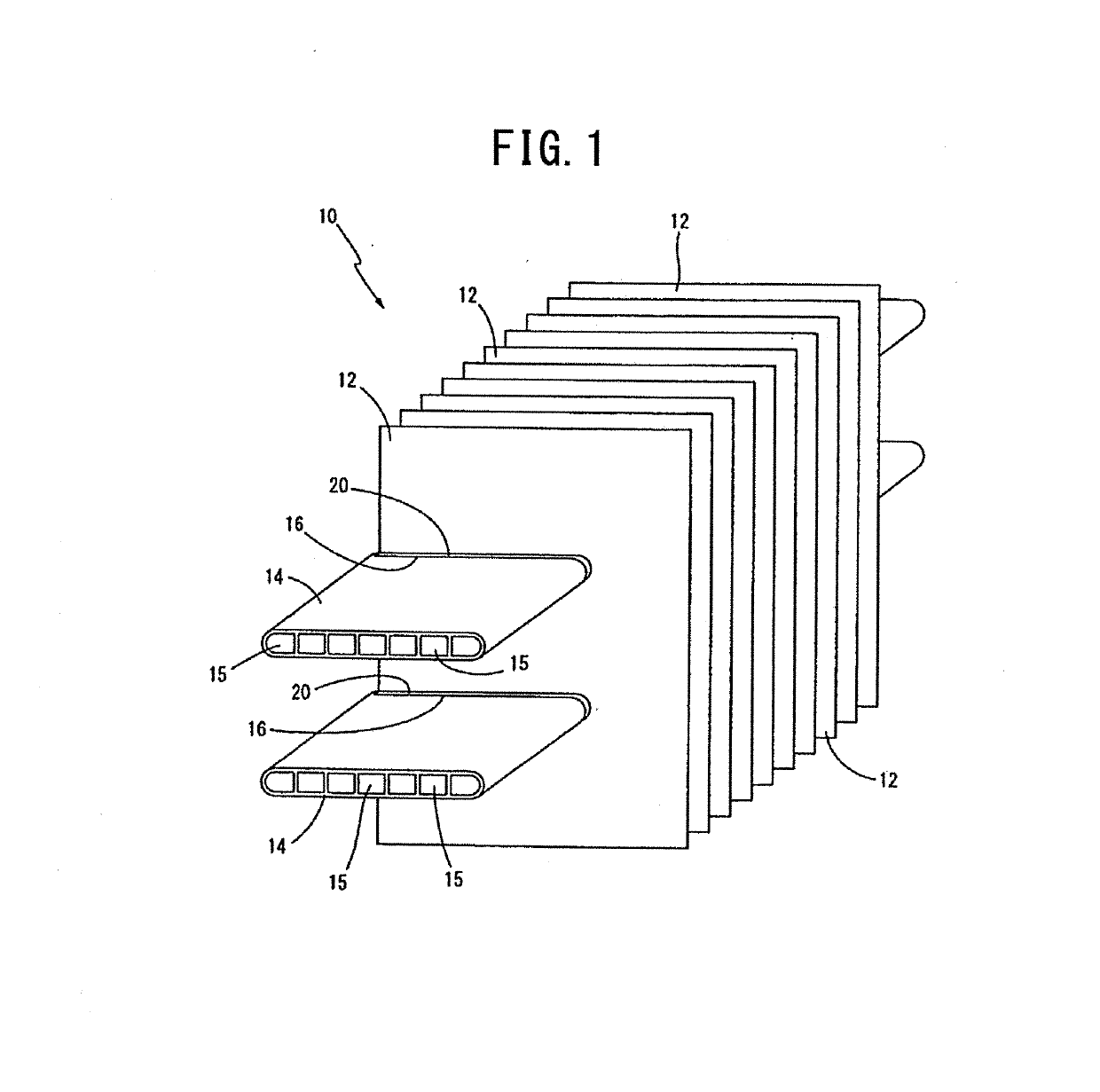

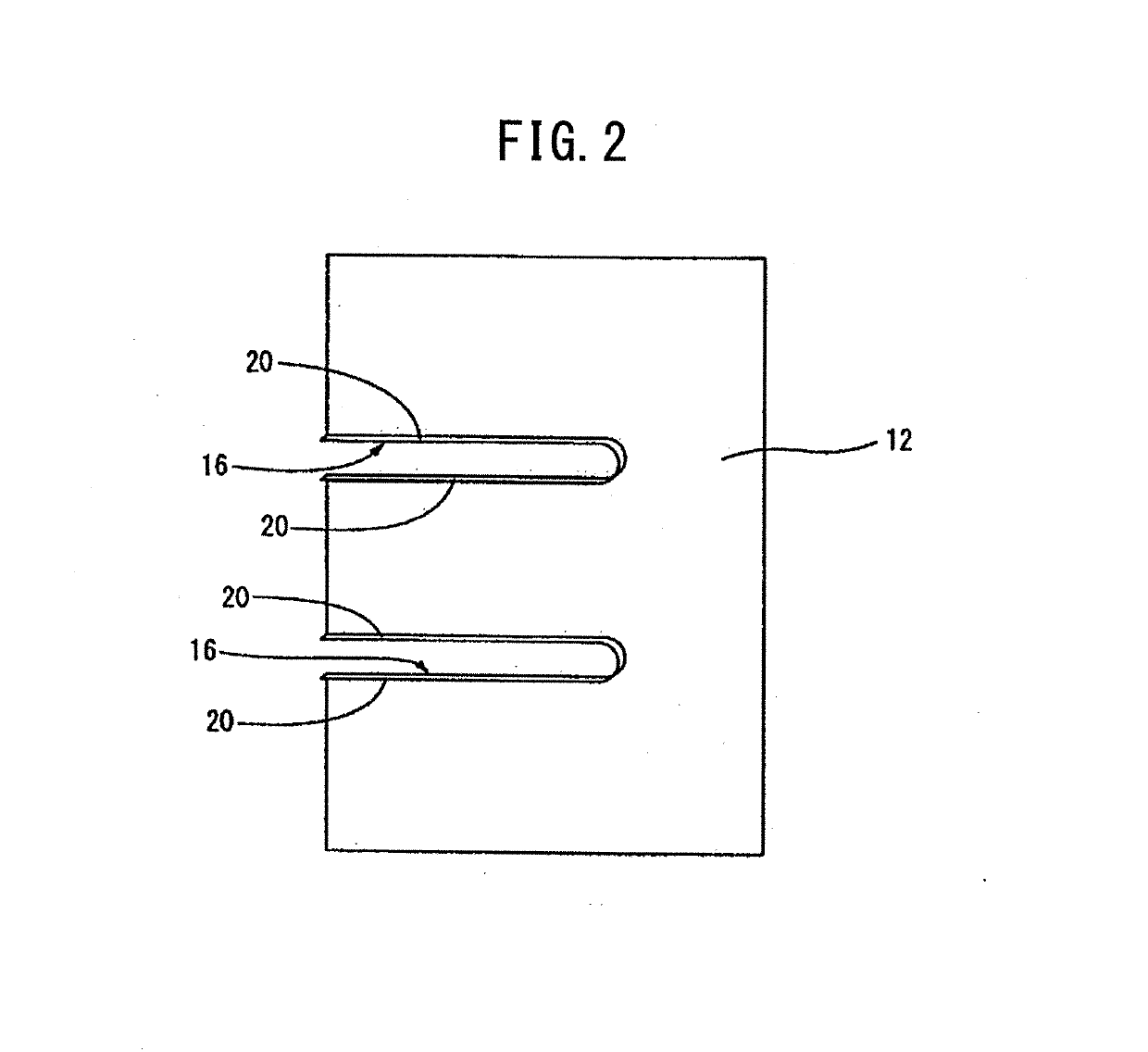

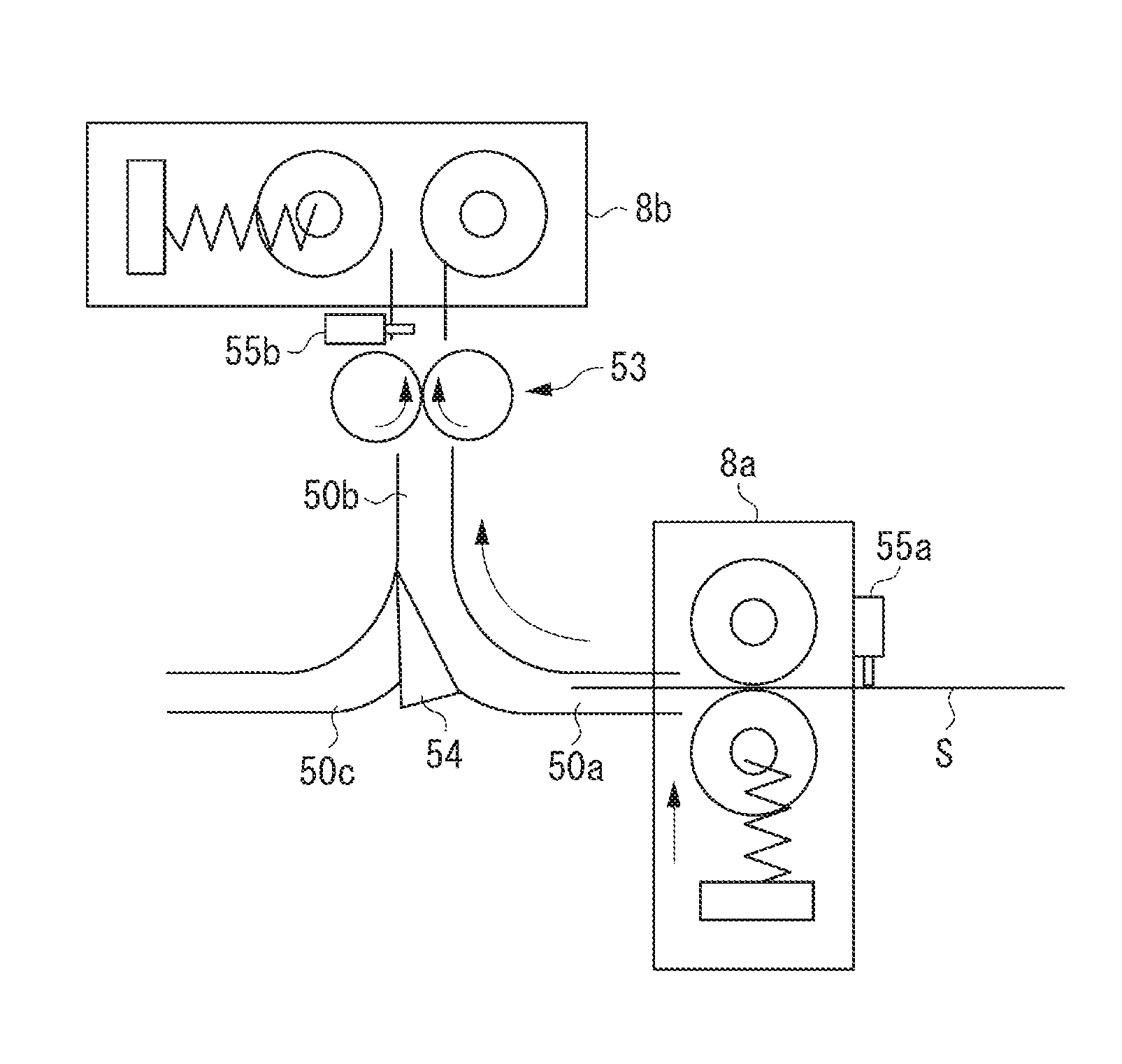

Sheets formatted for use in binding machines

InactiveUS20110298202A1Quality improvementIncrease surface areaToysBook making processesEngineeringMechanical engineering

Owner:HOCKING HAROLD P

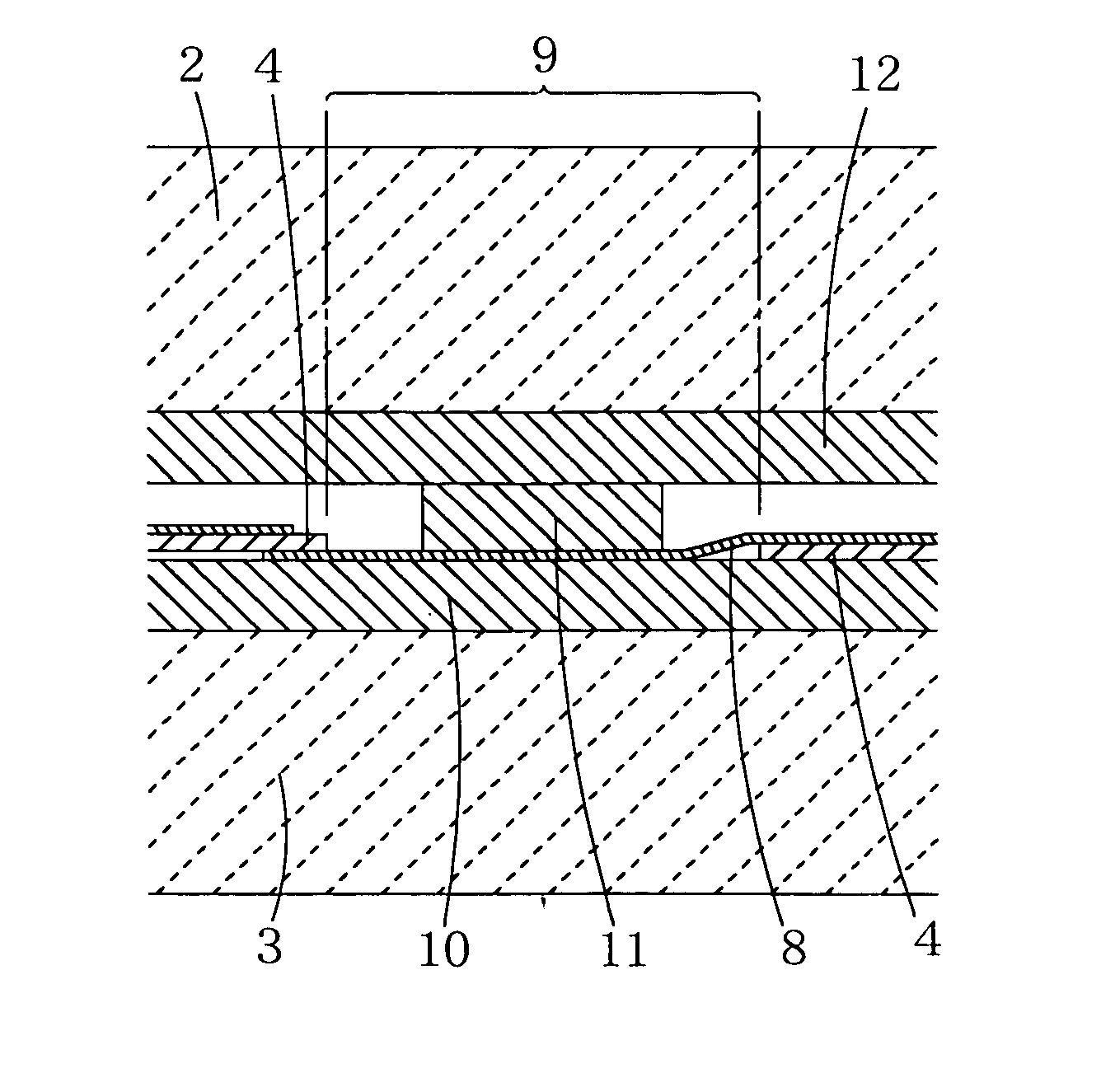

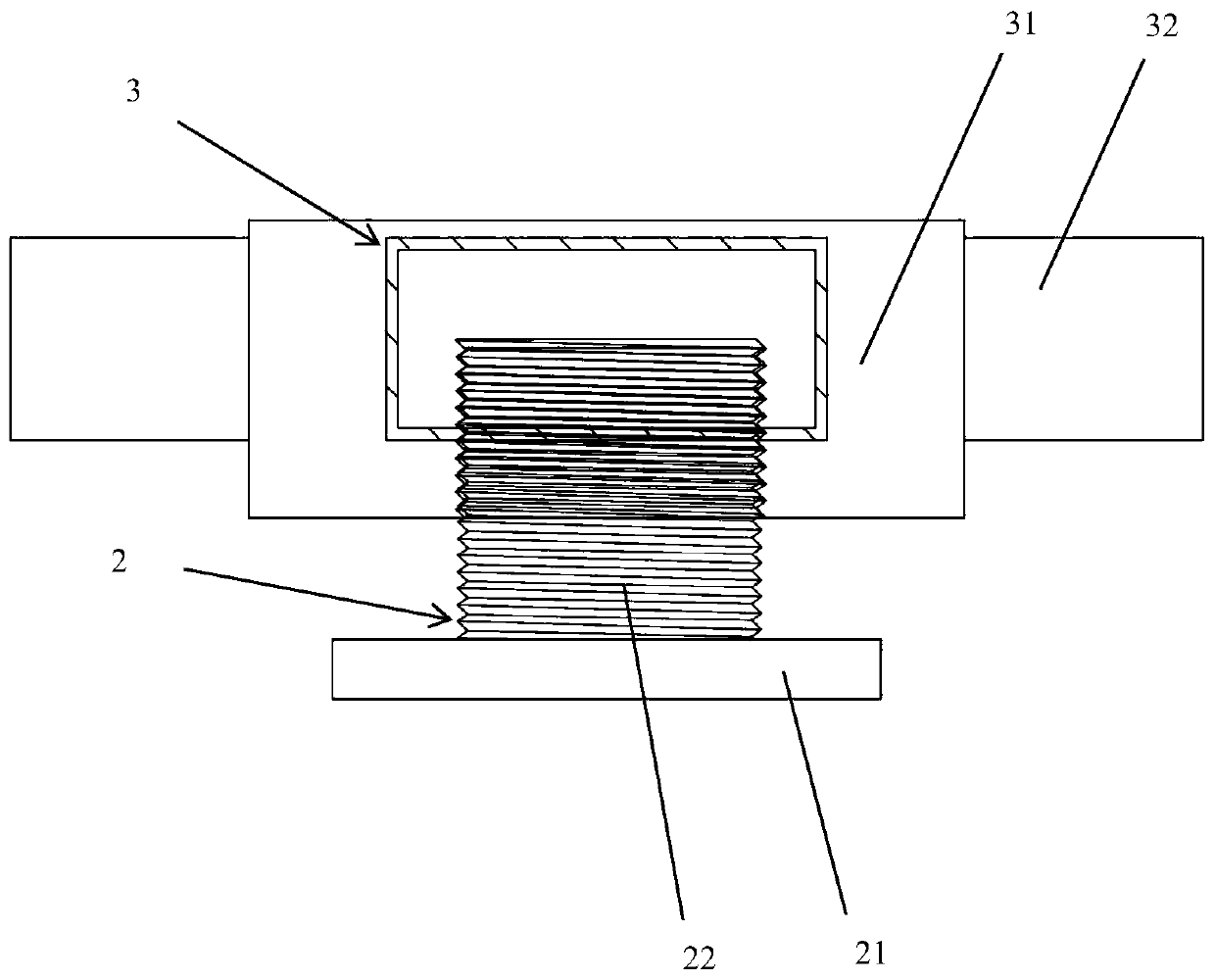

Solar battery module manufacturing method

ActiveUS7915518B2Reduce sheet thicknessAvoid breakingPV power plantsSolid-state devicesEngineeringSolar cell

A process of producing a solar battery module having plural solar battery cells sealed by a resin between a transparent panel of the light reception surface side and a back face panel, including arranging plural solar battery cells at a prescribed interval and mutually connecting them to each other by a conductor; arranging a first sealing resin sheet between the transparent panel and the solar battery cells; arranging a second sealing resin sheet between the back face panel and the solar battery cells; arranging sealing resin sheet pieces between the solar battery cells to sandwich them in-between the first and second sealing resin sheets; discharging air between the transparent panel and the back face panel; heating the resin for melting; and cooling the resin for sealing.

Owner:NAKAJIMA GLASS

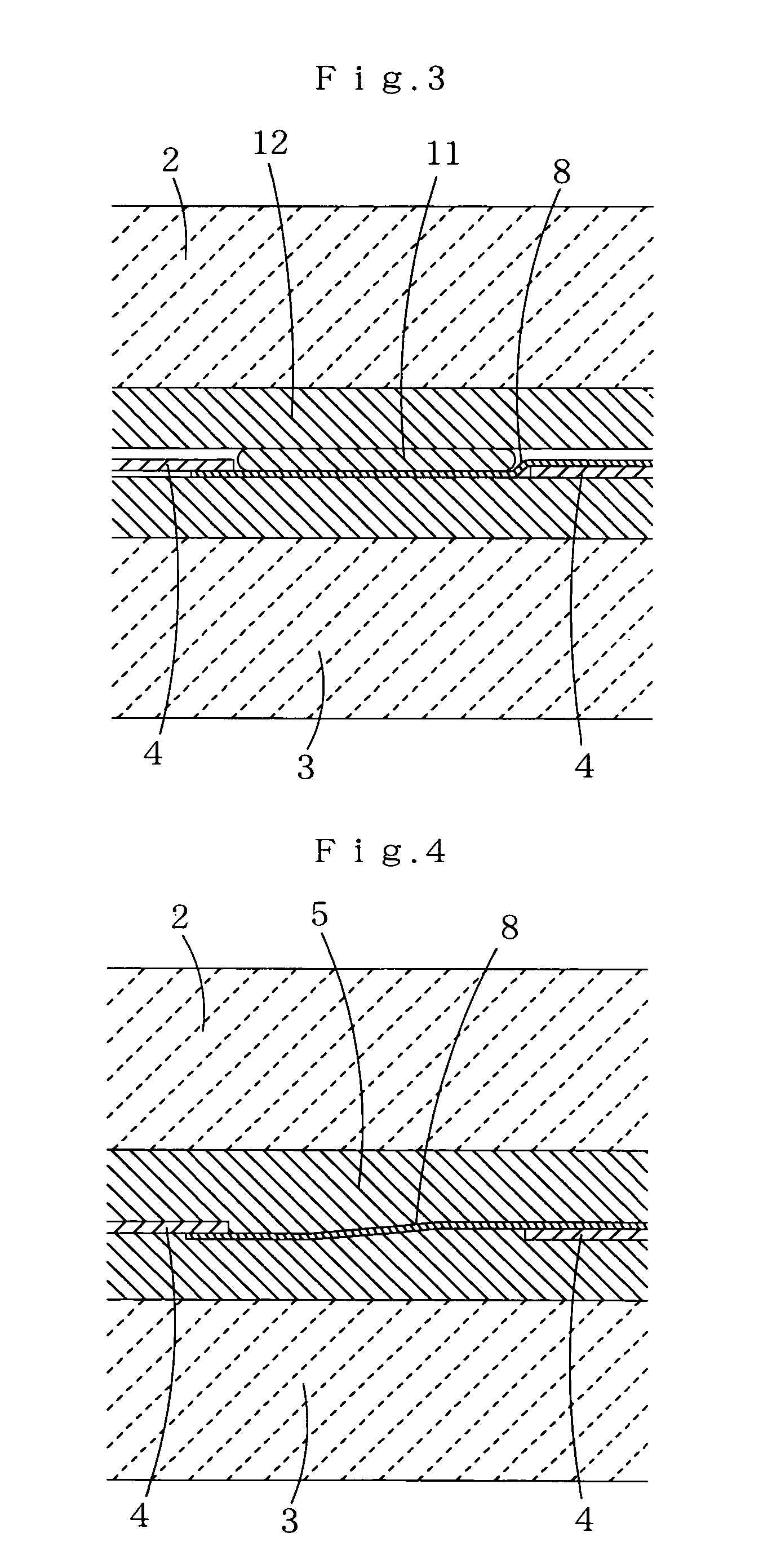

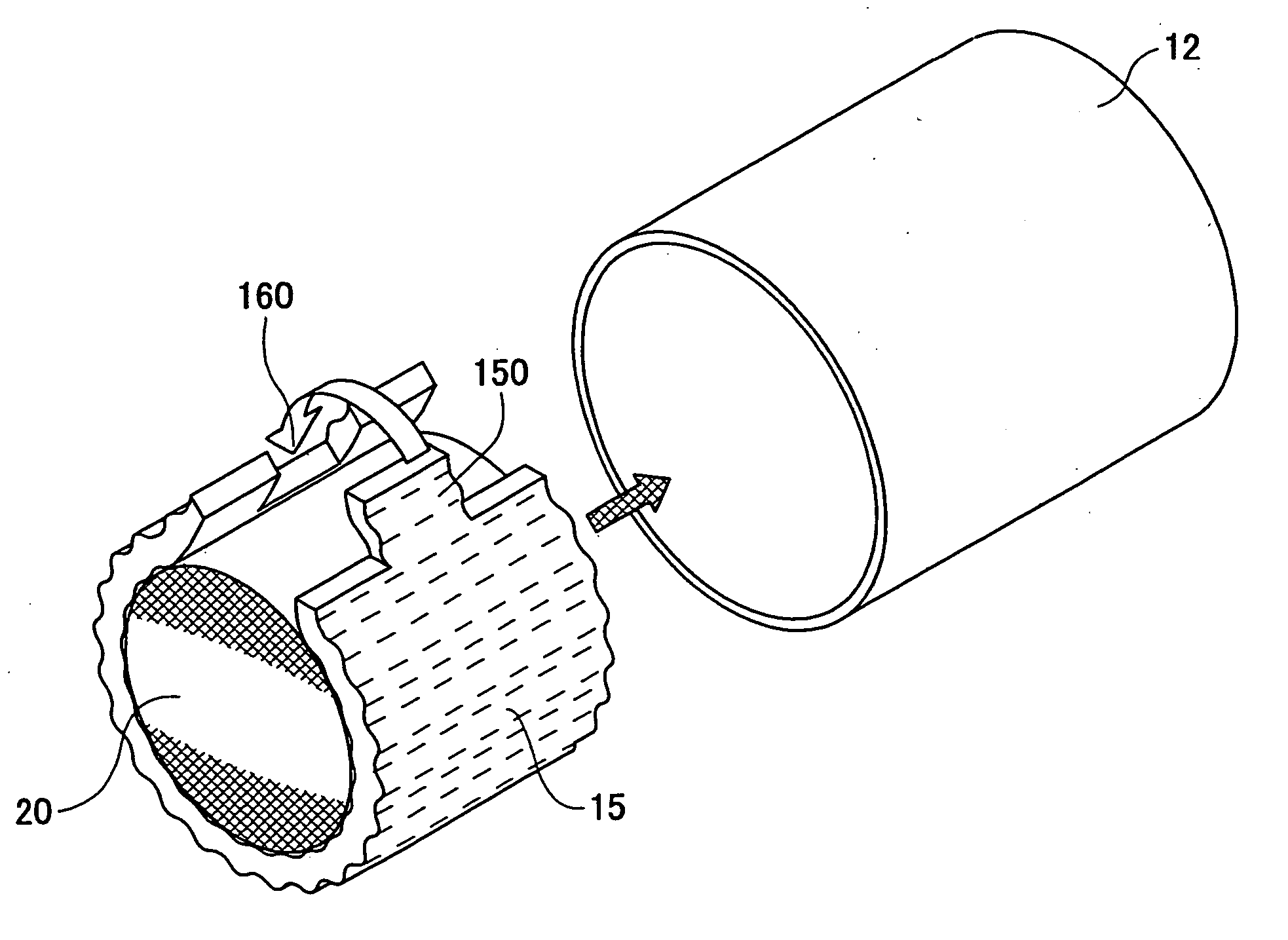

Holding and sealing member and exhaust emission control device

InactiveUS20070022747A1Increased durabilityImprove sealingInternal combustion piston enginesDispersed particle filtrationFiberEngineering

A holding and sealing member for use in an exhaust emission control device is disclosed that holds an exhaust gas treatment member. The holding and sealing member comprises a sheet member that is made of inorganic fibers and has a first surface and a second surface. The first and second surfaces are corrugated such that the corrugation height of the first surface is greater than the corrugation height of the second surface.

Owner:IBIDEN CO LTD

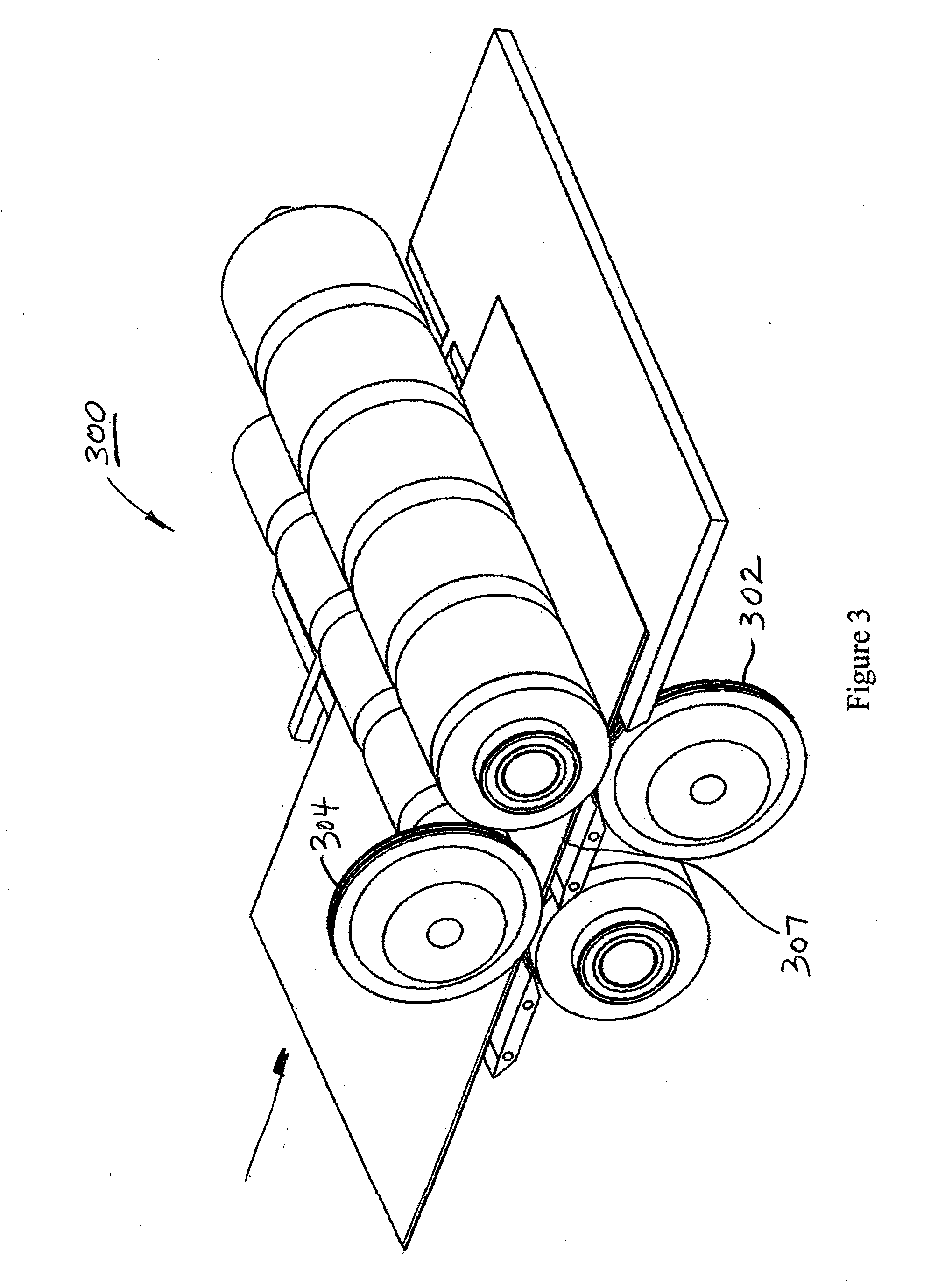

Continuous band for manufacturing bags for horticultural products and such like

ActiveUS20100024358A1Good mechanical resistanceOptimum protection against lightBag making operationsSynthetic resin layered productsBand shapeEngineering

The invention relates to a continuous band for producing bags for fruit and vegetable products, formed from a continuous plastic sheet (1) which has been die-cut to produce a series of small holes (3) which are closed using mesh or net fragments (4) fixed along the periphery of said holes by means of heat-sealing, gluing or any other conventional means. According to the invention, the area of the continuous sheet (1) intended to contain the handle is provided with a transverse patch (5) of pre-determined hardness in order to reinforce the area used to hold the bag once it has been filled, such that the thickness of the band-forming plastic sheet can be significantly reduced, specifically by a value of the order of 40%, without affecting the performance of the bag in terms of mechanical strength since the area in which the greatest strains are concentrated corresponds exactly to the area containing the handle.

Owner:CRISTOBAL MESEGUER

Heat exchanger and method of production

InactiveUS6971445B2Reduce sheet thicknessClosure meansStationary conduit assembliesPlate heat exchangerEngineering

A heat exchanger having a manifold defined by a plurality of connected closure pieces. A corner of the manifold is defined by the connected joint of three closure pieces, where one closure piece has a bent edge abutting an end of a second closure piece adjacent a generally flat section of a third closure piece. The bent edge of the one closure piece adjacent the manifold corner is a bend in a thin portion of the one closure piece, where the thin portion has a sheet thickness which is less than the sheet thickness of the adjacent portions of the one closure piece. Multiple corners of the manifold can be formed in this manner by thinning the thin and bending the portion, then connecting the closure pieces using solder to form a seal in the open cross section at the corners.

Owner:MODINE MFG CO

Amplified metal stud framing

ActiveUS10024059B2Reduce weightHigh weight ratioStrutsLoad-supporting pillarsEngineeringUltimate tensile strength

Embodiments include structural metal stud framing members with an improved web design. The structural metal stud framing member with the improved web design are referred to as an amplified metal stud member. Embodiments include a bracing structure and a stiffening structure to collectively increase the axial and lateral load capacity of the stud. In other words, embodiments increase the internal strength to weight ratio for both the overall axial and lateral load.

Owner:BS CONCEPTS LLC

Dragon-skeleton type elevated floor

PendingCN110952749AReduce sheet thicknessLighten the floor loadFalse floorsThin walledIndustrial engineering

The invention discloses dragon-skeleton type elevated floor. The dragon-skeleton type elevated floor comprises an adjustable supporting base and metal thin-wall square tubes, wherein the adjustable supporting base comprises a foundation bolt and a supporting base structure; the foundation bolt comprises a base and a screw, the screw is arranged on the base, and outer threads are arranged on the outer wall of the screw; the supporting base structure comprises a supporting base bearing table and four sleeve connector clips which are arranged on the outer wall of the supporting base bearing table; a threaded hole is formed in the supporting base bearing table, and penetrates through the supporting base bearing table along the middle axis of the supporting base bearing table; the screw is in threaded connection to the supporting base bearing table; the metal thin-wall square tubes are detachably arranged on the four sleeve connector clips in a sleeving mode; the upper surfaces of the metalthin-wall square tubes and the upper surface of the supporting base bearing table are positioned on the same horizontal plane. The invention further discloses a mounting leveling method for the dragon-skeleton type elevated floor. The dragon-skeleton type elevated floor can reduce the board thickness, increases indoor clear height, reduces manufacturing cost, quickens leveling speed, is great inintegral structural strength, can place movable floor thereon more stably and reliably.

Owner:SHANGHAI TRENDZONE CONSTRUCTION DECORATION GROUP CO LTD

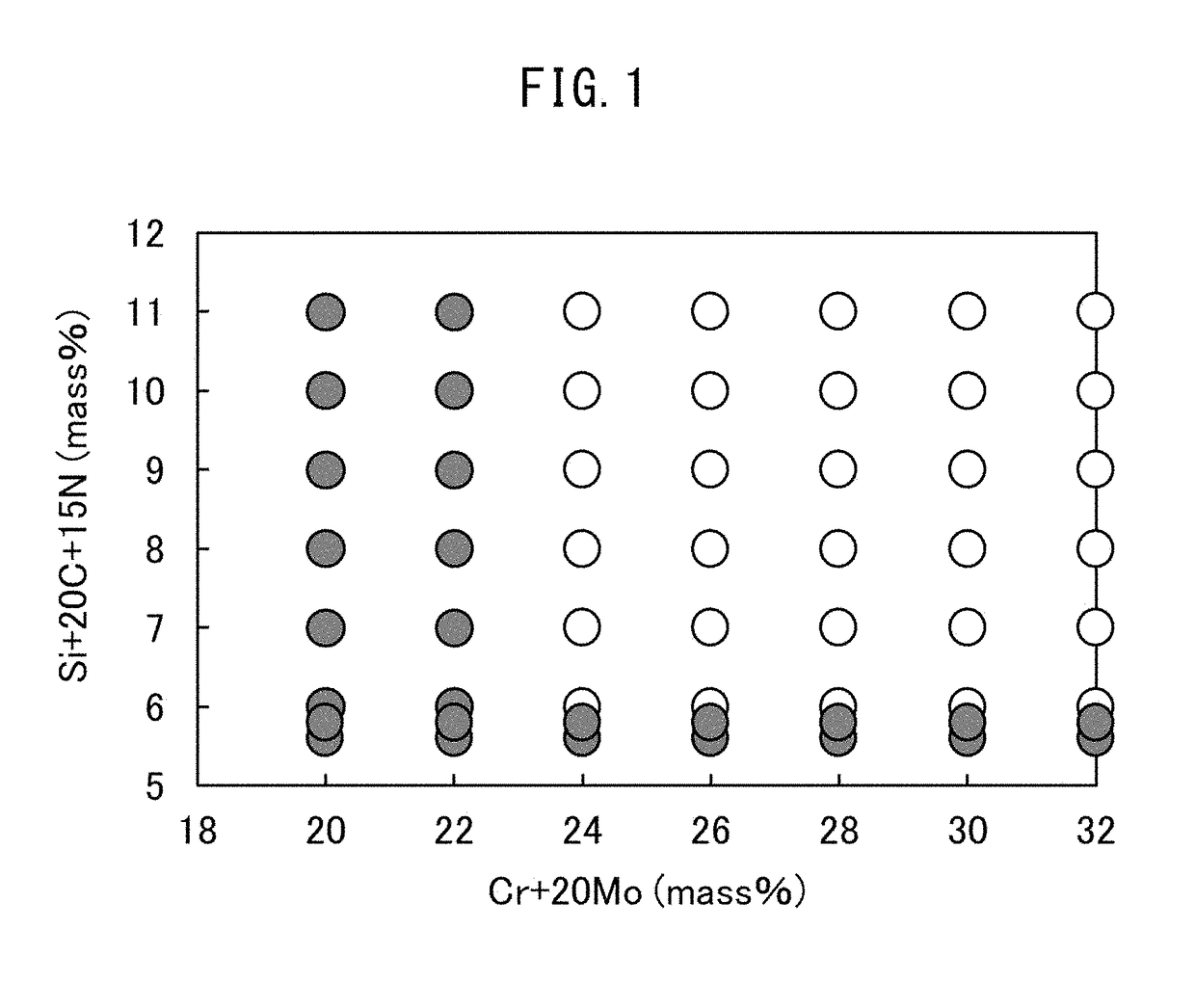

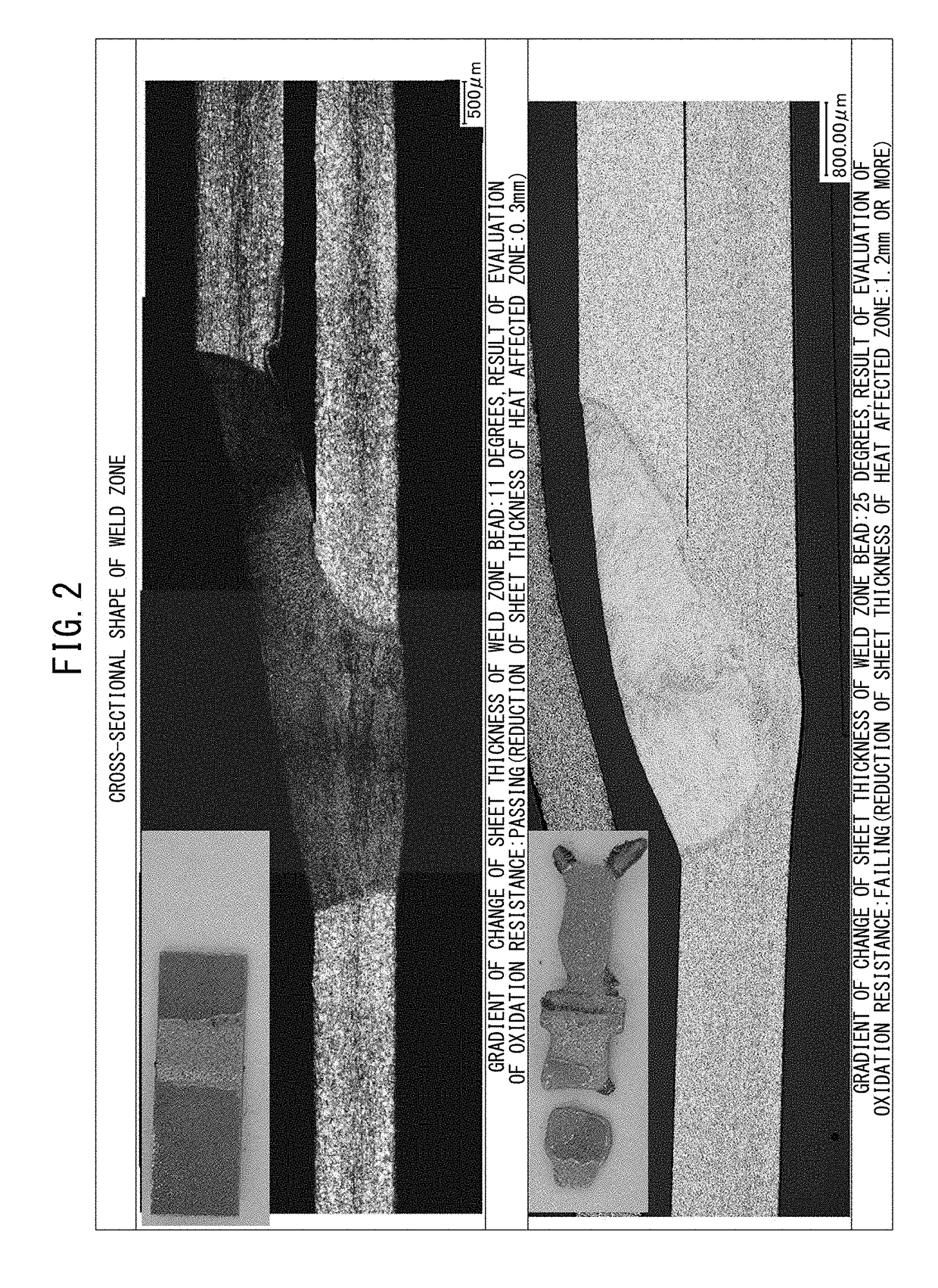

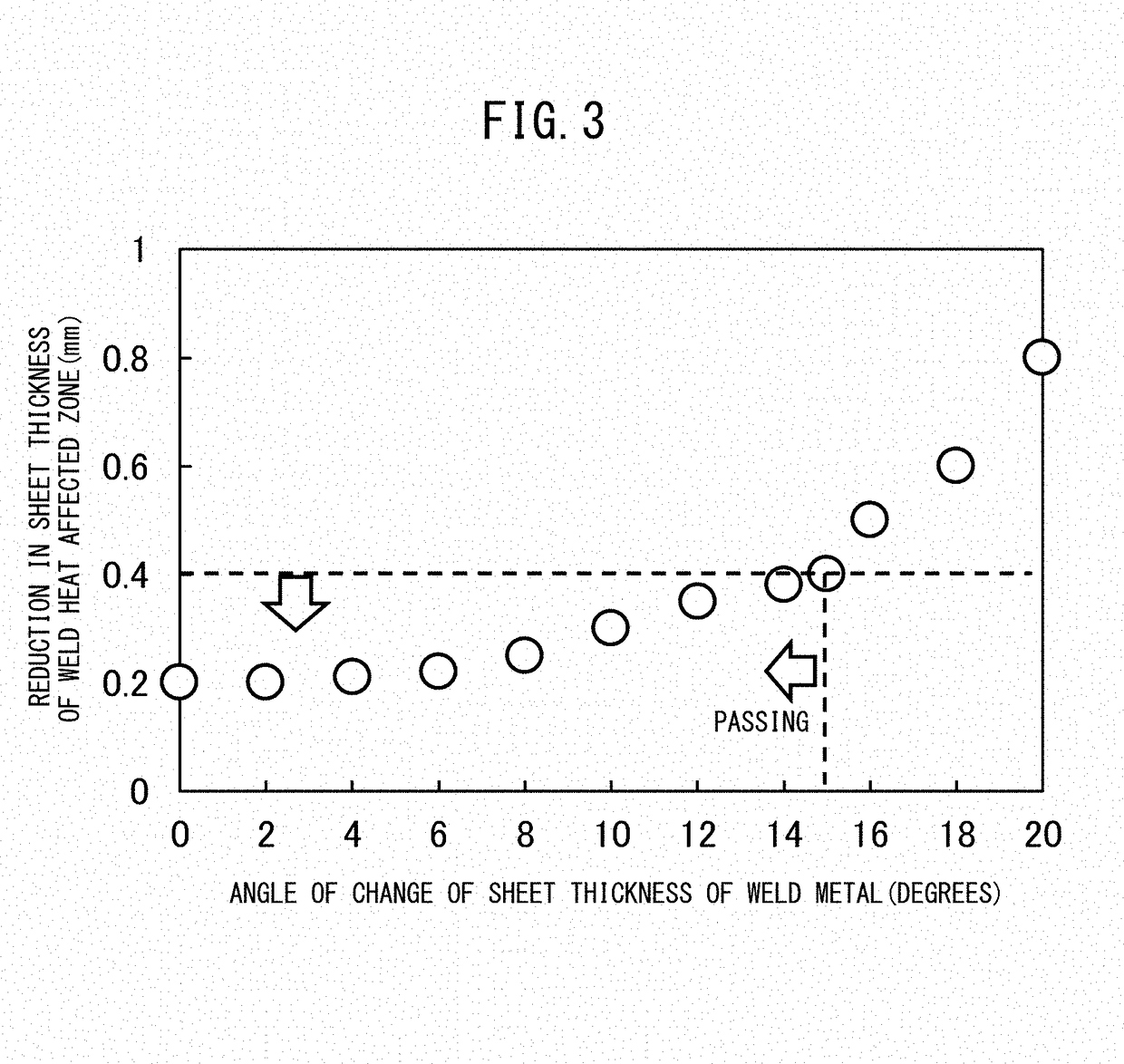

Stainless steel sheet for exhaust system part use excellent in intermittent oxidation characteristic and exhaust system part

InactiveUS20180080106A1Improve the immunityImprove fuel economySilencing apparatusFurnace typesDouble tubeUltimate tensile strength

A stainless steel sheet free of surface flaws, having an enhanced high temperature strength and corrosion resistance, not becoming brittle at a high temperature, and further exhibiting a high oxidation resistance enabling it to be suitably used as an inside pipe of a double pipe of an exhaust manifold, a turbocharger part, and other automobile exhaust system parts, which stainless steel sheet has a predetermined composition of chemical components and satisfies Cr+20Mo≧24.0%, and Si+20C+15N≧5.8%. Further, an automobile exhaust system part, excellent in both the oxidation resistances of the base material and weld zone using the above stainless steel sheet, having a gradient of change of sheet thickness between the weld metal and the base material of the above stainless steel sheet of 15 degrees or less.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

Solar battery module manufacturing method

ActiveUS20110189807A1Reduce sheet thicknessAvoid breakingSemiconductor/solid-state device manufacturingGlass/slag layered productsElectrical batteryEngineering

Provided is a process of producing a solar battery module 1 including plural solar battery cells 4 sealed by a resin 5 between a transparent panel 2 of the light reception surface side and a back face panel 3, which is characterized by arranging plural solar battery cells 4 at a prescribed interval and mutually connecting them to each other by a conductor 8; arranging a first sealing resin sheet 12 substantially covering the entire surface of the transparent panel 2 of the light reception surface side between the transparent panel 2 of the light reception surface side and the solar battery cells 4; arranging a second sealing resin sheet 10 substantially covering the entire surface of the back face panel 3 between the back face panel 3 and the solar battery cells 4; arranging sealing resin sheet pieces 18, 19 which are thicker than the solar battery cells 4 at a space 9 between the solar battery cells 4 so as to be sandwiched by the first sealing resin sheet 12 and the second sealing resin sheet 10; discharging air between the transparent panel 2 of the light reception surface side and the back face panel 3; and heating the resin 5 for melting and then cooling down it for sealing. According to this, when the plural solar battery cells 4 are arranged and sealed by the resin 5, breakage of the solar battery cells 4 can be prevented from occurring.

Owner:NAKAJIMA GLASS

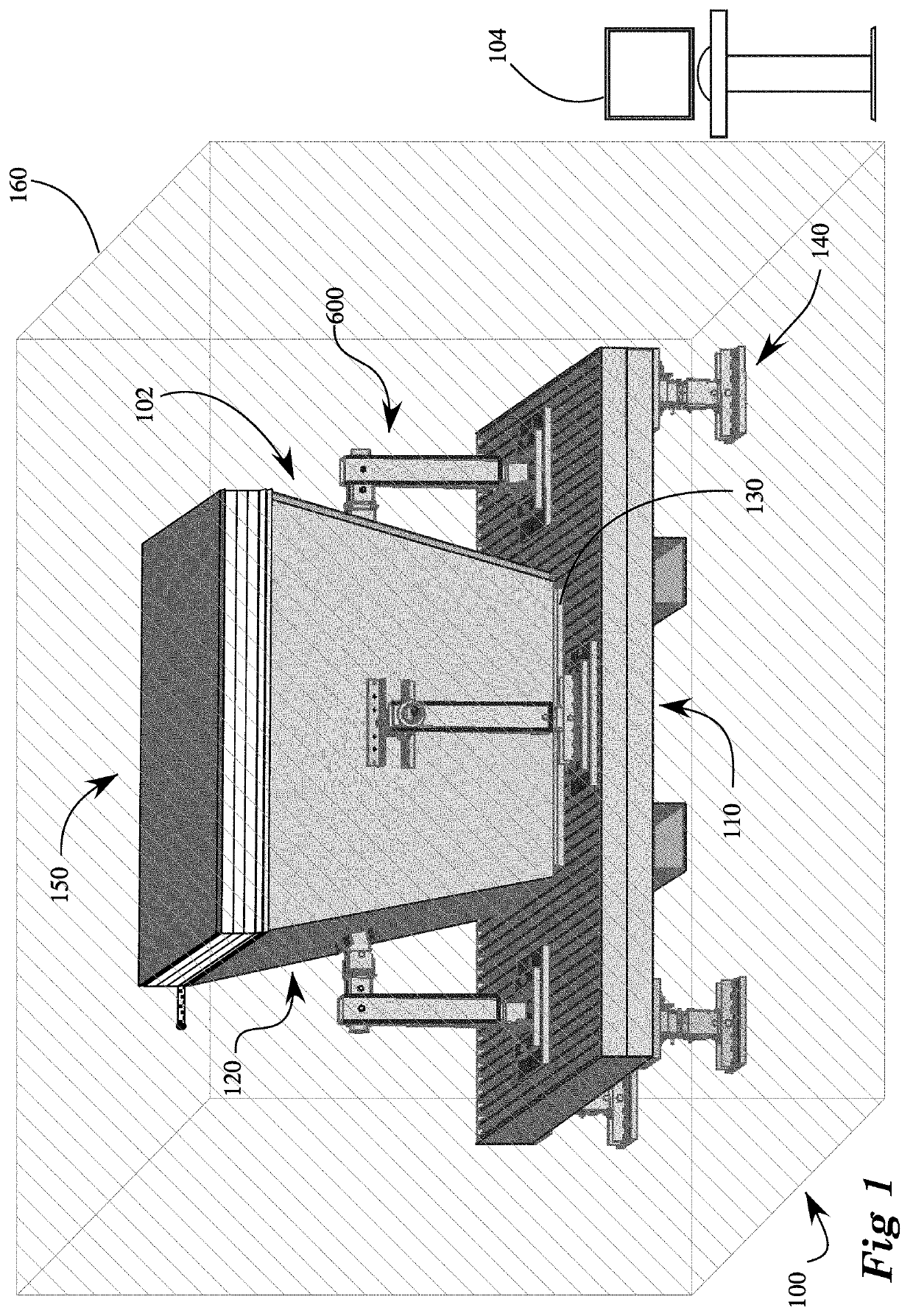

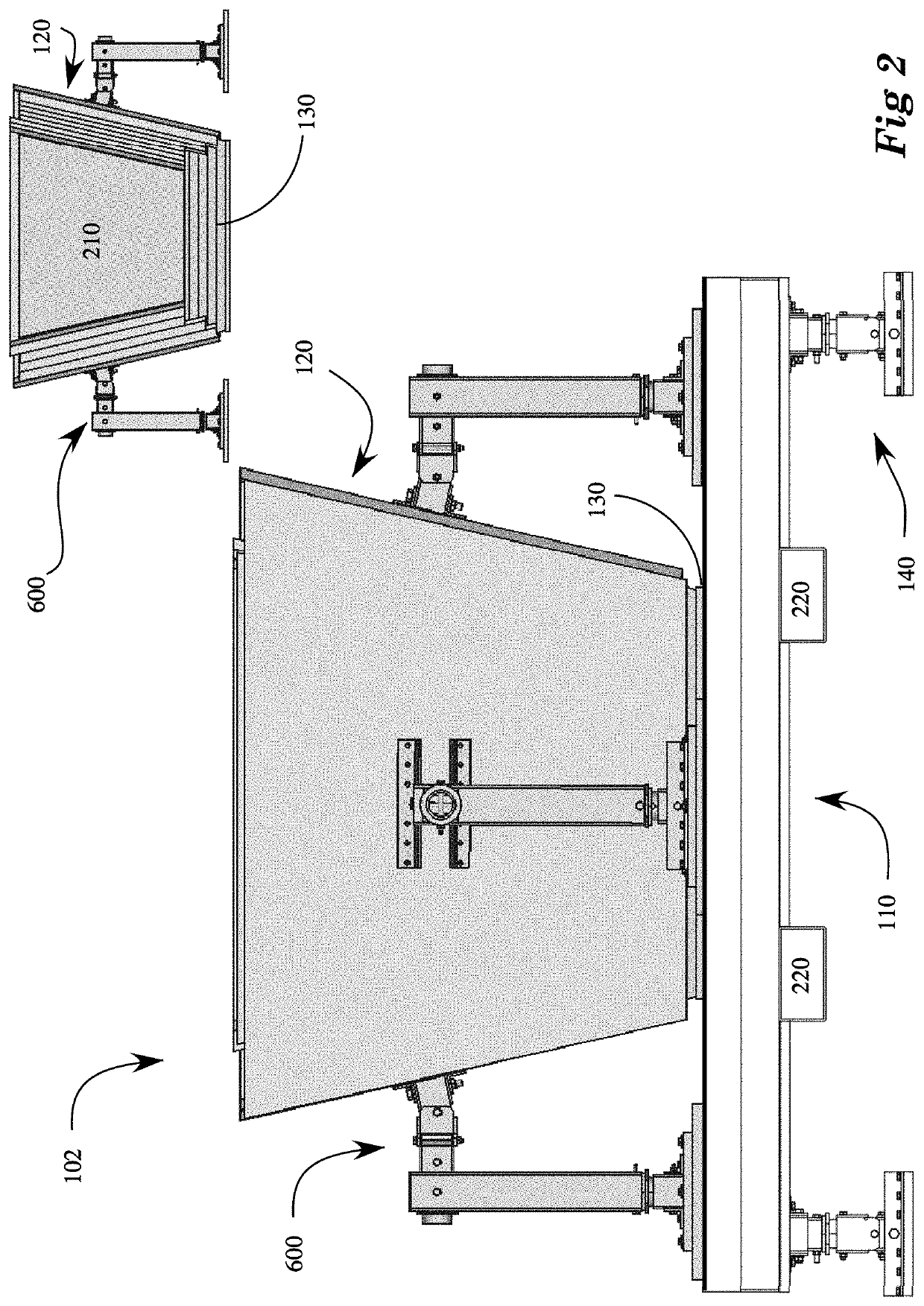

Thermophysical float glass process

ActiveUS11390552B1Improve efficiencyRelieve pressureGlass tempering apparatusFlat glassHigh intensity

A novel apparatus and method for producing flat glass by floating molten glass on liquid tin, significantly improving the efficiency of heating the tin and reducing or eliminating the need to anneal by eliminating the stress introduced by pulling the glass across the tin bath. The apparatus directly heats and melts the tin by exposure to high-intensity infrared energy through surfaces of the tin-containing tub, said tub made from a material that is transmissive at selected infrared wavelengths.

Owner:MASTEN JR JAMES W

Sheet for cutaneous application containing vitamin e or an ester thereof

ActiveUS20140328885A1Improve adhesionEasy to disassembleOrganic active ingredientsBiocideTG - TriglycerideSilicone Elastomers

Sheet for cutaneous application comprising a support layer made of loosely woven fabric embedded in a layer of silicone elastomer incorporating vitamin E or an ester thereof, wherein the layer of silicone elastomer has a thickness less than or equal to 2.0 mm and the silicone elastomer contains an elasticity modifier consisting of a triglyceride of saturated C8-C18 fatty acids.

Owner:HULKA SRL

Press forming die assembly

Owner:HONDA MOTOR CO LTD

Aluminum alloy fin material, aluminum alloy brazing sheet, and heat exchanger

InactiveUS20190162492A1Reduce sheet thicknessImprove adhesionCorrosion preventionHeat exhanger finsSurface layerHeat sink

An aluminum alloy fin material includes an aluminum alloy containing 1.50 to 5.00 mass % Si with the balance of Al and inevitable impurities, and has the function of being bonded by heating with a single layer. Assuming that in a cross section along the thickness direction of the fin material, the equivalent circle diameter of a Si particle is represented by D, a distance from a surface layer to the center of the Si particle is represented by L, the thickness of the fin material is represented by t, and a length parallel to the surface layer is represented by W, all Si particles that are present in the range of the length W and satisfy D≥L and L+D>0.04 t also satisfy 0≤ΣπD2<0.08 tW. An aluminum alloy brazing sheet includes, as a skin material, the fin material that is clad on a core material including an aluminum alloy. A heat exchanger includes the fin material or the brazing sheet that is used in a fin.

Owner:FURUKAWA SKY ALUMINUM CORP

Hot-rolled high strength steel sheet having excellent ductility, and tensile fatigue properties and method for producing the same

ActiveUS8075711B2Reduce sheet thicknessImprove ductilityFurnace typesHeat treatment furnacesTensile fatigueHigh intensity

Owner:JFE STEEL CORP

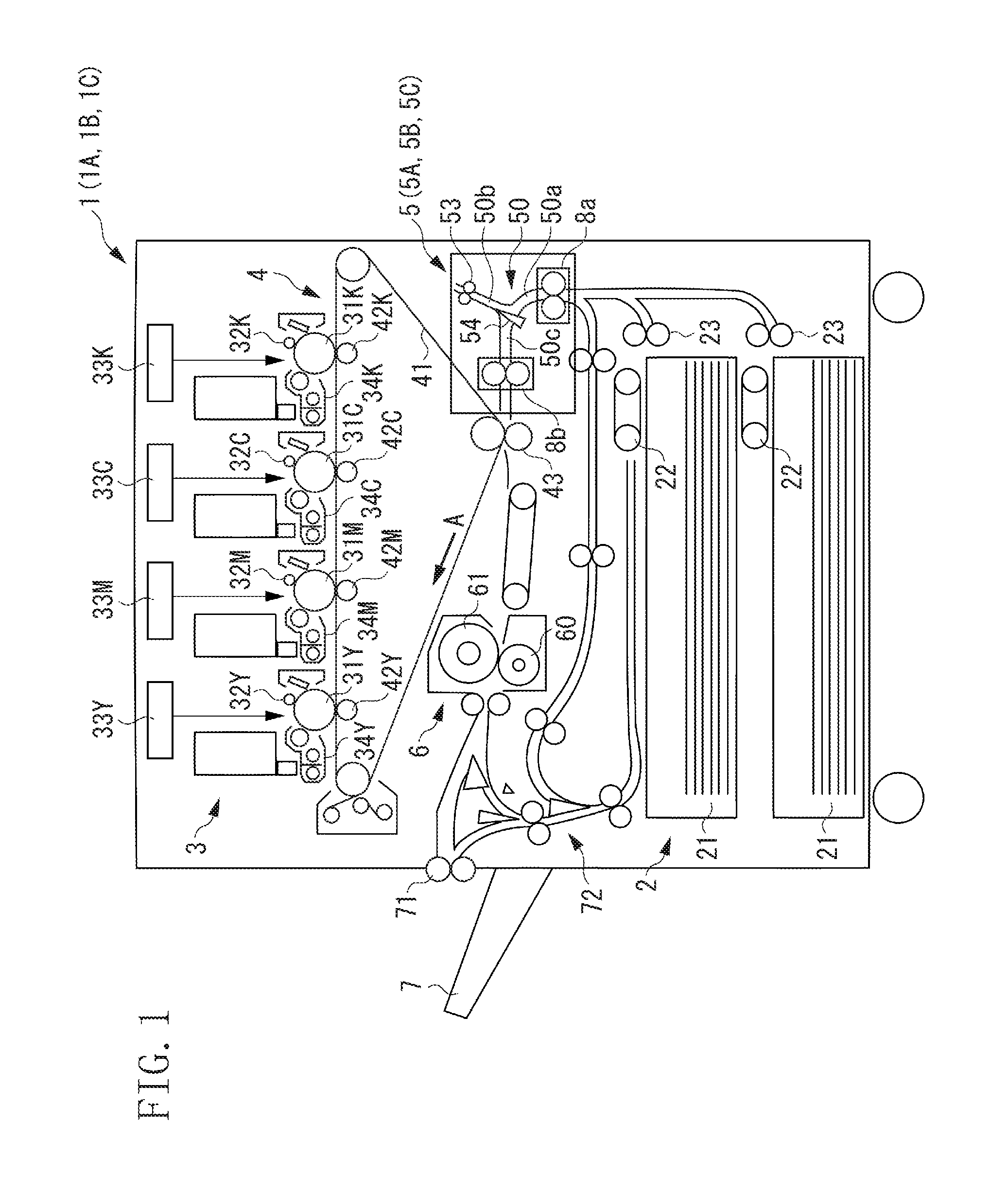

Sheet compression apparatus and image forming apparatus

InactiveUS9244419B2Increased durabilityReduce sheet thicknessOverturning articlesFunction indicatorsLeading edgeEngineering

Owner:CANON KK

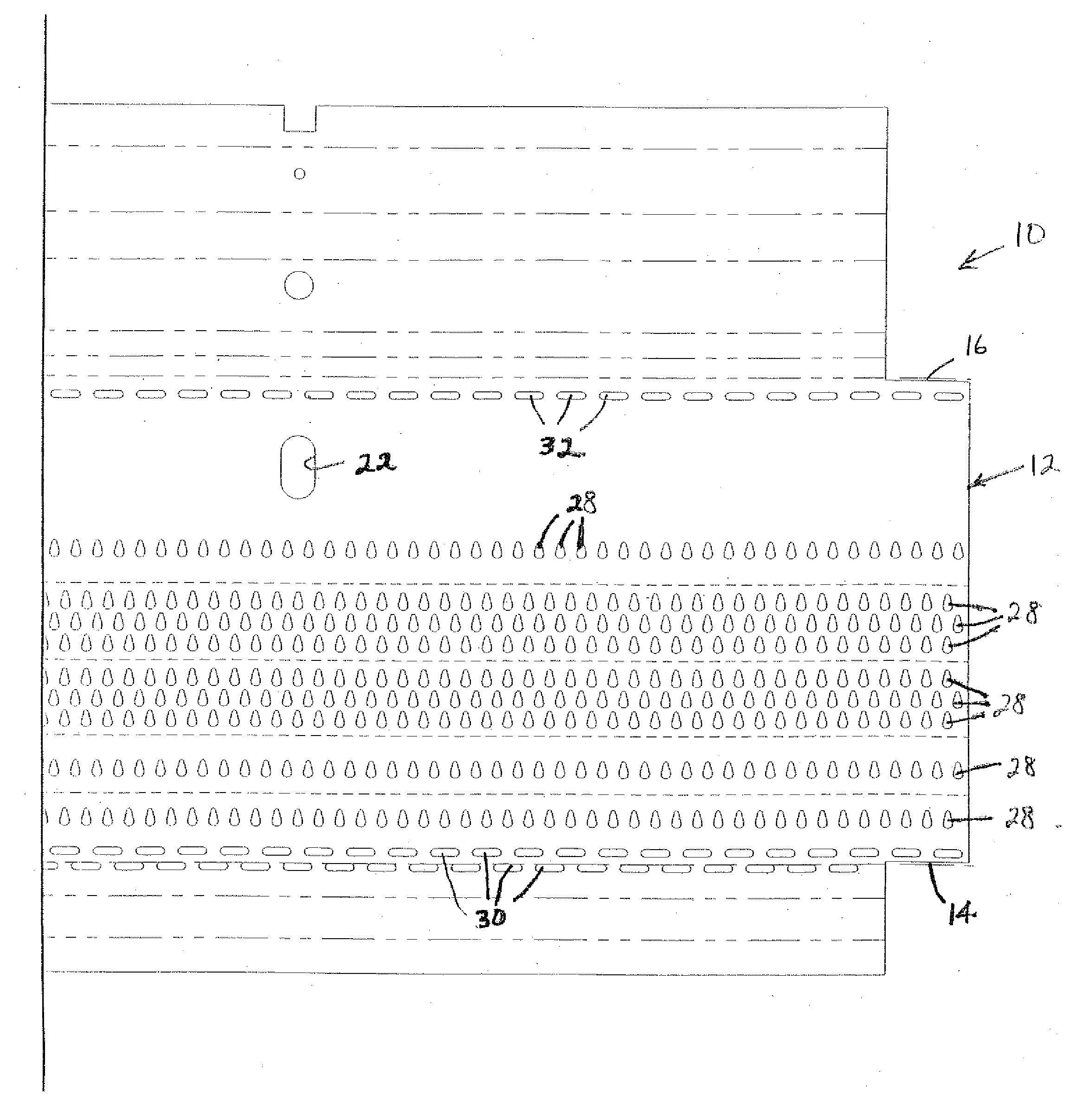

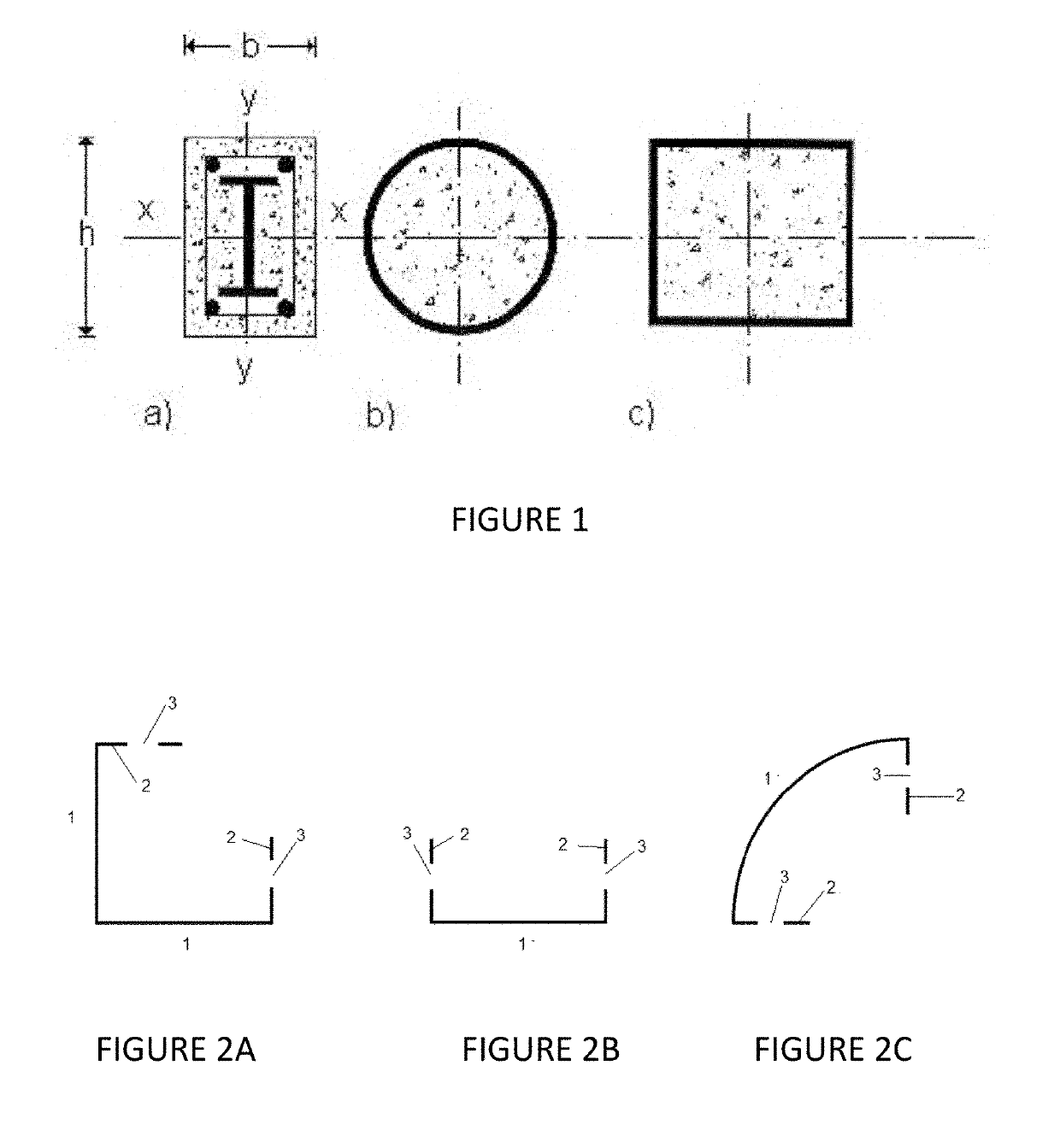

C-sections and composite decks formed by cold-formed sheets for a system of composite reinforced concrete columns

InactiveUS20190145102A1Avoid corrosionReduce sheet thicknessStrutsPillarsReinforced concrete columnC sections

The present application relates to reinforced concrete columns classed in the category of reinforced concrete according to the NSR-10 and ACI-318 standards, in which the tubular channel is formed by sections with cold-roll sheets (CR) which form C-sections with a core and at least on skid which projects into the inner space of the column, coming into contact with the concrete. The skid comprises along its length a series of perforations through which concrete can pass, allowing a composite column to be formed once the concrete has set, in which steel and concrete work together and mutually strengthen their qualities to such an extent that the thickness of the sheet can be reduced, rendering the product economically viable. Moreover, the invention relates to the composite deck comprising these C-sections and a concrete core confined in the inner space of the tubular channel.

Owner:SOLUCIONES E INNOVACIONES ESTRUCTURALES S AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com