Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "C sections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continued. Although C-sections can offer conveniences, they also carry risk. "Women really need to understand that a C-section is major abdominal surgery," says Jan Kriebs, a certified nurse mid ...

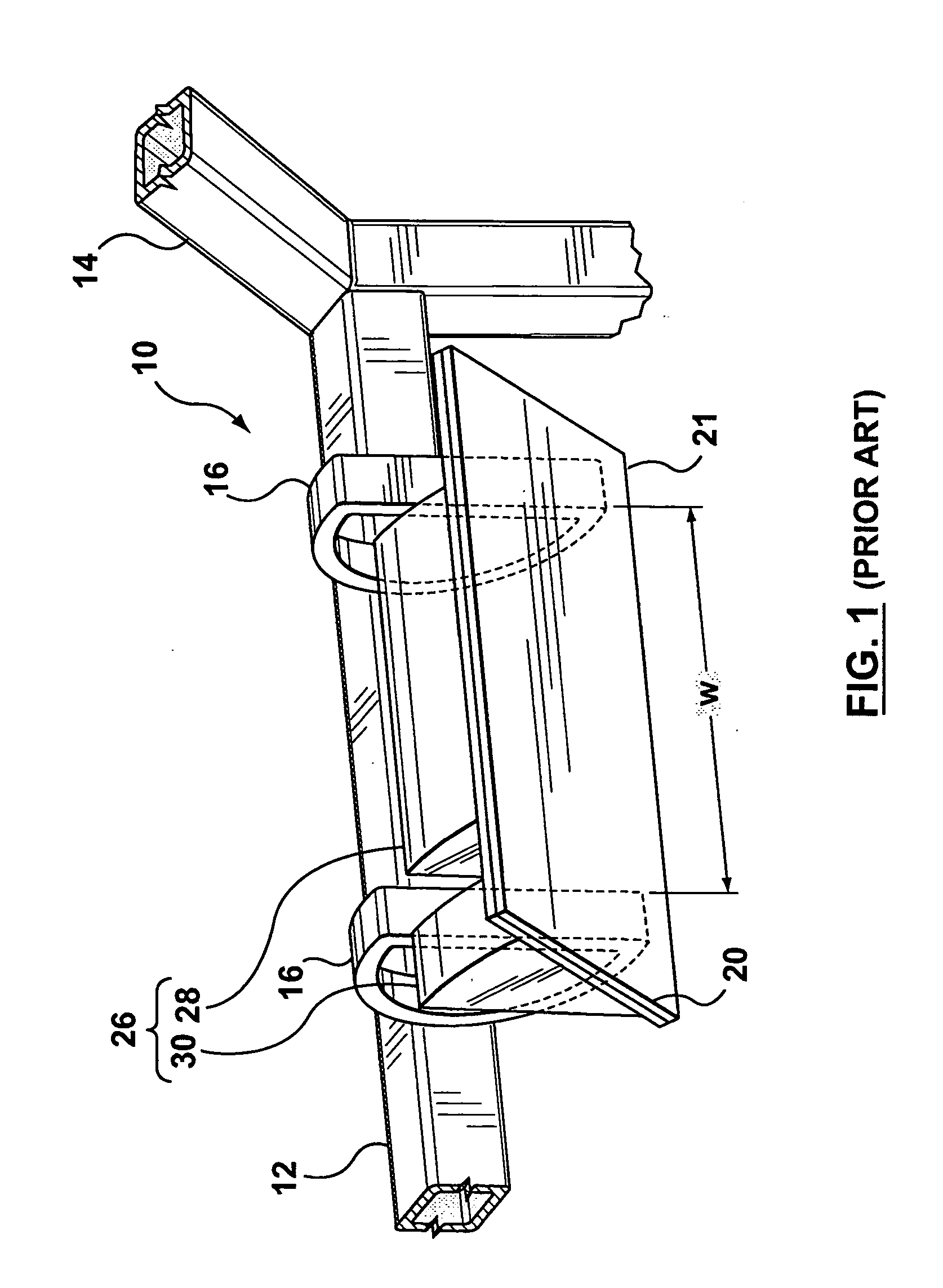

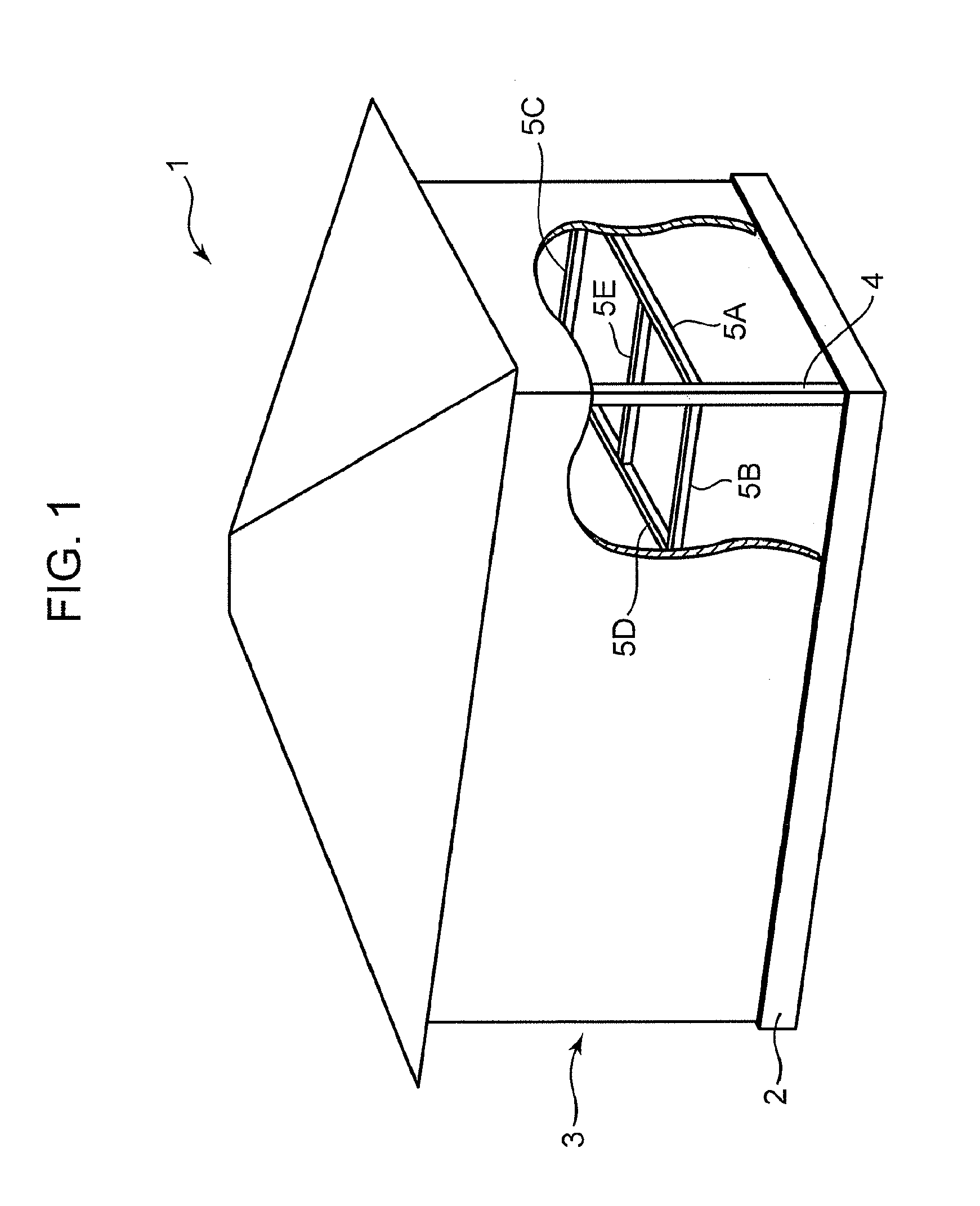

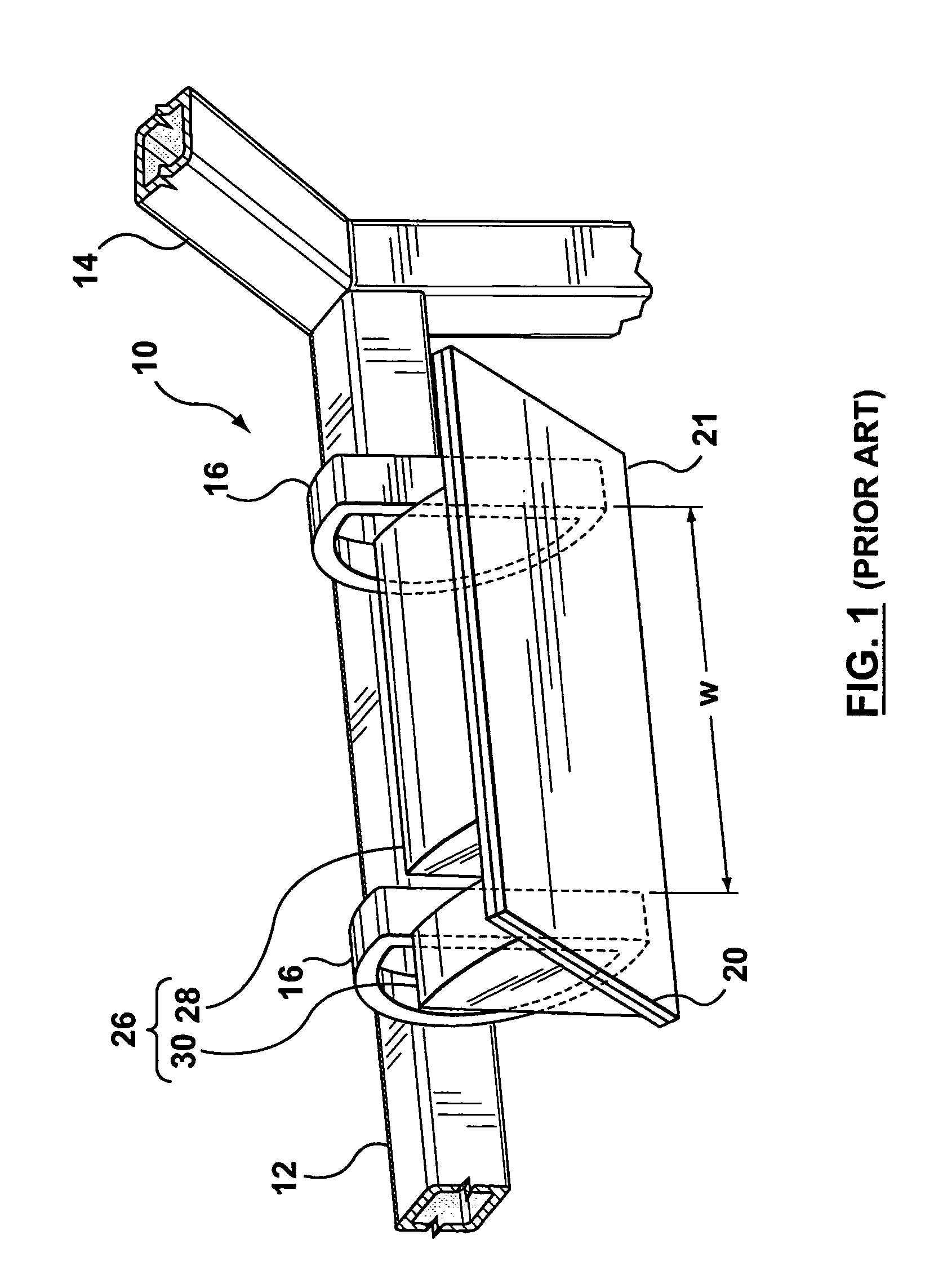

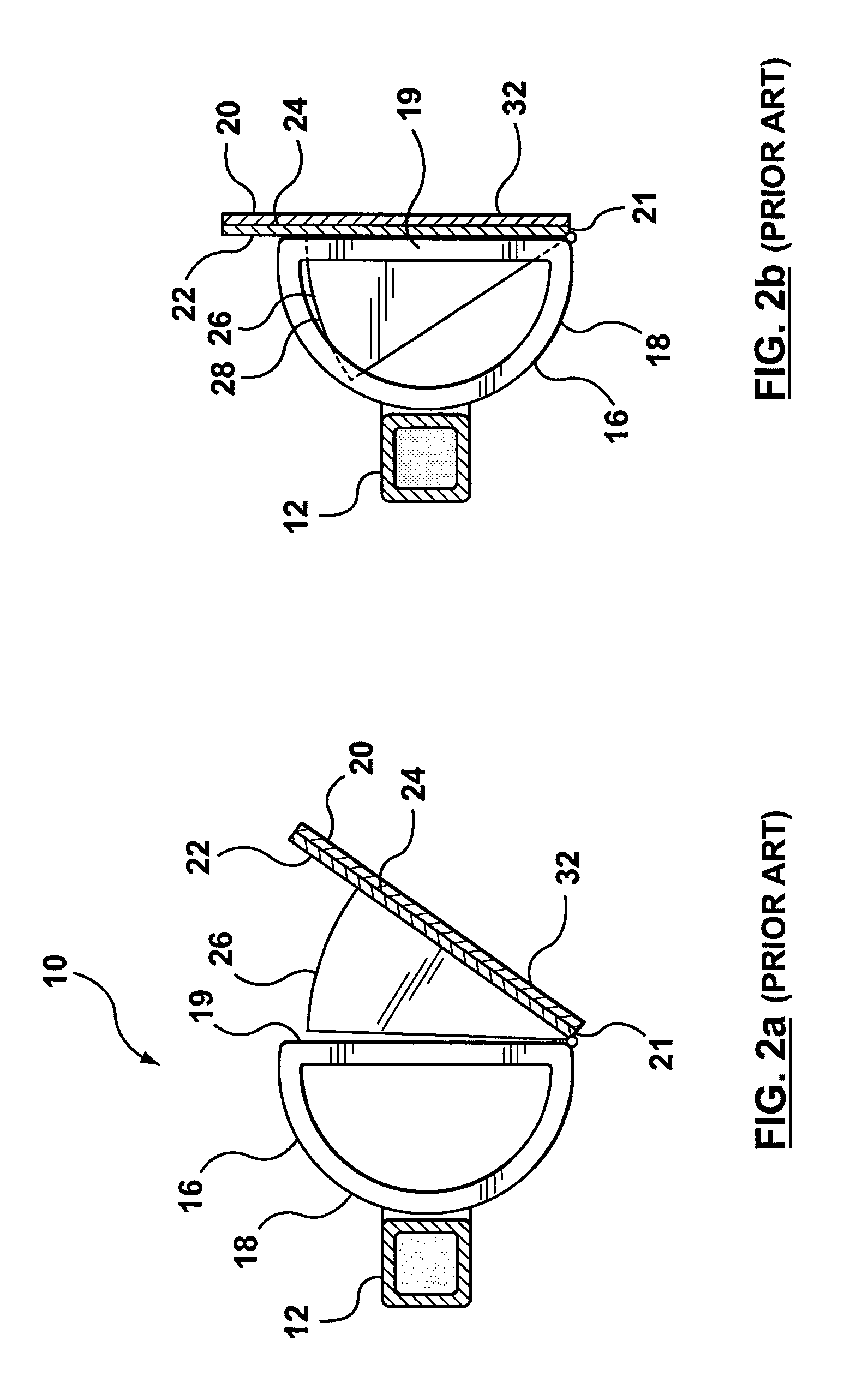

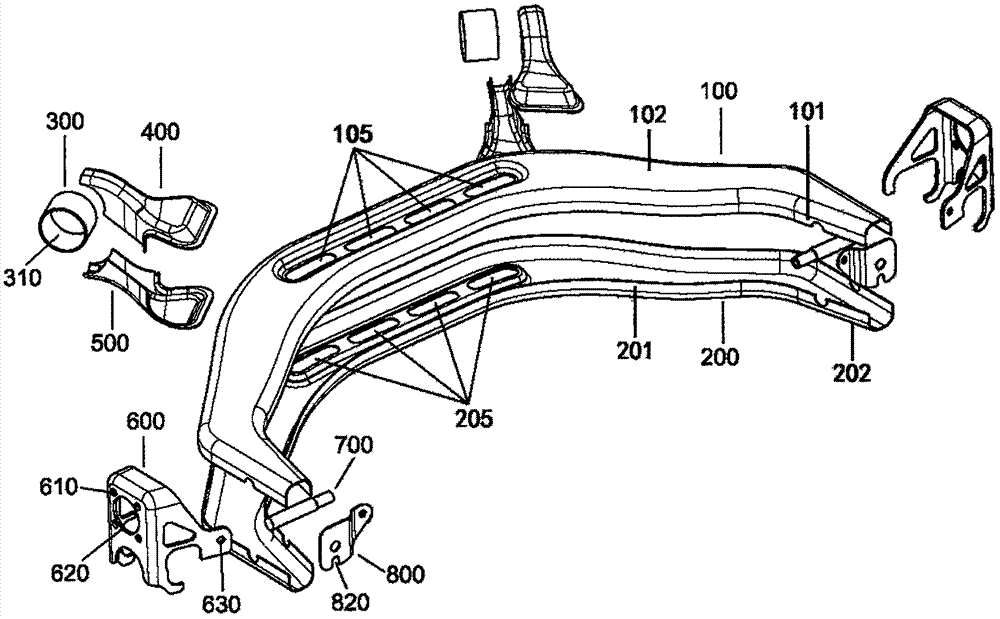

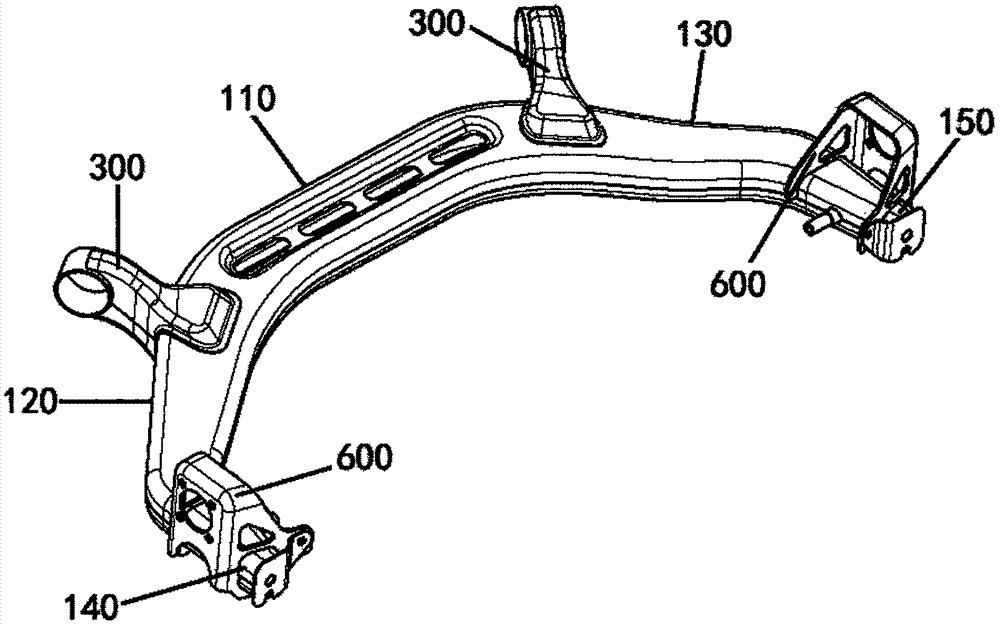

Instrument panel subassembly including a glove box door

An instrument panel subassembly for use in an instrument panel assembly in a motor vehicle is provided. The subassembly includes first and second generally C-shaped energy absorption brackets. The brackets have an aft facing C-section and upper and lower mounting ends. The brackets include attachment means for attaching the brackets to a vehicle structural member. The subassembly further includes a glove box door having an aft surface and a forward surface, and a bin. The glove box door includes hinge means for providing hinged movement of the glove box door relative to the first and second brackets between open and closed positions. The bin is within the C-section of the brackets when the glove box door is in a hingedly closed position.

Owner:ABC GROUP

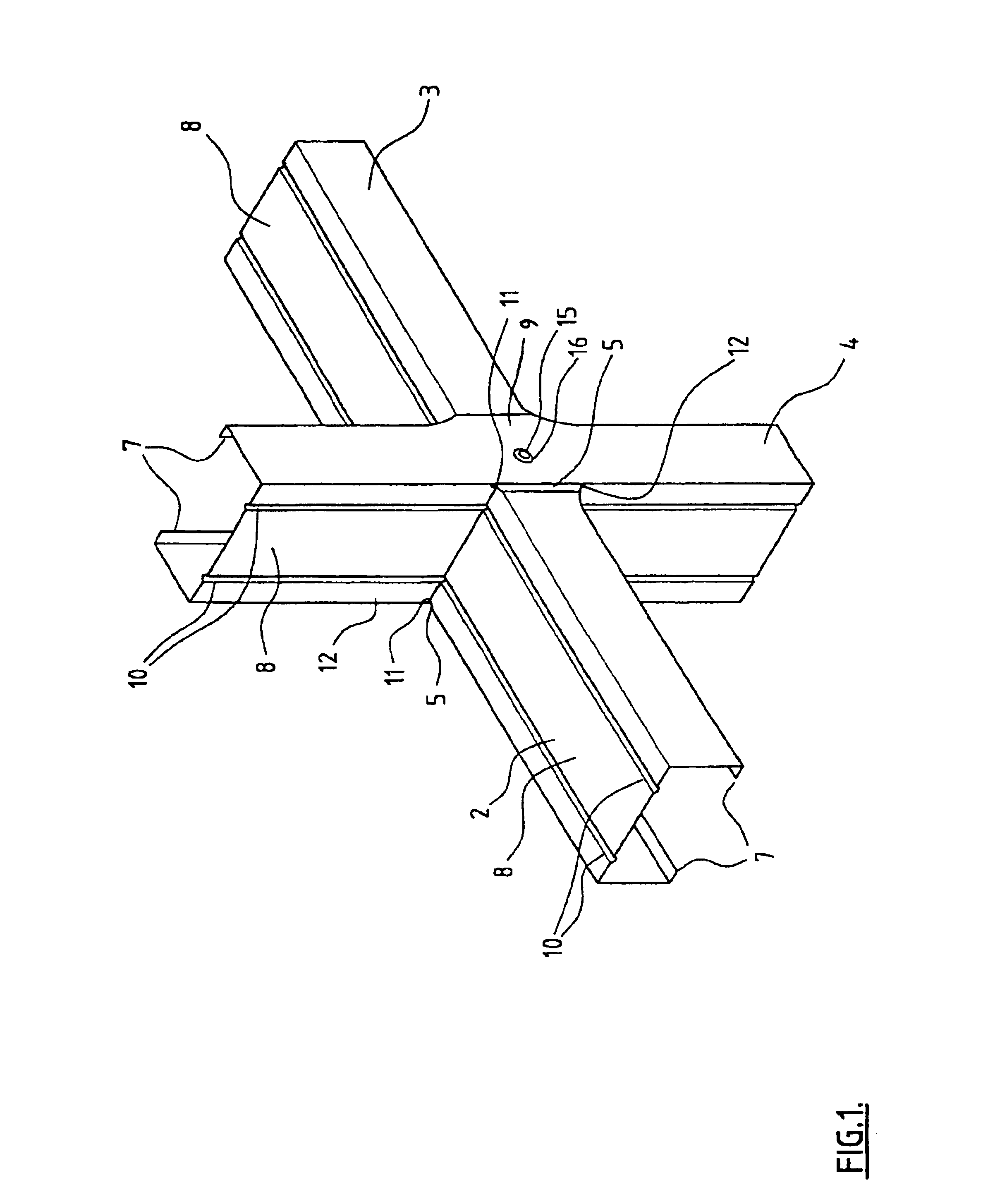

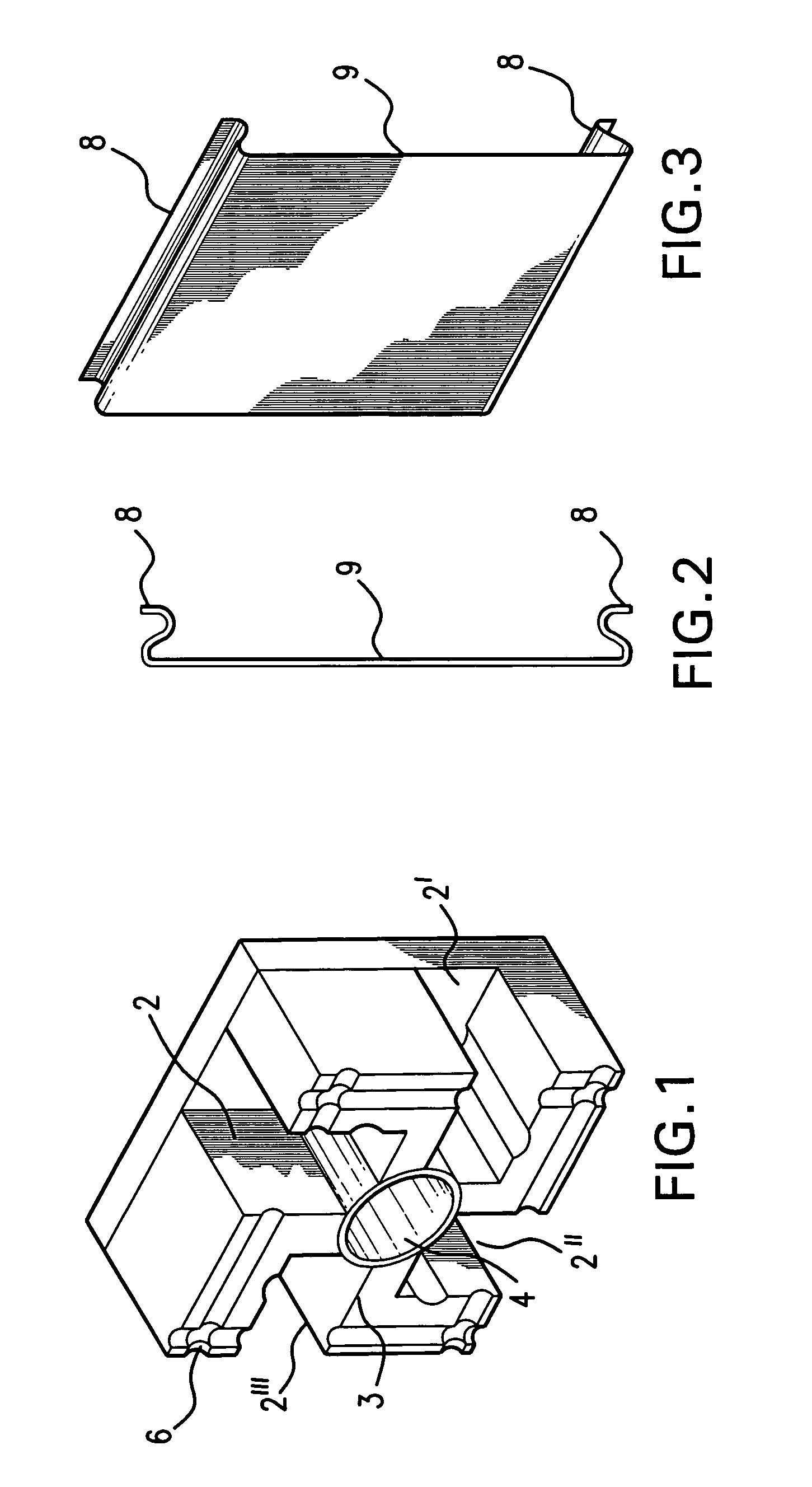

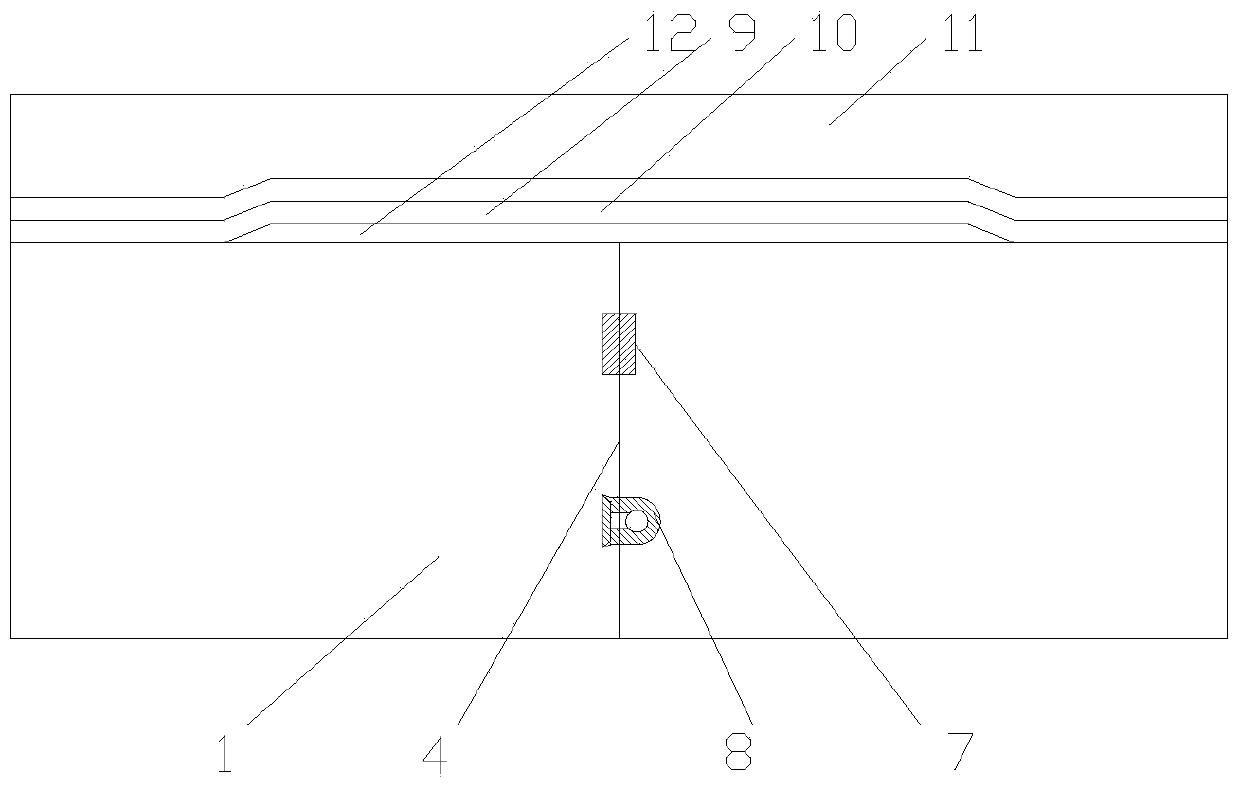

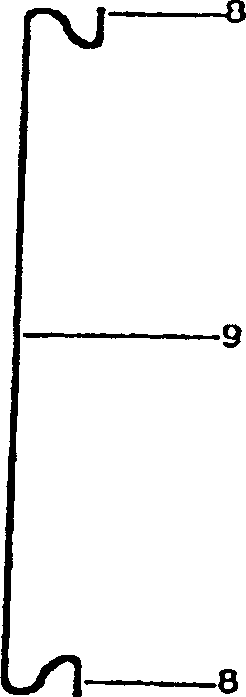

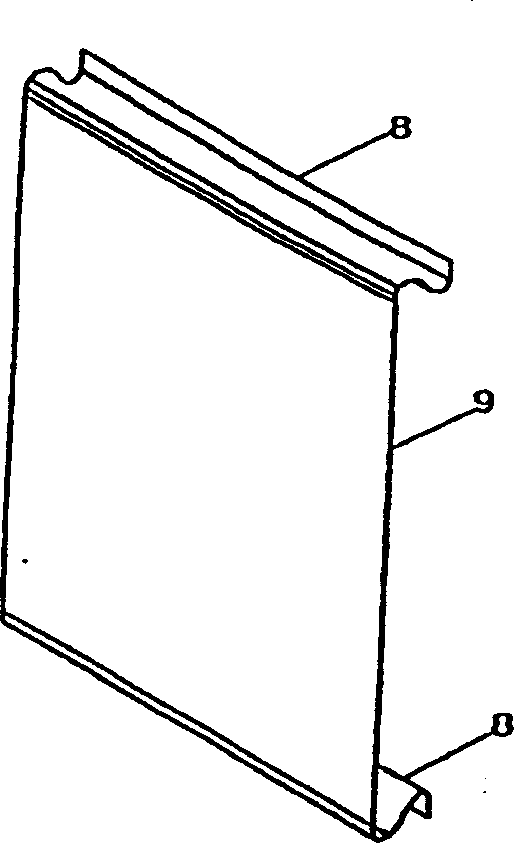

Method of making a frame member into U-section and C-section panel profiles

This invention relates to metal framing (2, 3, 4), in particular steel framing for building construction. The invention also relates to a method of constructing a metal frame assembly (2, 3, 4) and roll forming apparatus (41) for producing metal framing for building construction. The individual components of the metal frame (2, 3, 4), and assembly made from these components is adapted to provide for a substantially even planar surface without deformations, to which a cladding may be attached with a preferred even finish. The invention also includes roll forming apparatus (41) adapted for producing metal framing (2, 3, 4) of this type, and particularly adapted to produce metal frame members (2, 3, 4) having a predominantly C-section profile (7), with one or more portions of a U-section profile (9, 6), the U-section (9, 6) and C-section (7) profiles formed simultaneously on the same sheet metal strip (43). The apparatus (41) is also adapted to form narrowing or swaging of the channel at same or all U-section portions (6). The overall method of constructing a building frame assembly of the invention includes recording data defining a unit area in which a frame assembly is to fit, processing the data to design a frame assembly to fit that unit area, and controlling operation of roll forming apparatus (41) by a computing means using the processed data, to produce frame members (2, 3, 4) cut and formed ready for assembly to produce the required design of frame assembly.

Owner:FRAMEMAX INC

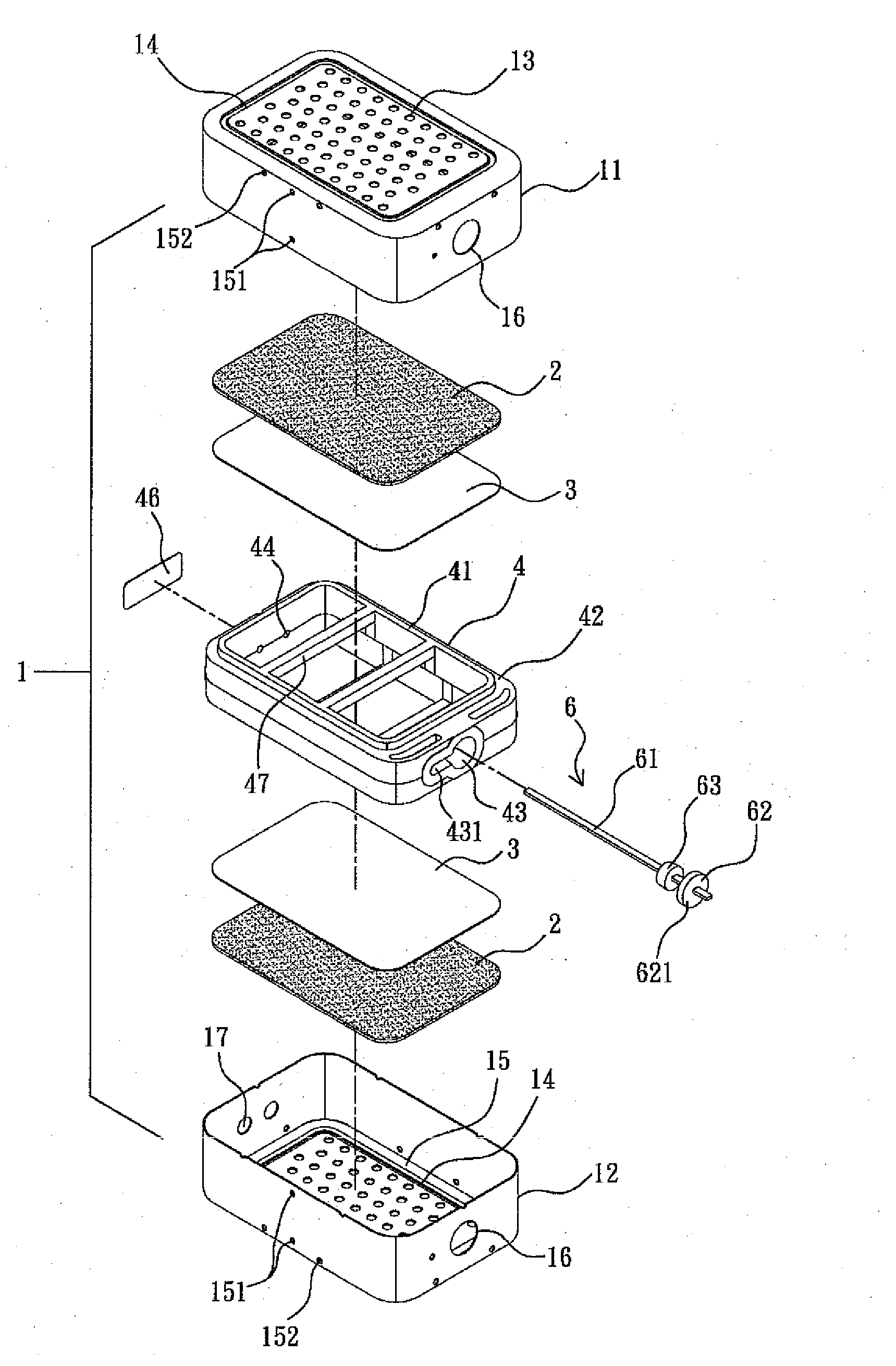

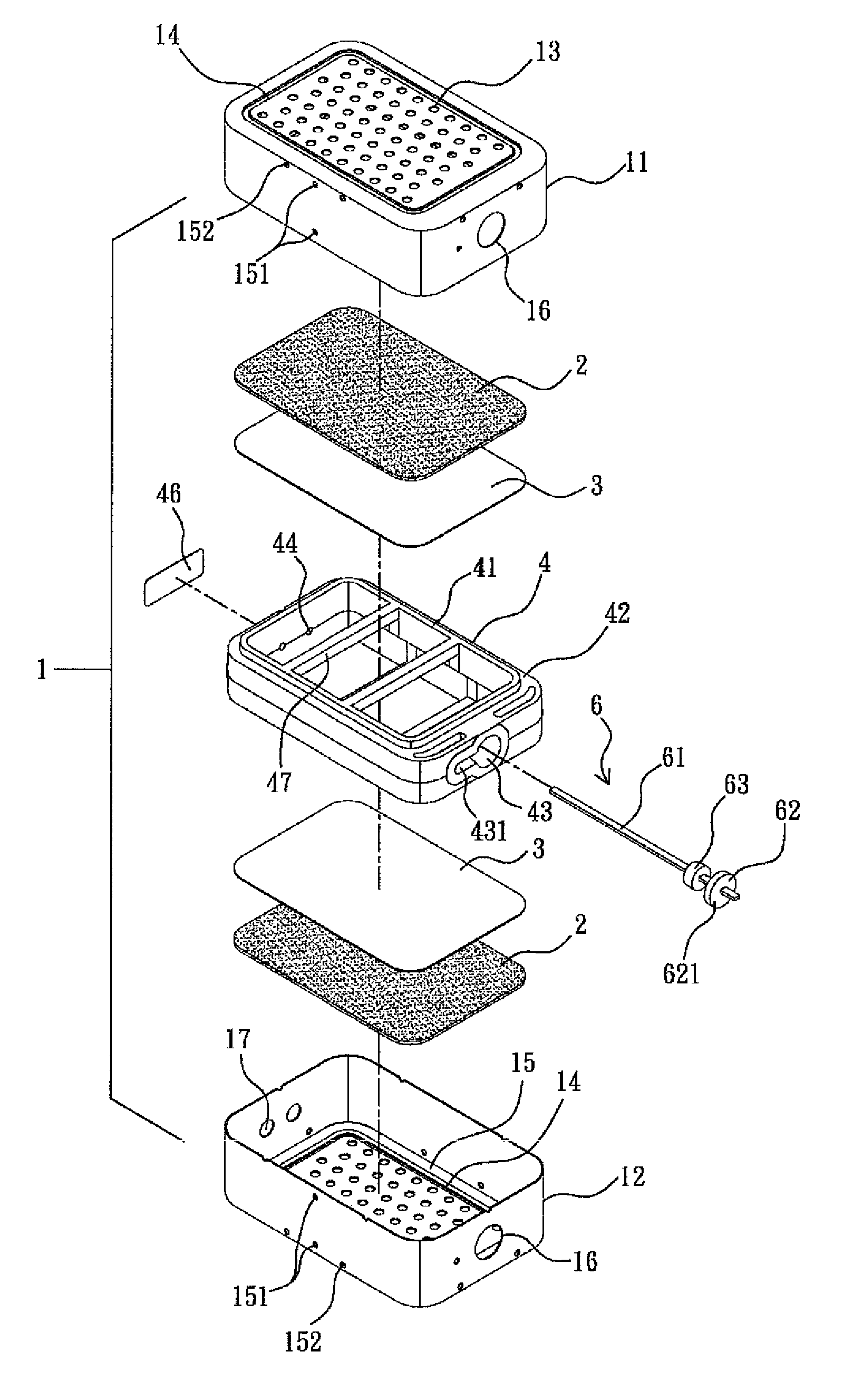

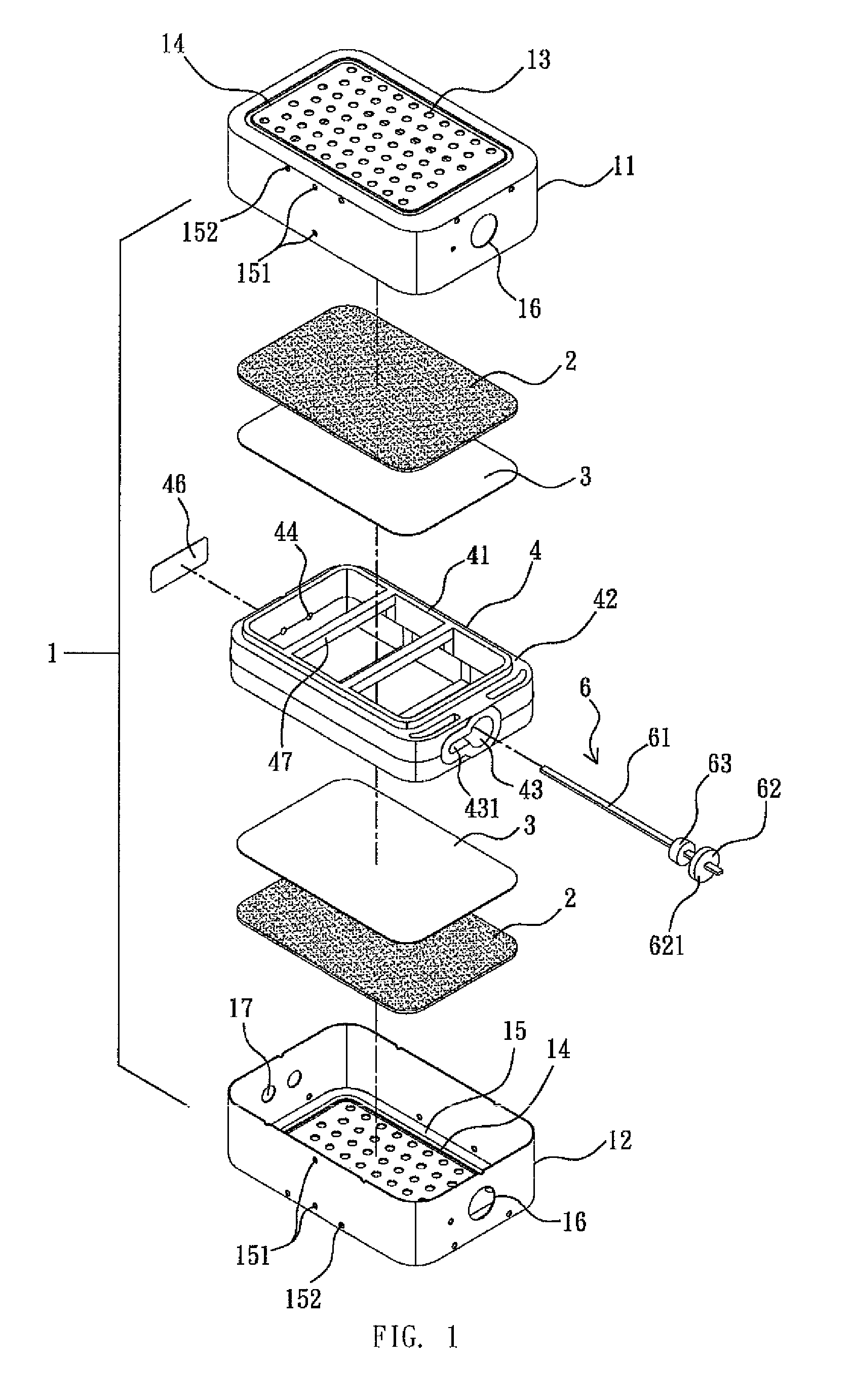

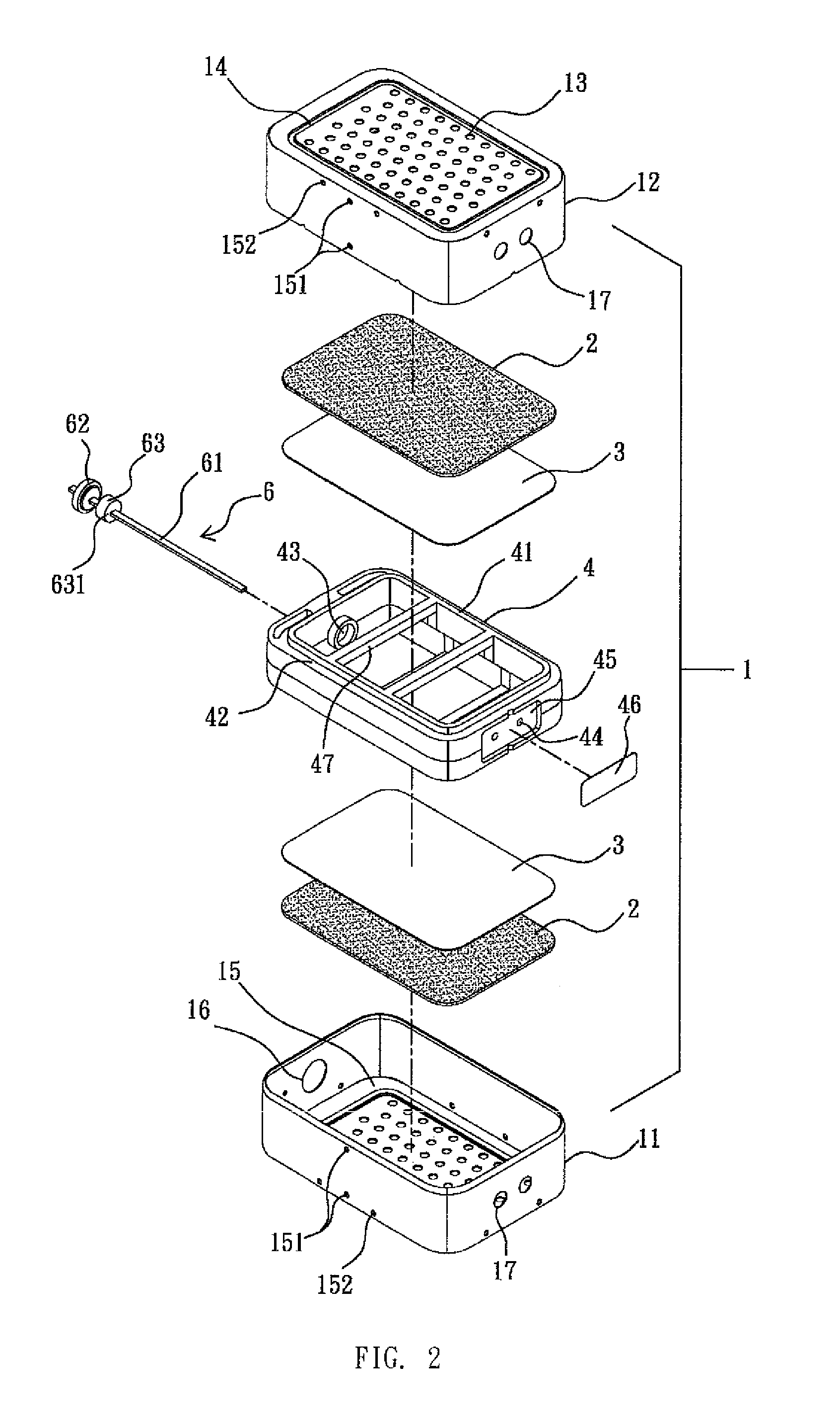

Packaging structure of low-pressure molded fuel cell

InactiveUS20100173206A1High viscosityIncrease elasticityFuel and primary cellsFuel cells groupingC sectionsFuel cells

A packaging structure of a low-pressure molded fuel cell comprises a hot melt adhesive layer, which is formed through a low-pressure molding process using a hot melt adhesive that has specific material properties and will become molten when being heated. The molten hot melt adhesive is injected into the cell via injection holes formed on a housing or a mounting element to flow through a C-sectioned flow channel, so as to tightly enclose and bond to edges of the air cathode and separator for the cell. After the hot melt adhesive is solidified, a chemical-resistant hot melt adhesive layer with good sealing and enclosing ability as well as high adhesion strength and elasticity, being bubble removed at controlled pressure and the hot melt adhesive material is formed to firmly bond to the cell components and tightly seal the cell, so as to effectively prevent electrolyte in the cell from leaking.

Owner:HIGH TECH BATTERY INC

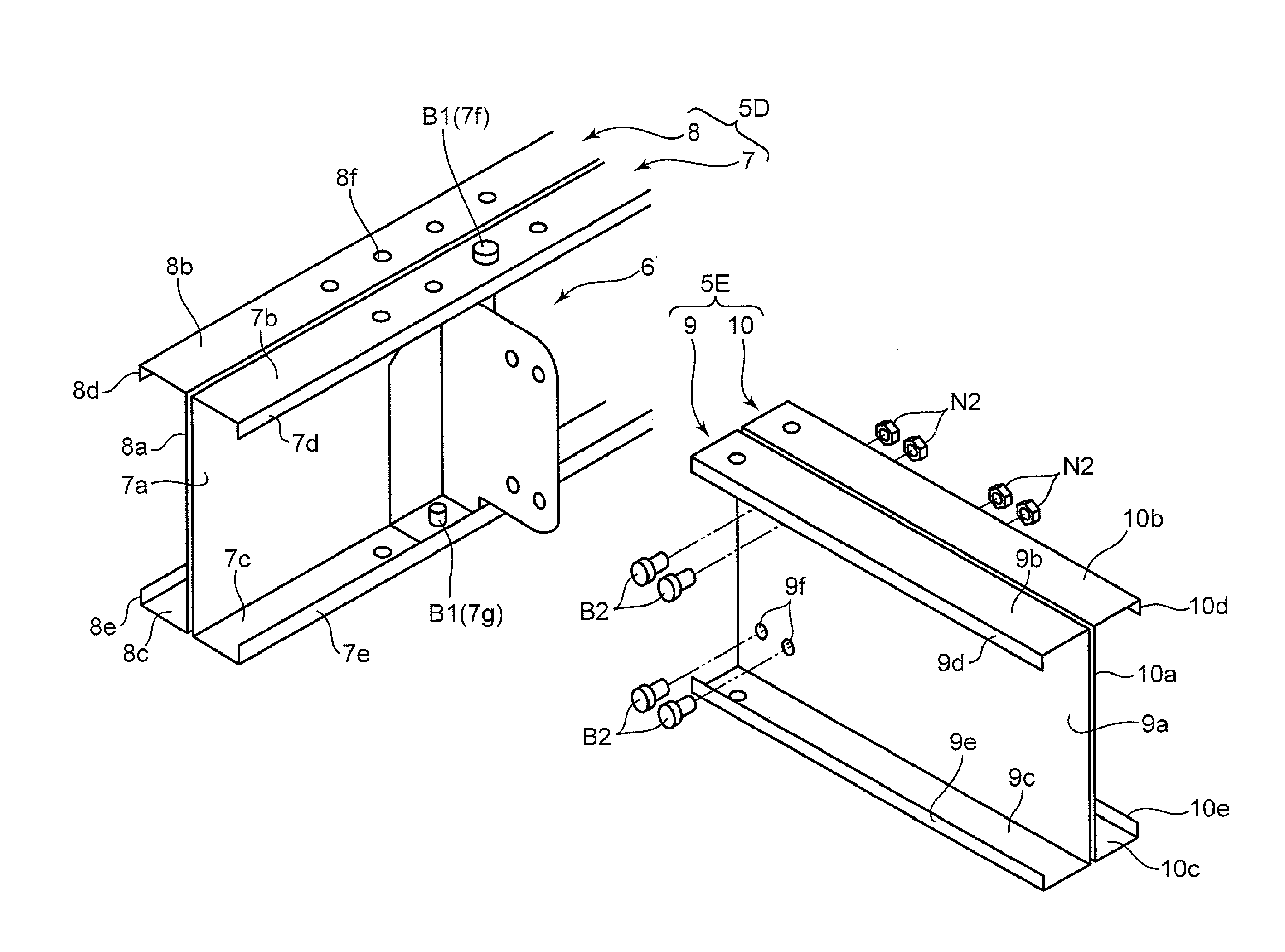

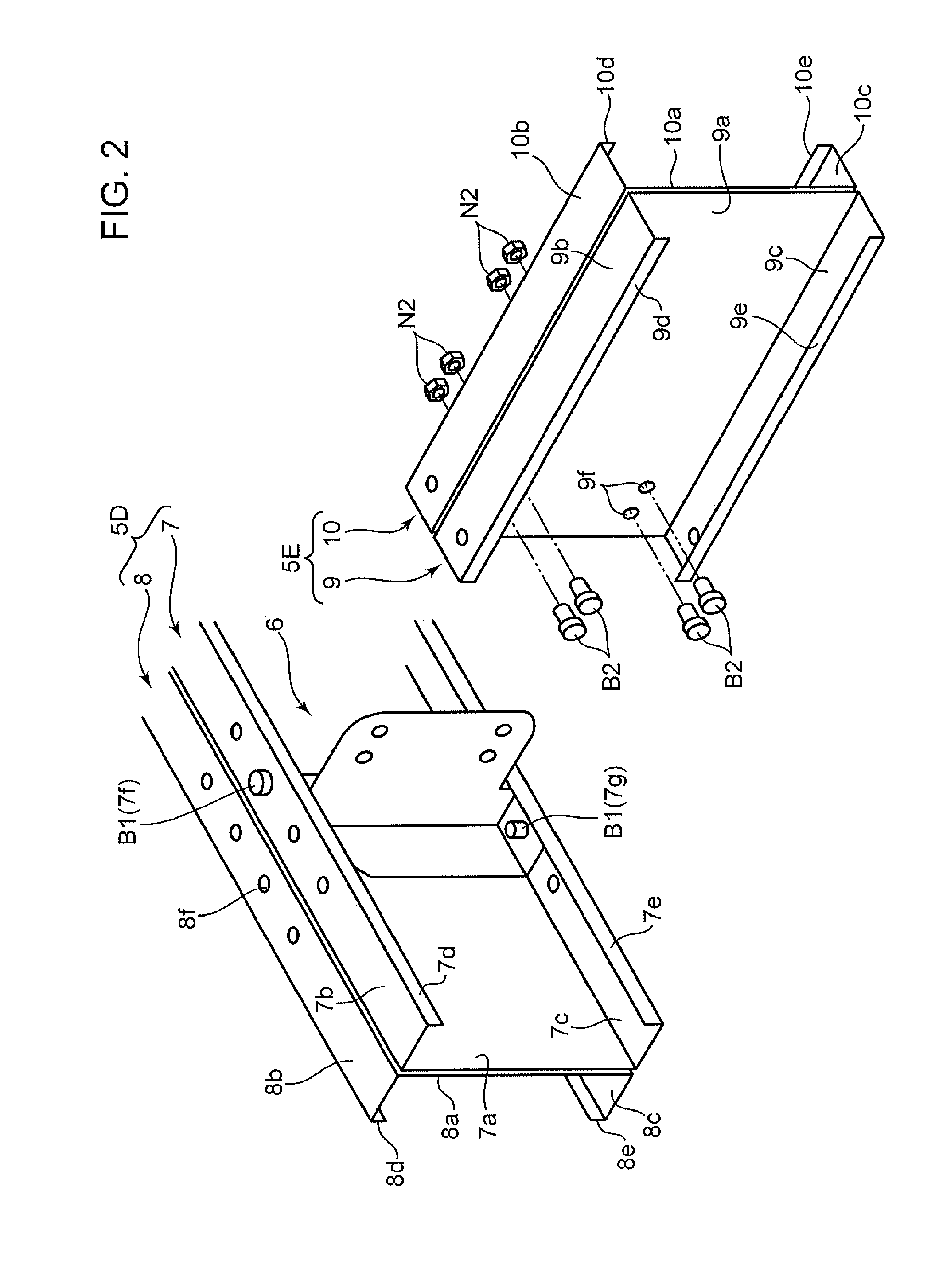

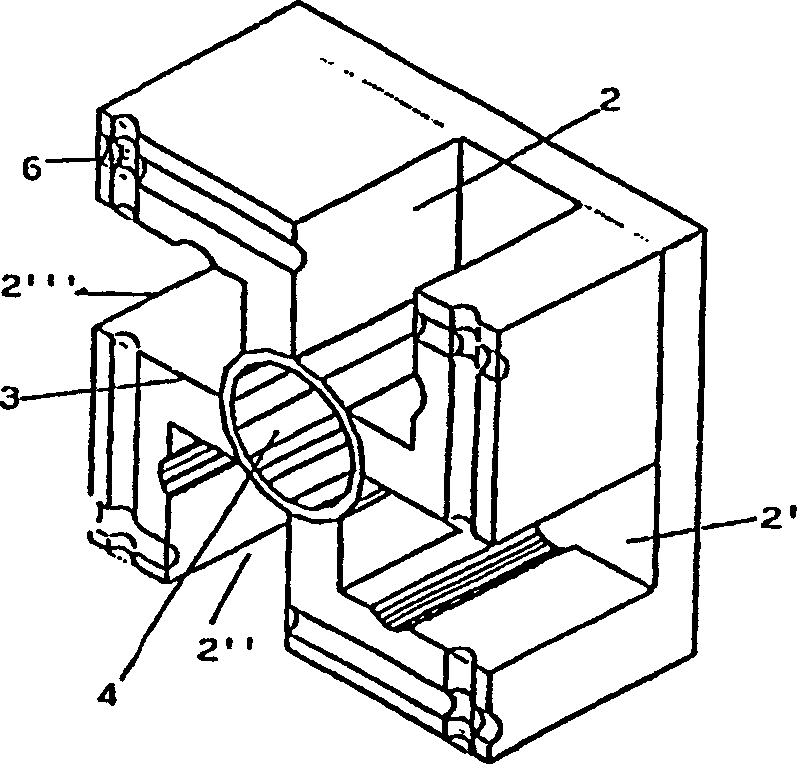

Connecting fitting, frame provided with same, and building using frame

The connecting fitting comprises a band-like section 14 and a back plate 11 that can be inserted between the flanges 7b, 7c by passing between lips 7d, 7e, in an insertion attitude, and a joining section 15 that can join a beam 5E in a state where the band-like section 14 and the back plate 11 are inserted between the flanges 7b, 7c. The band-like section 14 has a pair of abutting sections 14b, 14c that can abut respective inner surfaces of both flanges 7b, 7c of a C-section steel 7, in an attachment attitude resulting from rotation from the insertion attitude by a predetermined angle.

Owner:NIPPON STEEL CORP +1

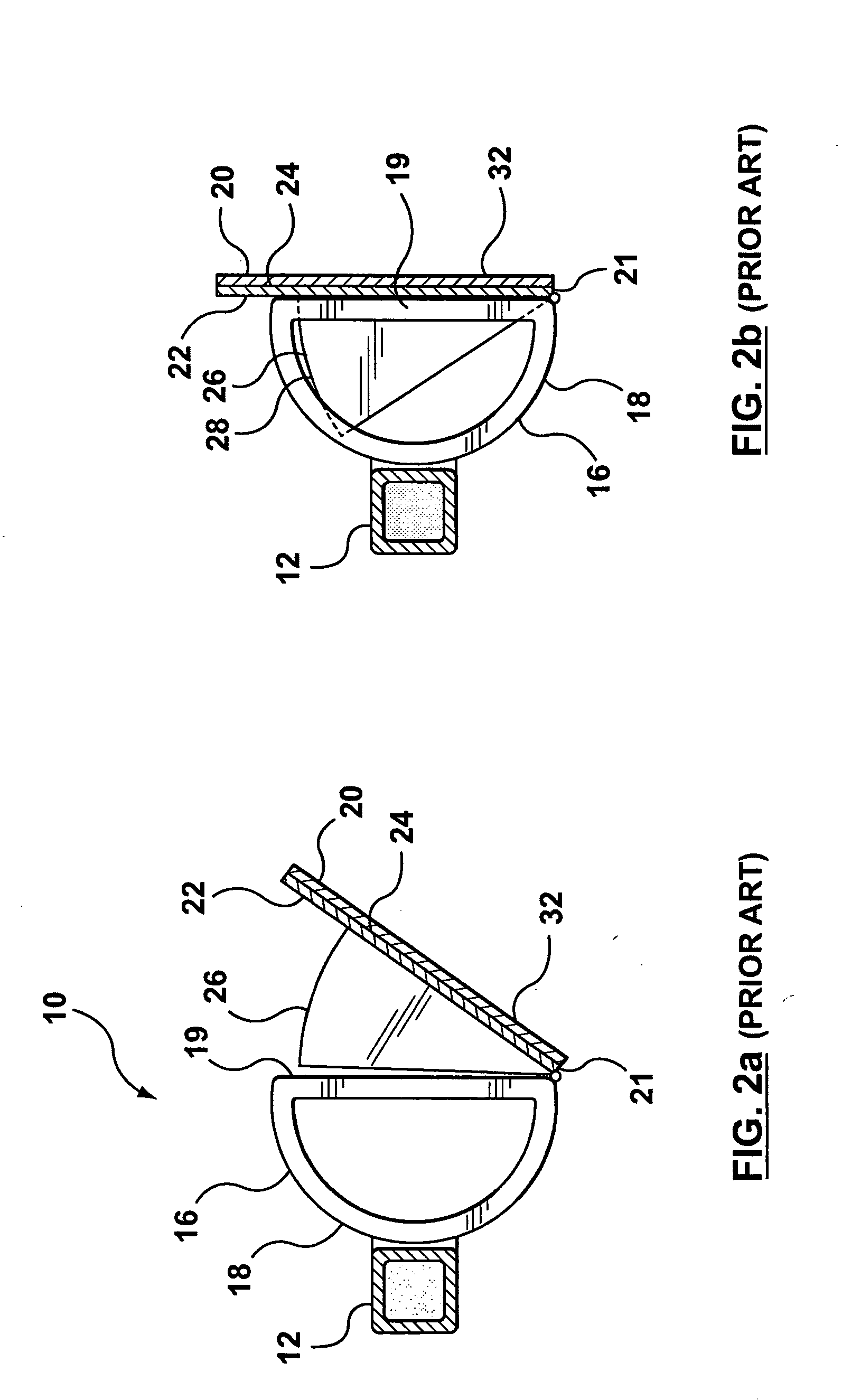

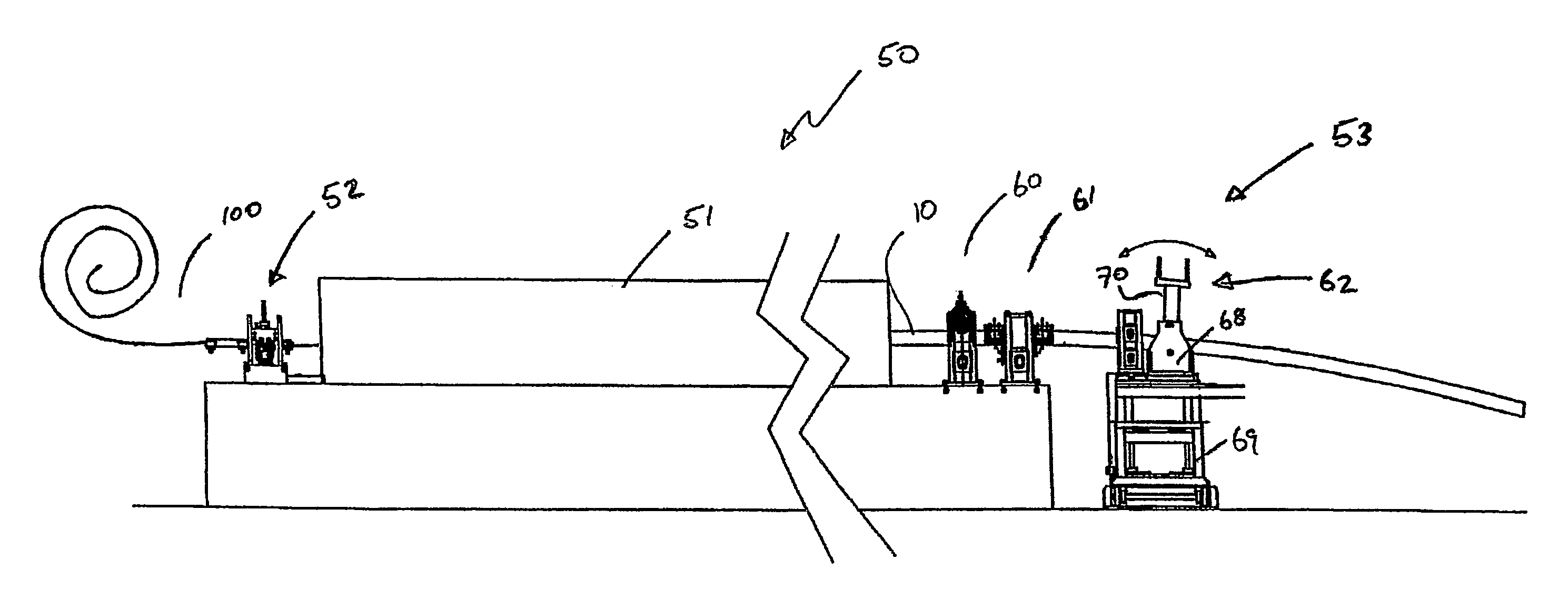

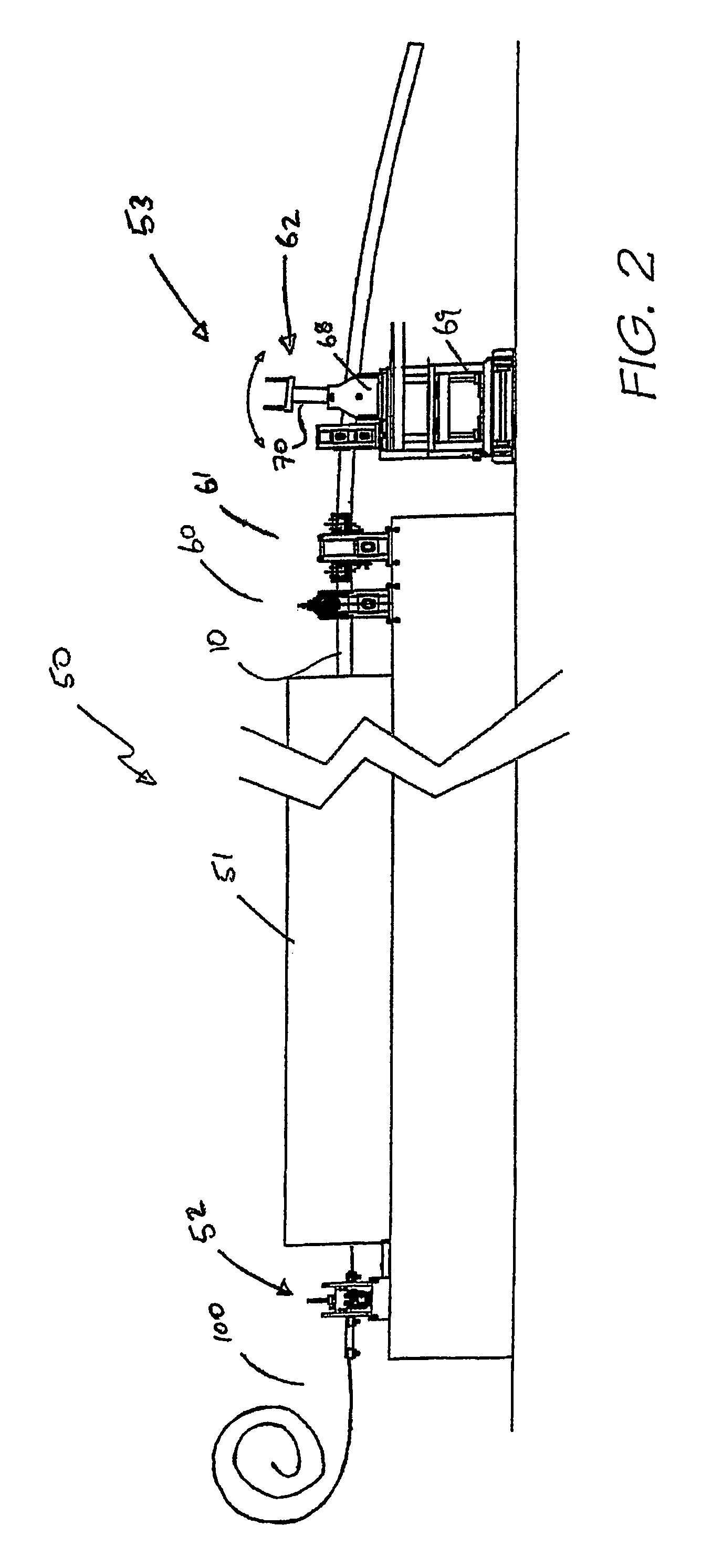

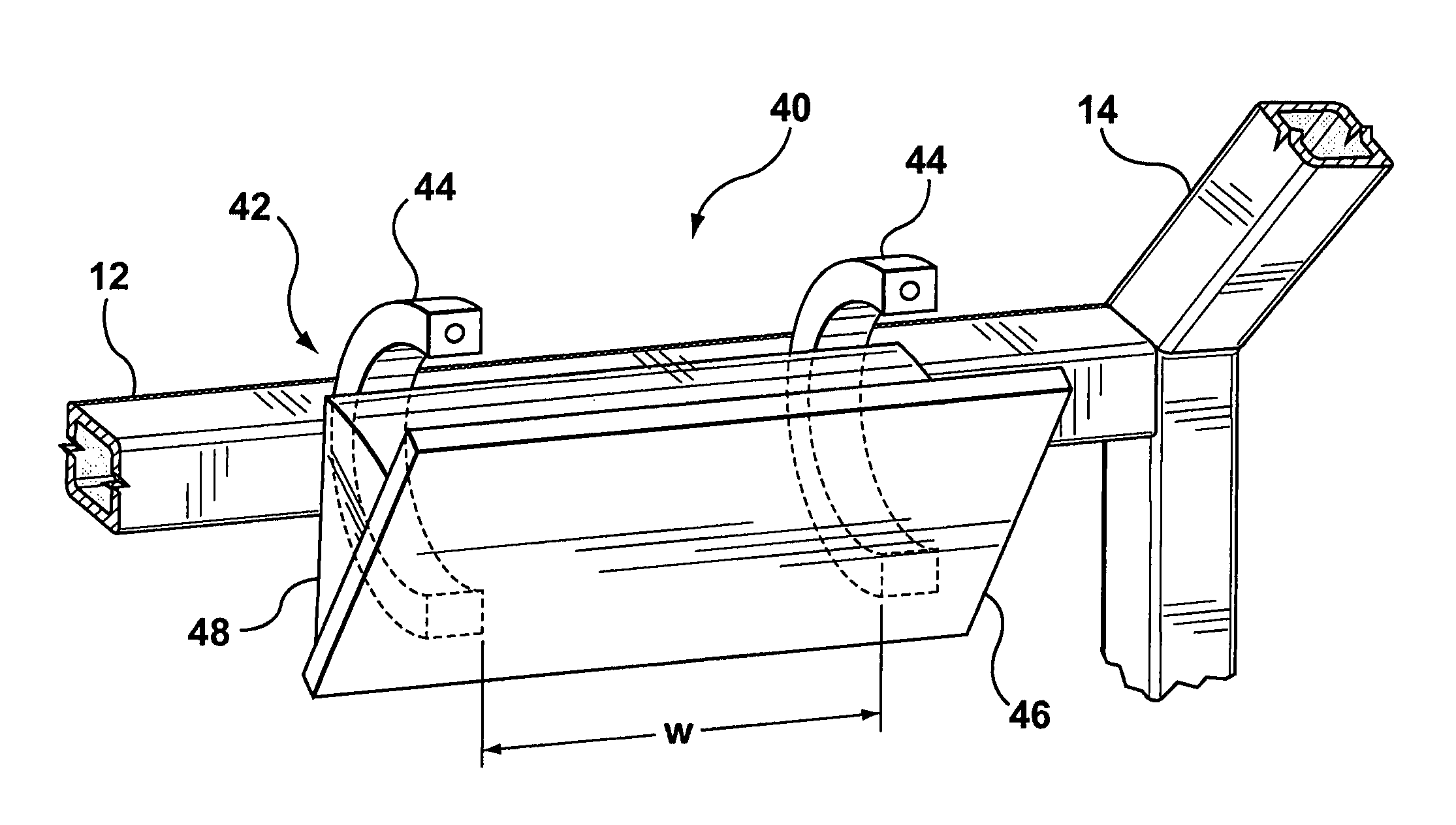

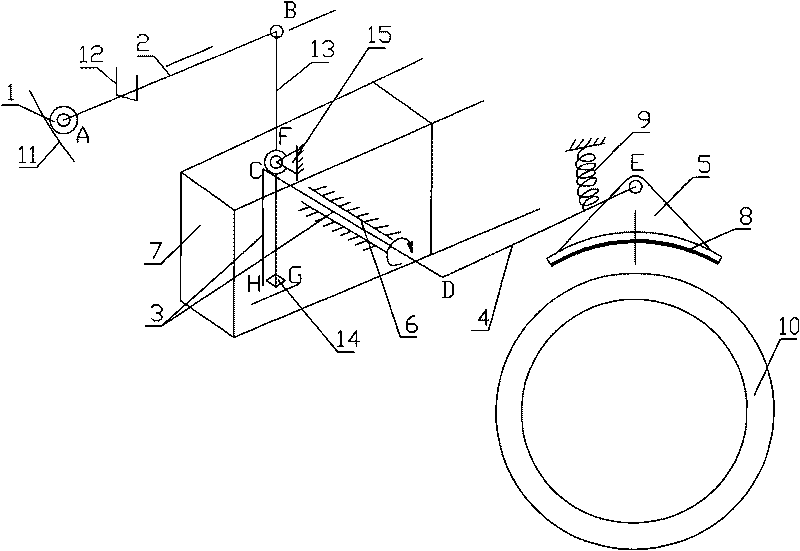

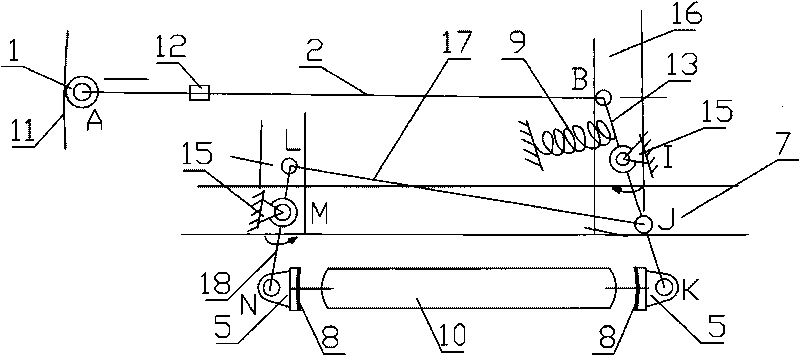

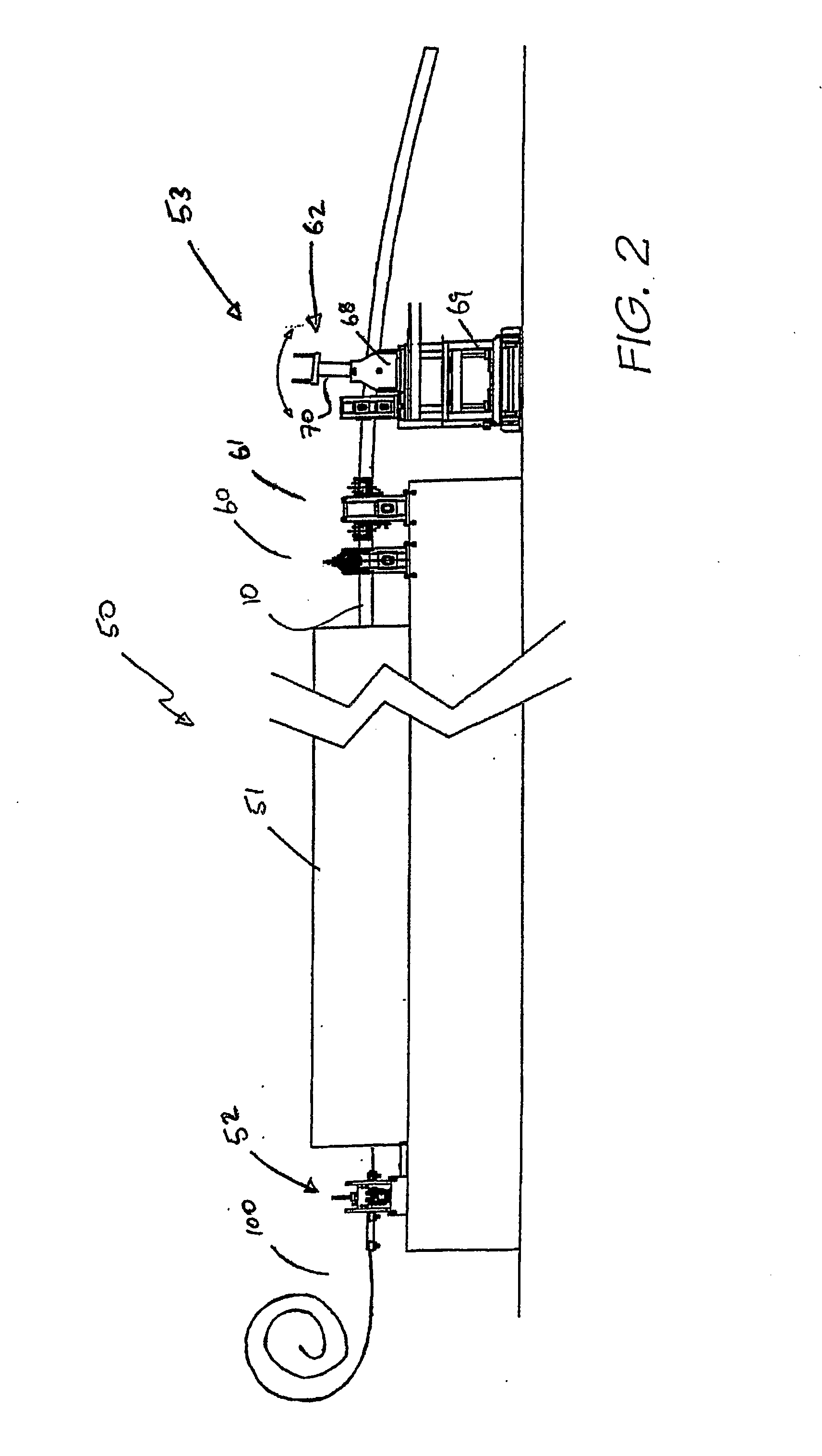

Forming apparatus for precambered metal sections

InactiveUS7310984B2Easy to introduceIncrease the areaShearing machinesMetal working apparatusC sectionsMechanical engineering

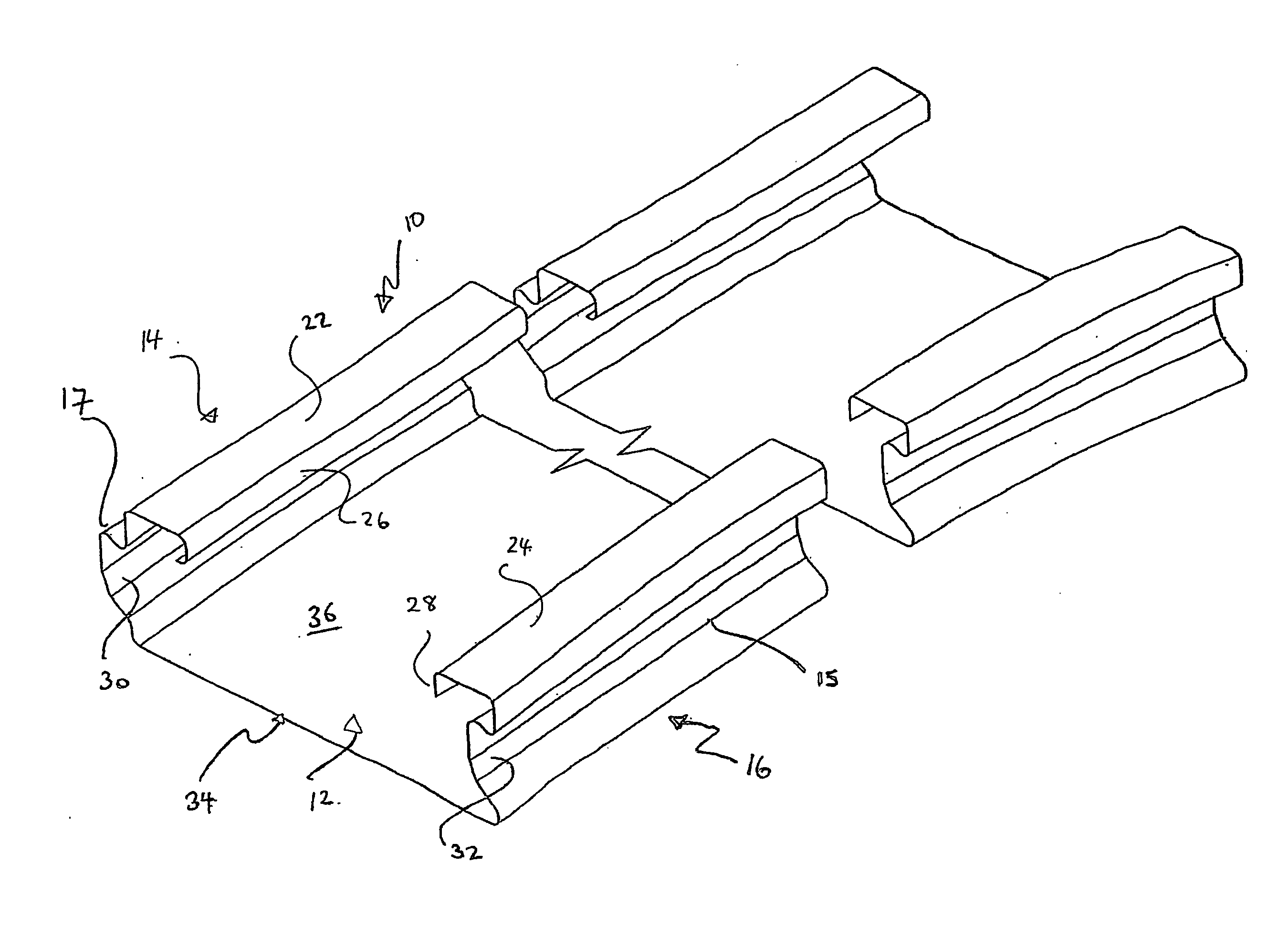

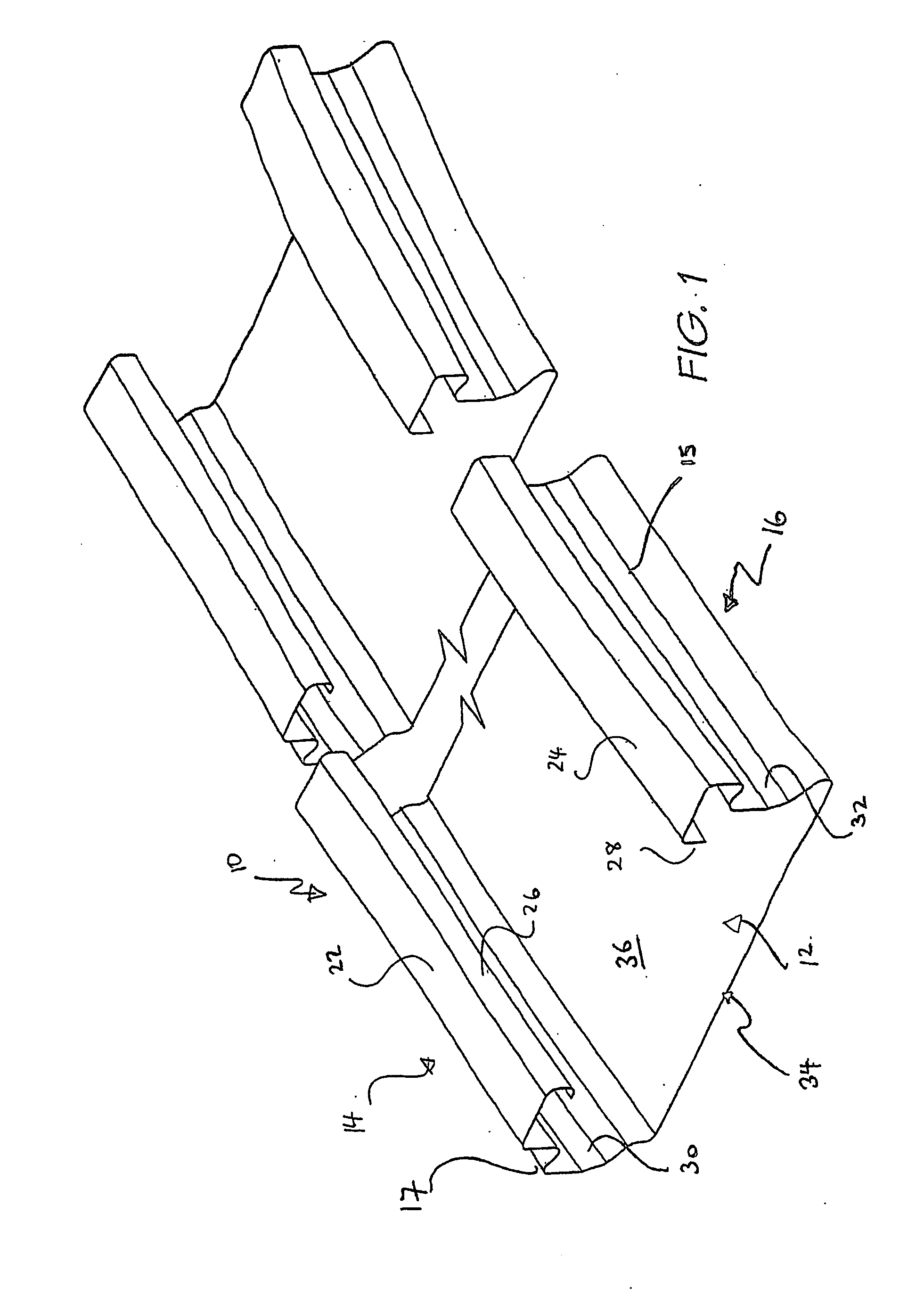

A forming apparatus (50) includes a roll former (51) operative to roll form a metal strip (100) to form a profiled metal section (10) of generally C section profile including a pan (12) and a pair of upstanding edge margins (14 and 16). The section profile incorporates a longitudinal precamber which is introduced by the forming apparatus by incorporating a prestretching apparatus (52) upstream from the roll former (51), and a bending apparatus (53) located downstream of the roll former (51). The prestretching apparatus differentially stretches the metal strip (100) in its longitudinal direction so as to form portions (101, 102), which are more elongated than a laterally adjacent portion (103) of the strip (100). The differential stretching compensates for longitudinal shortening of the metal strip in forming the profiled section in the roll former (51). The bending apparatus (53) uses a (3) point bending process and includes a reaction stage (60), a fulcrum stage (61), and an action stage (62). The action stage (62) which induces loading onto the profiled section (10) so as to bend the section about the fulcrum stage (61) is incorporated with the shearing assembly. A method of forming a metal section from sheet metal strip is also disclosed. In a further aspect a shearing assembly is disclosed which is height adjustable and which also includes a cutting element (77) and shearing block (78) which are pivotally mounted to an assembly frame (74).

Owner:BLUESCOPE STEEL LTD

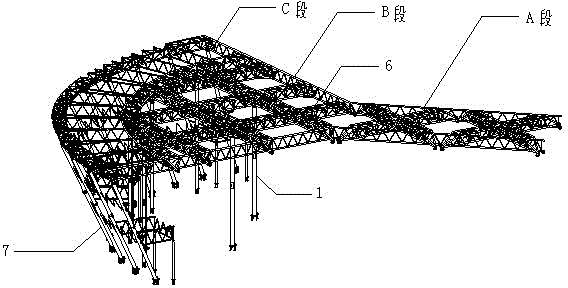

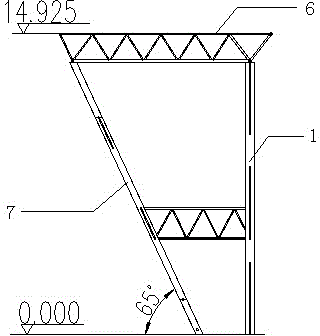

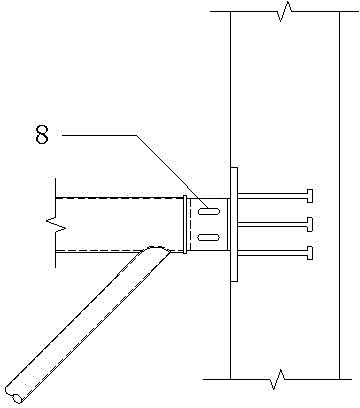

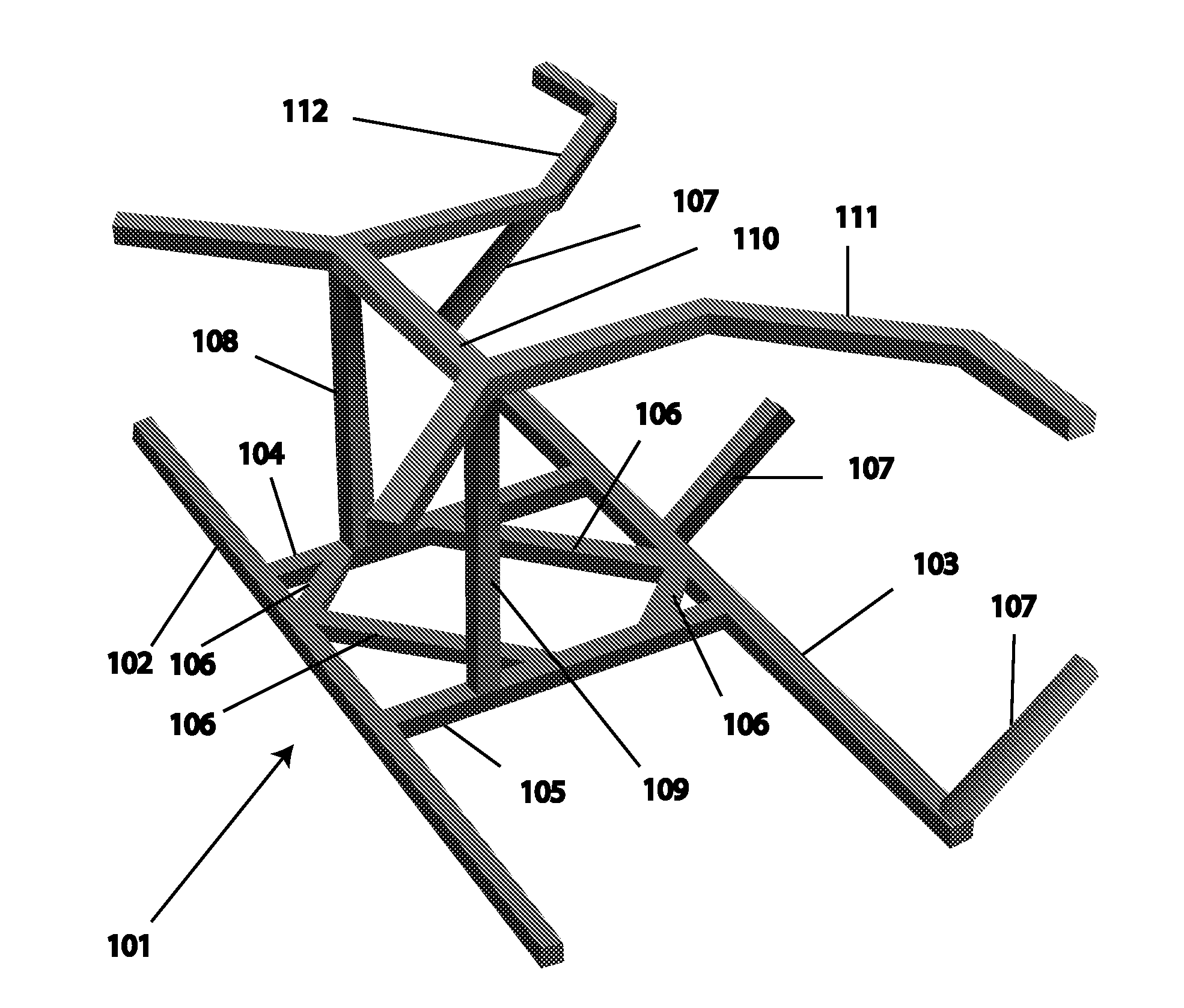

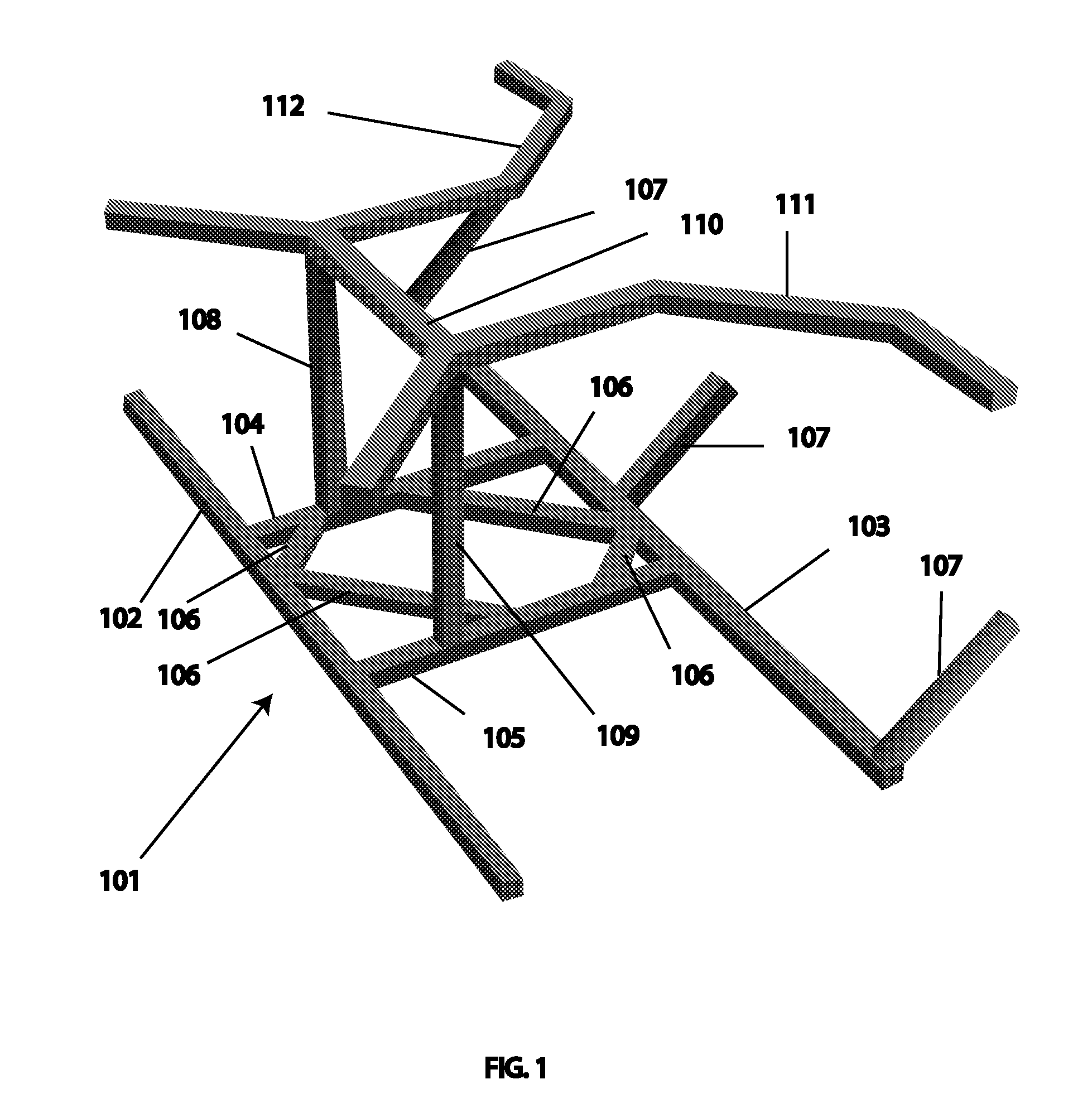

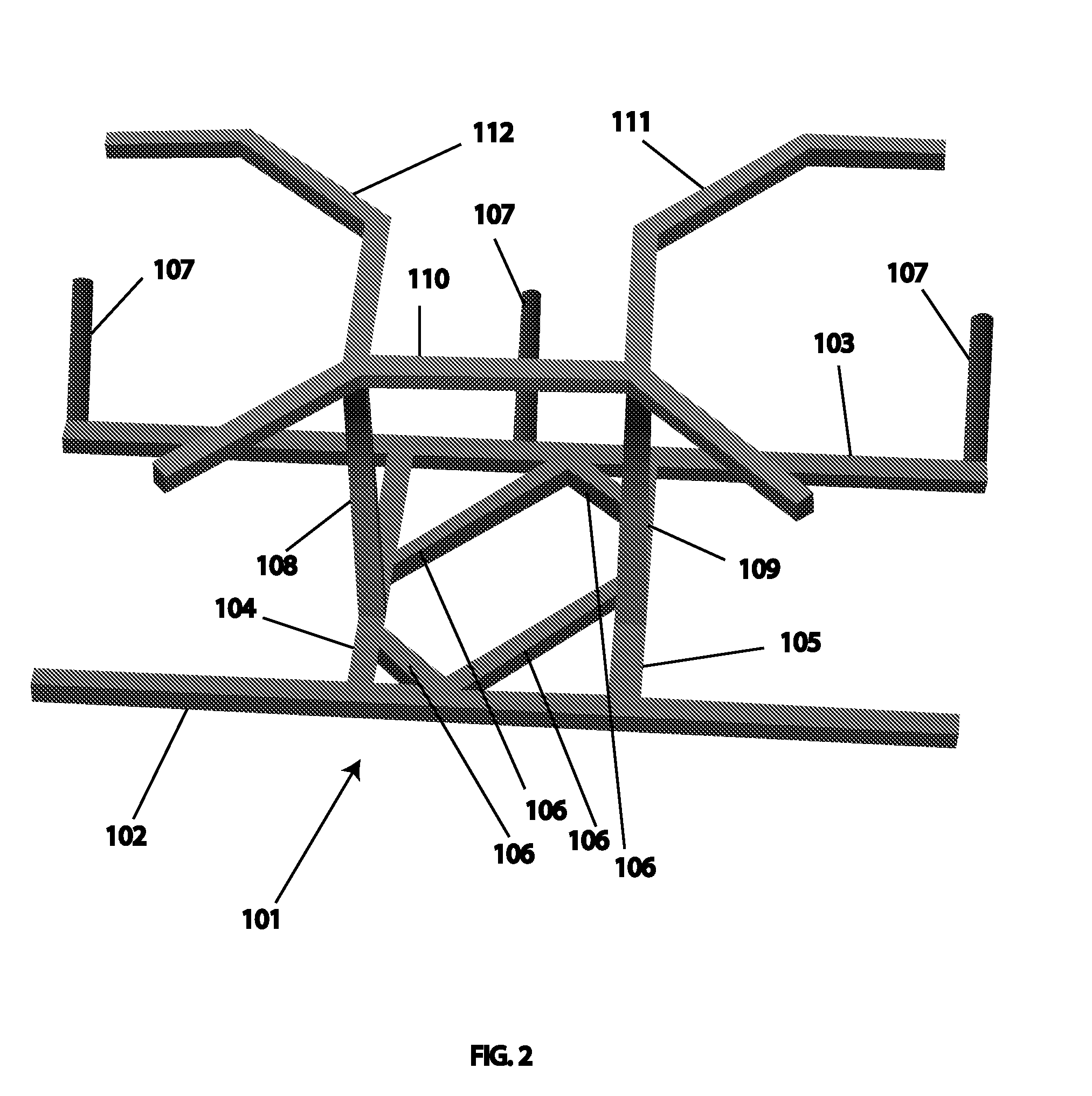

Curved surface space pipe truss structure and mounting method thereof

ActiveCN105780995AAdvantage structureMerit methodBuilding roofsGirdersC sectionsMechanical equipment

The invention relates to a curved surface space pipe truss structure. The curved surface space pipe truss structure comprises a rectangular A section roofing truss frame, a sector shape B section roofing truss frame and a sector shape front C section roofing truss frame and is characterized in that the sector shape B section roofing truss frame is arranged at the middle of the curved surface space pipe truss structure, and a sector handle part of the sector shape B section roofing truss frame is connected with the rectangular A section roofing truss frame; a sector front part of the sector shape B section roofing truss frame is connected with the sector shape front C section roofing truss frame, wherein the rectangular A section roofing truss frame is formed by connecting two crossed truss frames, and the rectangular A section roofing truss frame and the sector shape B section roofing truss frame are supported by a plurality of standing columns (1) which are perpendicular to the ground, and the level elevation of the top of the A section roofing truss frame and the top of the B section roofing truss frame is greater than or equal to 15m; the sector front part is connected with the sector shape front C section roofing truss frame and is supported by the jointed supporting of the standing columns (1) and oblique columns (7). According to the curved surface space pipe truss structure and the mounting method thereof, methods of assembling roof truss frames on the ground and whole-section hoisting are adopted, and the curved surface space pipe truss structure has the advantages of being succinct and convenient to construct, and short in construction period, the construction quality is easy to guarantee, the amount of large-scale mechanical equipment is reduced, and the construction cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

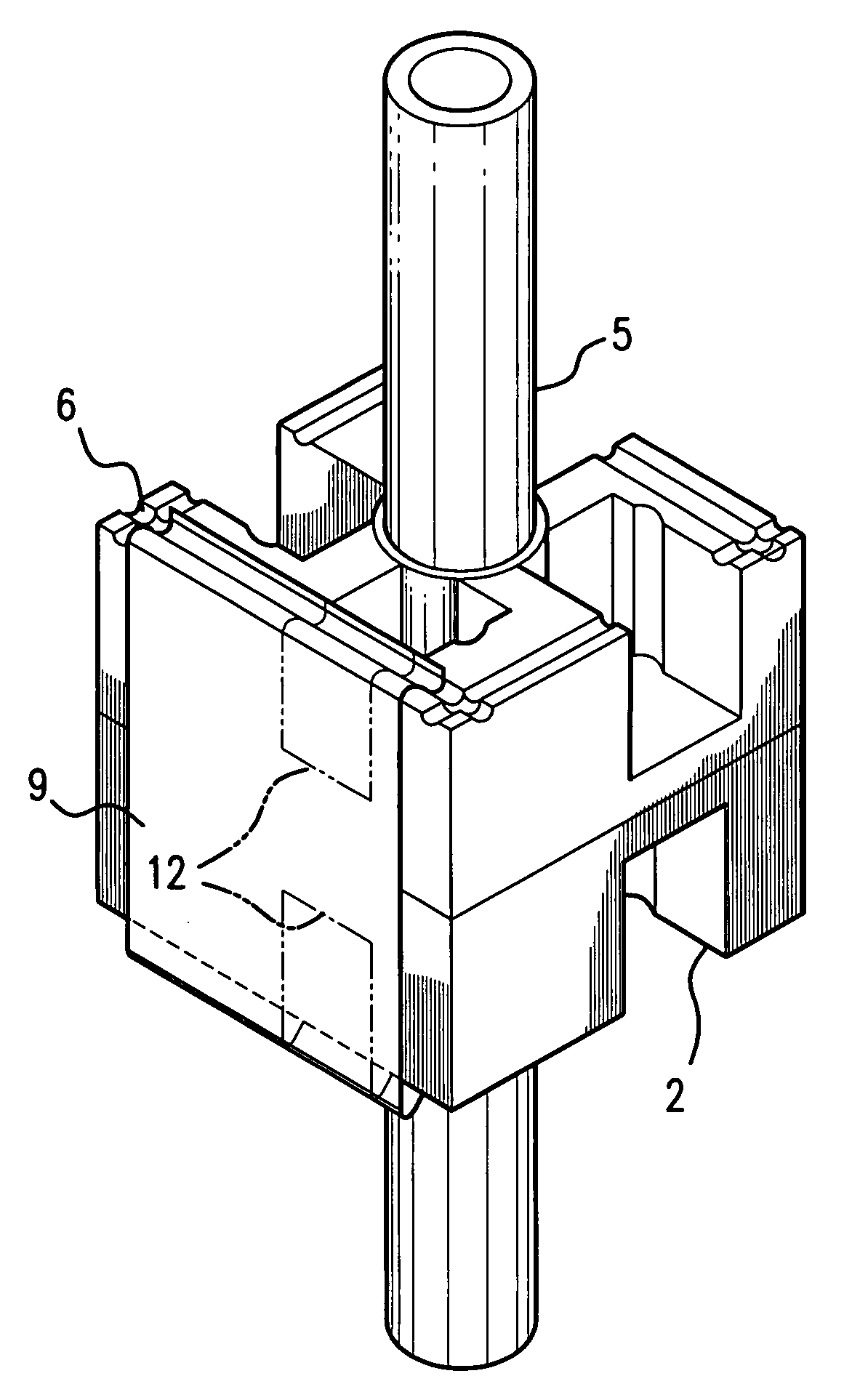

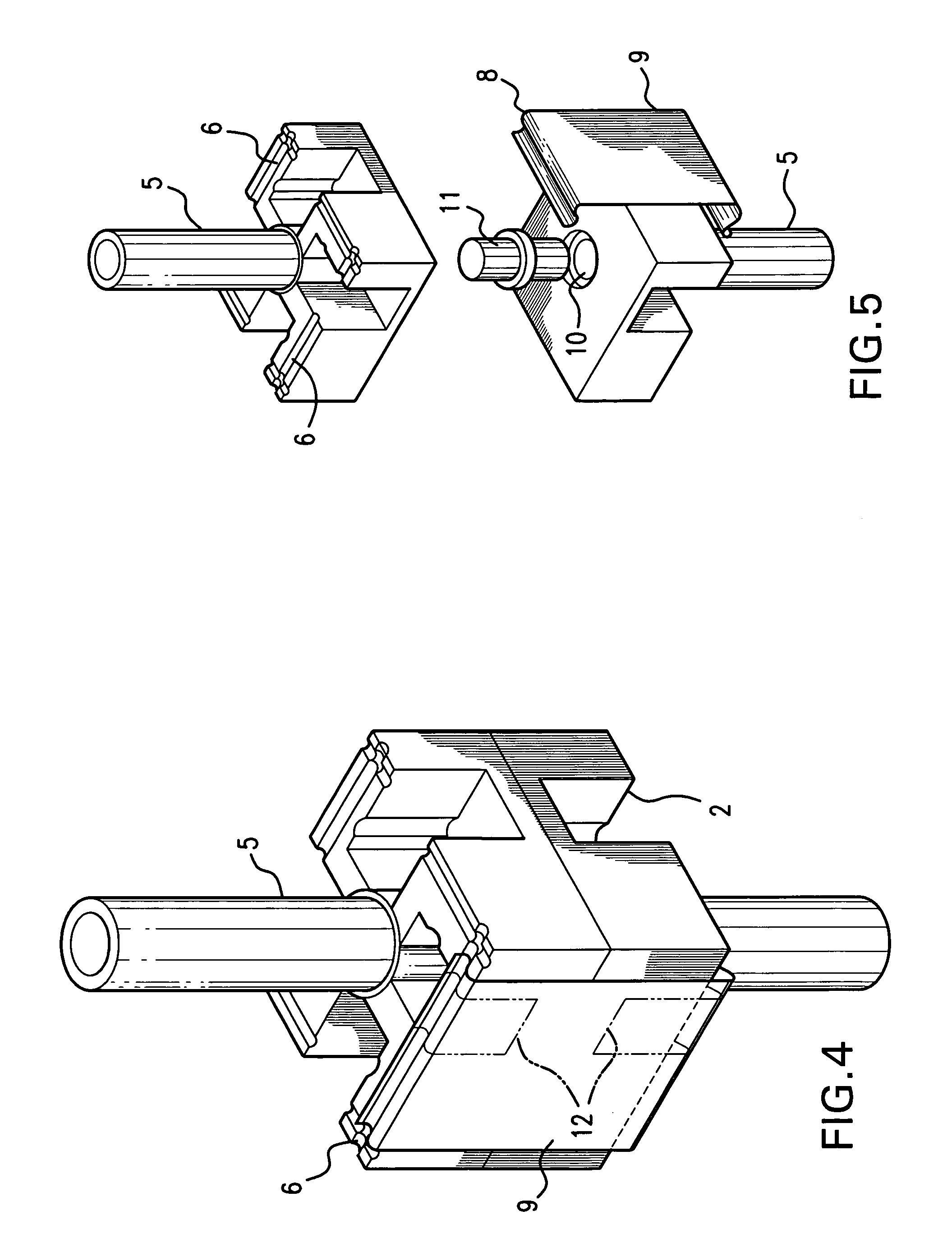

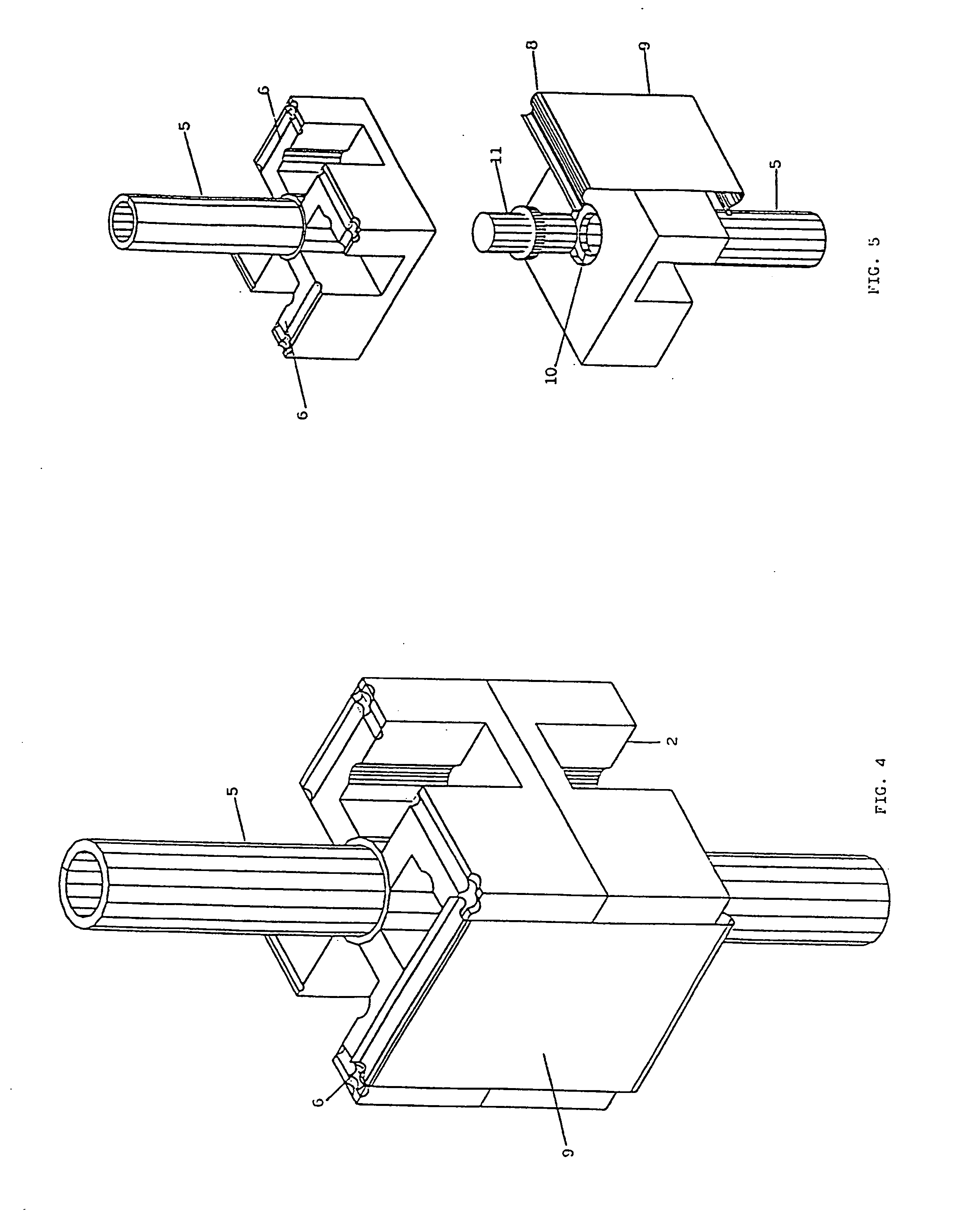

Structures which can be dismantled and folded, consisting of interconnecting tubular elements

InactiveUS6996946B1The process is simple and fastEasy to operateSnap fastenersStructural elementsC sectionsUniversal joint

Owner:CAZZOLARO SERGIO

Instrument panel subassembly including a glove box door

An instrument panel subassembly for use in an instrument panel assembly in a motor vehicle is provided. The subassembly includes first and second generally C-shaped energy absorption brackets. The brackets have an aft facing C-section and upper and lower mounting ends. The brackets include attachment means for attaching the brackets to a vehicle structural member. The subassembly further includes a glove box door having an aft surface and a forward surface, and a bin. The glove box door includes hinge means for providing hinged movement of the glove box door relative to the first and second brackets between open and closed positions. The bin is within the C-section of the brackets when the glove box door is in a hingedly closed position.

Owner:ABC GROUP

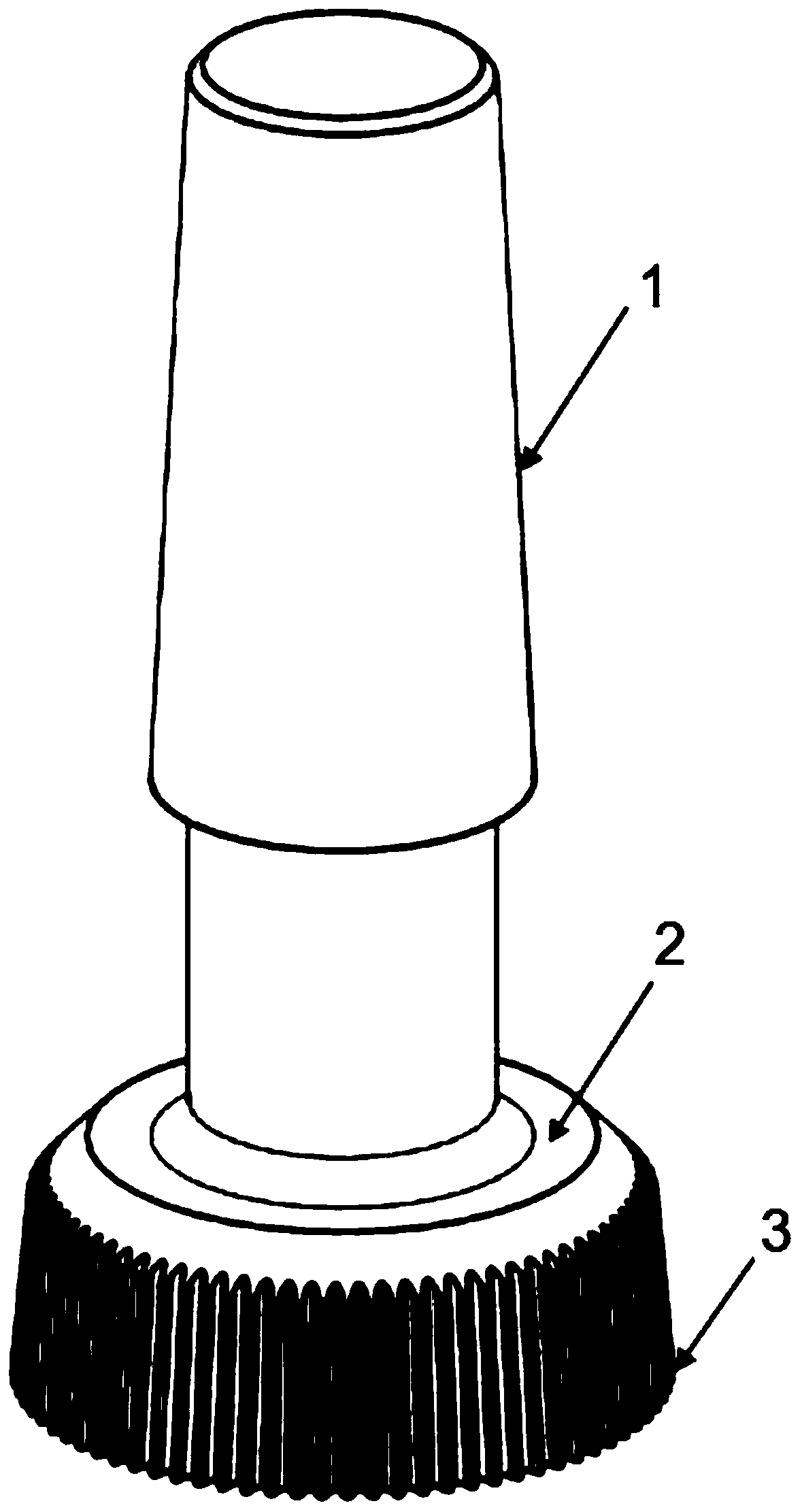

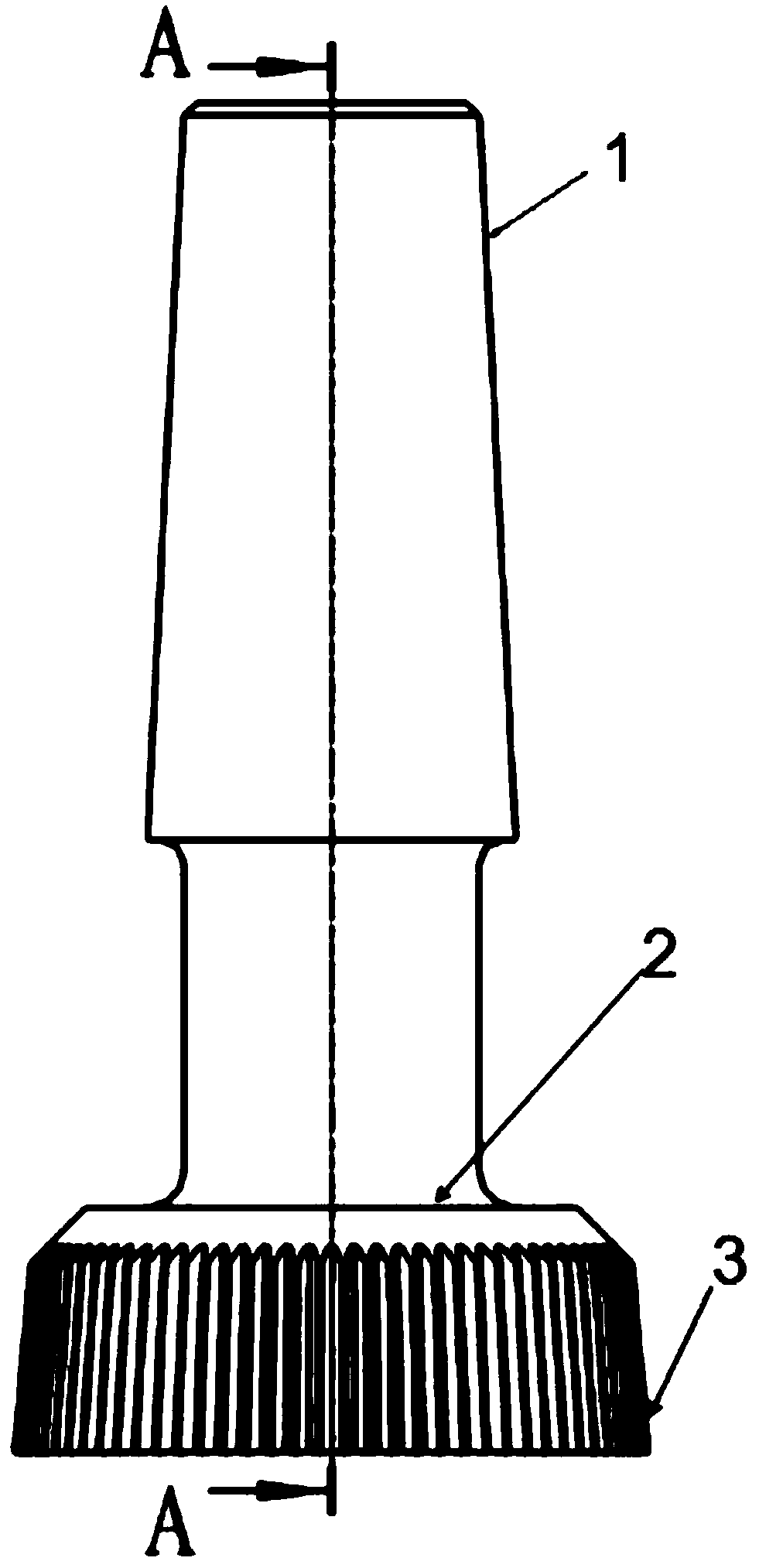

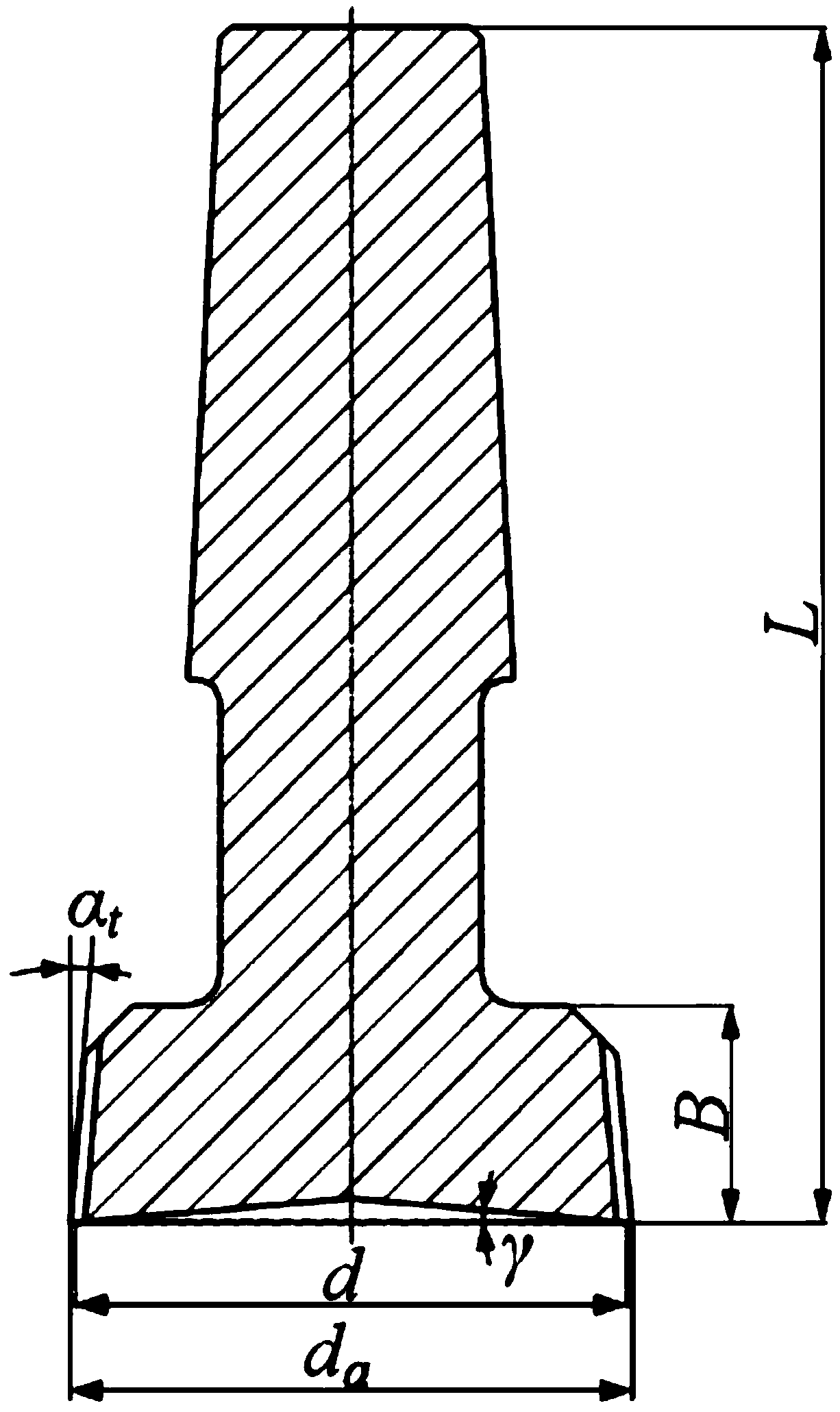

Anticompress and anti-bending shouldered hook-shape teeth screwed connection structure

InactiveCN101063502AImprove performanceAvoid stickingDrilling rodsDrilling casingsC sectionsCoupling

The invention provides a hook-tooth thread connecting structure with resistance to compression and bending, comprising a coupling B with inner thread at two ends, conical sealing surface and torque shoulder and an annular tube A with outer thread at two ends, conical sealing surface and torque shoulder, wherein the outer thread of the end of annular tube A is screwed with inner thread of the end of coupling B by hook-tooth thread, D section of inner thread of the end of coupling B is provided with inner torque shoulder and inner sealing conical surface, C section of outer thread of the end of annular tube A is provided with outer torque shoulder and outer sealing conical surface, and the inner sealing conical surface of the end of coupling and the outer sealing conical surface of the end of annular tube respectively contact the outer and inner torque shoulder. The hook-tooth thread has the advantages that the connecting structure has good property with high-pressure and high bending load, achieves the same compression and collapsing strength with the tube body and realizes the optimizing main sealing surface of metal to metal to achieve higher and more reliable air-impermeability, thereby realizing the non-leaking of gas with high-pressure and high bending load.

Owner:TIANJIN PIPE (GROUP) CORP

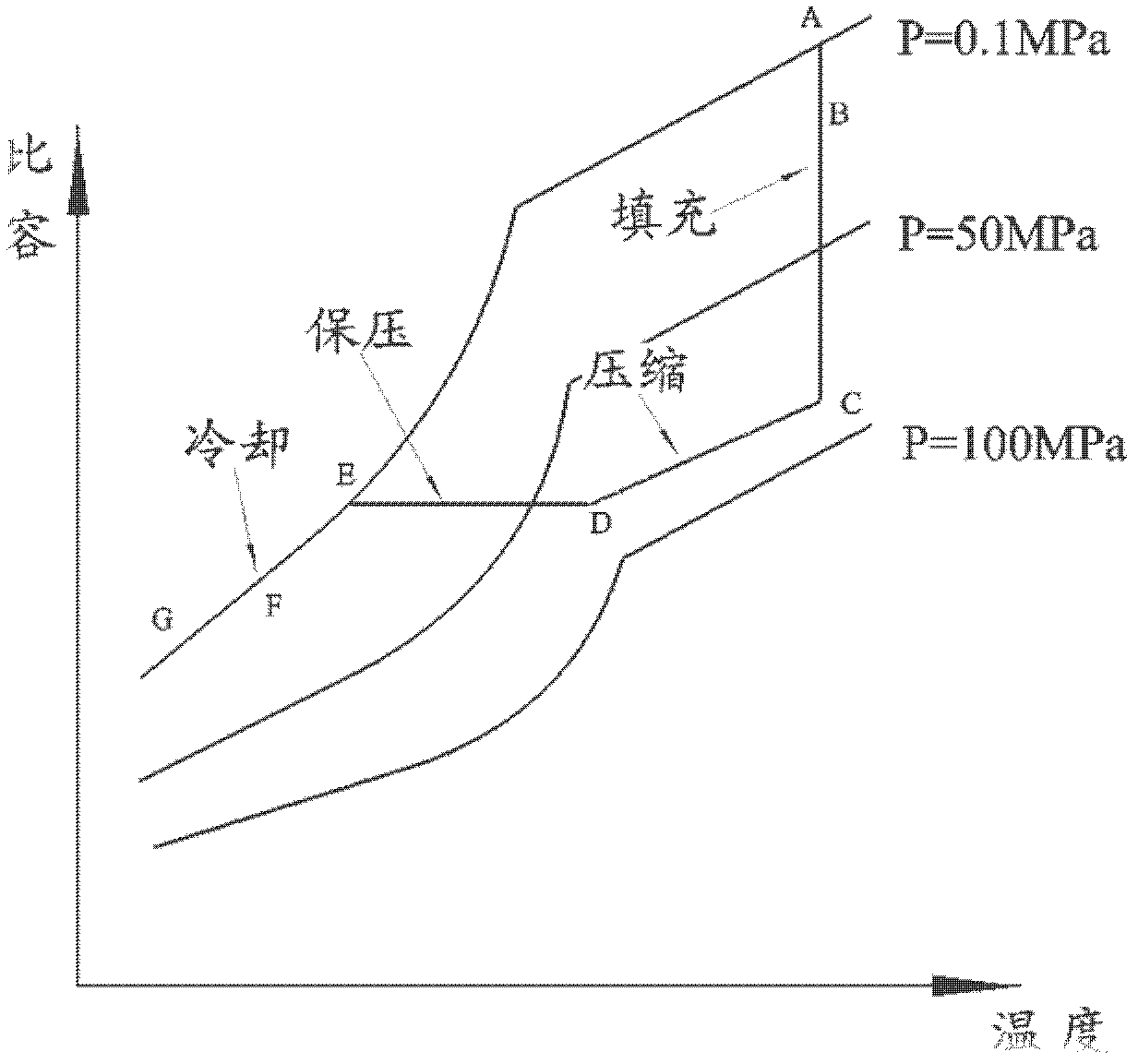

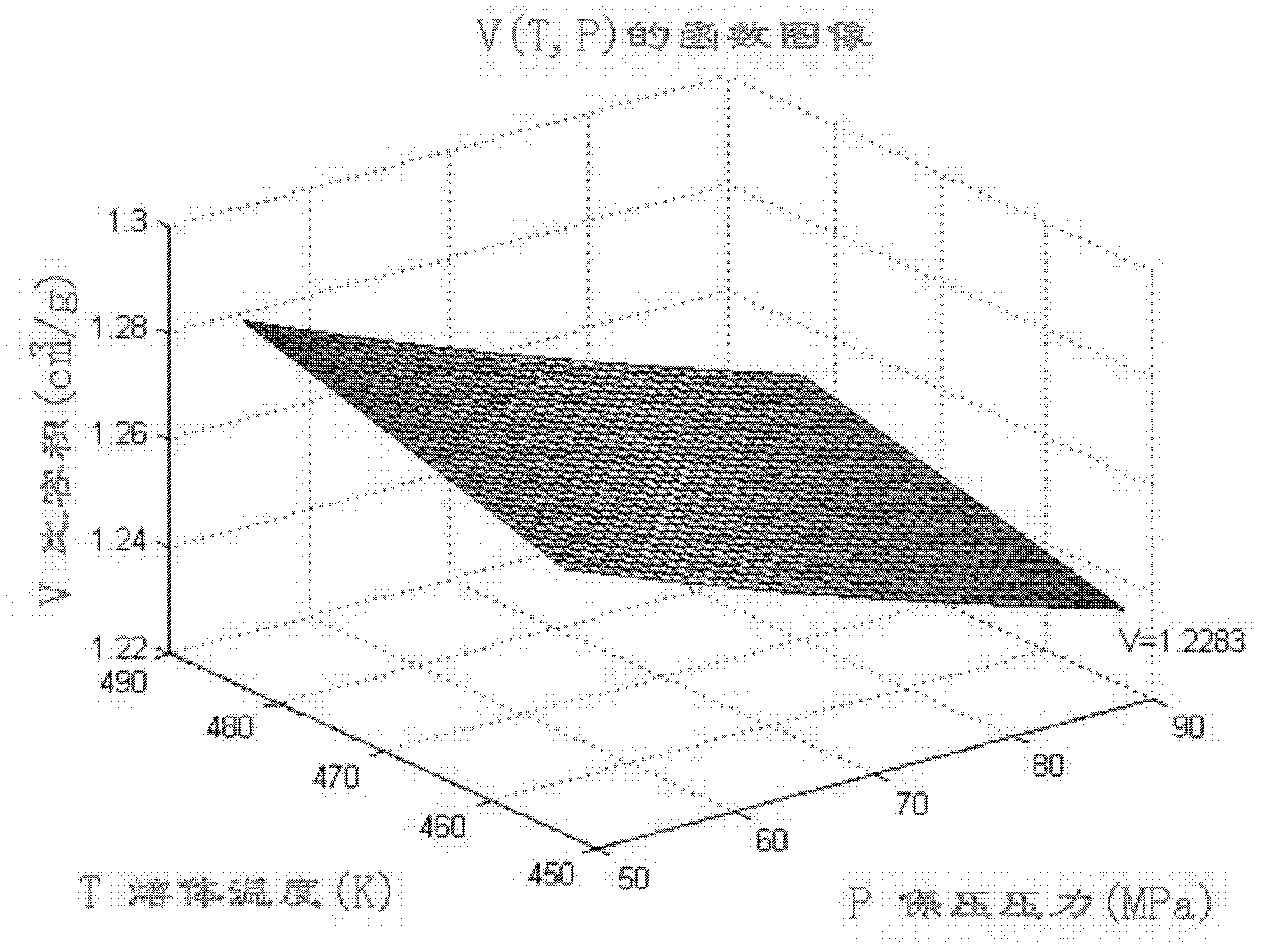

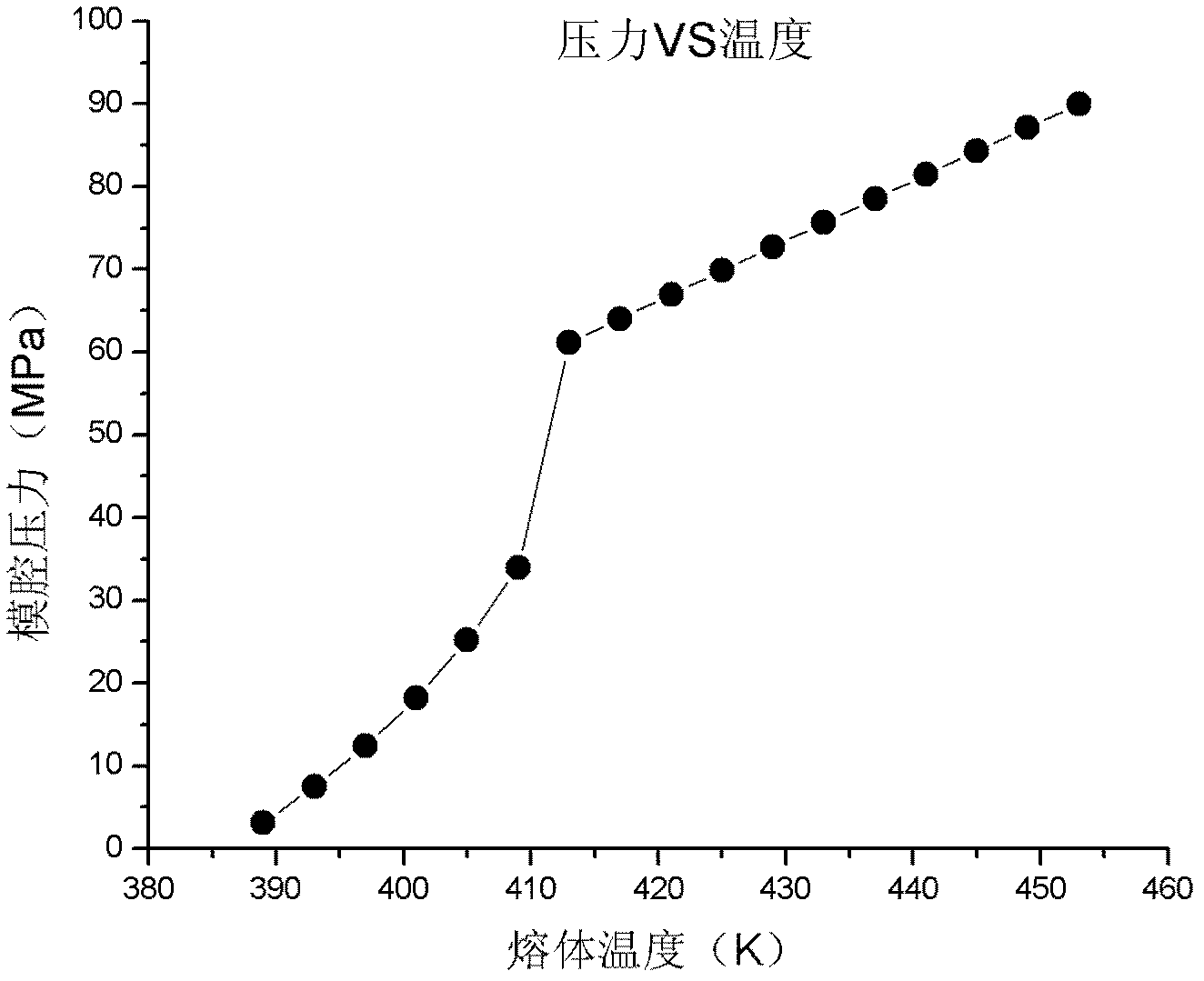

Isometric process control method utilizing PVT (pressure-volume-temperature) relation of polymers

The invention discloses an isometric process control method utilizing PVT (pressure-volume-temperature) relation of polymers. An injection process includes a first step: a PVT curve of an injection molding material is obtained according to the category and the characteristics of the material, an A-B-C-D-E-F process route is obtained from the curve, and an A-B-C section is an injection molding stage; a second step: constant-pressure packing is realized under the maximum packing pressure for a period of time, then isometric packing is carried out, and a C-D section is an isobaric compression stage; a third step: a D-E section is an equal-ratio volume packing stage, a material in a cavity cannot be changed, and cannot backflow or be increased along with reduction of the temperature of the cavity, and packing pressure of melt is obtained by means of calculation by the aid of a Tait equation and physical parameters provided by a PVT database; and a final step: an E-F section is a constant-pressure cooling stage. The constant-pressure packing is realized before the equal-ratio volume packing is realized, the melt is in a flowing state during the constant-pressure packing, accordingly excessively packing alignment is avoided, warpage is low, and quality repeat precision is high.

Owner:BEIJING UNIV OF CHEM TECH

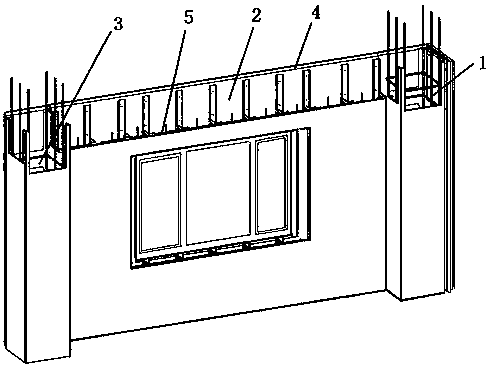

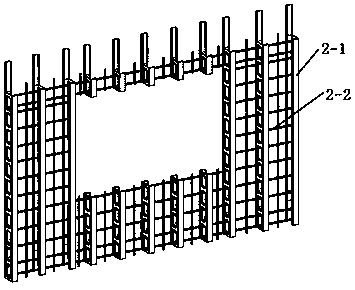

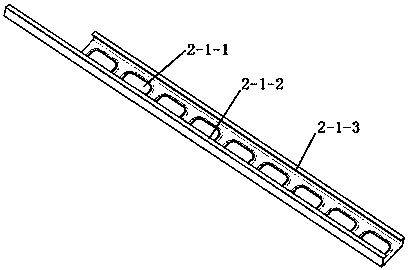

Frame joint assembly type wall assembly

The invention provides a frame node assembled wall component. It includes a panel frame and a column frame, the column frame includes a side column frame and a central column frame, the panel frame is composed of C-shaped steel and connecting steel bars, the C-shaped steel has through holes, and the column frame is composed of square steel pipes , There are through holes on the four side walls of the square steel pipe. The panel frame of the present invention takes C-shaped steel as the main body, and the column frame takes square steel pipes as the main body. There are several through holes on the four side walls of the C-shaped steel and the square steel pipes, so that after the wall frame is assembled, each concrete pouring cavity The through holes communicate with each other, after the concrete is poured, the concrete load-bearing parts in each part are connected to each other, and the concrete forms a good combination with the C-shaped steel, the square steel pipe, the connecting steel bar, and the load-bearing steel bar. Therefore, the present invention is more conducive to the overall performance of the body of the wall.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

Three-arc harmonic gear slotting cutter and tooth profile design method thereof

ActiveCN109630652ATransmission overcomingImprove carrying capacityGeometric CADGearingC sectionsKinematics

The invention discloses a three-arc harmonic gear slotting cutter, and belongs to the technical field of harmonic speed reducer gear machining cutters. A basic tooth profile of cutter teeth is composed of three arc sections which are sequentially tangent. The radius of the upper arc section is rho 1, the radius of the middle arc section is rho 2, and the radius of the lower arc section is rho 3. The invention further discloses a tooth profile design method of the three-arc harmonic gear slotting cutter. Through the tooth profile design method, a flexible gear three-arc tooth profile and a rigid gear three-arc tooth profile which meet the conditions are designed; and on the basis of the obtained rigid gear three-arc tooth profile, the gear meshing kinematics method is adopted, and an A section theoretical conjugate tooth profile, a B section theoretical conjugate tooth profile and a C section theoretical conjugate tooth profile are obtained. Arc fitting is adopted, and the upper arc section Ac1, the lower arc section Ac3 and related parameters of the upper arc section Ac1 and the lower arc section Ac3 are obtained. Through the plane analytic geometry method, the middle arc section Ac2 and related parameters of the middle arc section Ac2 are obtained. Finally, according to the machined harmonic gear technology requirements, auxiliary parameters are determined, and accordingly thepurpose of machining of a work tooth profile of a three-arc harmonic gear is achieved.

Owner:SICHUAN UNIV

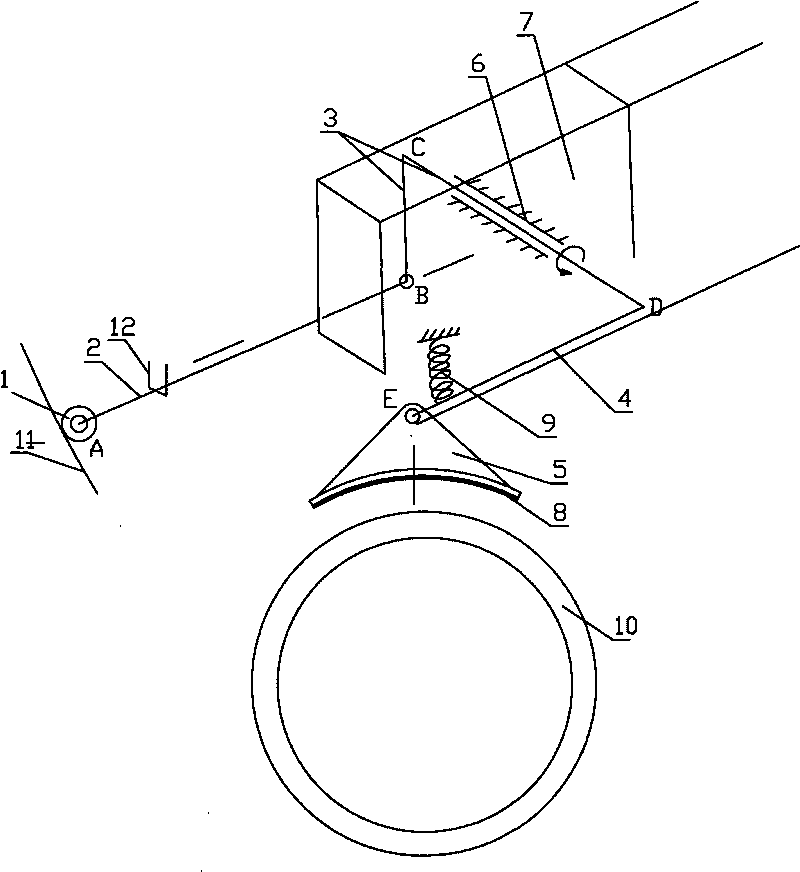

Device for cushioning automobile crash by tires

InactiveCN101695922ANo need to change the chassis structureEasy to installAutomatic initiationsC sectionsEngineering

The invention discloses a device for cushioning automobile crash by tires and relates to a scheme for lightening the crash of the automobile industry, particularly to a flat-end van. The device comprises bumpers, a longitudinal beam and tires and is characterized in that the longitudinal beam is provided with a support sleeve; an L-type oscillating bar is installed in the support sleeve, one end of the L-type oscillating bar is articulated with a push rod; the push rod is connected with positioning wheels by a hanging rail fixed on an automobile body, and the positioning wheels are freely connected with the front bumper of an automobile; the other end of the L-type oscillating bar is perpendicularly connected with a spline of a press rod; the proportion of the press rod and the B-C section of the L-type oscillating bar is 1-3:1; the press rod is hung on the automobile body by a spring and articulated with a press block; the center line of the press block is superposed with the circumferential center line of the surface of each tire; the press block is in a triangle, and the lower part is in an inner concave arc and is lined with a rubber layer. The invention has the advantages of novel structure, simple and convenient installation, and the like, reduces the cost and improves the safety without carrying out large structural reformation on the original automobile.

Owner:宋立

Log supporting and guiding apparatus for improved burning

InactiveUS20110000476A1Space maximizationHigh strengthDomestic stoves or rangesGratesC sectionsEngineering

A log supporting and guiding apparatus for improved burning, the apparatus comprising: a base which rests on a fireplace floor or fireplace grate, the base comprising a front bar, back bar, a left connecting bar, a right connecting bar, and a plurality of strength reinforcing bars; a plurality of log retaining bars which are functionally attached to the base and angled off of the fireplace floor or fireplace grate; a left upright bar which is perpendicular, functionally attached to the left connecting bar at the bottom of the left upright bar, and closer to the front bar than the back bar; a right upright bar which is perpendicular, functionally attached to the right connecting bar at the bottom of the right upright bar, and closer to the front bar than the back bar; a cross bar which functionally connects the top of the left upright bar with the top of the right upright bar; a c-section bar for holding a log upright, which is functionally attached to the top of the right upright bar; and an inverted c-section bar for holding a log upright, which is functionally attached to the top of the left upright bar.

Owner:KLEVE ROBERT B +1

Road passage underground project construction method

ActiveCN103590424AGuaranteed two-way trafficEfficient constructionArtificial islandsUnderwater structuresSurface layerC sections

The invention discloses a road passage underground project construction method which includes the following steps: (1) dividing a construction ground into three sections, namely an A section on one side, a B section on the other side and a C section in the middle, (2) closing the C section, constructing the C section, excavating earth in the surface layer, and making a roof plate of the C section, (3) backfilling the earth of the C section, constructing the A section, excavating earth in the surface layer to a bottom plate base layer, and making a base plate of the A section, (4) making wall plates of the A section, (5) making a roof plate of the A section, (6) backfilling the A section with the earth, constructing the B section, excavating earth in the surface layer to a bottom plate base layer, making a base plate of the B section and a base plate of the C section, making wall plates of the B section, and making a roof plate of the B section, and (7) backfilling the B section with the earth.

Owner:李涛 +2

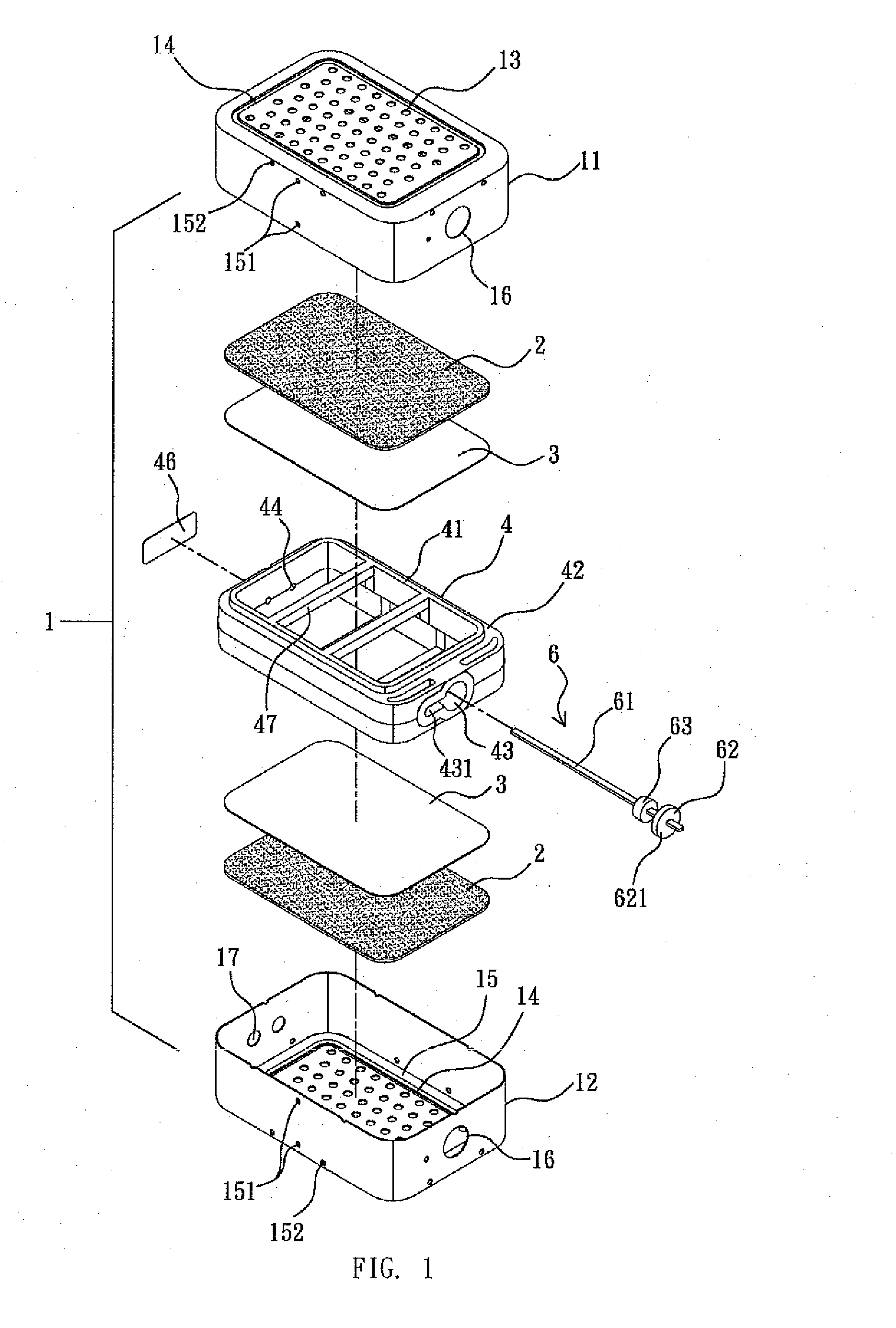

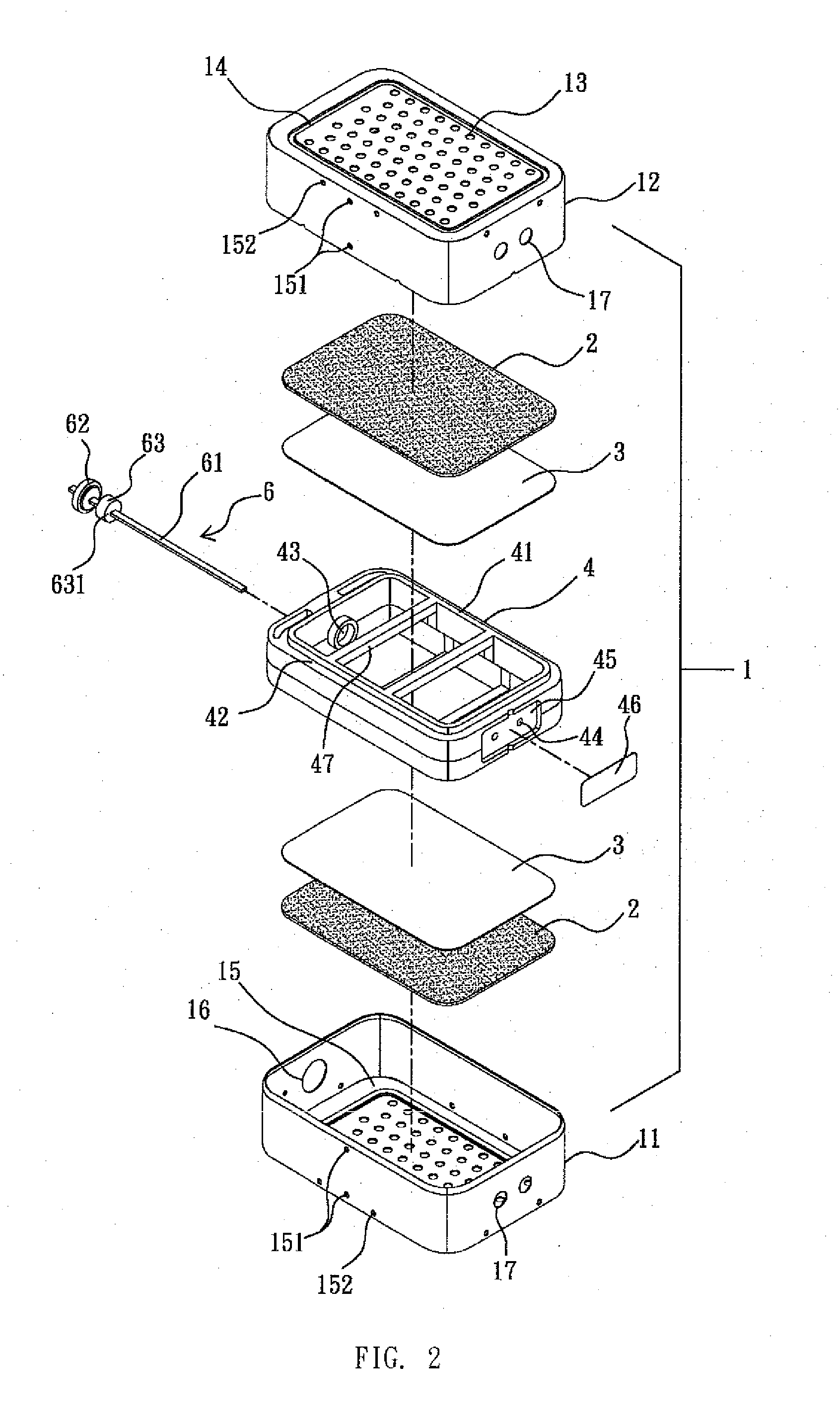

Packaging structure of low-pressure molded fuel cell

InactiveUS8551672B2Efficient removalSimple processFuel and primary cellsFuel cells groupingC sectionsFuel cells

Owner:HIGH TECH BATTERY INC

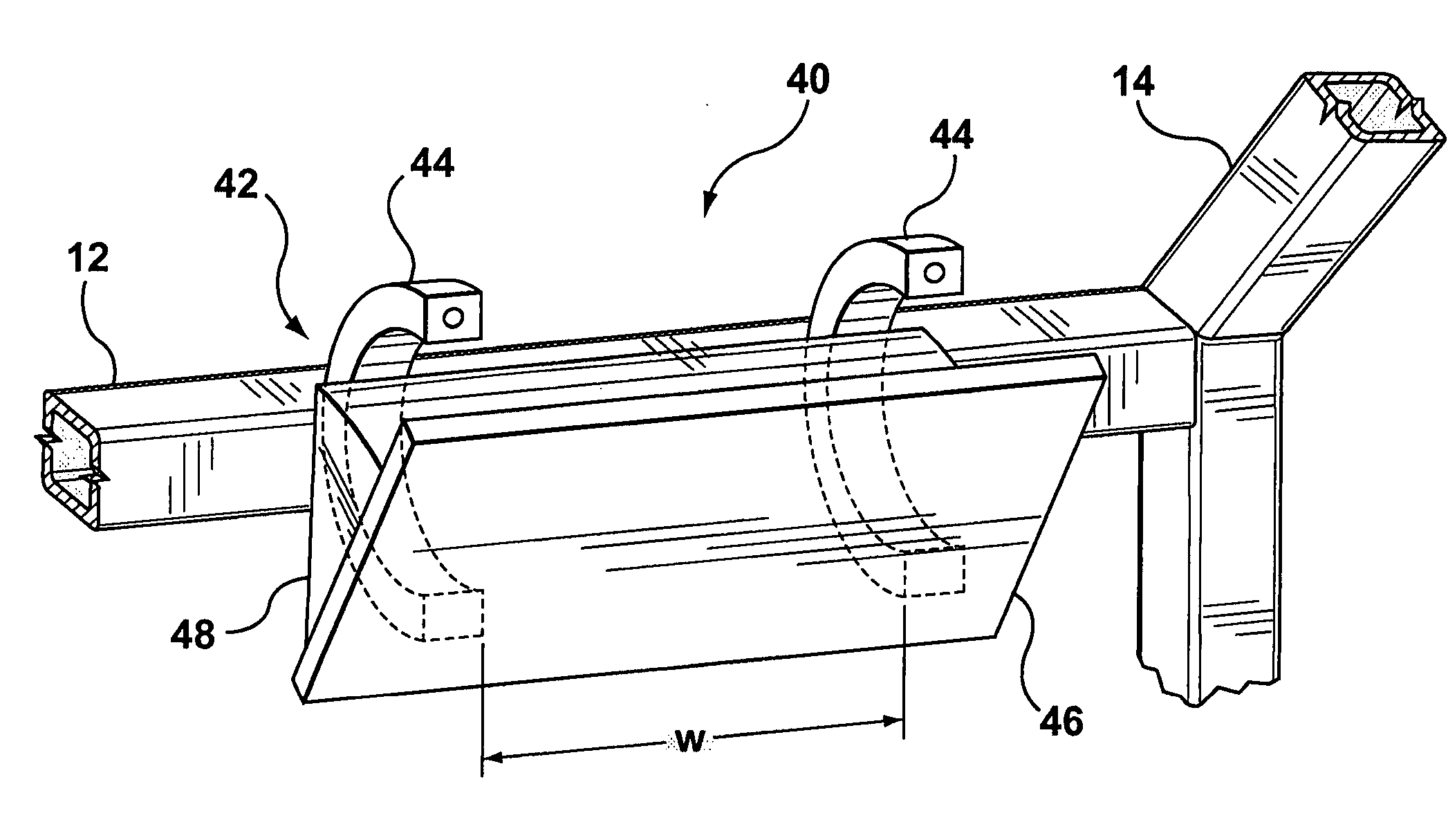

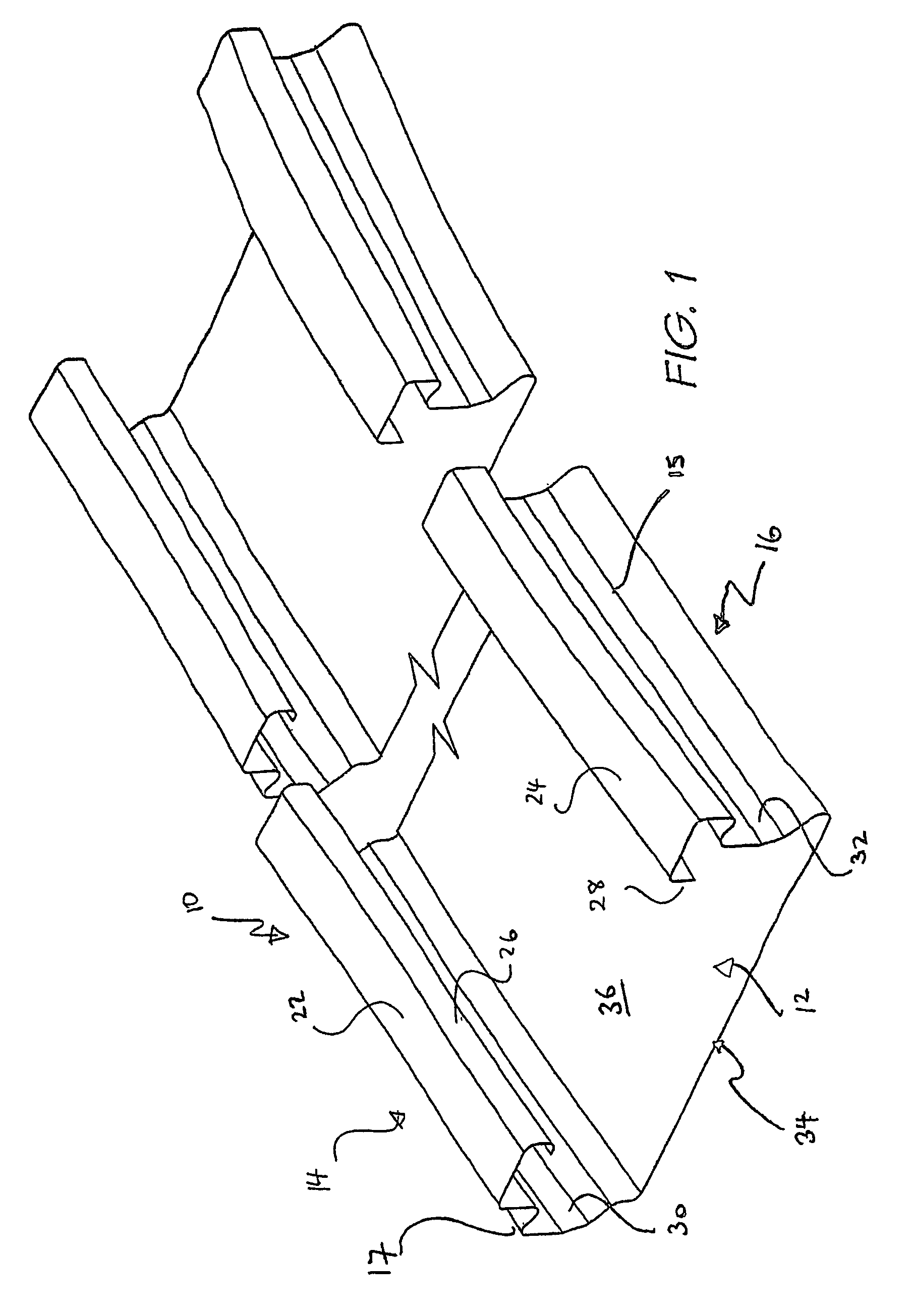

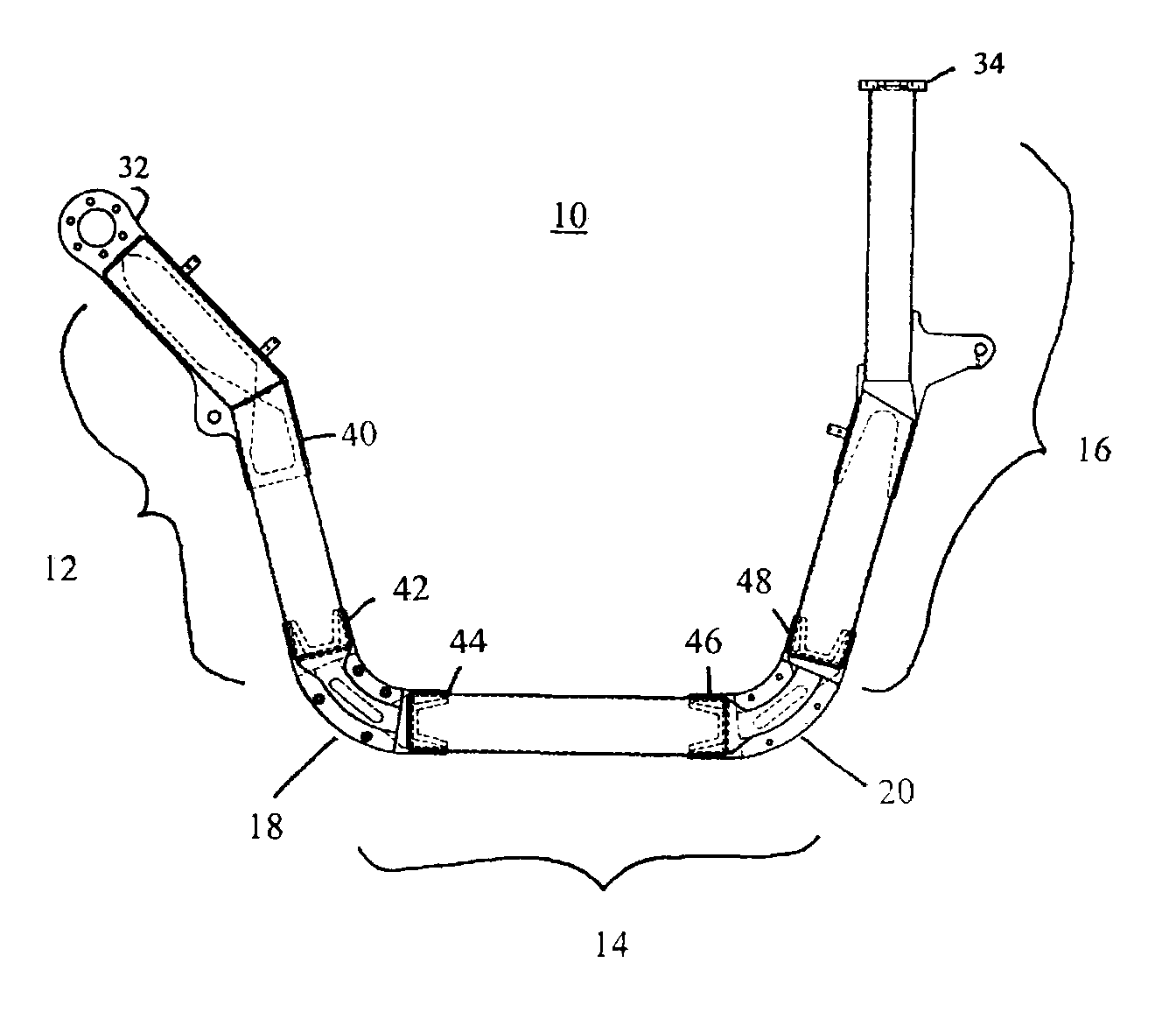

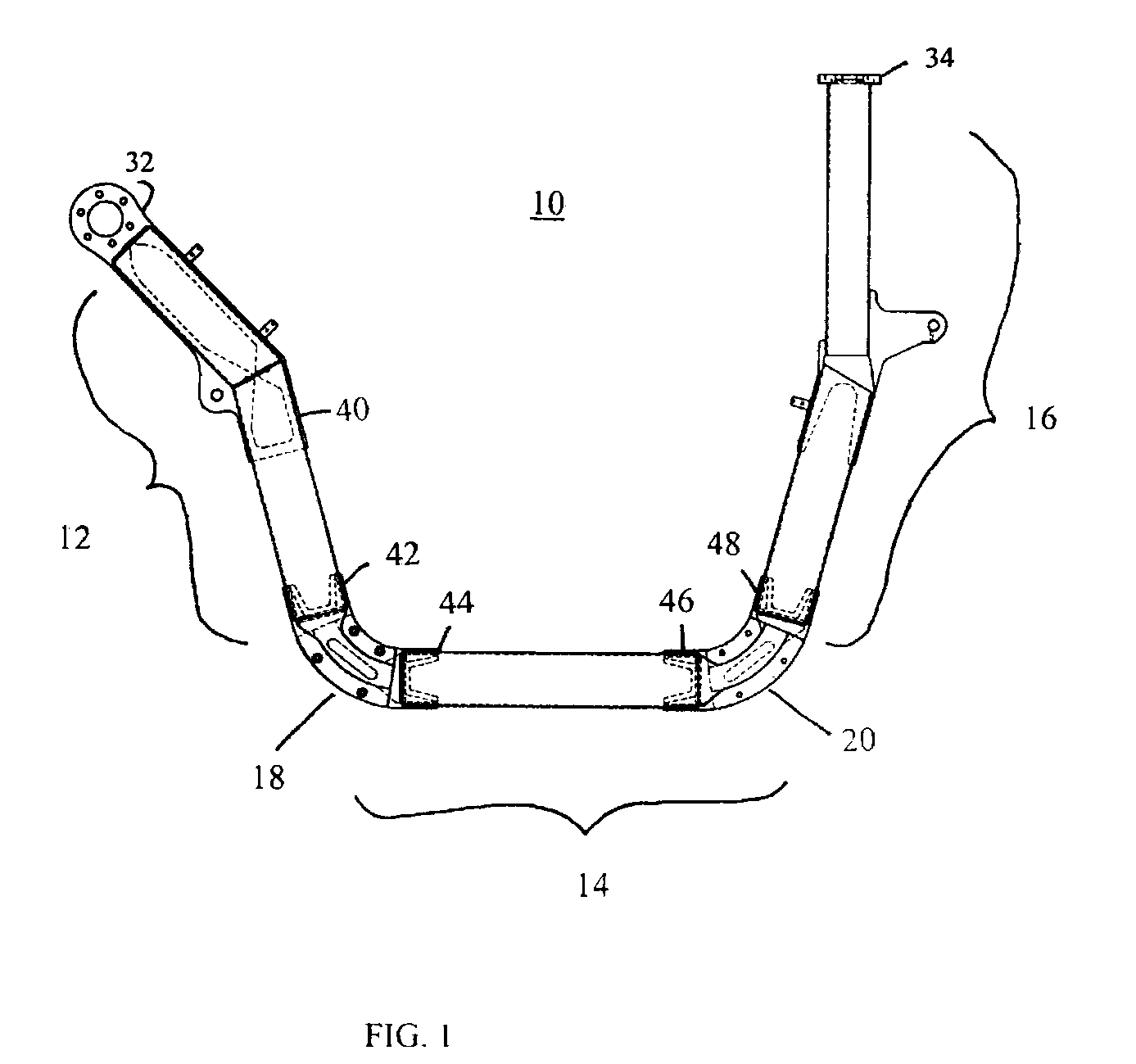

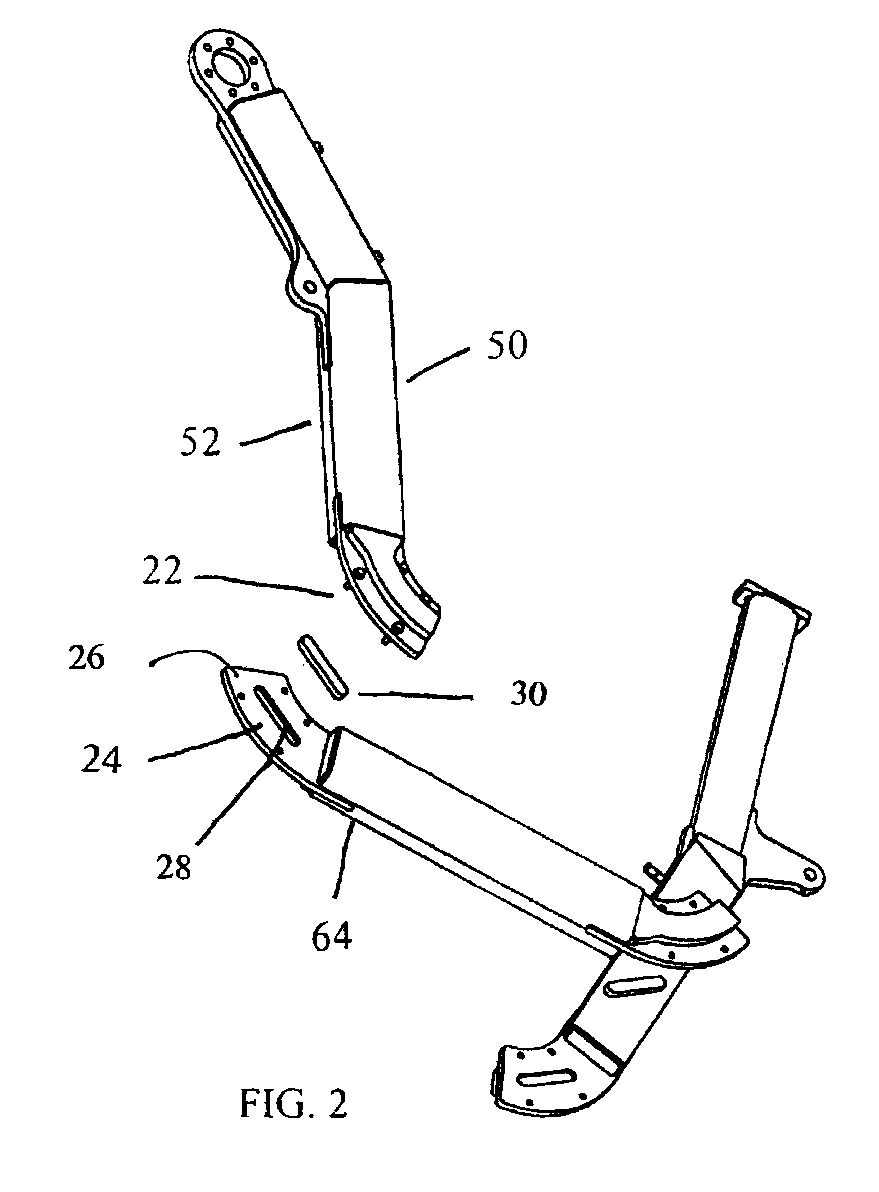

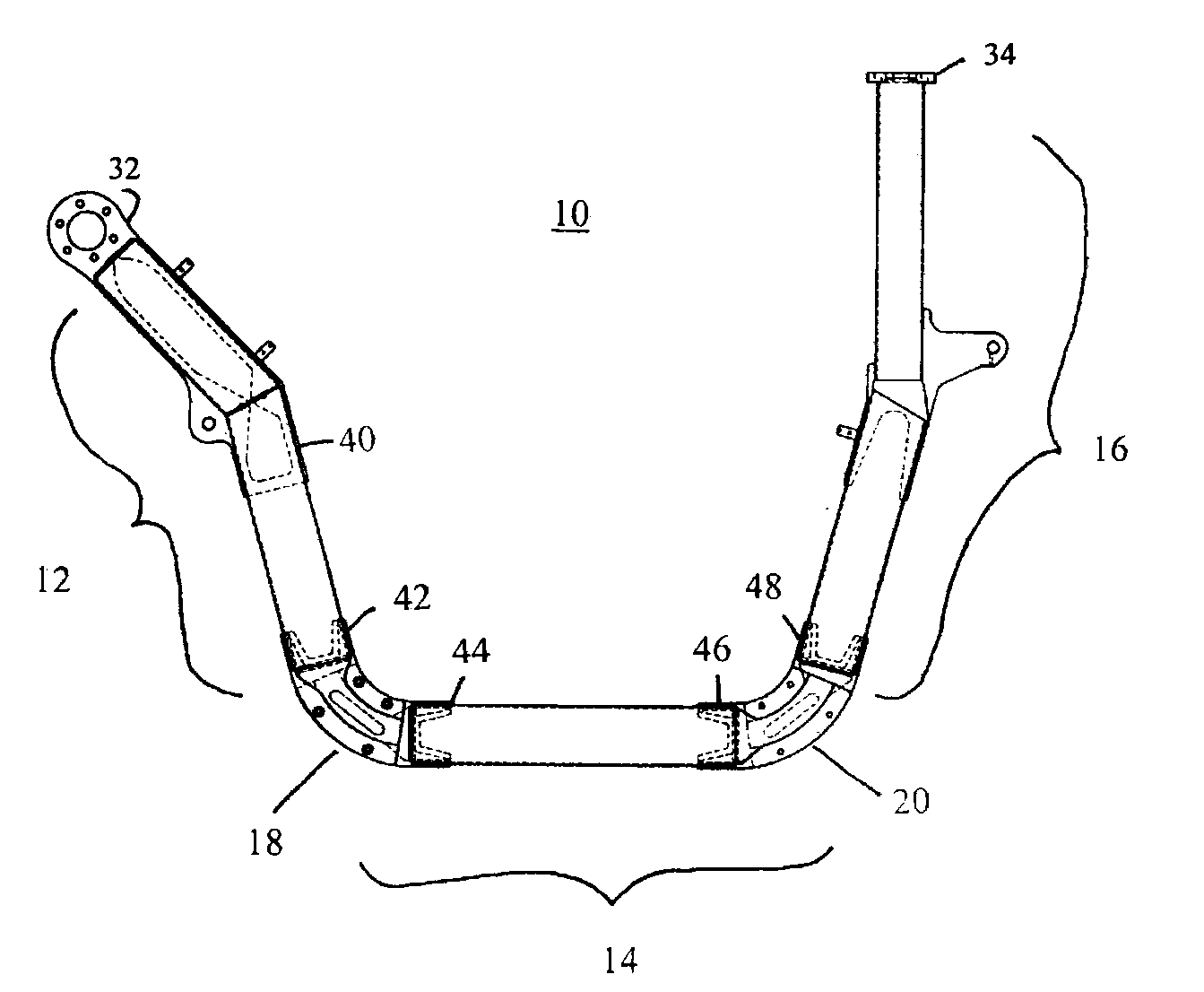

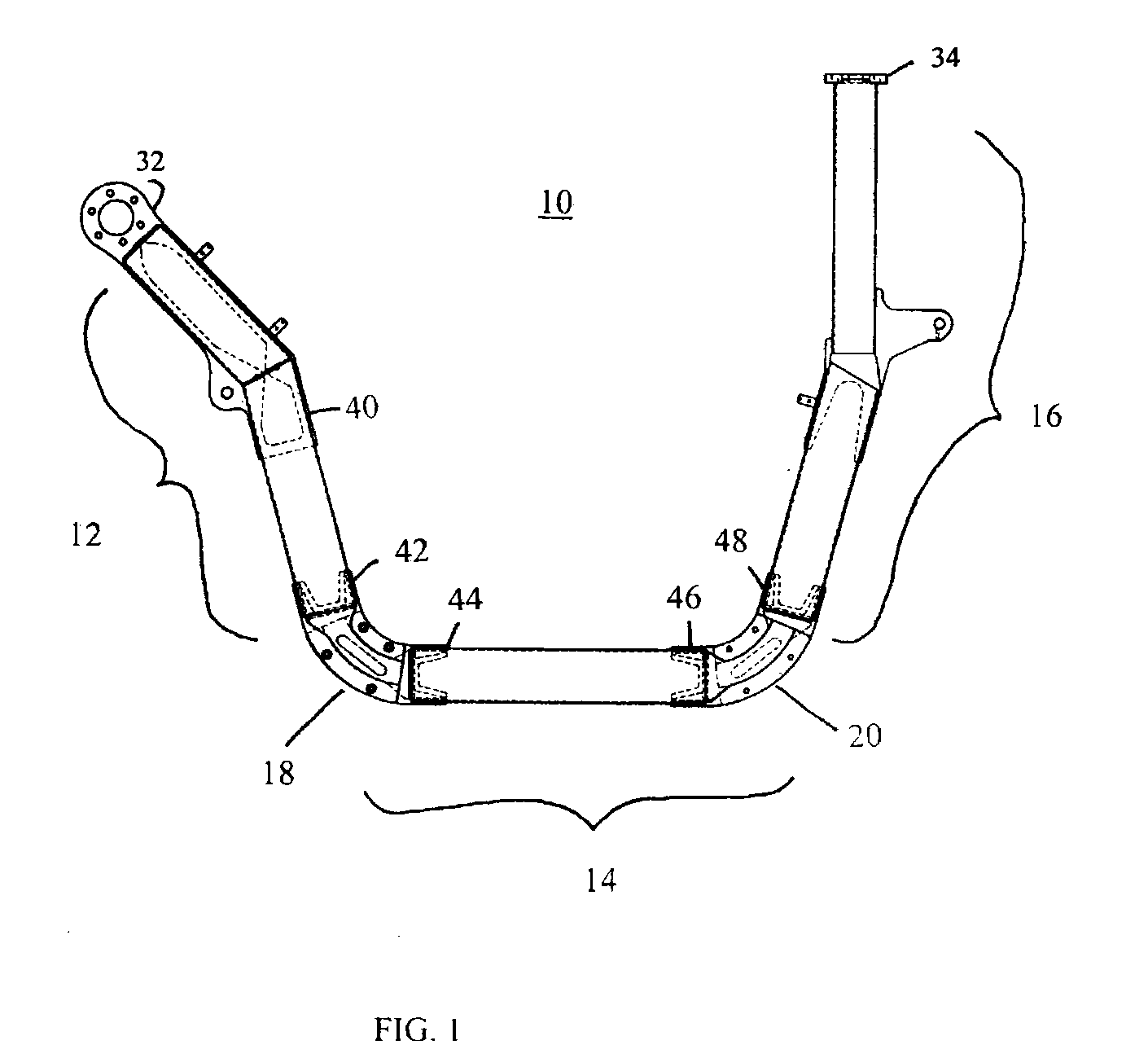

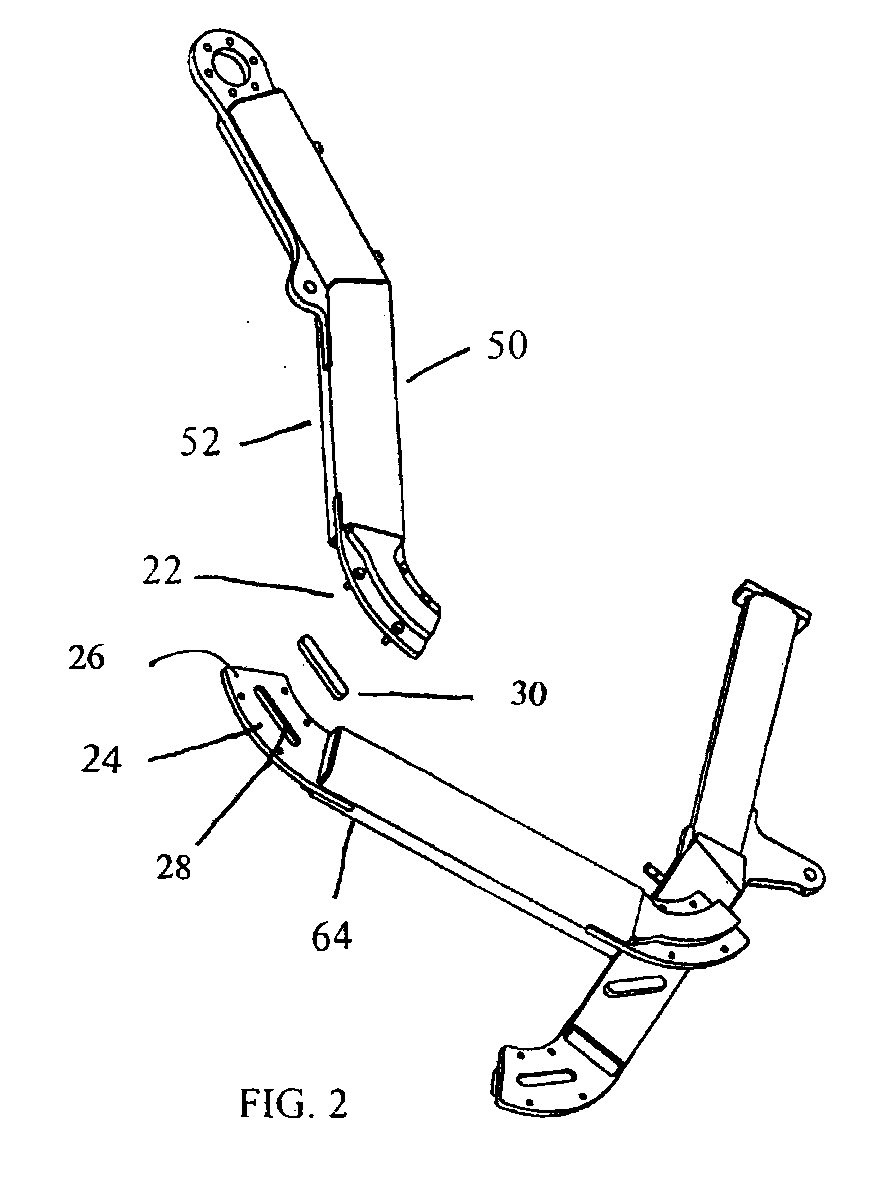

Three piece lift arm apparatus and method

ActiveUS8584362B2High strengthReduce distortion problemsArticle unpackingVehicle componentsC sectionsEngineering

The present invention is a refuse truck lift arm with sections that are bolted, not welded, together. Where the sections are joined together there is a recess and key arrangement. The key is seated in the recess of each half and straddles the inner face that divides them. In this way, shear forces that would otherwise be entirely borne by the bolts are also placed on the key. Each of the three sections, called “weldments,” are welded together in a novel way. The welding placement and sequence reduces welding distortion. Two C-shaped steel pieces are used for each straight section of each weldment. First, interior reinforcing brackets are welded into each C-section. Next, the two C-shaped sections are welded together, with the weld being between the edges that will form the thin side of the arm.

Owner:CURBTENDER INC +1

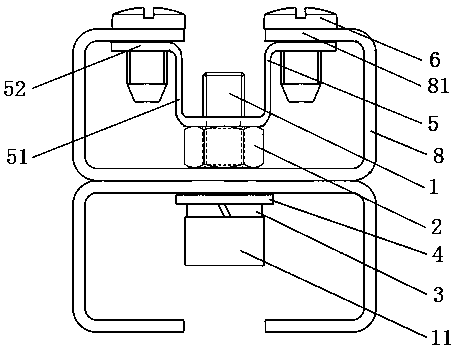

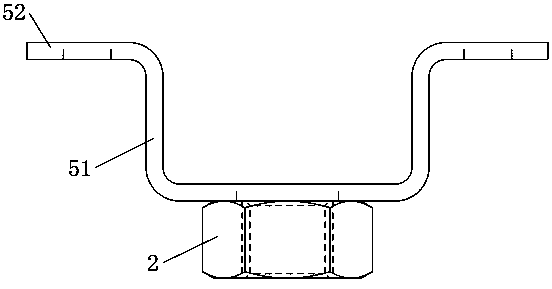

Forming apparatus for precambered metal sections

InactiveUS20060174674A1Easy to introduceIncrease volumeShearing machinesMetal working apparatusMetal stripsC sections

A forming apparatus (50) includes a roll former (51) operative to roll form a metal strip (100) to form a profiled metal section (10) of generally C section profile including a pan (12) and a pair of upstanding edge margins (14 and 16). The section profile incorporates a longitudinal precamber which is introduced by the forming apparatus by incorporating a prestretching apparatus (52) upstream from the roll former (51), and a bending apparatus (53) located downstream of the roll former (51). The prestretching apparatus differentially stretches the metal strip (100) in its longitudinal direction so as to form portions (101, 102), which are more elongated than a laterally adjacent portion (103) of the strip (100). The differential stretching compensates for longitudinal shortening of the metal strip in forming the profiled section in the roll former (51). The bending apparatus (53) uses a (3) point bending process and includes a reaction stage (60), a fulcrum stage (61), and an action stage (62). The action stage (62) which induces loading onto the profiled section (10) so as to bend the section about the fulcrum stage (61) is incorporated with the shearing assembly. A method of forming a metal section from sheet metal strip is also disclosed. In a further aspect a shearing assembly is disclosed which is height adjustable and which also includes a cutting element (77) and shearing block (78) which are pivotally mounted to an assembly frame (74).

Owner:BLUESCOPE STEEL LTD

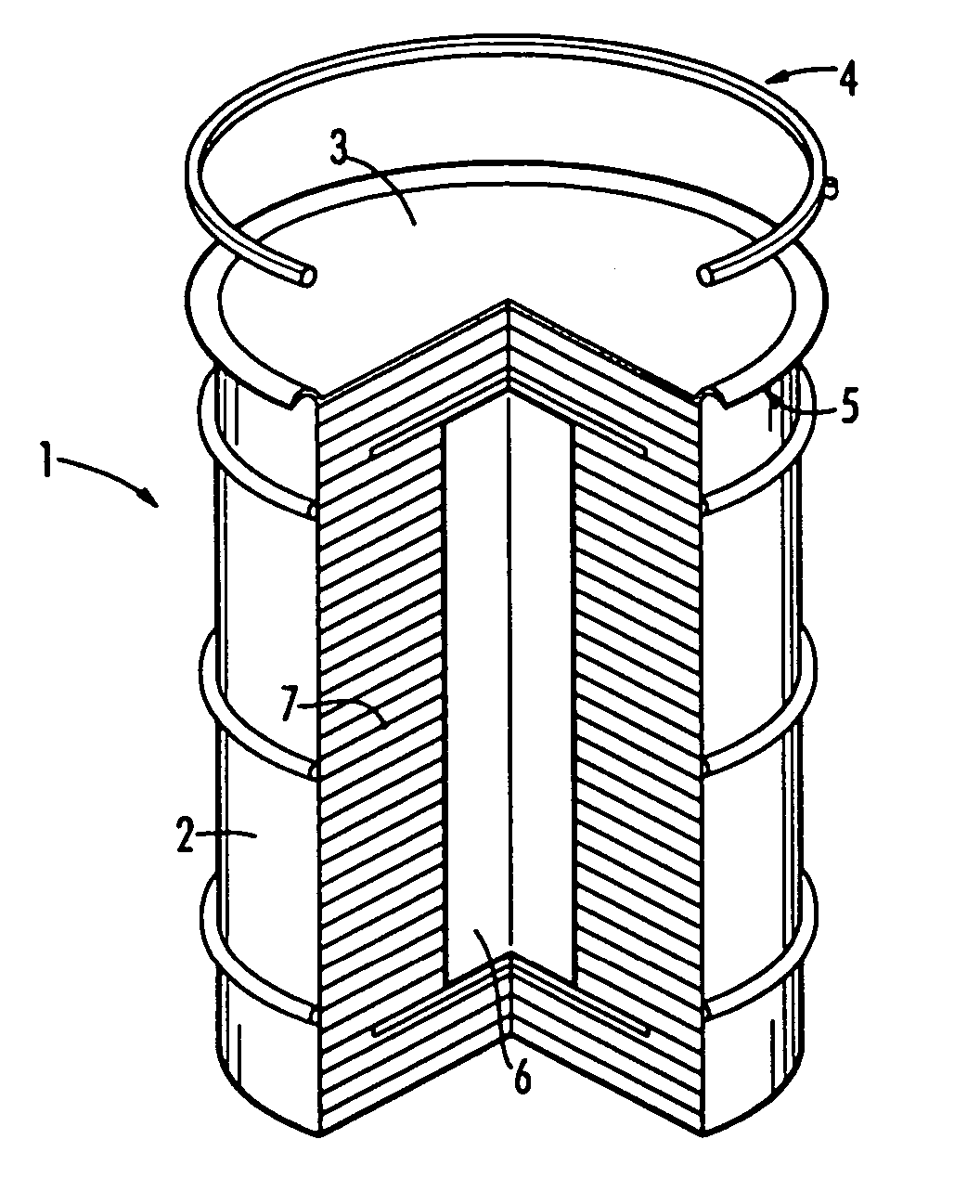

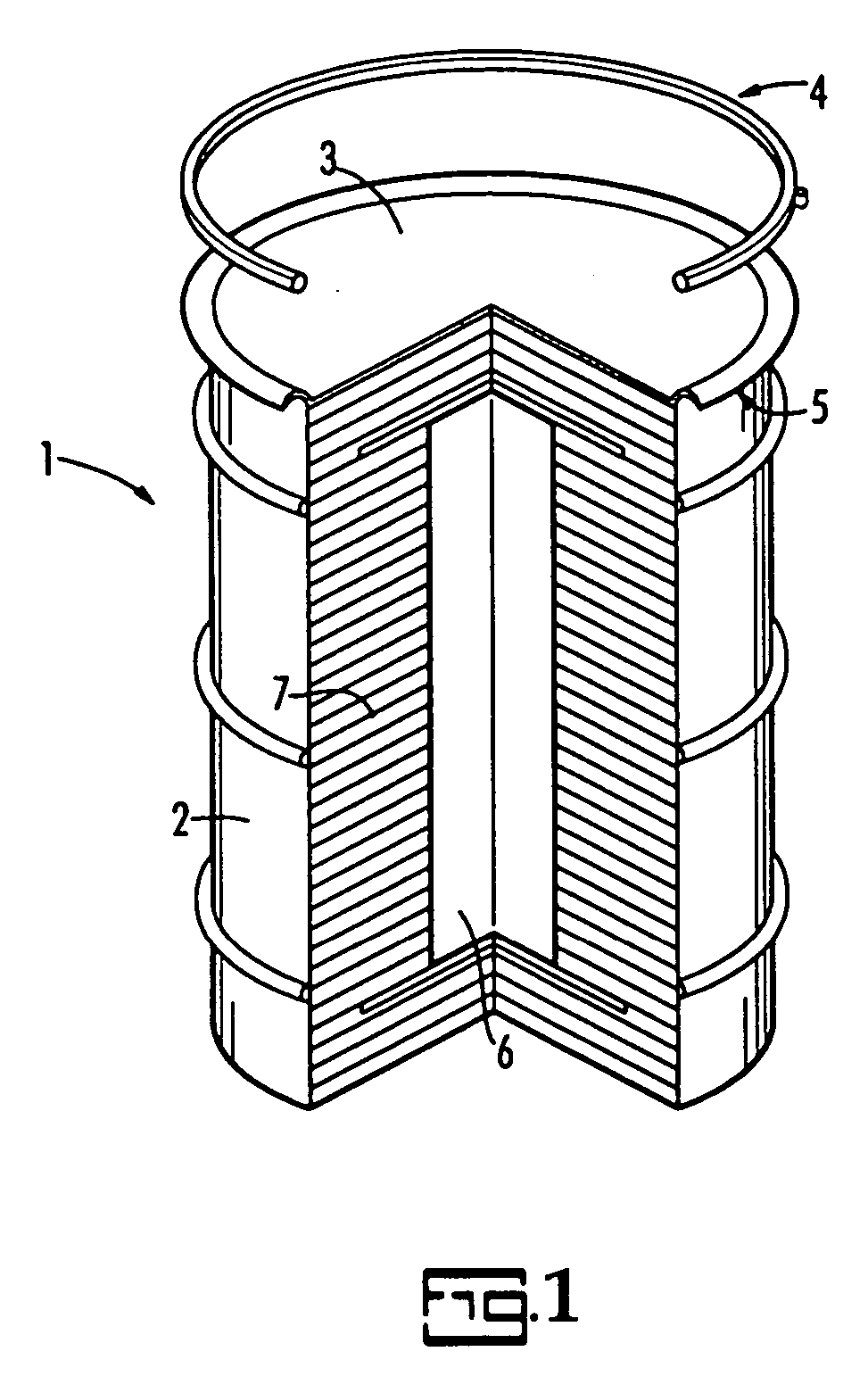

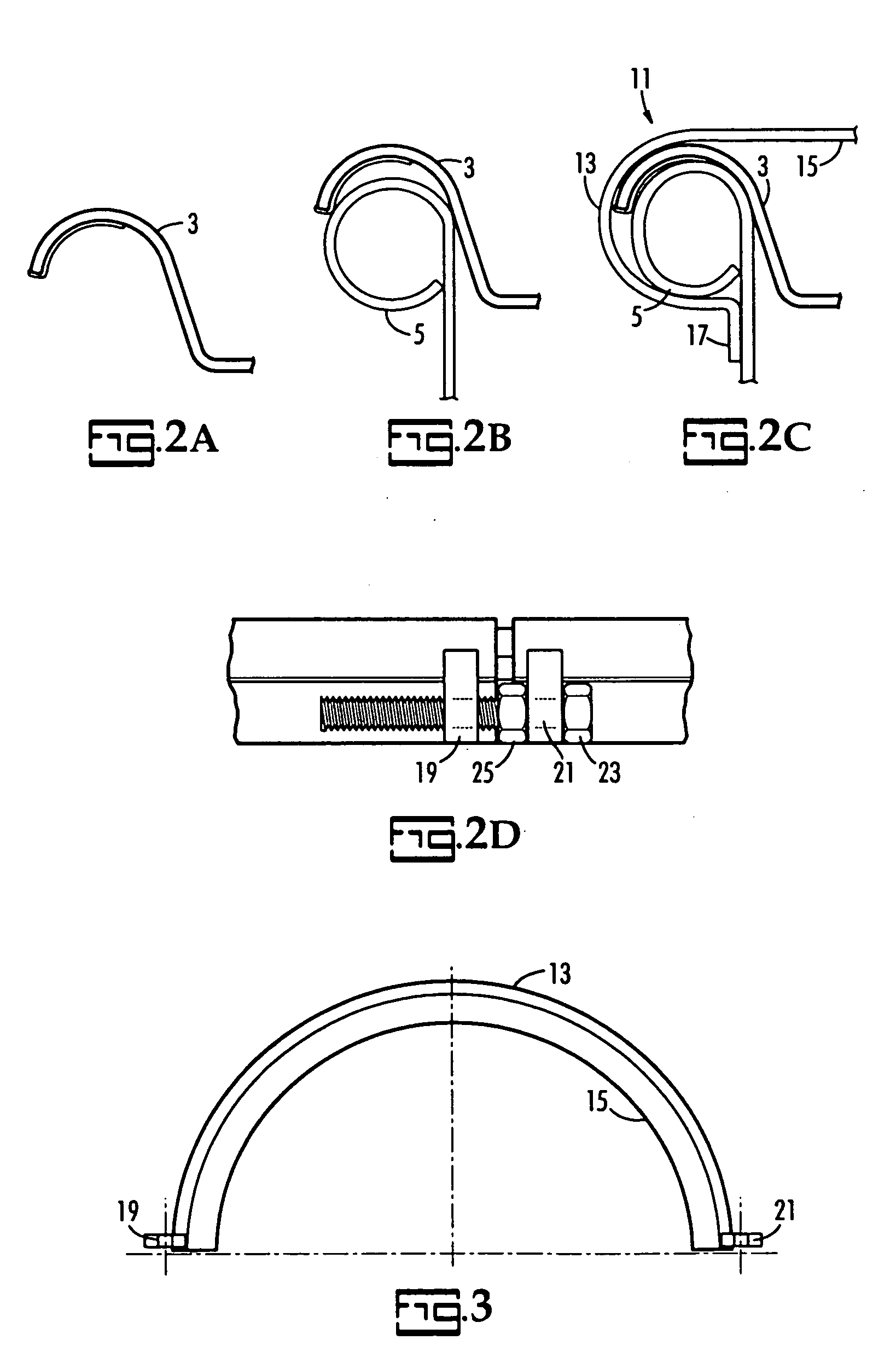

Clamshell closure for metal drum

Closure ring to retain a lid in contact with a metal drum in central C-section conforming to the contact area between a lid and the rim of a drum and further having a radially inwardly directed flange and a vertically downwardly directed flange attached to the opposite ends of the C-section. The additional flanges reinforce the top of the drum by reducing deformation when the drum is dropped and maintain the lid in contact with the drum. The invention is particularly valuable in transportation and storage of fissile material.

Owner:BATTELLE SAVANNAH RIVER ALLIANCE LLC

Three piece lift arm apparatus and method

ActiveUS20100111656A1High strengthReduce distortion problemsArc welding apparatusArticle unpackingC sectionsEngineering

The present invention is a refuse truck lift arm with sections that are bolted, not welded, together. Where the sections are joined together there is a recess and key arrangement. The key is seated in the recess of each half and straddles the inner face that divides them. In this way, shear forces that would otherwise be entirely borne by the bolts are also placed on the key. Each of the three sections, called “weldments,” are welded together in a novel way. The welding placement and sequence reduces welding distortion. Two C-shaped steel pieces are used for each straight section of each weldment. First, interior reinforcing brackets are welded into each C-section. Next, the two C-shaped sections are welded together, with the weld being between the edges that will form the thin side of the arm.

Owner:CURBTENDER INC +1

Structures which can be dismantled and folded, consisting of interconnecting tubular elements

InactiveUS20060123734A1Improve stabilityEasy to operateBuilding componentsTowersC sectionsUniversal joint

Owner:CAZZOLARO SERGIO

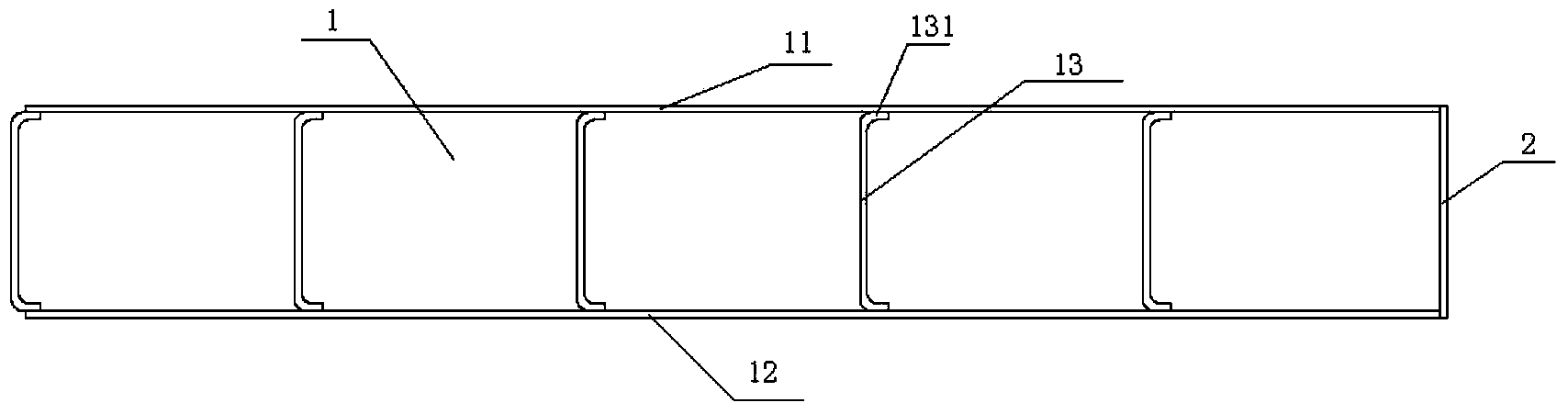

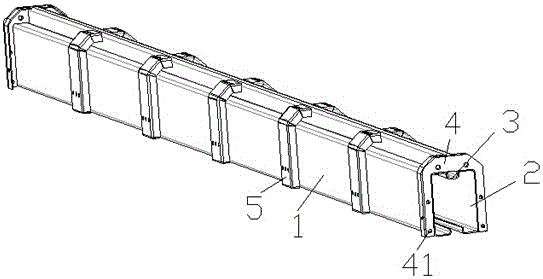

Steel tube bundle combination structure composed of steel plates and C-sections

The invention discloses a steel tube bundle combination structure composed of steel plates and C-sections. The steel tube bundle combination structure is formed by a steel tube bundle assembly, the steel tube bundle assembly is formed by sequentially connecting a plurality of steel tube units, each of the steel tube units has a cavity, and concrete is cast in the cavity; each of the steel tube units is formed by dividing a web between an upper flange and a lower flange paralleling to the upper flange, each of the upper flange and the lower flange is a continuous steel plate is a continuous steel plate, two end portions of the web have folding segments paralleling to the upper flange and the lower flange and having a same folding direction, and two ends of each of the folding segments are welded to the upper flange and the lower flange respectively; a front web and a lower web, the upper flange and the lower flange enclose to form the steel tube units; and the webs form a separation plate between adjacent steel tube units. In a steel tube bundle combination structural member, the steel tube bundle is made in a factory, and forms an integral body together with concrete cast in the steel tube bundle; and the steel tube bundle combination structural member can be used as a vertical bearing member, and can also be used as a lateral force resistance member.

Owner:HANGXIAO STEEL STRUCTURE

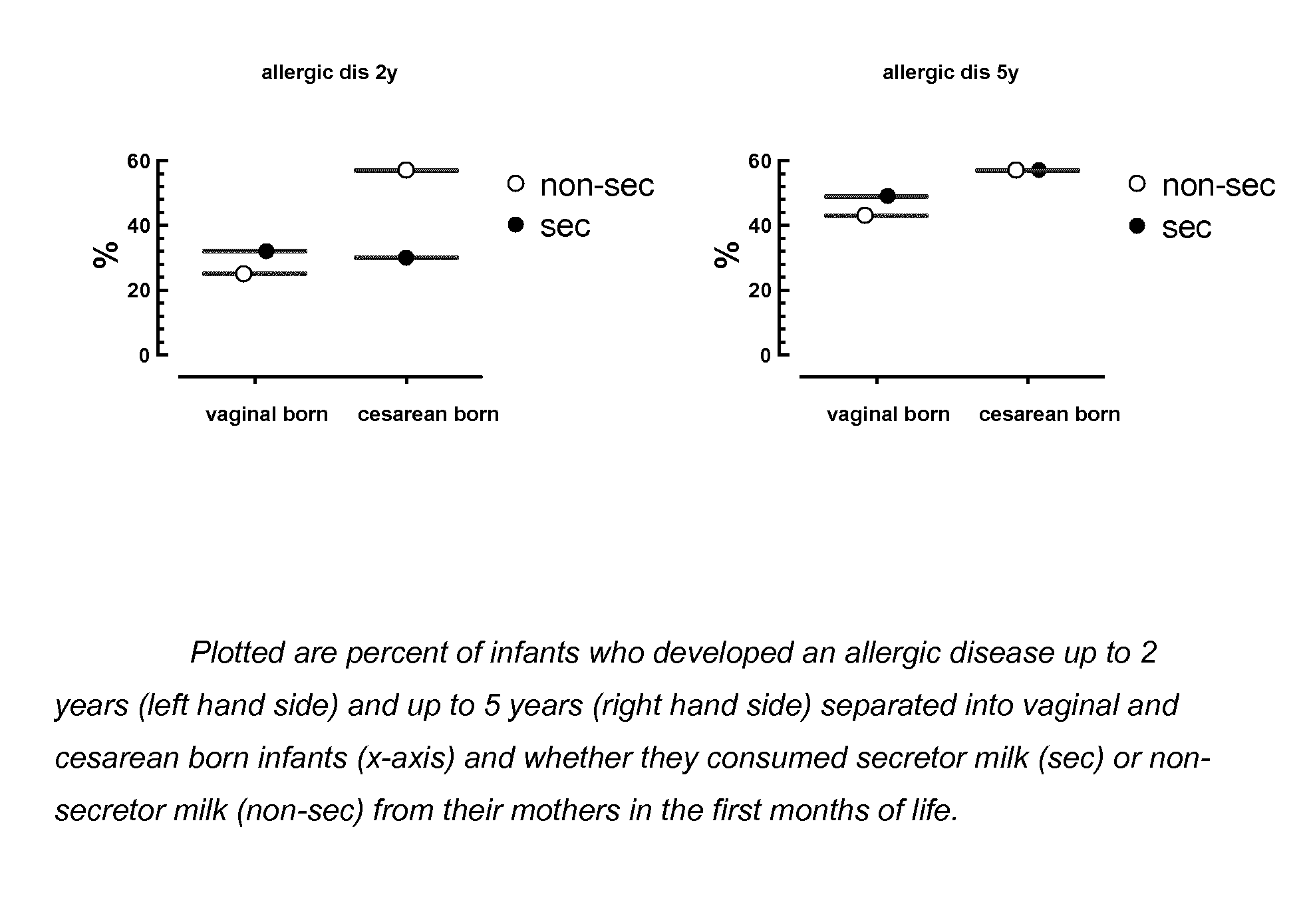

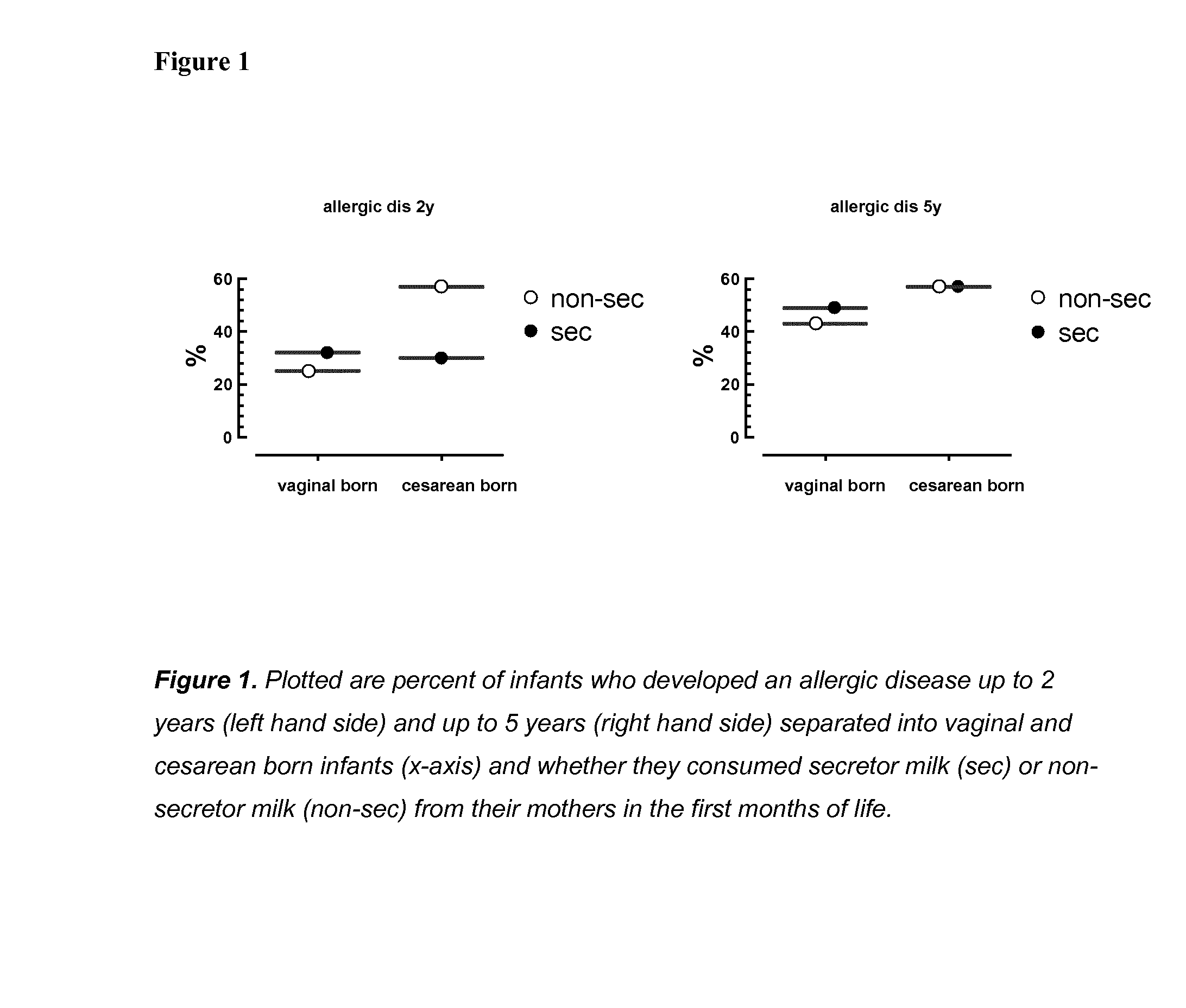

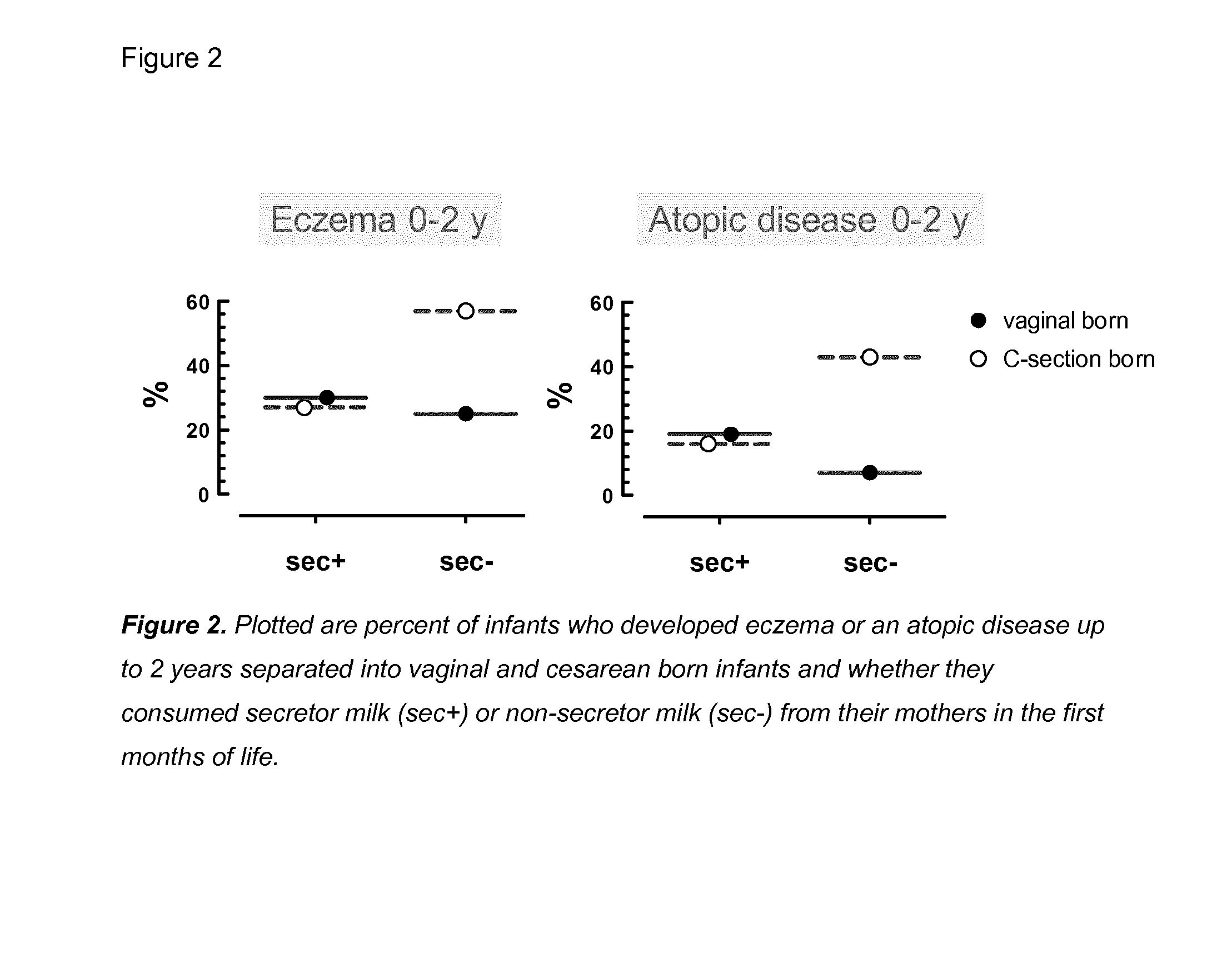

Compositions for preventing or treating allergies in infants from or fed by non secretor mothers by providing fucosylated-oligosaccharides in particular among infants at risk or born by c-section

ActiveUS20160296543A1Improve anti-allergic effectOrganic active ingredientsVitamin food ingredientsFucosylationC sections

The present invention relates to a composition comprising at least one fucosylated oligosaccharide, for use in preventing allergies and / or treating allergies and / or reducing the occurrence or the risk of allergies in an infant or a young child born from a mother deficient in at least one fucosylated oligosaccharide(s) or fed with a mother's milk deficient in at least one fucosylated oligosaccharide(s). The use of said composition in infant formula, milk fortifier or children's food is foreseen.

Owner:SOC DES PROD NESTLE SA

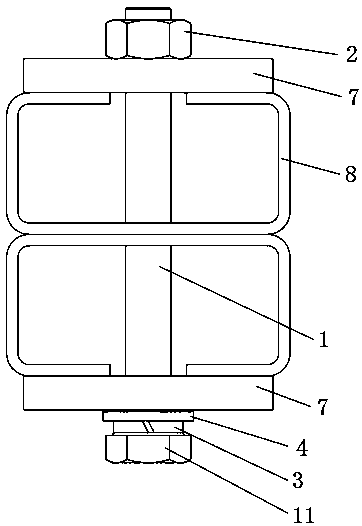

Combined-cabinet

PendingCN109038263APrevent looseningImprove connection reliabilitySubstation/switching arrangement casingsC sectionsEngineering

The invention relates to a combined cabinet. At least two cabinet body are included in that combine cabinet, each cabinet body comprises a cabinet body frame and a wall plate mounted on the cabinet body frame, the cabinet frames of two adjacent cabinets are provided with paired C-profiles which are arranged correspondingly and have opposite openings, A through-hole is arrange at that correspondingposition on the pair of C-shaped bar, One of the paired C-profiles is also provided with a groove-type connector therein, A groove of the groove-type connector is connected with an inner flange of acorresponding C-section, a groove bottom position of the groove-type connector is provided with a threaded hole for threaded connection with a connecting bolt threaded into the other one of the pairedC-sections through a through hole, and a groove inner space of the groove-type connector constitutes an accommodating space for accommodating the connecting bolt. The switch cabinet can be operated by only one person, which is convenient to operate and saves time and labor. The rear slot connector and bolt of the switch cabinet are all located in the C-section so as to avoid interference with thedoor lock and the hinge.

Owner:HENAN SENYUAN ELECTRIC CO LTD

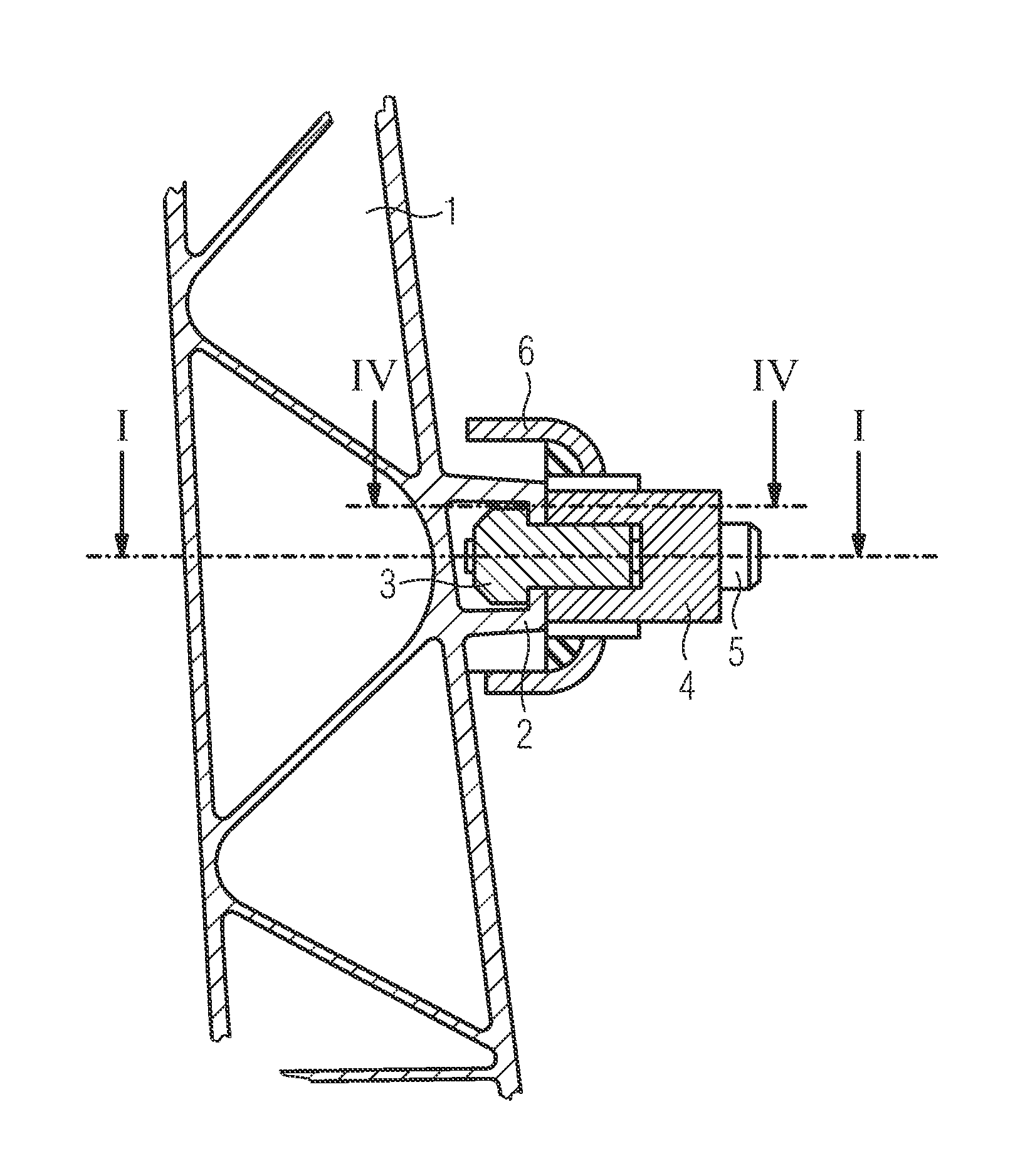

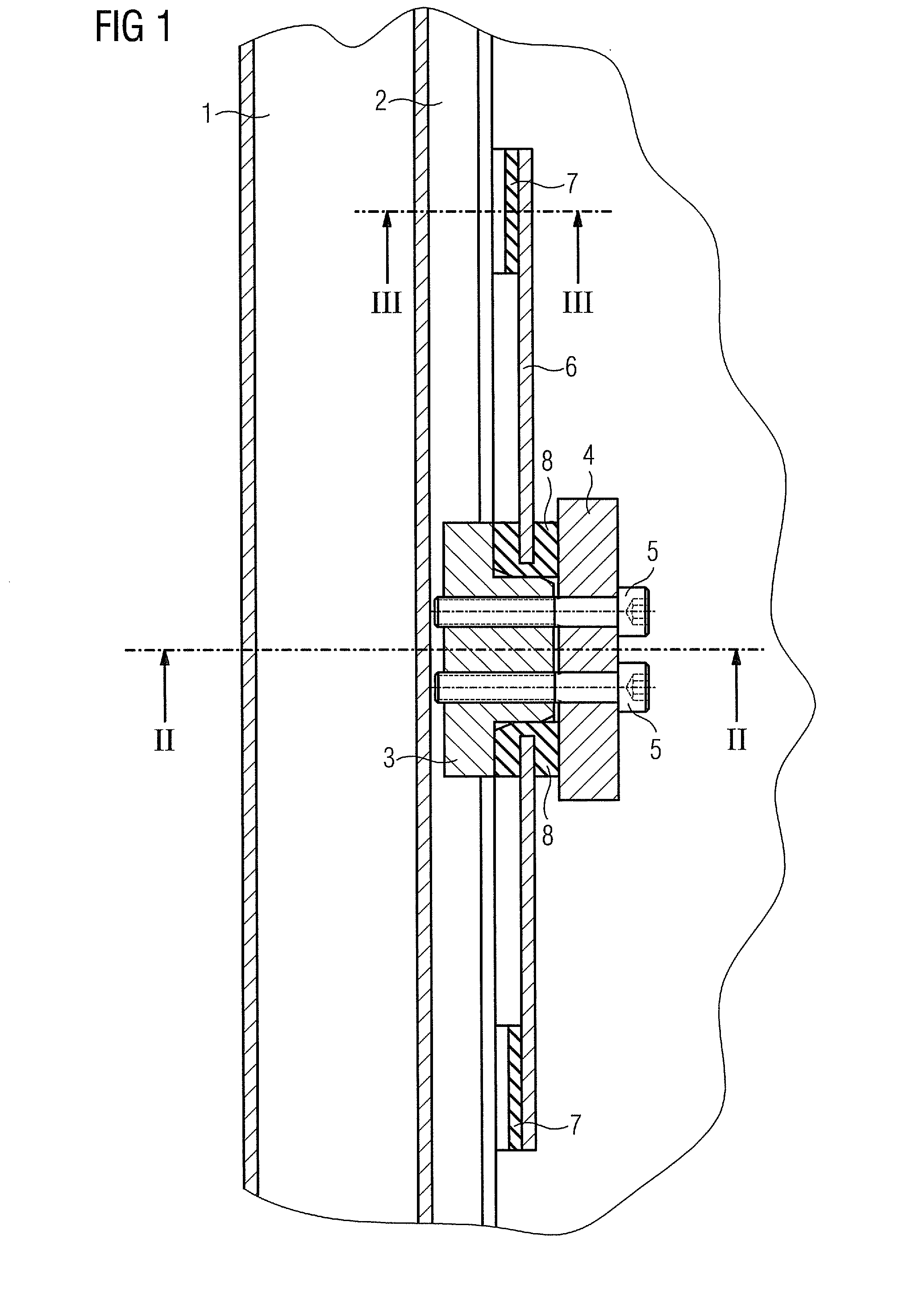

Fastening arrangement for a wall-supported and floor-supported element of an interior fitting of a vehicle

InactiveUS8845225B2Improve carrying capacityEqually distributedStands/trestlesKitchen equipmentTransverse forceC sections

Owner:SIEMENS AG

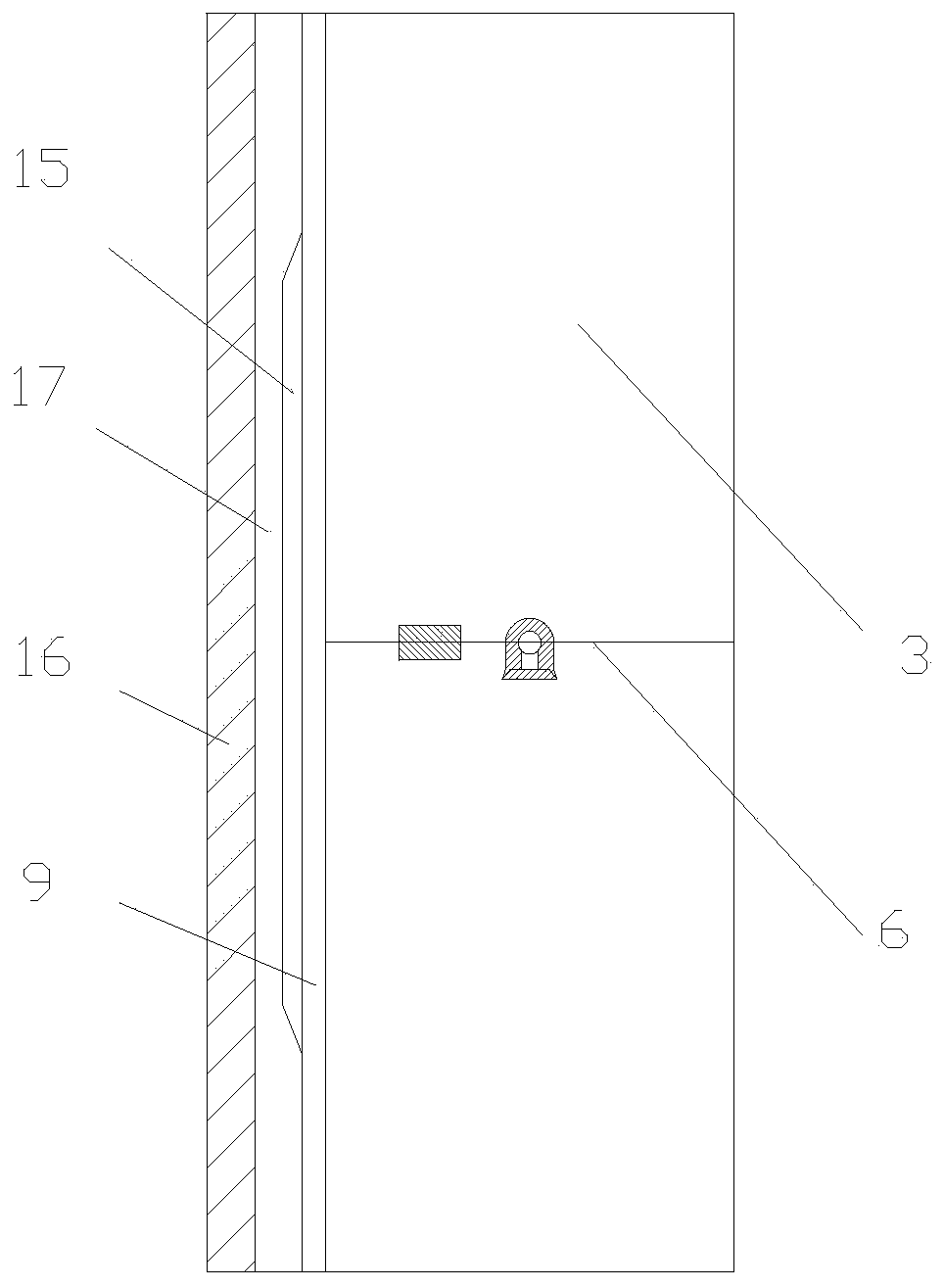

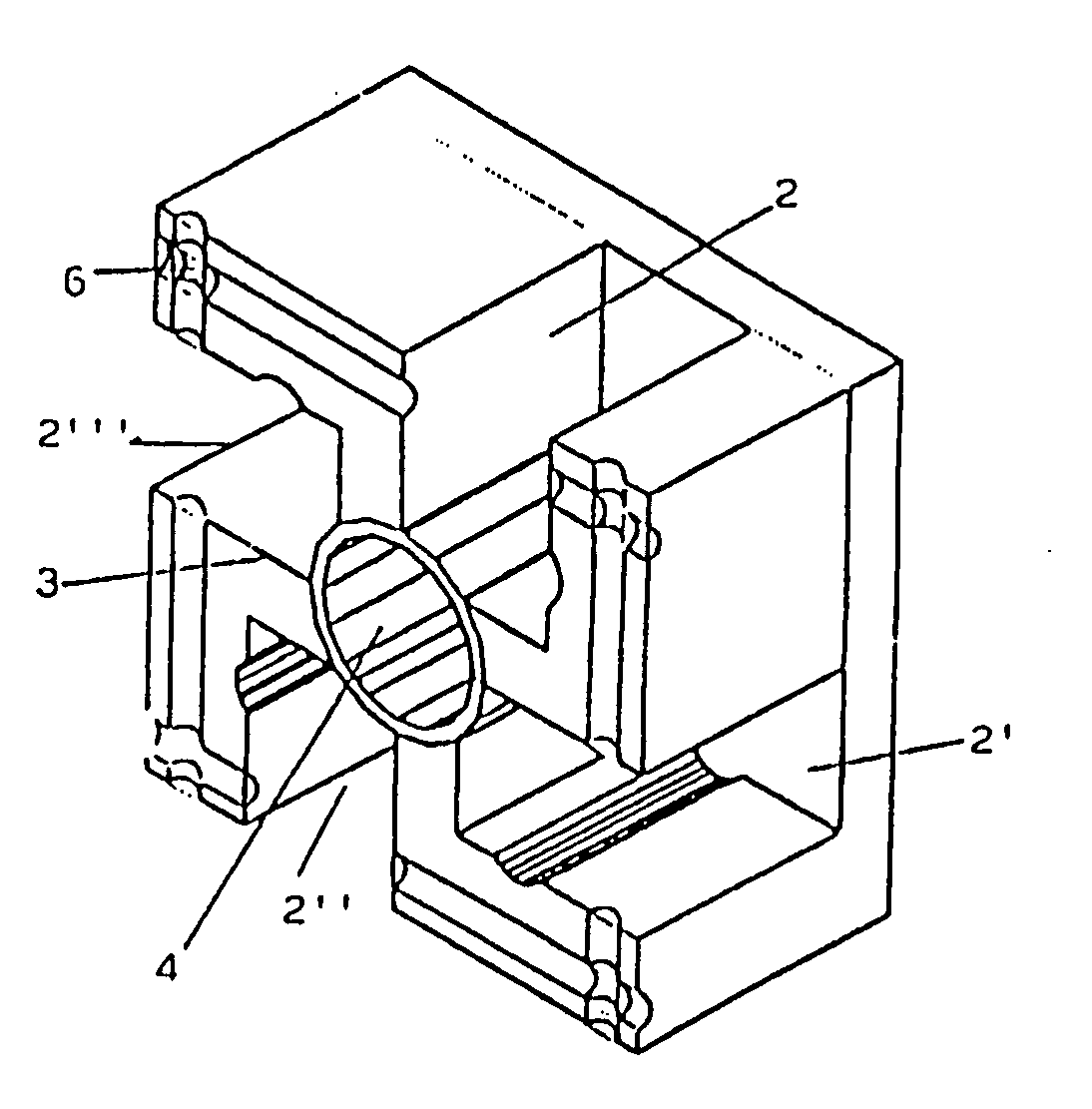

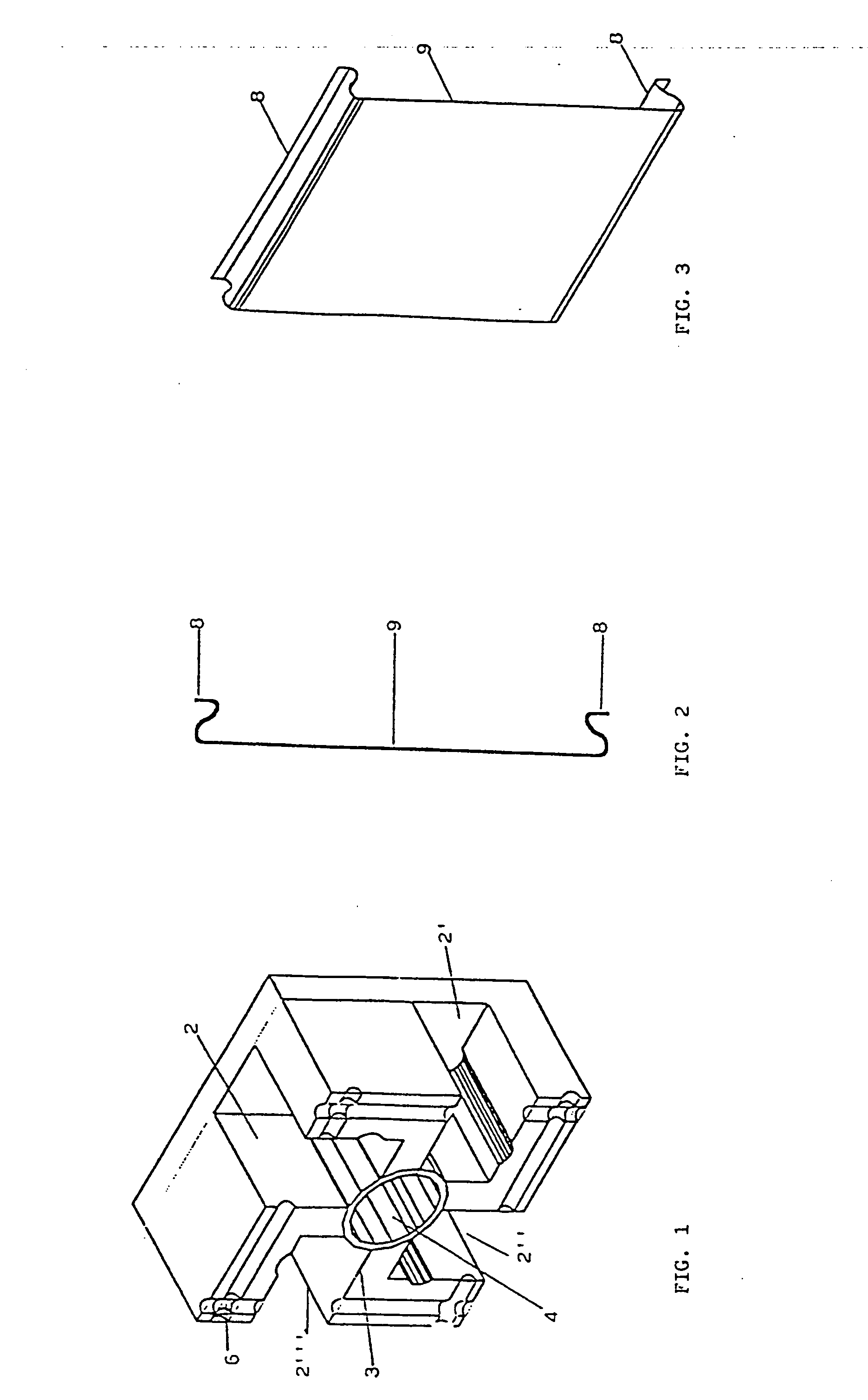

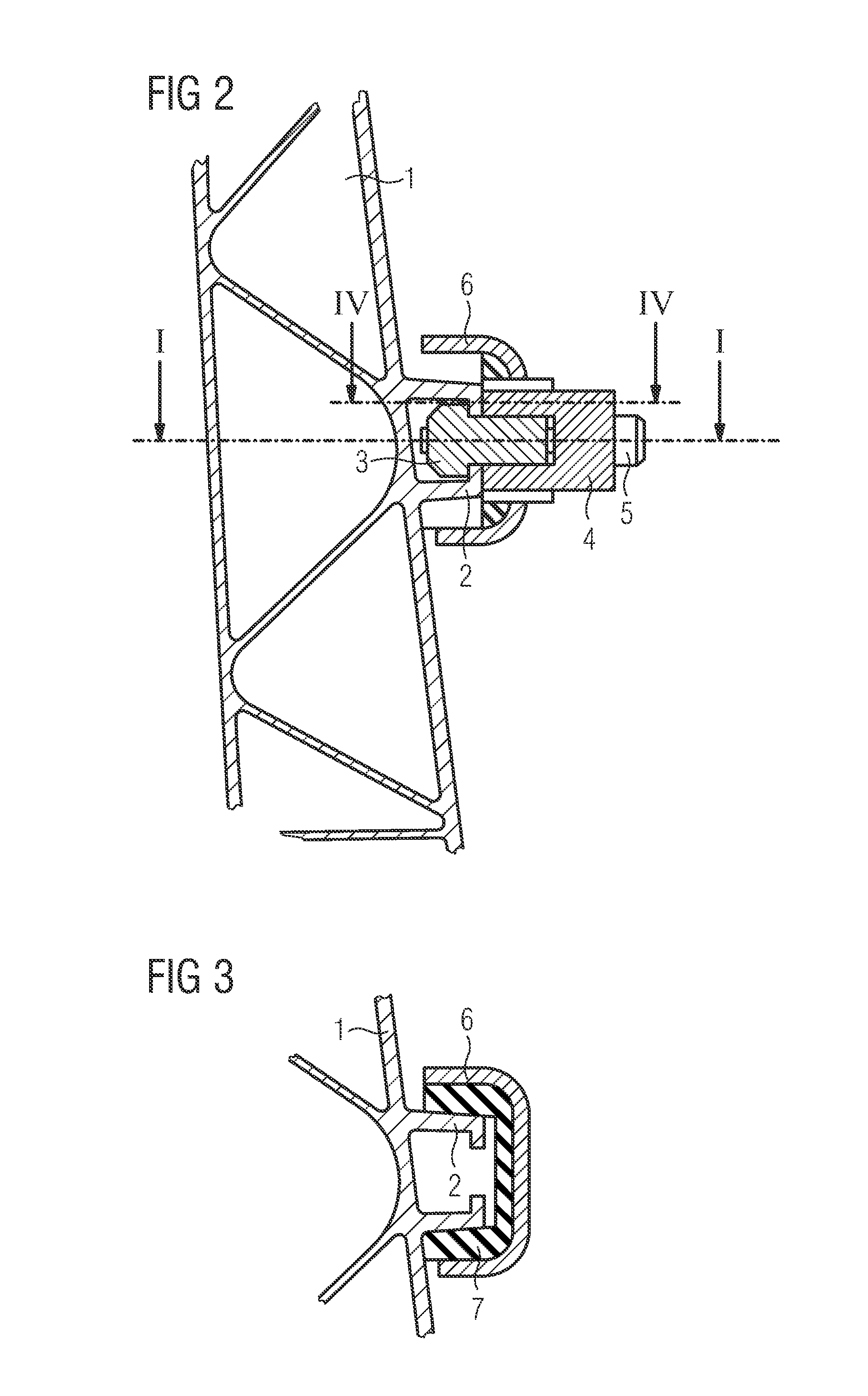

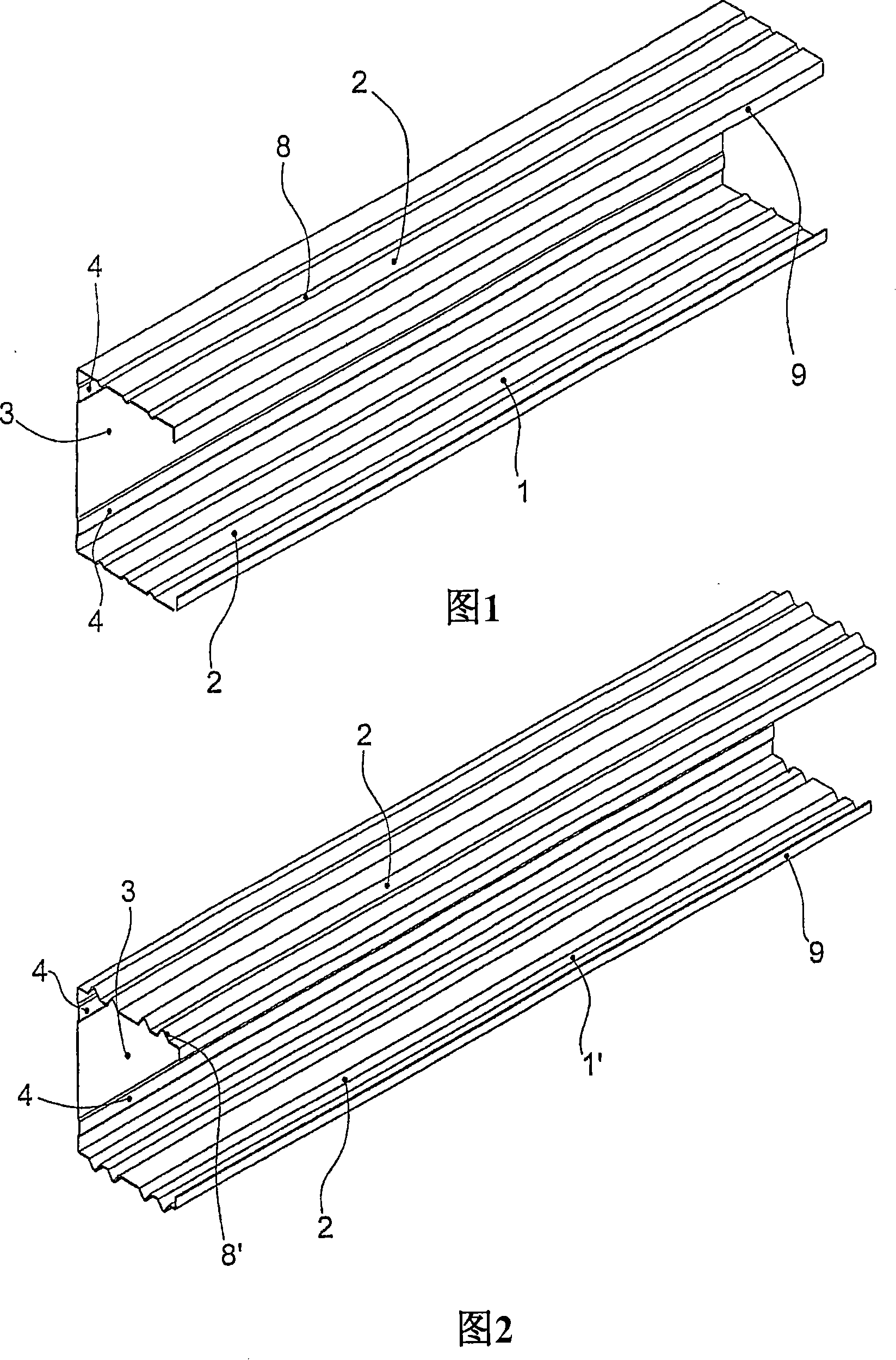

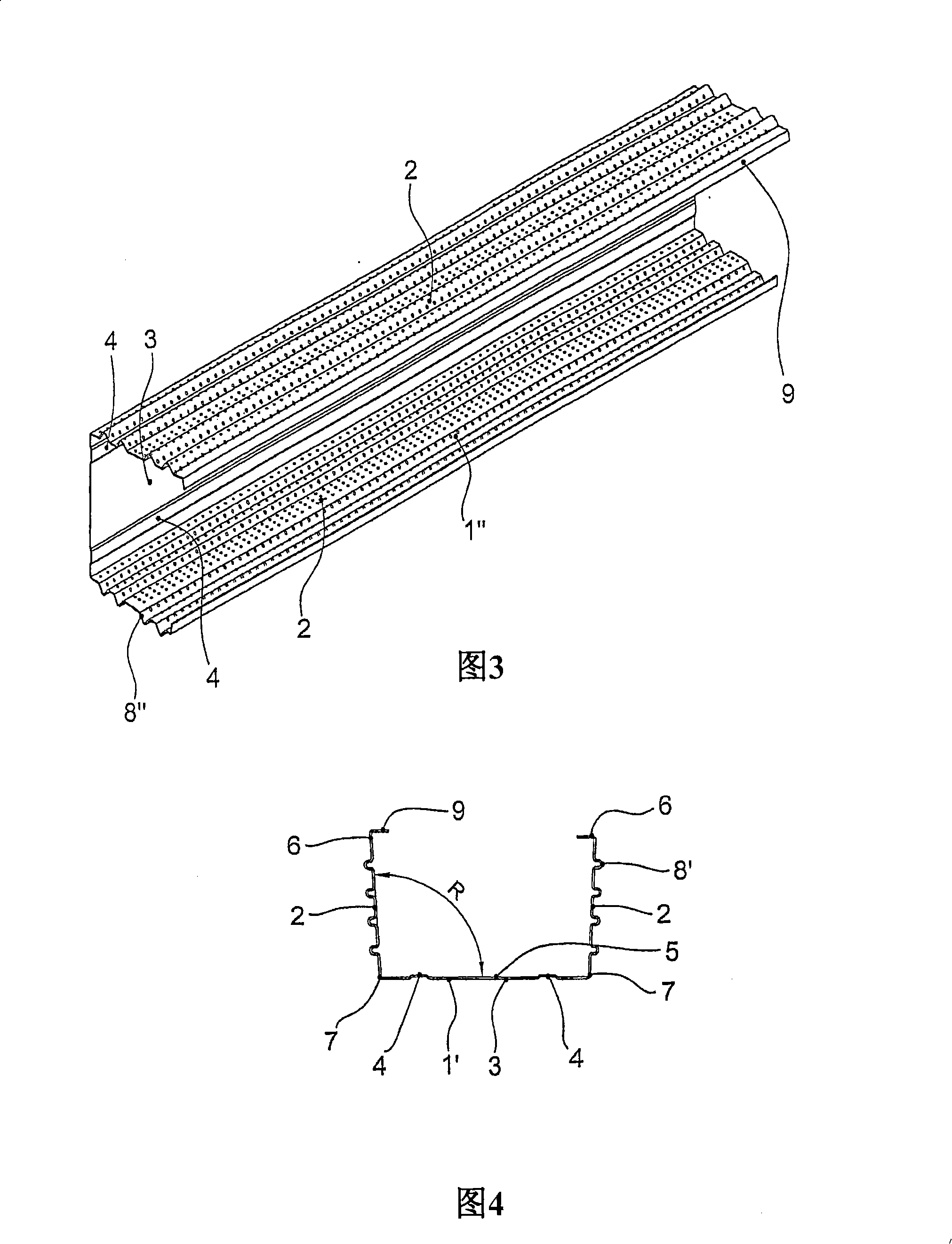

C-shaped profile and partition comprising a C-shaped profile

The present invention relates to a C-section bar (1, 1' and 1'') which is made of metal plate and a wall partition that is used to be covered at the two sides, and the section bar is provided with two side parts (2) and a base part (3) connected with the side parts (2). The invention is characterized in that the base part (3) synthesizes an angular aperture (R) larger than 90 degrees to at least one side part (2) in the no-load state of the C-section bar (1, 1' and 1'').

Owner:RICHTER SYST

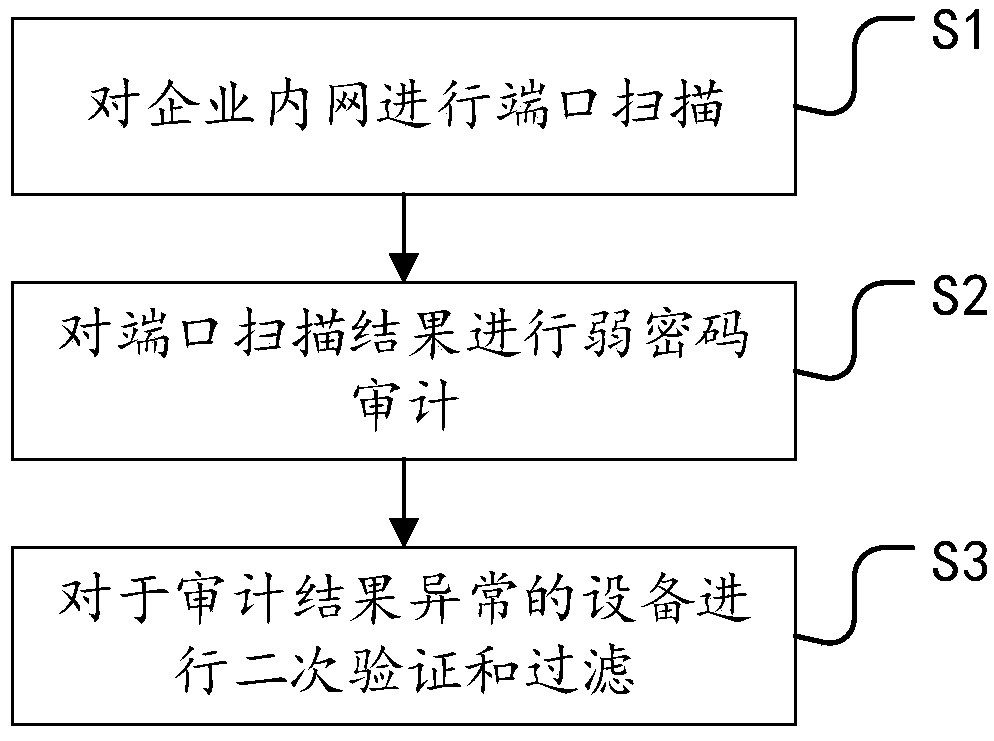

Method and system for rapidly detecting enterprise intranet equipment SSH weak password

InactiveCN108965264AImprove weak password detection efficiencyImprove detection efficiencyTransmissionC sectionsIp address

The invention provides a method and a system for rapidly detecting an enterprise intranet equipment SSH weak password. The method comprises the following steps that S1, port scanning is performed on the enterprise intranet; S2, weak password auditing is performed on the port scanning result; and S3, secondary verification and filtering are performed on the equipment of which the audit result is abnormal. The IP address range of each mechanism is accurate to the C section through full IP range pin detection of the enterprise intranet, then port scanning is performed on the enterprise intranet by using zmap and weak password auditing and secondary verification are performed on the scanning result so that the SSH weak password of various types of equipment in the enterprise intranet can be rapidly discovered, the problems of difficult detection and low efficiency of the SSH weak password caused by the complex intranet environment and high number of active IPs can be solved, the weak password detection efficiency of the intranet equipment can be enhanced and the risk that the attacker remotely logs in the enterprise intranet for attack can be reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Structures which can be dismantled and folded, consisting of interconnecting tubular elements

Owner:塞尔焦·卡佐拉罗

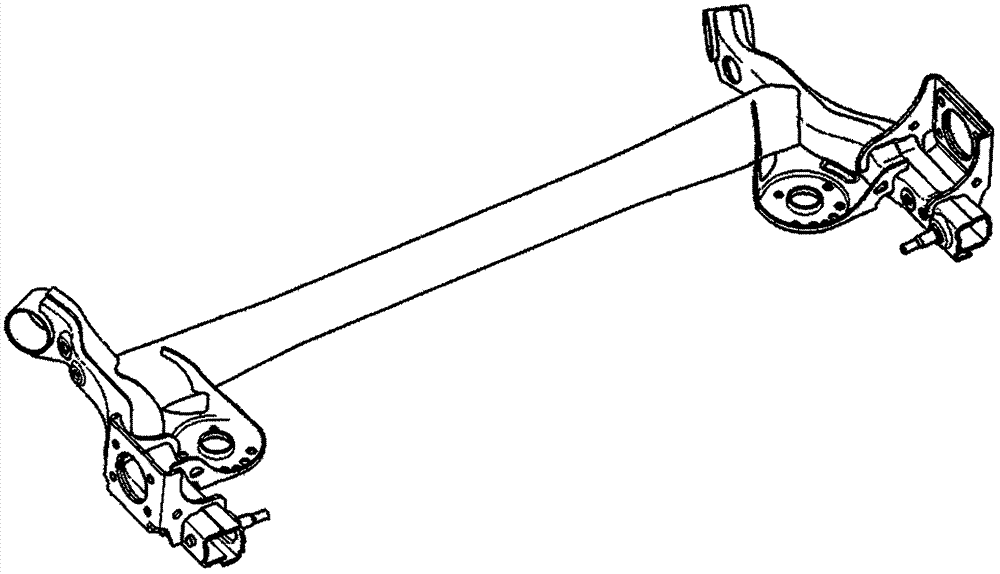

Torsion beam welding assembly structure

The invention relates to a torsion beam welding assembly structure and belongs to the technical field of automobile design and manufacture. The torsion beam welding assembly structure comprises a sheet metal structure formed by welding in a fastened mode two vertical surfaces of a C-section-shaped grooved upper plate and two vertical surfaces of a C-section-shaped grooved lower plate; the sheet metal structure is composed of a middle beam section, a left end and a right end at both ends of the middle beam section, and left and right transitional sections between the middle beam section and thetwo ends; the left end and the right end, as well as the left transitional section and the right transitional section, are structurally symmetric. The torsion beam welding assembly structure integrates a left longitudinal arm and a right longitudinal arm with the cross beam without T-shaped lap welding, and has a cross section in a closed structure, thereby being higher in fatigue performance than common open beams; meanwhile, the torsion beam welding assembly structure is regular in integral shape, smooth in welding joints, capable of reducing the number of the welding joints, and favorableto achieving robot welding.

Owner:IAT AUTOMOBILE TECH

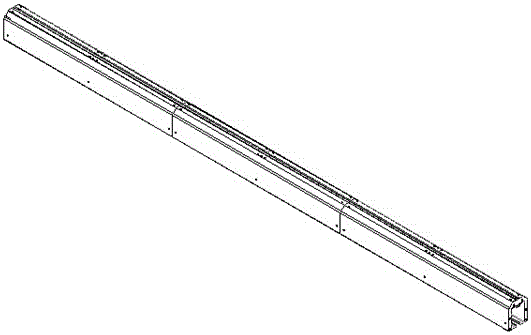

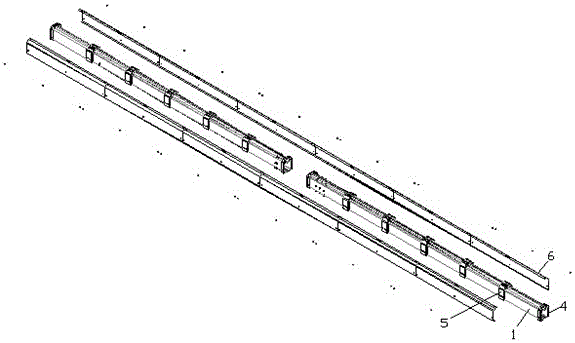

A spliced bottom beam track that prevents deformation from light and temperature difference

ActiveCN105041090BPrevent thermal deformationImprove structural strengthGates/doorsWing suspension devicesC sectionsThermal deformation

The invention discloses a spliced bottom beam track for preventing deformation due to light temperature difference, comprising: a first C-shaped steel, a second C-shaped steel and a rectangular steel pipe, the outer sides of the first C-shaped steel and the second C-shaped steel are respectively covered with C-shaped For the protective cover, several reinforcing ribs are provided between the outer sides of the first C-shaped steel and the second C-shaped steel and the C-shaped protective cover, and the ends of the first C-shaped steel and the second C-shaped steel are provided with tabs to The bottom beam is spliced, and threaded mounting holes are respectively arranged on the first straight channel steel and the second straight channel steel. Through the above method, the jointed bottom beam rail of the present invention that prevents deformation due to light temperature difference has high structural strength, good ventilation and heat dissipation, avoids thermal deformation of the first C-shaped steel and the second C-shaped steel, and adopts a spliced structure, which is convenient Installation and maintenance replacement, reducing installation and post-use costs.

Owner:张家港集优特防护设施有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com