Curved surface space pipe truss structure and mounting method thereof

An installation method and pipe truss technology, applied in the field of truss structure, can solve the problems of difficult construction of inclined column stability, deformation and damage of truss structure, inconvenient installation of roof truss, etc., and achieve easy engineering quality assurance, reduced construction costs, and simple construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

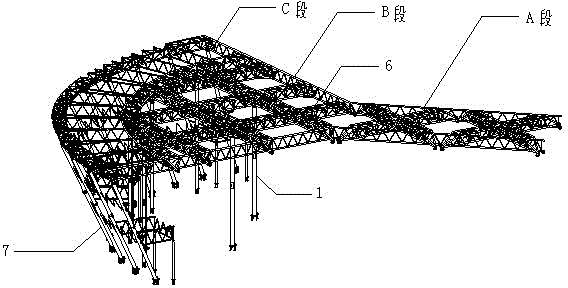

[0064] The main entrance of the administrative building of Kuwait International Airport adopts a curved space truss structure. see now figure 1 , figure 1 It is a schematic diagram of a curved space tube truss structure according to an embodiment of the present invention. As shown in the figure, the curved space tube truss structure includes a rectangular section A roof truss, a fan-shaped B-section roof truss and a fan-shaped front C-section roof truss, and is characterized in that:

[0065] The fan-shaped B-section roof truss is arranged in the middle of the curved space tube truss structure, the fan handle is connected to the rectangular A-section roof truss, and the fan front is connected to the fan-shaped front C-section roof truss.

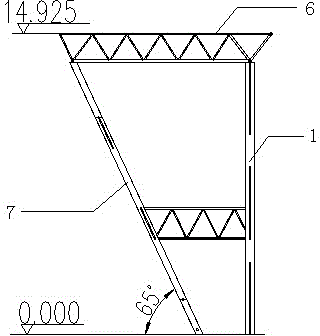

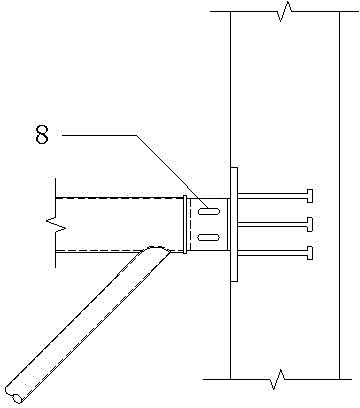

[0066] Among them: the rectangular section A roof truss is composed of two cross-shaped trusses connected, the rectangular section A roof truss and the fan-shaped section B roof truss are supported by several columns 1, and the columns are...

Embodiment 2

[0068] The main entrance of the administrative building of Kuwait International Airport adopts a curved space truss structure. The roof trusses are composed of steel pipes with diameters of 193mm, 159mm, 121mm, and 60mm. The materials are all S275N. The heaviest weight of a single roof truss is 2.8 tons. The total length of the main entrance truss is 60m, the total width is 57m, and the total weight is about 137 tons.

[0069] The installation method of the curved surface space pipe truss structure of the present invention is to manufacture the truss members domestically, transport them by sea in containers, assemble them at overseas construction sites, and then hoist them. It is characterized in that it includes the following steps:

[0070] a. Preparatory work before construction

[0071] (1) Prepare site operating conditions

[0072] "Three connections and one leveling" at the construction site; the relevant foundation floor and other projects are basically completed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com