Power generation fabric structure and preparation method thereof

A technology of fabric structure and conductive fabric, applied in the directions of generators/motors, knitting, electrical components, etc., can solve the problems of mutual contact of multiple piezoelectric yarns, short circuit of smart fabrics, affecting the user experience of smart fabrics, etc. The effect of avoiding short circuit phenomenon and improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

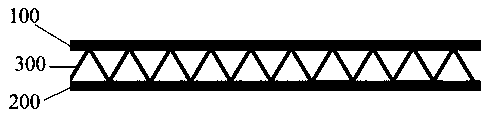

[0034] Figure 4 It is a method flow chart of a method for preparing a power generating fabric structure shown according to an exemplary embodiment, as shown in Figure 4 As shown, the preparation method of the power generating fabric structure comprises:

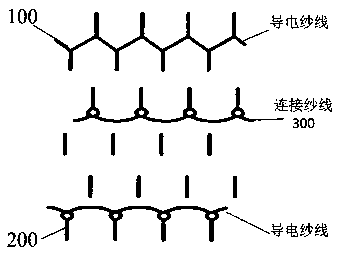

[0035] Step 401: Weaving a first conductive fabric and a second conductive fabric with conductive yarns.

[0036] The conductive yarn is one of silver-plated conductive yarn and polyamide / stainless steel staple fiber blended yarn.

[0037] Step 402: using the core electrode as the core layer and the PVDF fiber as the shell layer to prepare a connecting yarn with a shell-core structure.

[0038] Step 403: Ground the core electrode of the connected yarn, and polarize it with a voltage of 6kV for 4 minutes. The direction of the polarized electric field is from the shell layer of the connected yarn to the core layer. After polarization, the connected yarn is clamped between two pieces of grounded metal The surface decharge t...

Embodiment 1

[0044] (1) The first conductive fabric and the second conductive fabric are respectively woven with silver-plated conductive yarns.

[0045] (2) Using carbon black / polyethylene as the core layer and PVDF fiber as the shell layer, a connecting yarn with a shell-core structure was prepared.

[0046] (3) The core electrode of the connecting yarn is grounded, and a voltage of 6kV is used to polarize for 4 minutes. The direction of the polarized electric field is from the shell layer of the connecting yarn to the core layer. The surface decharge treatment was carried out between two grounded metal plates for 5 minutes, and the direction of the dipoles in the connecting yarn after the surface decharge treatment was directed from the shell layer to the core layer.

[0047] (4) Using the connecting yarn to connect the first conductive fabric and the second conductive fabric, and connecting the conductive yarns in the first conductive fabric and the second conductive fabric through wir...

Embodiment 2

[0050] (1) Using polyamide / stainless steel staple fiber blended yarn to weave the first conductive fabric and the second conductive fabric respectively.

[0051] (2) Using graphene / polyethylene as the core layer and PVDF fiber as the shell layer, a connecting yarn with a shell-core structure was prepared.

[0052] (3) The core electrode of the connecting yarn is grounded, and a voltage of 6kV is used to polarize for 4 minutes. The direction of the polarized electric field is from the shell layer of the connecting yarn to the core layer. The surface decharge treatment was carried out between two grounded metal plates for 5 minutes, and the direction of the dipoles in the connecting yarn after the surface decharge treatment was directed from the shell layer to the core layer.

[0053] (4) Using the connecting yarn to connect the first conductive fabric and the second conductive fabric, and connecting the conductive yarns in the first conductive fabric and the second conductive f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com