Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Engineering quality is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

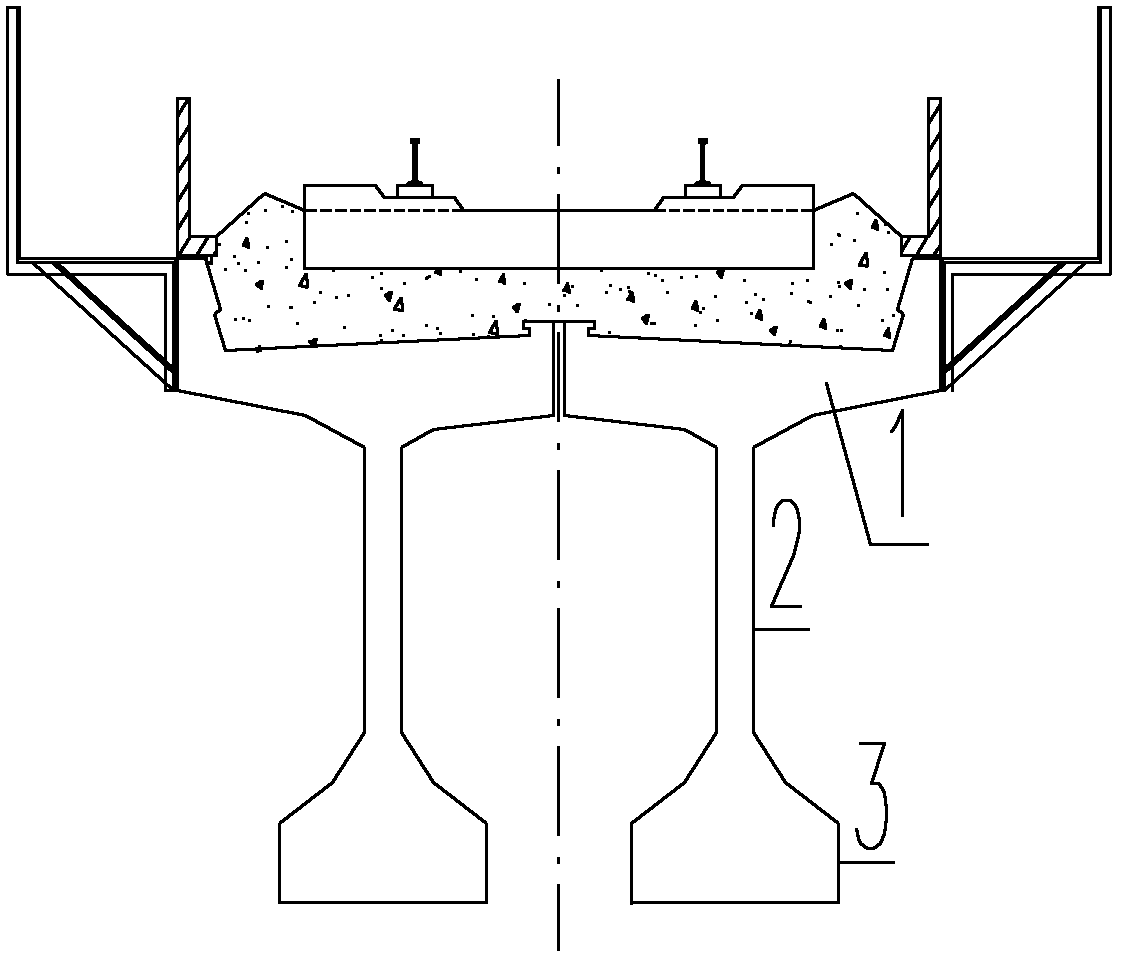

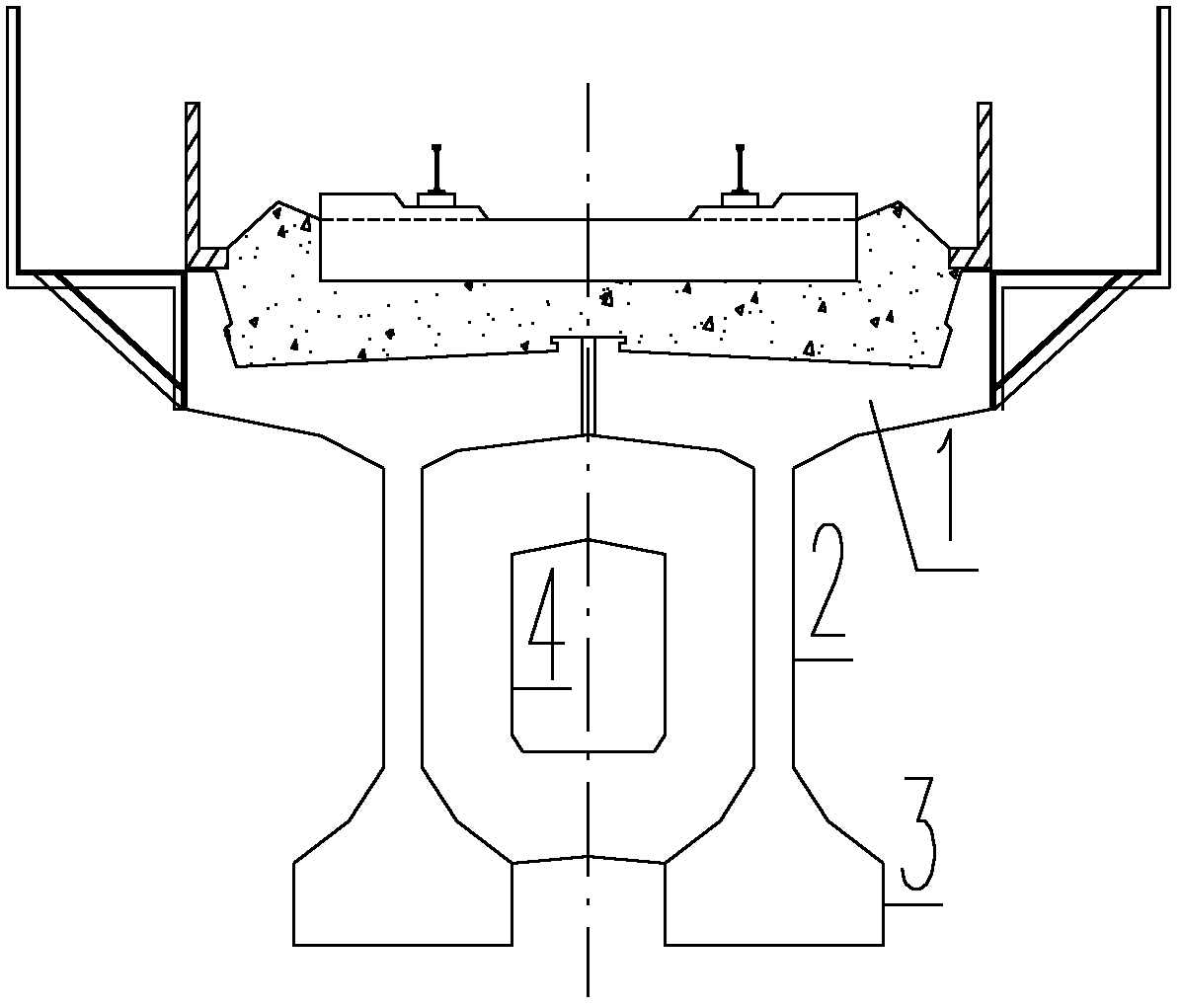

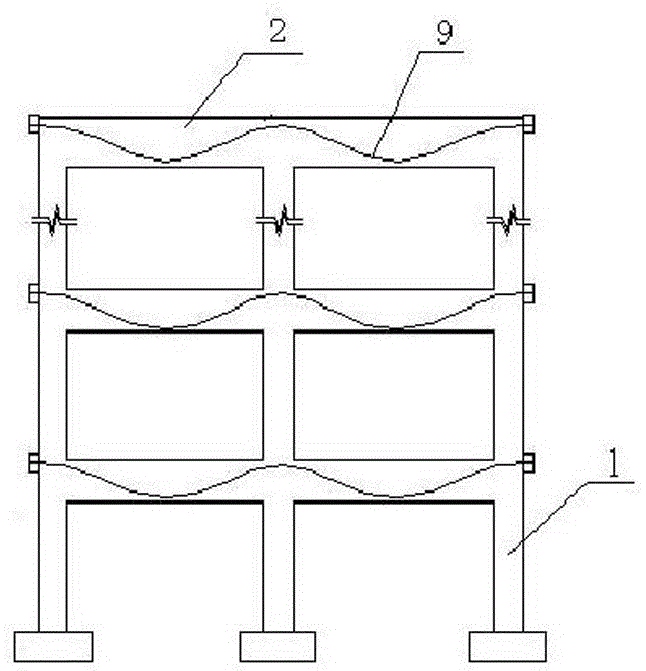

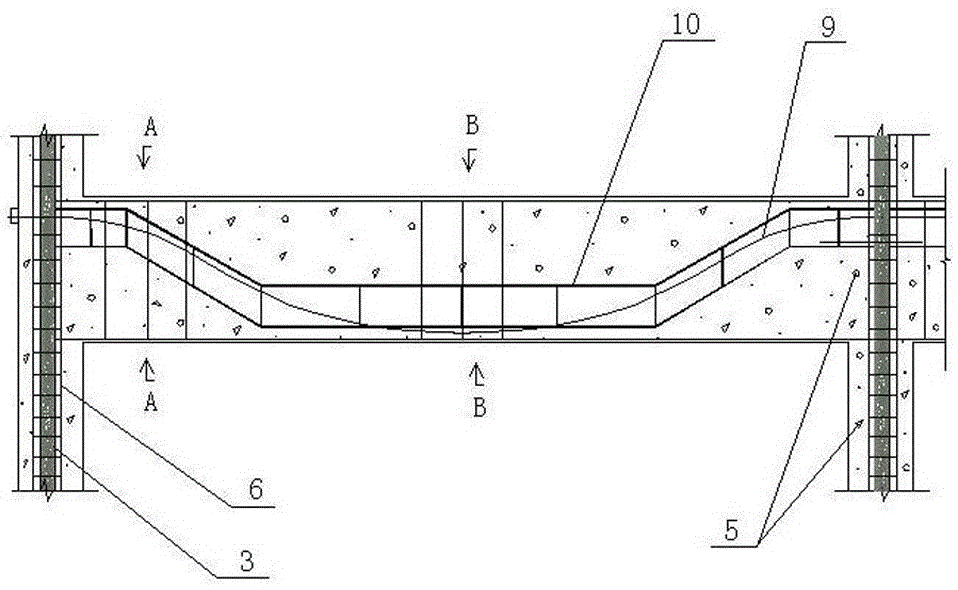

Self-balancing external prestressing strengthening method for bridge structure

ActiveCN102587296AReduce the burden onGive full play to the role of reinforcementBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

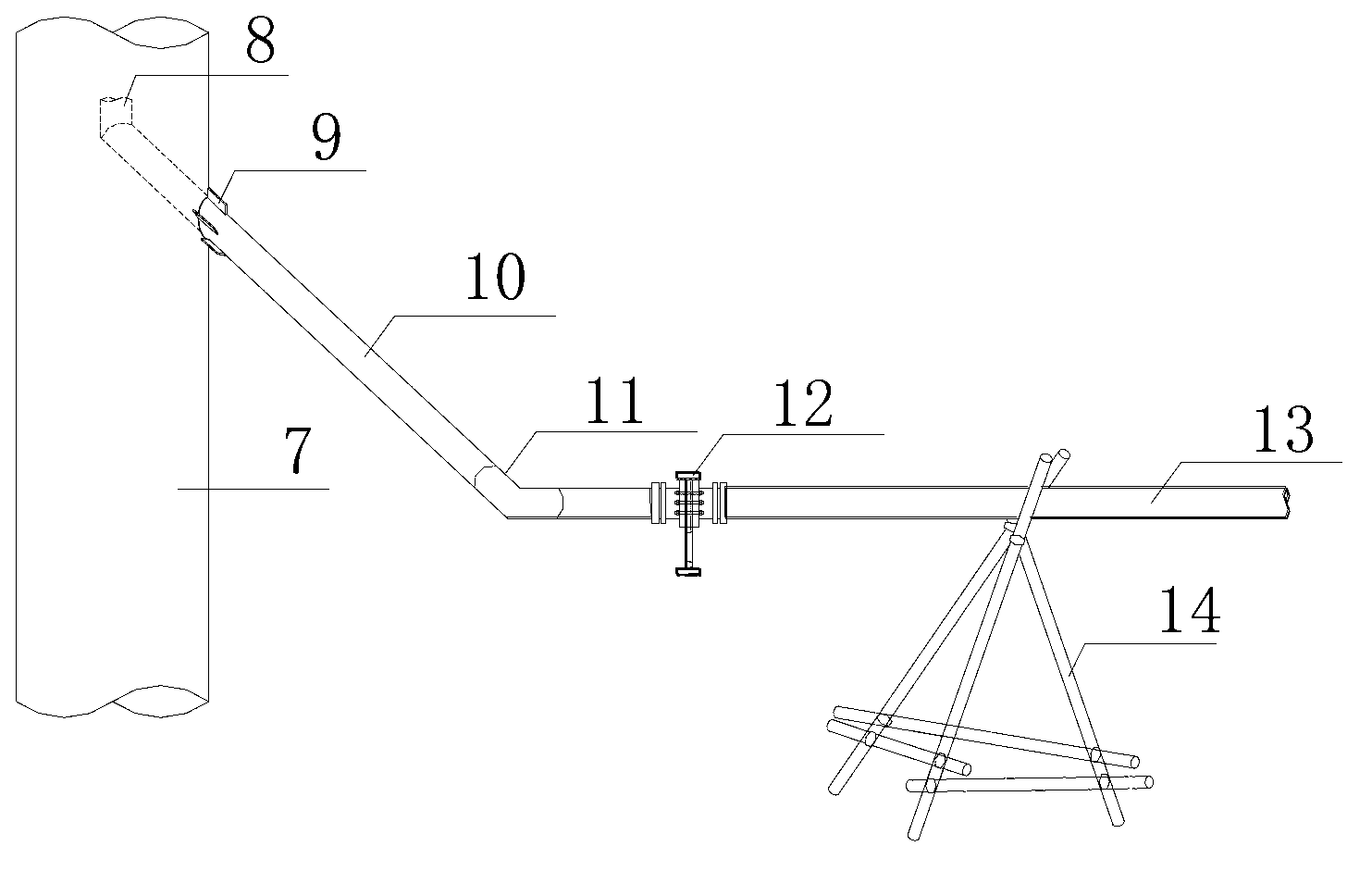

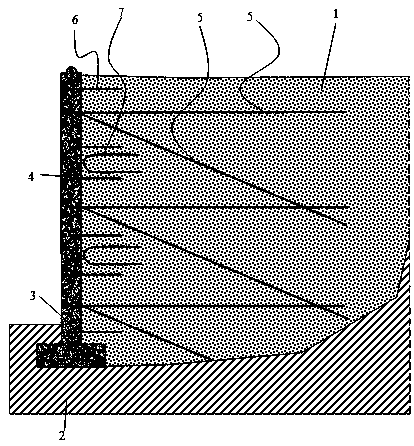

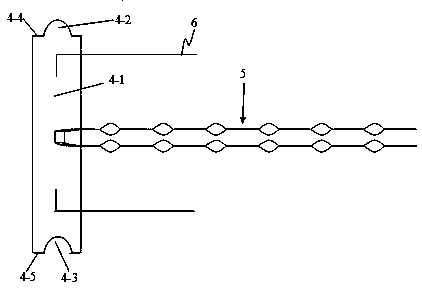

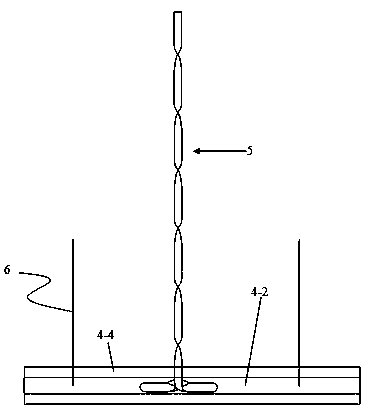

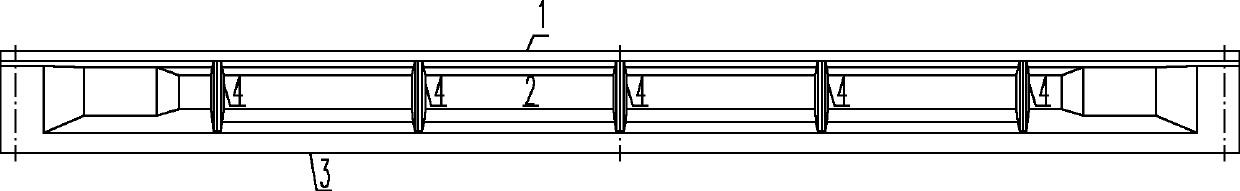

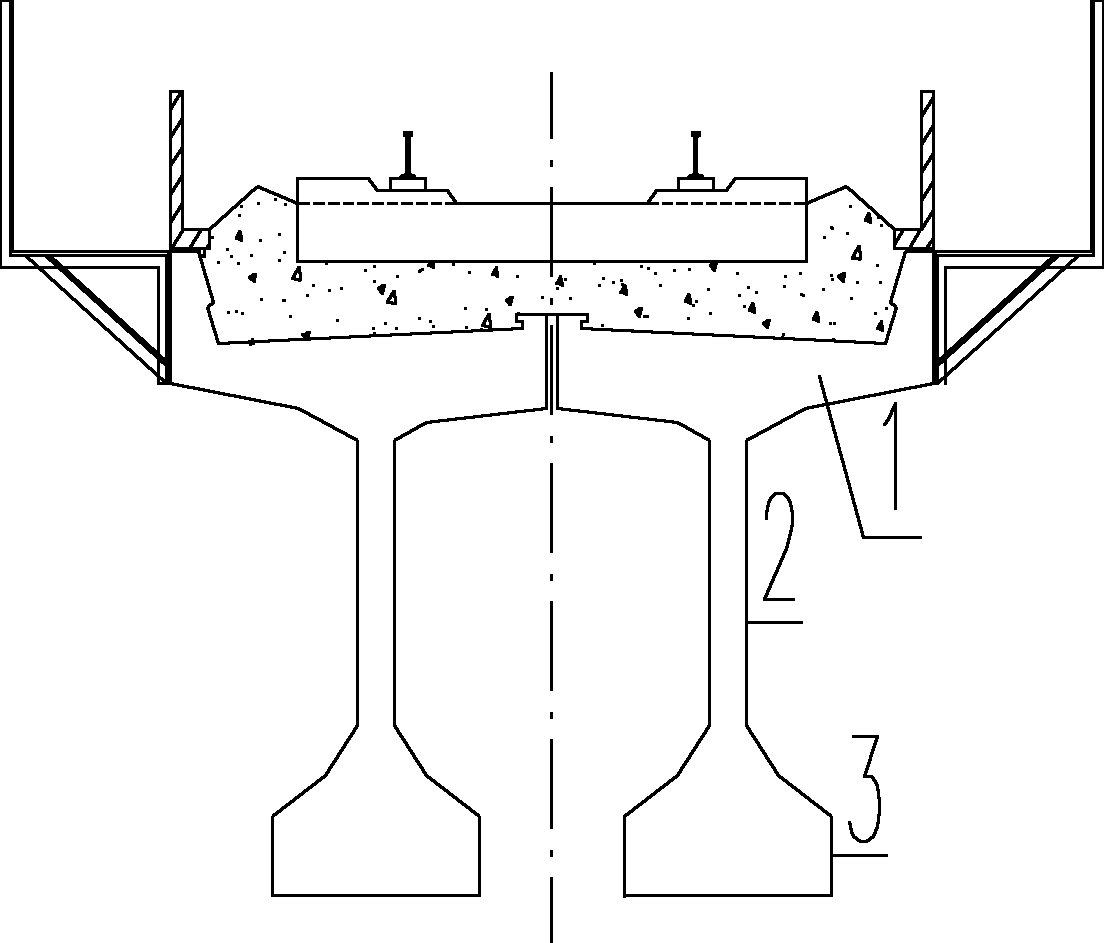

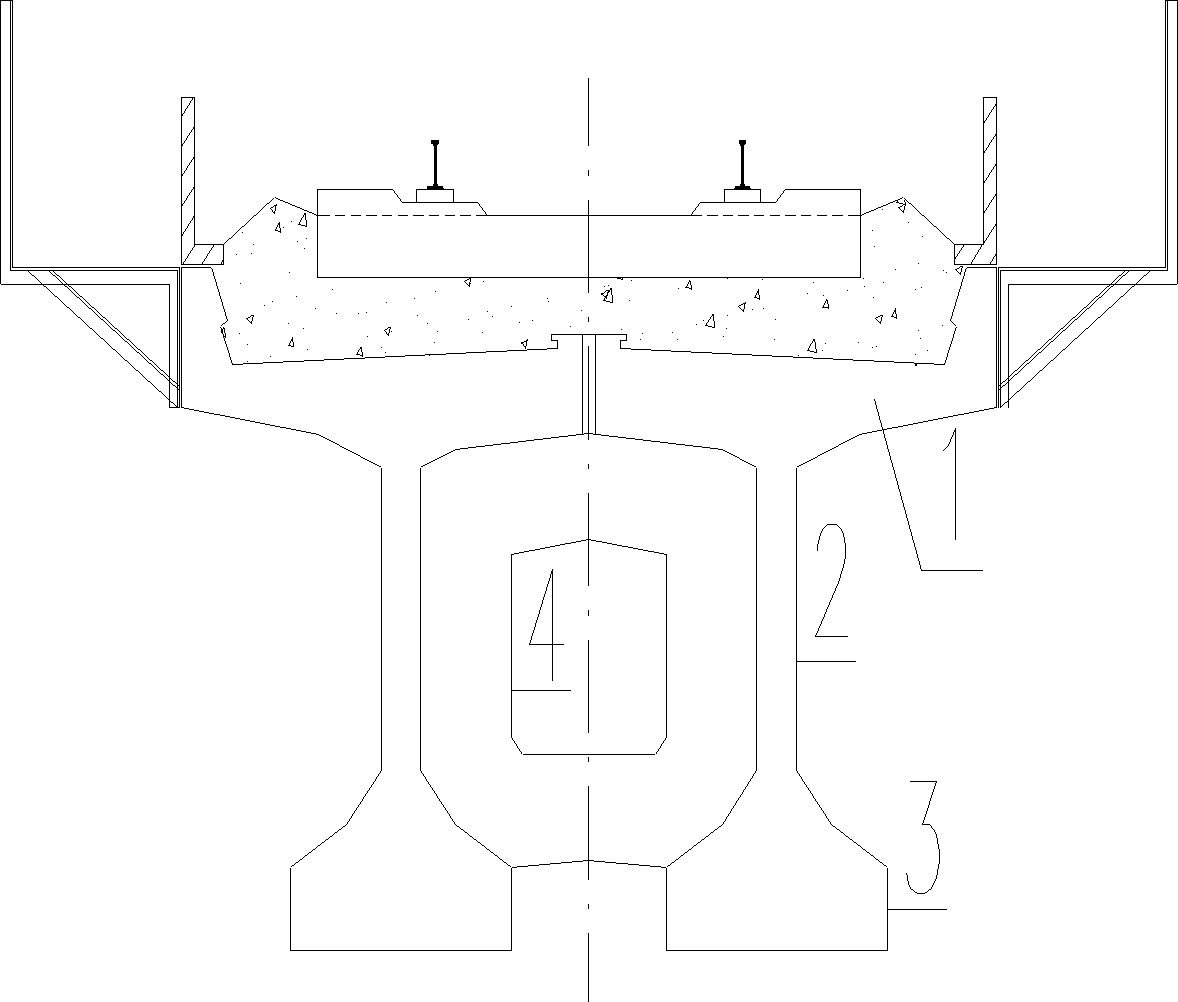

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

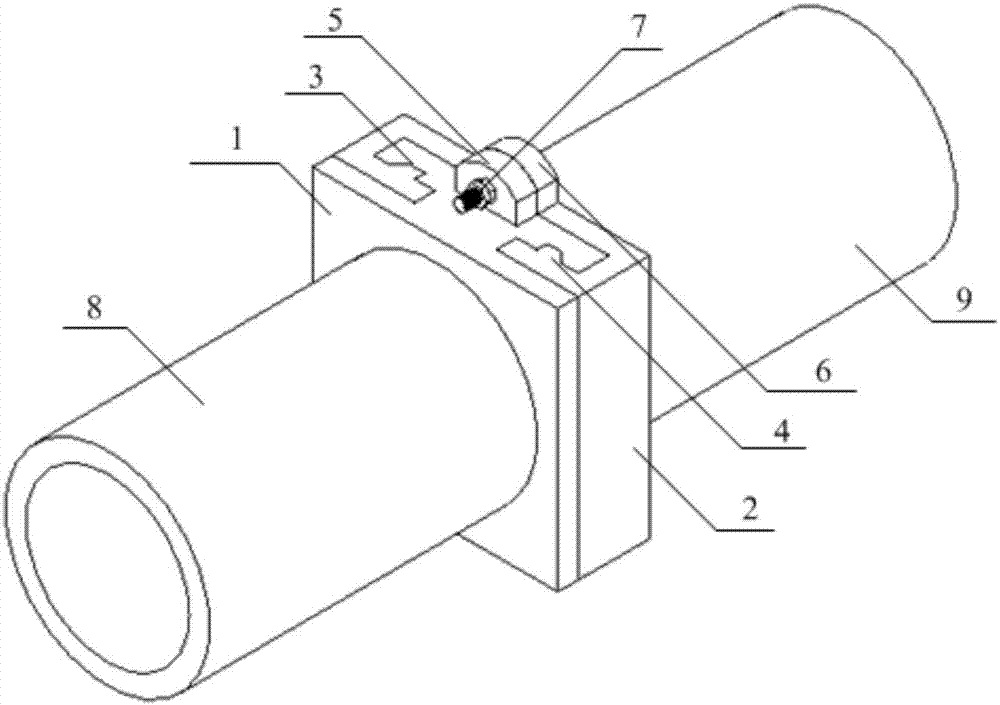

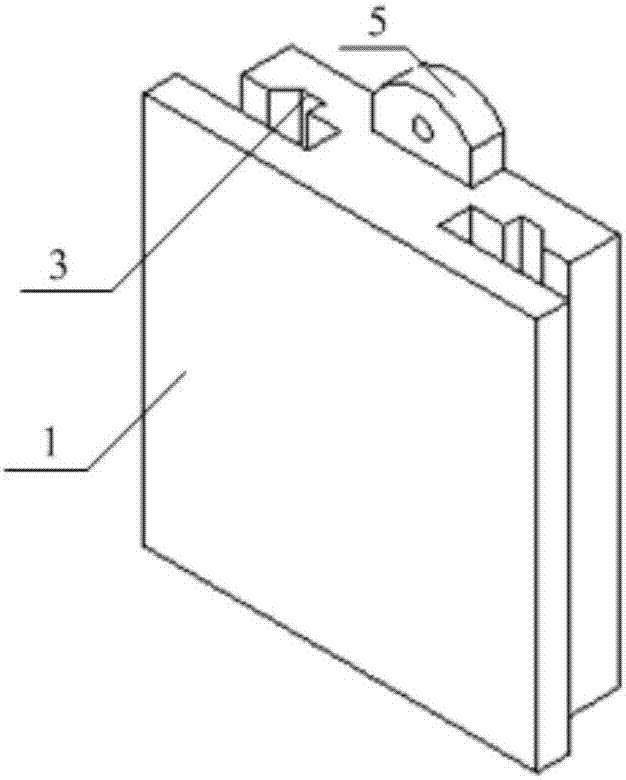

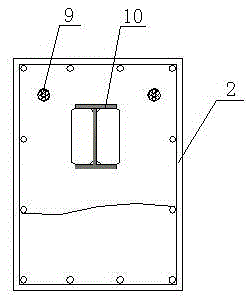

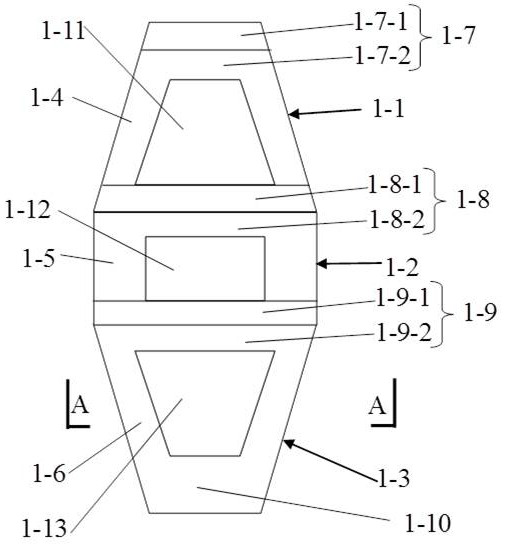

Steel structure tenon-mortise connector and connecting method thereof

PendingCN107060088AImprove welding qualityReduce pollutionBuilding constructionsTongue and grooveFlange

The invention discloses a steel structure tenon-mortise connector which comprises a tenon and a mortise. The tenon is of an I-steel structure, the mortise is a T-shaped steel sliding groove, and the I-steel structure and the T-shaped steel sliding groove are tightly combined in a tenon-mortise mode. In addition, grooves are formed in the two sides of an upper flange of the I-steel tenon in the height direction correspondingly, protruding heads are arranged on the two sides of a flange of the T-shaped steel sliding groove in the height direction correspondingly, and the protruding heads and the grooves are completely matched. The tenon and the mortise are anchored through a fixing bolt, and are connected with a first steel member and a second steel member correspondingly before connected. The invention further provides a connecting method of the steel structure tenon-mortise connector. The connector between the steel members is the tenon-mortise assembled connector, not only is the size of the original members at the joint not reduced, but also the size is enhanced at the joint, and firm connection of the members is guaranteed; and moreover, the combination face of the tenon-mortise connector is large, high section shear-resistance capacity is achieved, and the safety degree is higher.

Owner:HOHAI UNIV

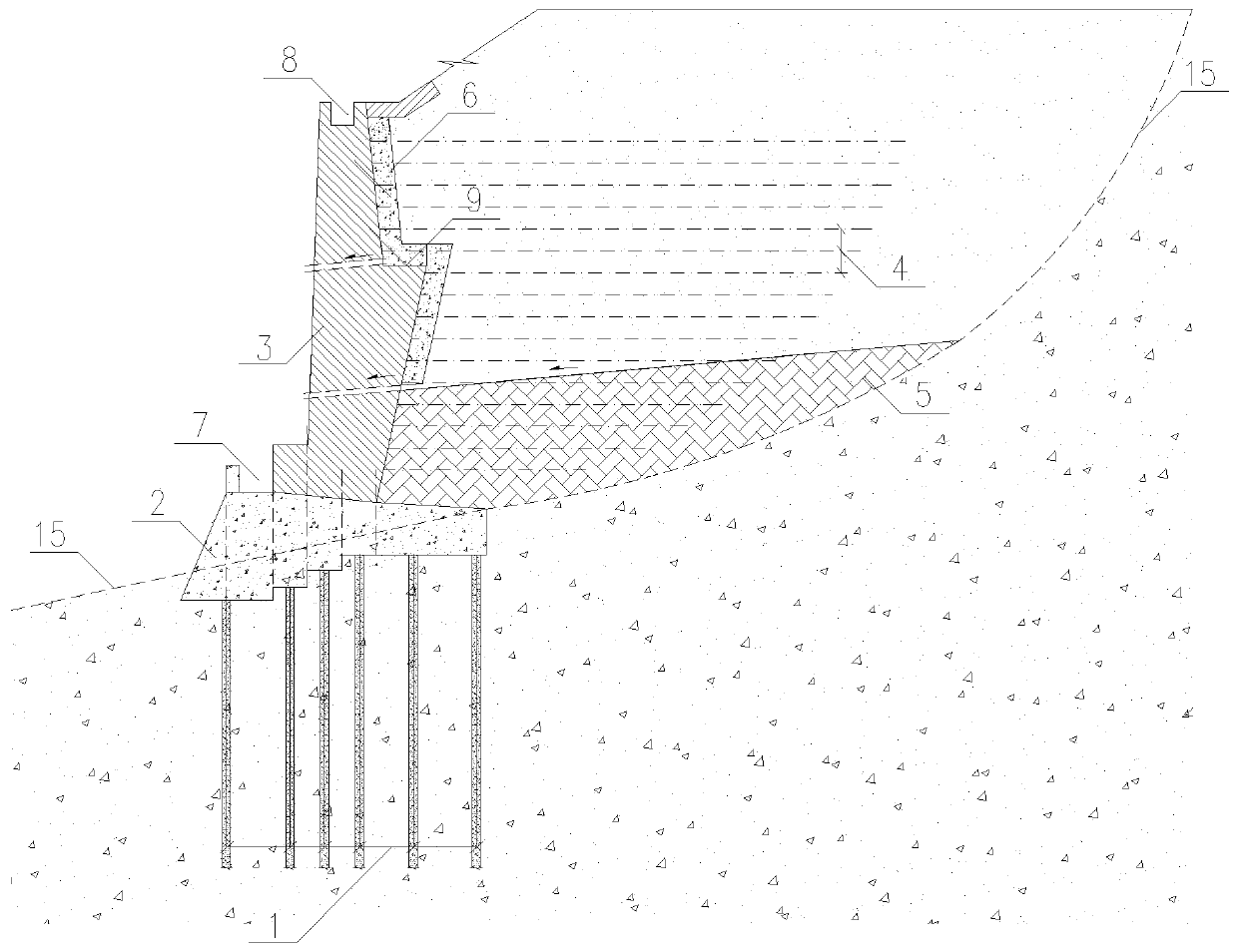

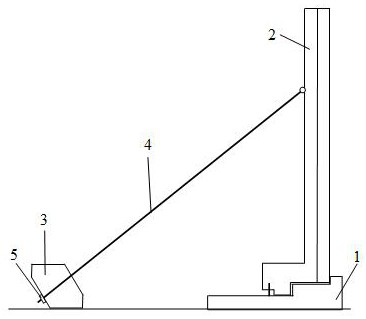

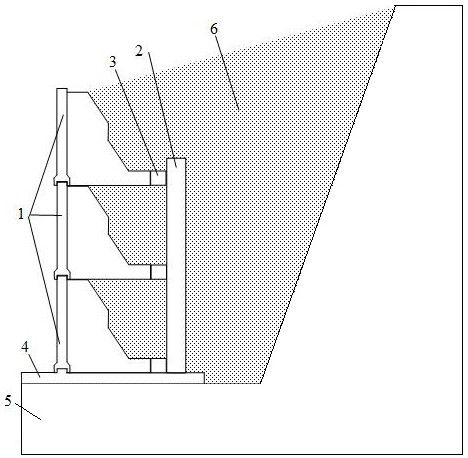

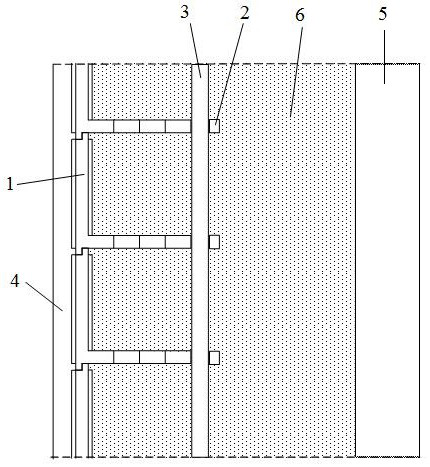

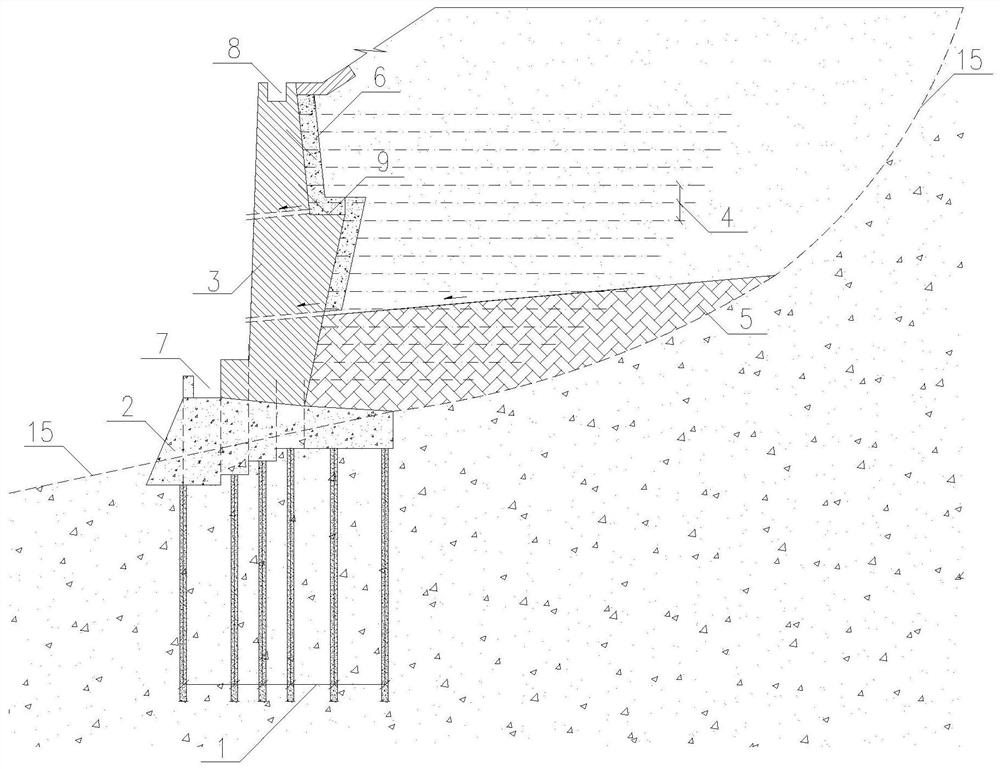

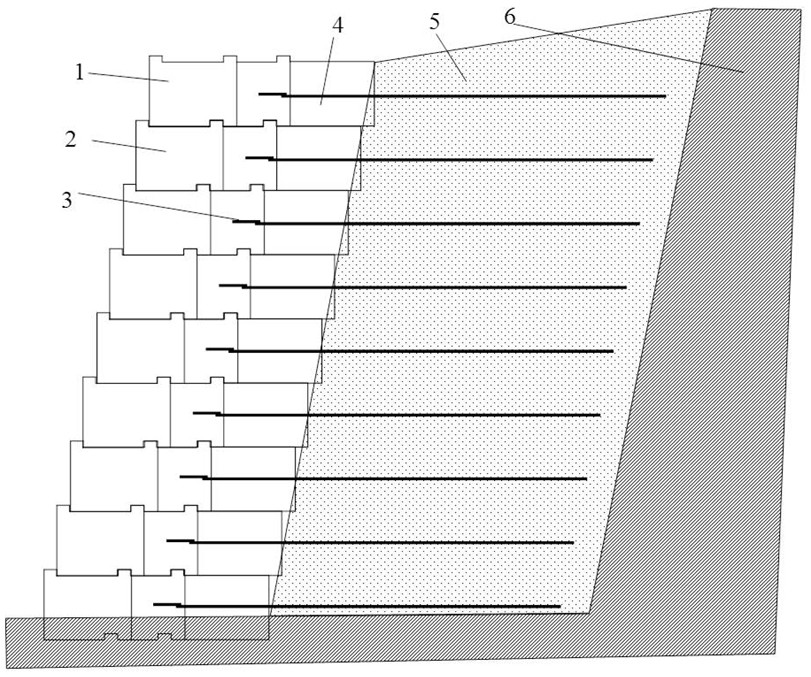

Steel anchor pipe reinforced weathered rock stratum reinforced balance weight type retaining wall structure and construction method

ActiveCN109736346AImprove stabilityReduce earth pressureArtificial islandsUnderwater structuresEconomic benefitsGeogrid

The invention discloses a steel anchor pipe reinforced weathered rock stratum reinforced balance weight type retaining wall structure and a construction method, the weathered rock stratum is reinforced by the steel anchor pipes through grouting inside and outside the pipes, the bearing capacity of a treated rock mass foundation is greatly improved, and the foundation bearing requirement of an upper embankment retaining structure is completely met. Meanwhile, the stability of the treated weathered rock stratum is improved, the steel anchor pipe can also serve as a side slope anti-sliding structure, and the effect of preventing sliding and reducing disasters on an original weathered rock stratum side slope is achieved. According to the reinforced soil (balanced weight type) retaining wall, breakthrough of the wall thickness size of a traditional retaining wall is achieved, and meanwhile laying of the geogrid has great significance for the stability of the retaining wall. The constructionmethod is mature in technology and reasonable in procedure, has the advantage of rapid construction and has outstanding economic benefits. The method has a wide prospect in application of road embankment filling and retaining structures on weathered rock stratum geology.

Owner:CHINA FIRST HIGHWAY ENG +1

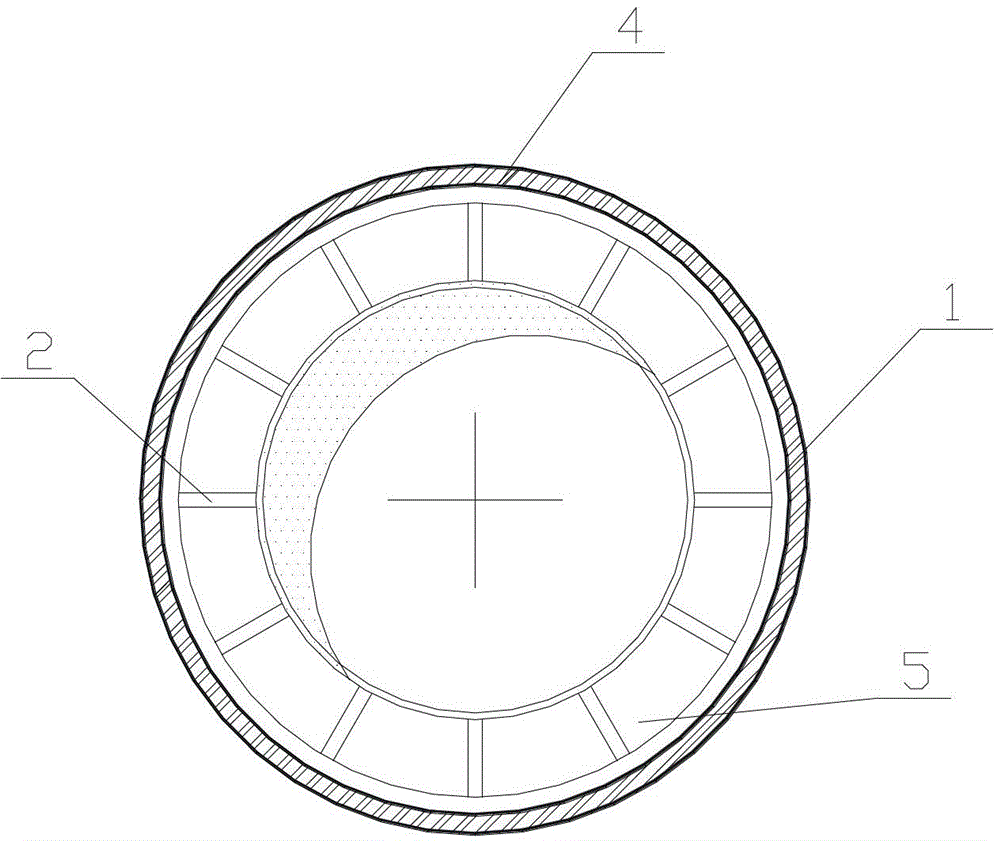

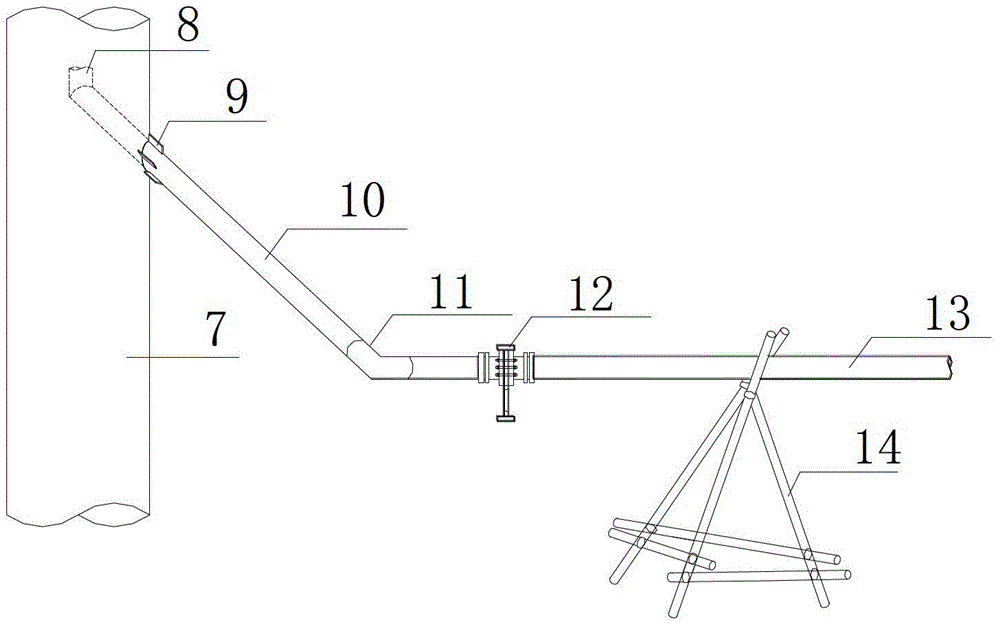

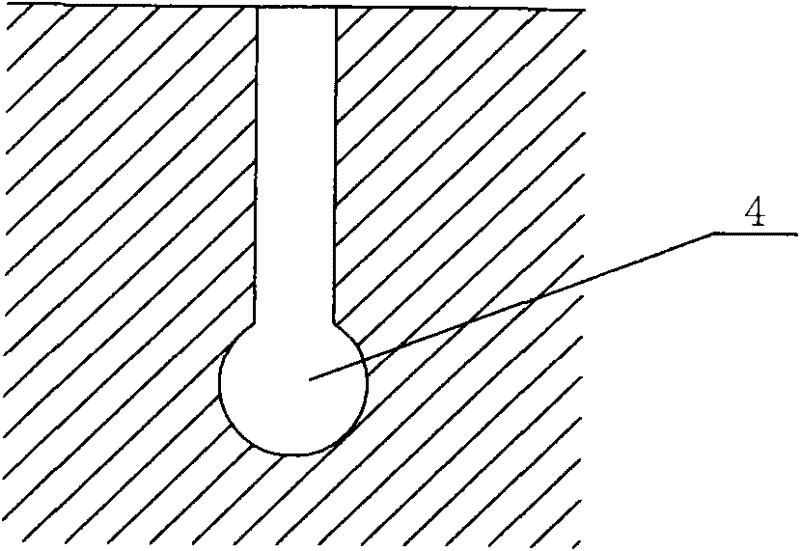

Method for lifting concrete in ultrahigh reducing steel pipe column

ActiveCN103195167AReduce frictional resistanceSmooth liftBuilding constructionsCement mortarMaterials science

The invention discloses a method for lifting concrete in an ultrahigh reducing steel pipe column. The method includes the steps of firstly, pumping water, performing pressuring and lifting with the water instead of concrete until the water overflows out of the top of the column, making small holes at the bottom of the column to discharge the water after lifting and pressuring, and soldering the small holes; secondly, lifting at one cubic meter of cement mortar, lifting concrete closely following the cement mortar, making a runner in the front of the cement mortar, and lifting the concrete once. The inner surface of the steel pipe column is lubricated by pumping the water first and making the front runner with the cement mortar, resistance of friction between the concrete and the inner surface of the steel pipe column is reduced greatly, and the concrete following the cement mortar can be lifted smoothly. Therefore, the method allows the concrete in the ultrahigh reducing steel pipe column to be lifted once, construction efficiency is high, and construction quality is guaranteed easily.

Owner:中建六局第一建设有限公司 +1

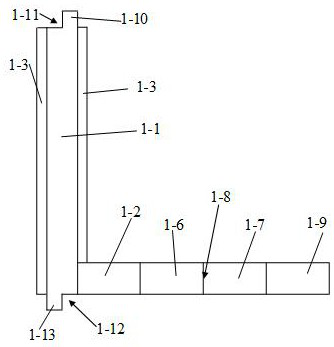

Strengthened anchoring fabricated type concrete retaining wall

InactiveCN108951694AImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresRoad engineeringPublic Facility

The invention provides a strengthened anchoring fabricated type concrete retaining wall, and belongs to the technical field of city underground road engineering and public facilities. Convex opening concrete prefabricated T-shaped plates are located on original soil, and arc-shaped concave connectors of concave-convex opening concrete fabricated flat plates are matched with arc-shaped convex connectors of the convex opening concrete prefabricated T-shaped plates; and a spiral long extending arm provided with a strengthening anchoring tie bar is horizontal, and the other one inclines downwardsby 30 degrees-45 degrees to be crossed with the horizontal spiral long extending arm on the lower layer. The strengthened anchoring fabricated type concrete retaining wall has the beneficial effects that mold plates can be saved, the construction condition during manufacturing is improved, the labor productivity is improved, the construction progress is accelerated, and the construction quality isguaranteed. Standardization, light and thin making and universalization of the fabricated type concrete retaining wall are achieved. The anchoring performance, the integrality, the stability and thesafety performance of the concrete retaining wall are obviously improved, cost is low, and project quality is easily guaranteed.

Owner:SHENYANG JIANZHU UNIVERSITY

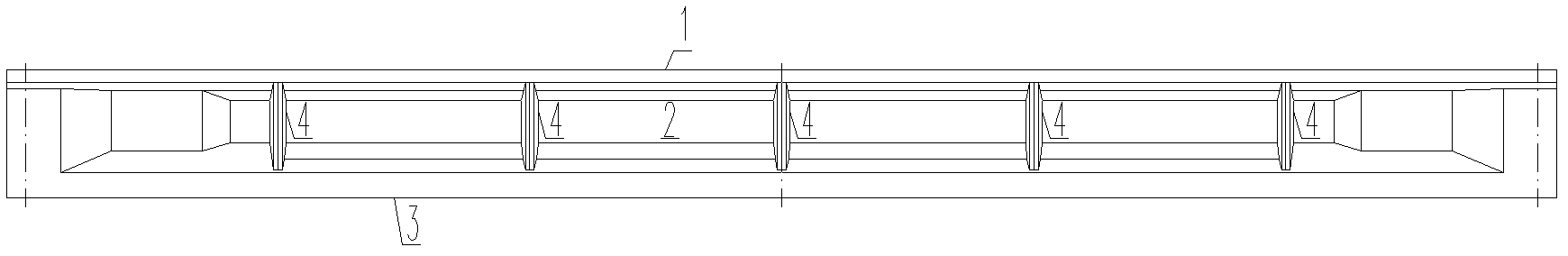

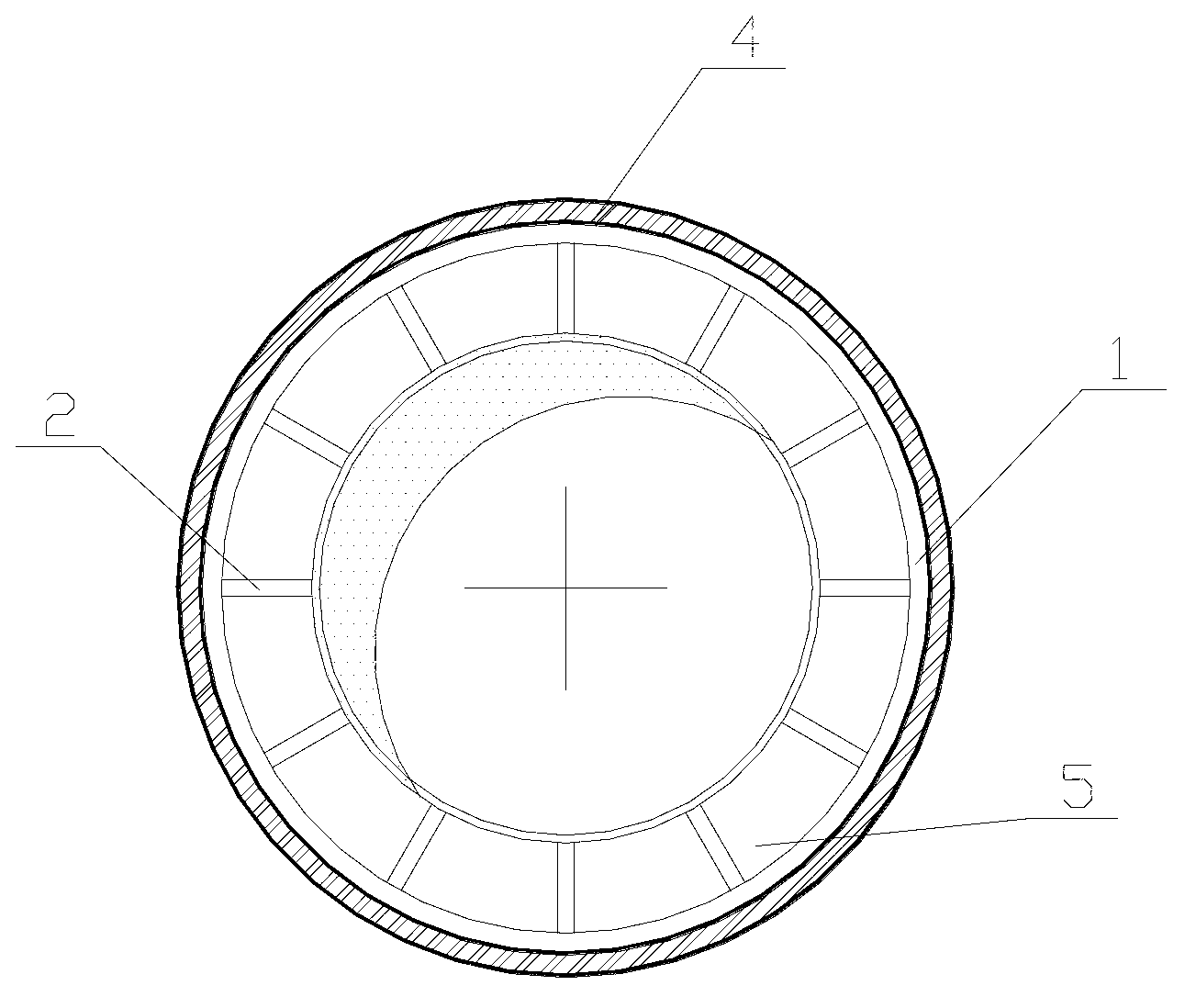

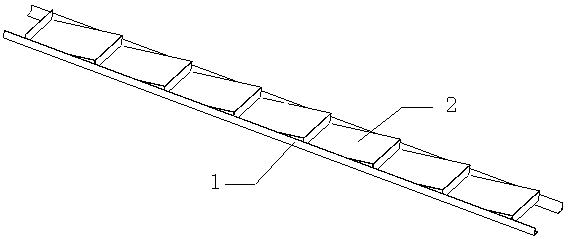

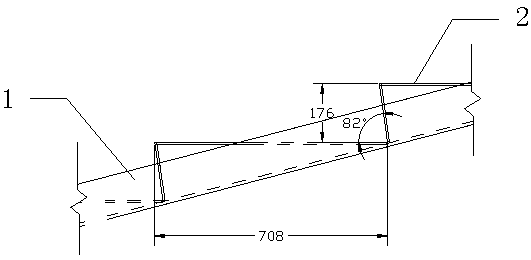

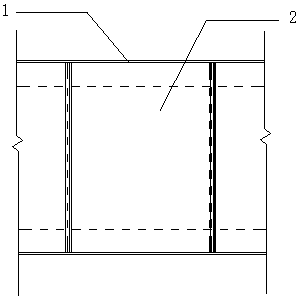

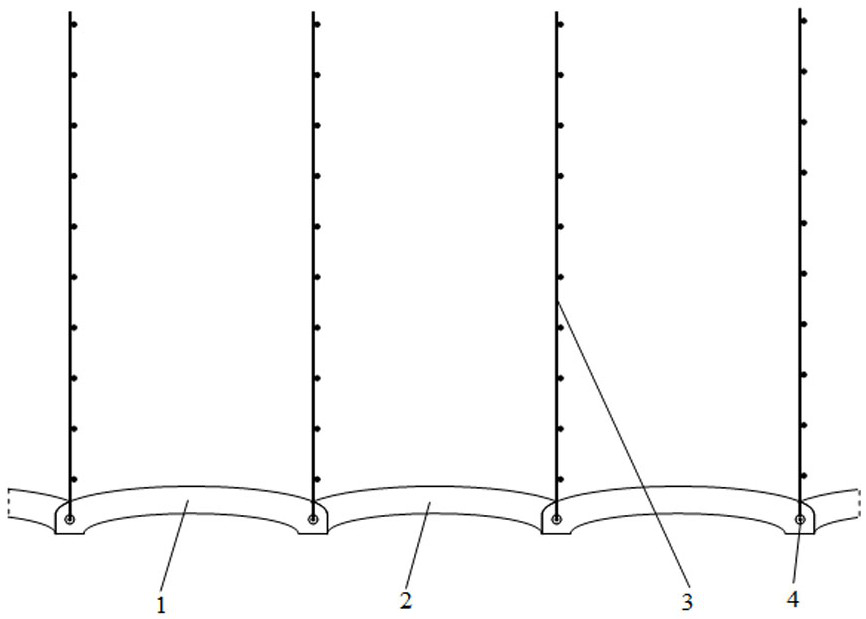

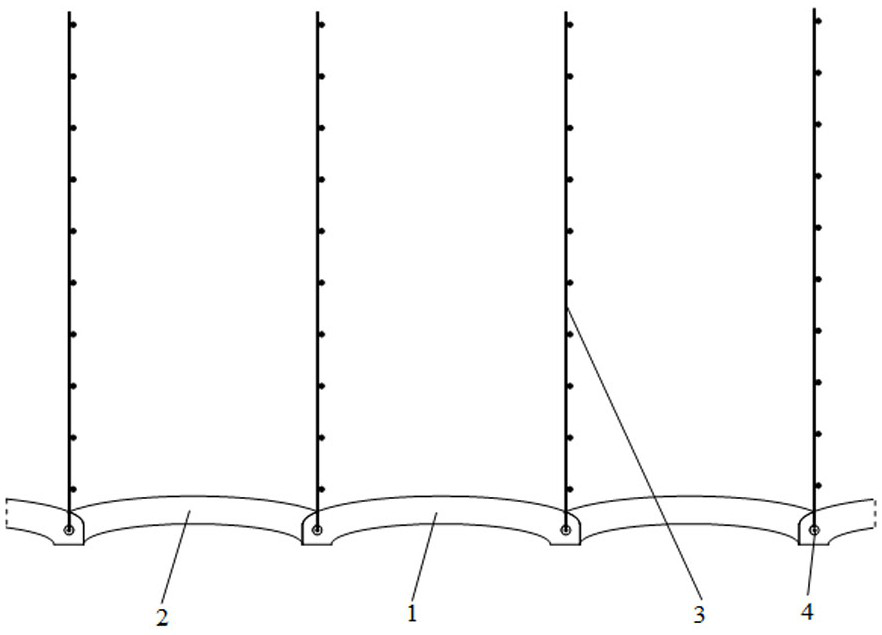

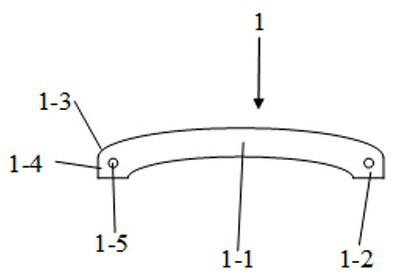

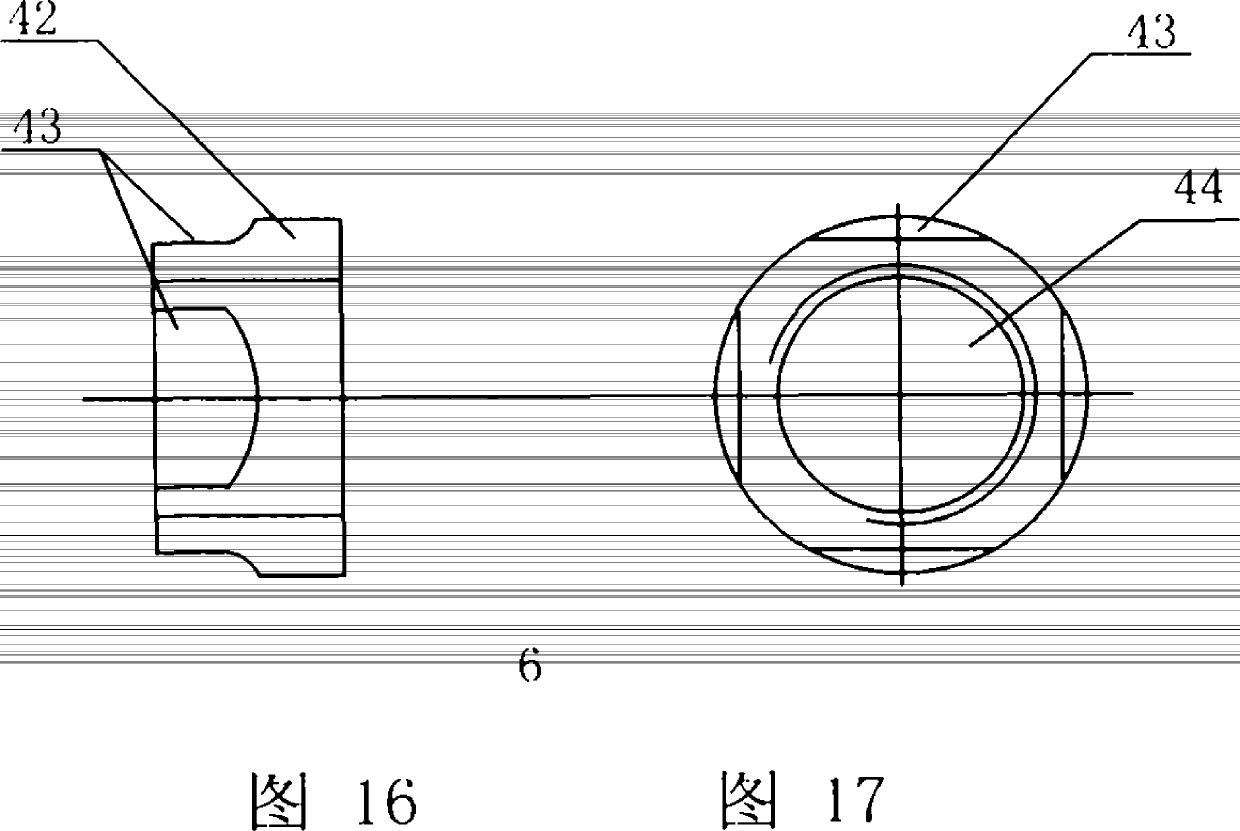

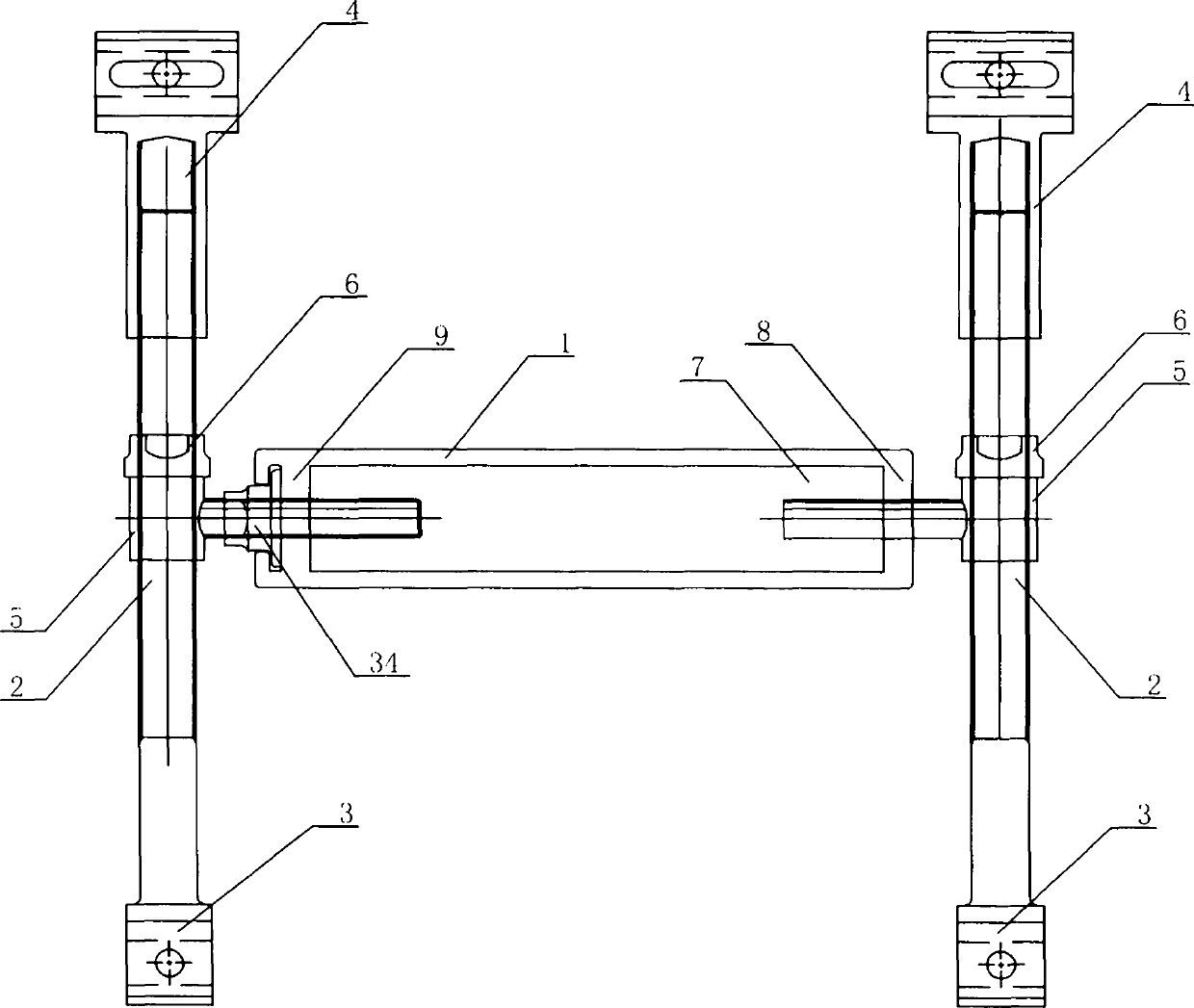

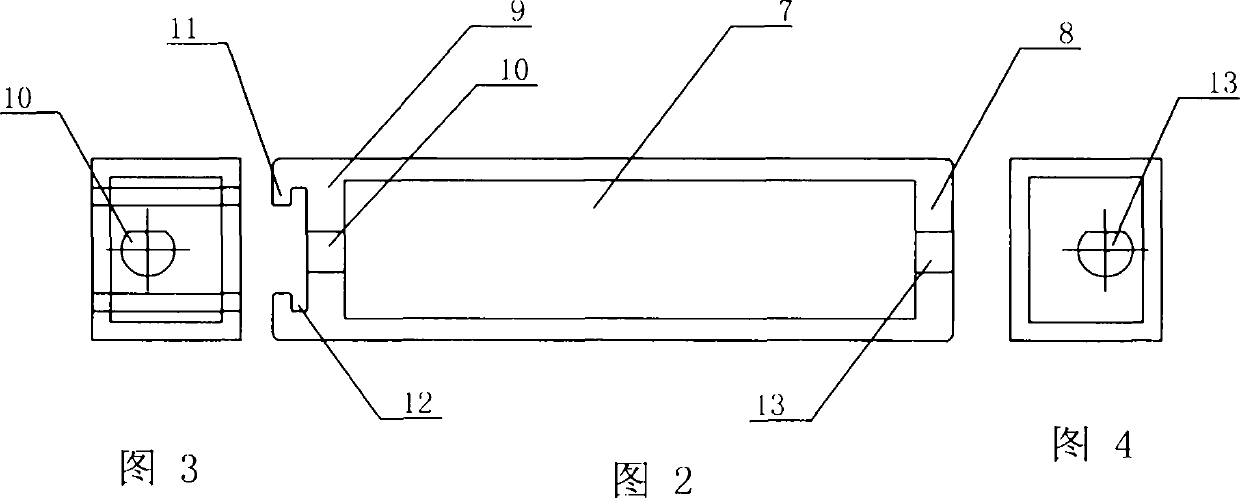

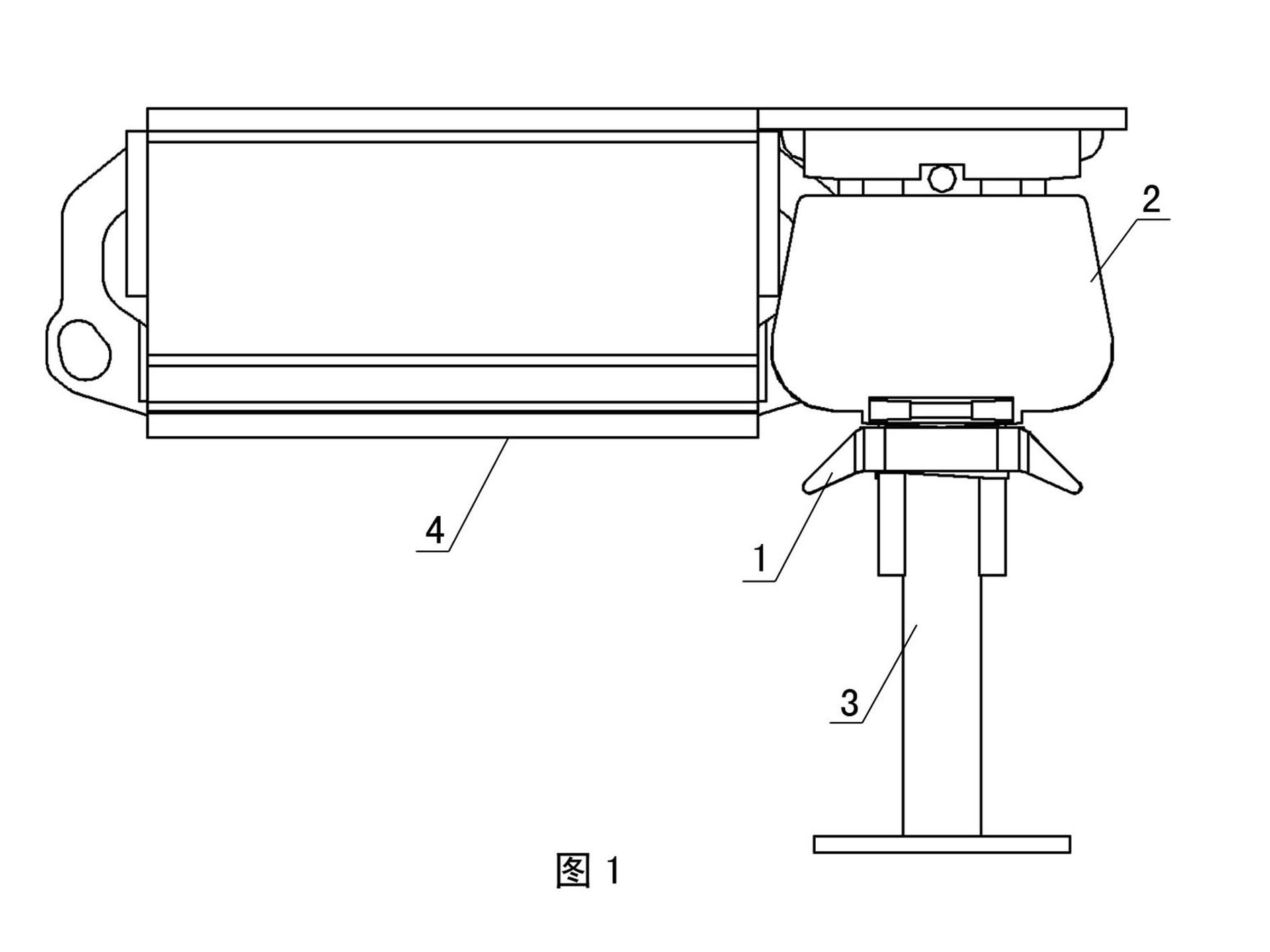

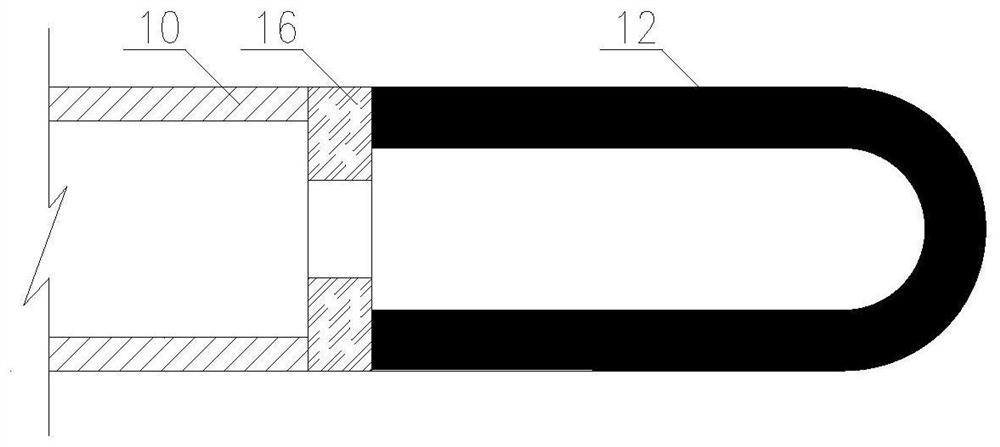

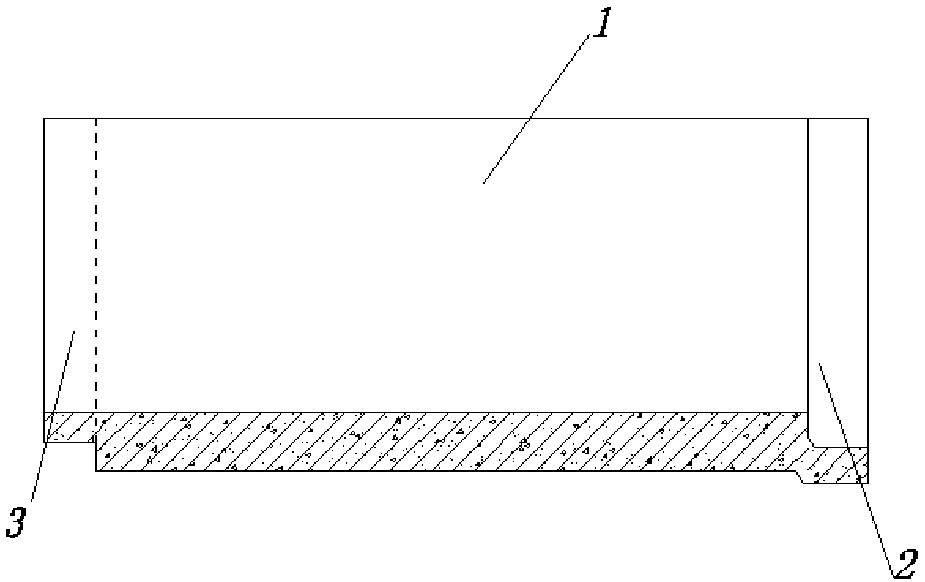

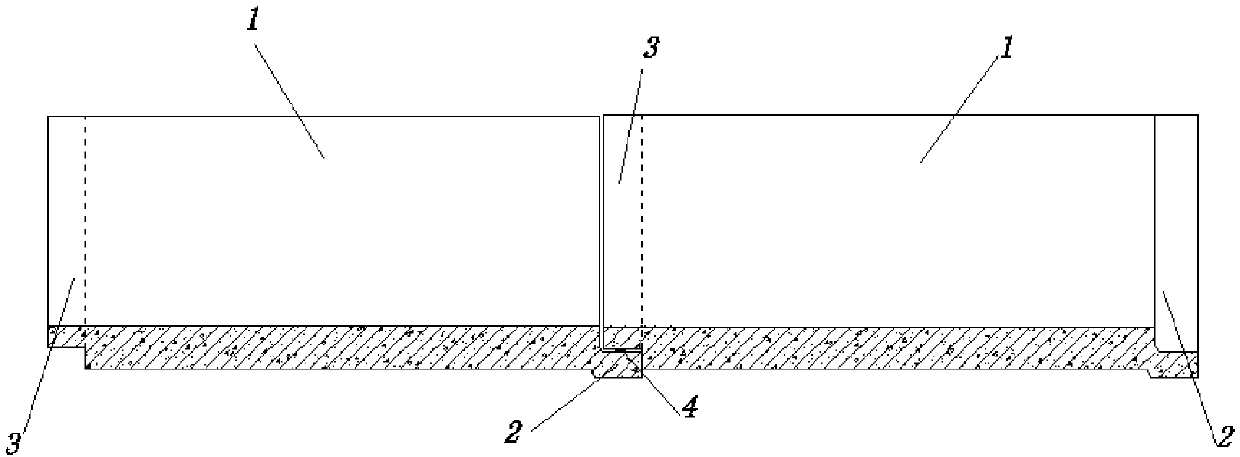

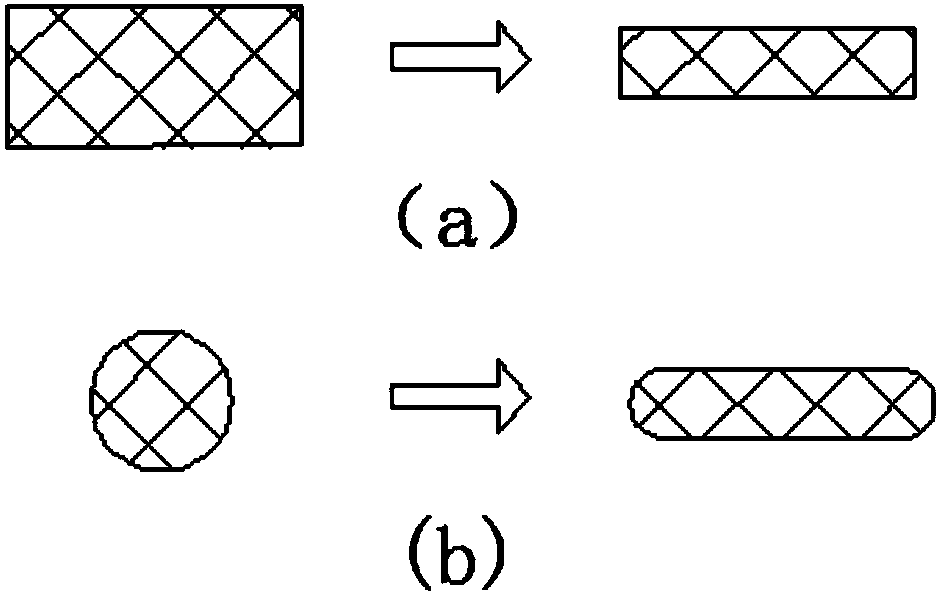

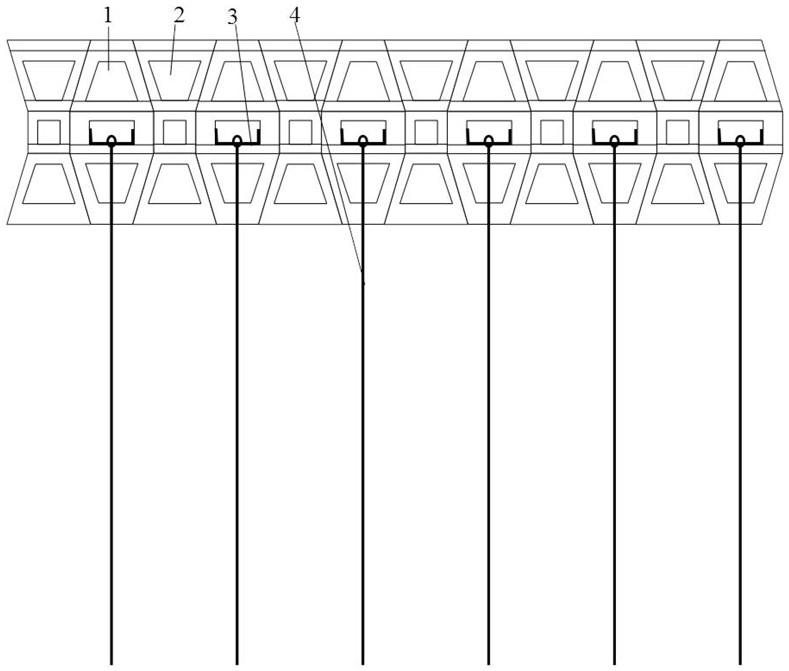

FRP framework type rail sleeper structure

ActiveCN103952949AHigh degree of industrial constructionImprove mechanical propertiesBallastwayStructural engineeringTongue and groove

The invention relates to the technical field of a railway rail, in particular to an FRP framework type rail sleeper structure, which comprises rail sleeper cross beam components, wherein each rail sleeper cross beam component is made of FRP materials, and is a hollow I-shaped cross section beam type component consisting of an upper wing plate, a lower wing plate and a middle web plate, first polyurethane hard foam bodies are filled in hollow inner cavities of the I-shaped cross section beam type components, tongue-and-groove structures are arranged at the two ends of the rail sleeper cross beam components, the two adjacent rail sleeper cross beam components are connected into a whole through rail sleeper longitudinal beam components, each rail sleeper longitudinal beam component is also made of FRP materials, and is a hollow box-shaped cross section beam type component consisting of a top plate, a bottom plate and two side plates, second polyurethane hard foam bodies are filled in hollow inner cavities of the box-shaped cross section beam type components, and the two ends of the rail sleeper beam components are provided with tenons matched with the tongue-and-groove structures of the rail sleeper cross beam components. The rail sleeper structure is applicable to high-speed railways and has the advantages that the service life is long, and the use cost is low.

Owner:张锡祥

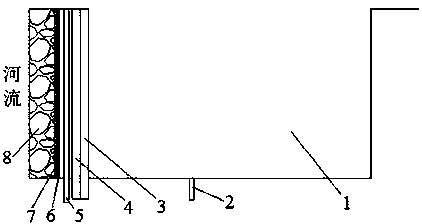

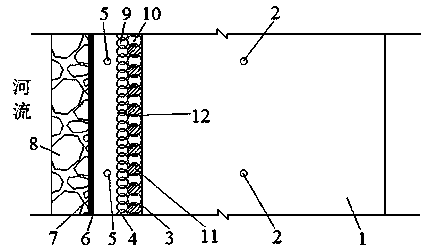

Foundation pit water stop system adjacent to river permeable stratum and construction process thereof

The invention provides a foundation pit water stop system adjacent to a river permeable stratum and a construction process thereof. A cofferdam, a protective wall, a waterproof wall, a second precipitation well, a clay bite pile group and a first bite pile group which are sequentially arranged are included; and the bottoms of all precipitation wells, clay bite piles, plain concrete piles and reinforced concrete piles enter an impervious layer. According to the scale of a foundation pit, engineering geology and hydrogeological conditions, the scope and scale of the cofferdam are determined; theprotective wall is constructed in a stacking manner, waterproof geotextile is laid, the cofferdam is piled up, the precipitation wells are drilled, water suction pumps are mounted in all the precipitation wells, and the water level of the precipitation wells on the side far from a river is made be higher than the water level in the precipitation wells near the river; the clay bite pile group is built; a bite pile group of the reinforced concrete piles and the plain concrete piles is built; and the adjacent reinforced concrete piles and plain concrete piles are wrapped with one-way grouting sleeve valve tubes, and the foundation pit water stop system adjacent to the river permeable stratum is built. By means of the water stop system, surrounding and intercepting of water is formed throughmultiple water-stopping lines, and the needs of project water stopping are effectively met.

Owner:中铁科学研究院有限公司

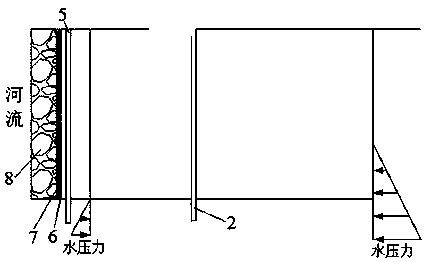

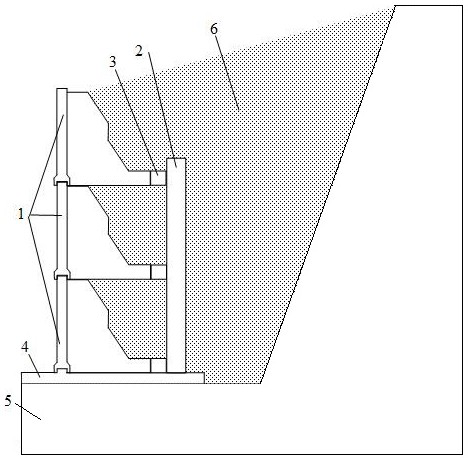

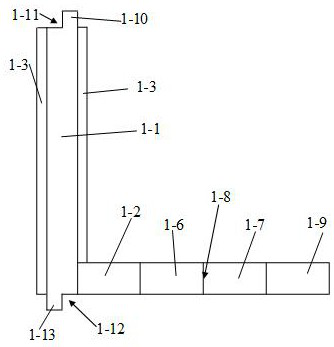

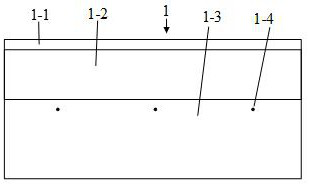

Prefabricated L-shaped concrete multilayer multi-step retaining wall

ActiveCN112523256AImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresArchitectural engineeringPrecast concrete

The invention belongs to the technical field of retaining walls, and particularly relates to a prefabricated L-shaped concrete multilayer multi-step retaining wall which comprises L-shaped step prefabricated concrete retaining wall plates, concrete stand columns, concrete cross beams and the like. A connecting groove in the bottom of the L-shaped stepped precast concrete retaining wall plate is matched with a tooth tenon of the bottom plate with the tooth tenon. More than two layers of L-shaped step precast concrete retaining wall plates are assembled layer by layer from bottom to top, the L-shaped step precast concrete retaining wall plates are connected with concrete cross beams, the concrete cross beams are connected with concrete stand columns one by one, and the space between the L-shaped step precast concrete retaining wall plates and original soil is filled with filling soil. The anchoring performance, integrity and stability of the concrete retaining wall can be improved, the L-shaped step prefabricated concrete retaining wall plates, the concrete stand columns and the concrete cross beams form the retaining wall in spatial distribution, the bearing capacity of a wall bodycan be improved, the safety performance is improved, the cost is low, and the engineering quality is easy to guarantee.

Owner:沈阳促晋科技有限公司

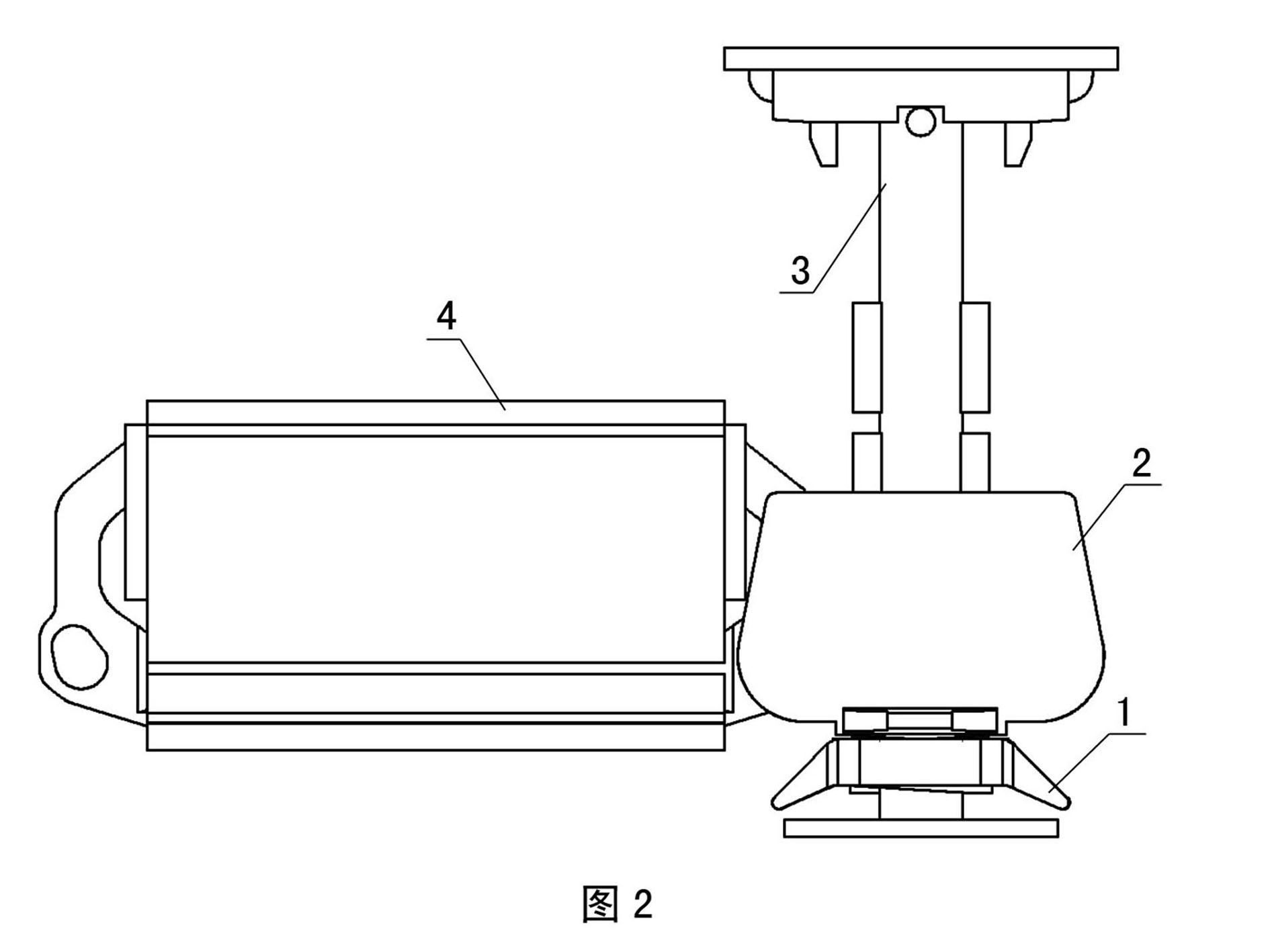

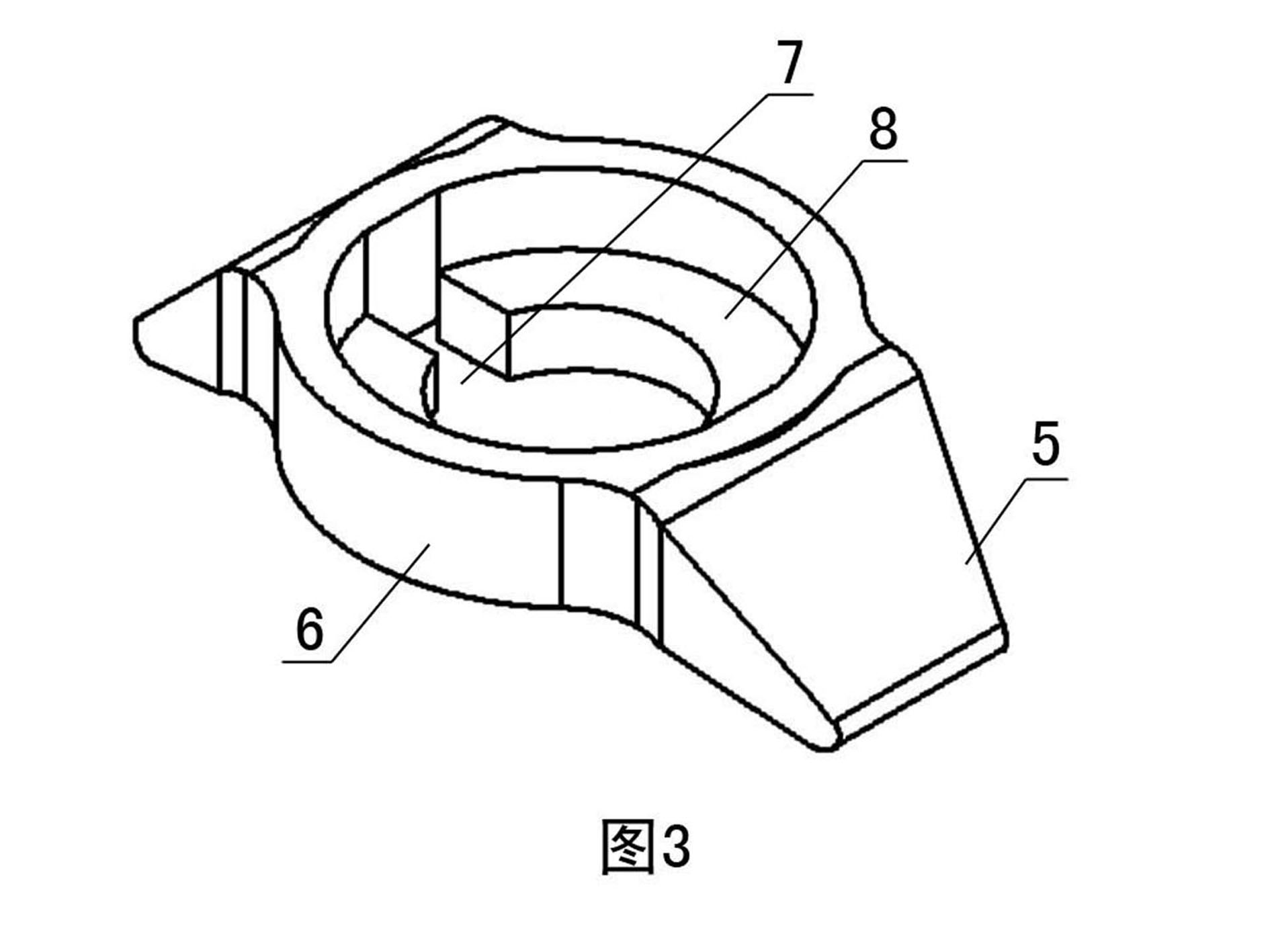

Special clamping tool for stepping board assembly and application method thereof

InactiveCN108994500ASimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a special clamping tool for stepping board assembly. The clamping tool includes a top board, baffle plates and an adjusting bolt; and the clamping tool is characterized in thatthe length of the top board (3) determines according to the width of a stepping board which is 150 mm; baffle plates include a first baffle plate (4) and a second baffle plate (5) which are same in size; a nut (7) is fixedly welded in a through hole opening on the inner side of the second baffle plate; the nut matches a bolt (6), so that one end of the bolt is fixedly welded with a backing plate(8), and the other end of the bolt is placed on the outer side of the second baffle plate; and the screw length of the bolt can movably adjust the distance between the backing plate and the first baffle plate. The clamping tool and application method have advantages of being simple in clamping device structure, convenient in making, concise in construction, convenient and short in construction period, and can ensure engineering quality, so that large scale stepping board assembly engineering can be realized, and high precision rapid assembly can be achieved.

Owner:MCC5 GROUP CORP SHANGHAI

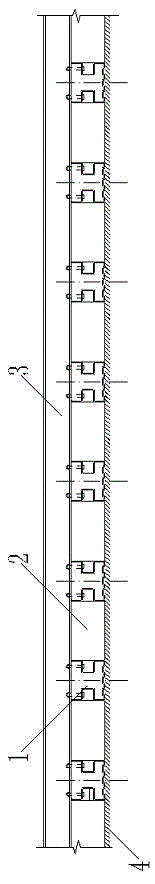

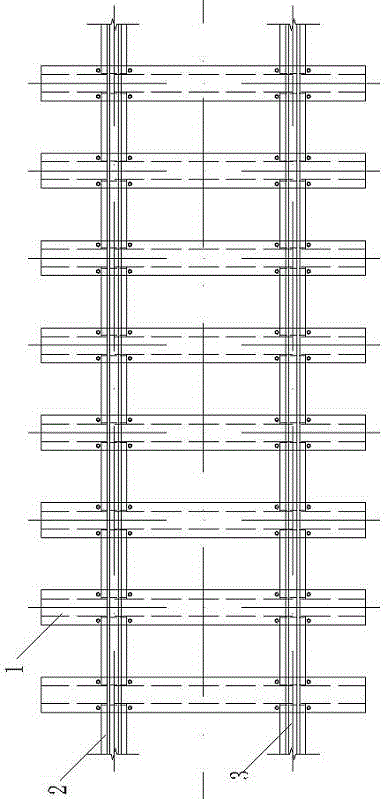

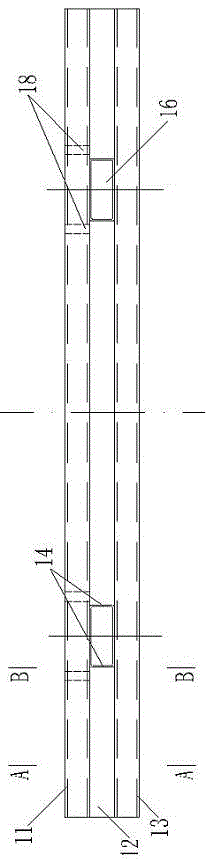

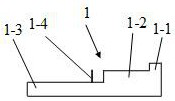

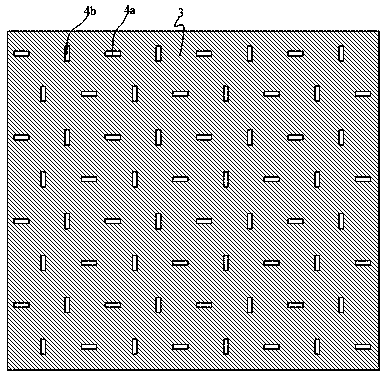

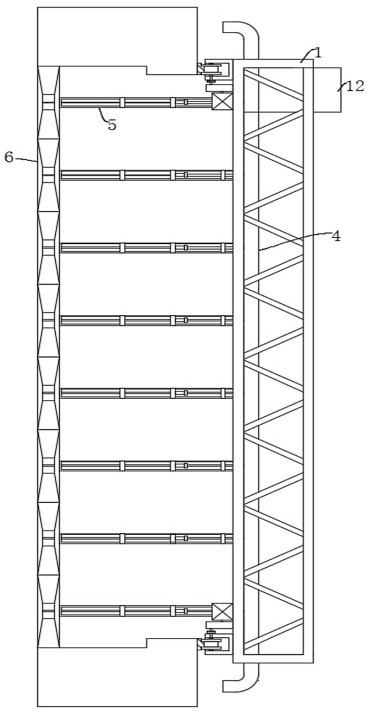

Dry hanging assembly for dry hanging of wall bricks, dry hanging structure for wall bricks and dry hanging construction method for wall bricks

PendingCN112360083AReduce workloadEngineering quality is easy to guaranteeCovering/liningsStructural engineeringWaste material

The invention relates to a dry hanging assembly for dry hanging of wall bricks, a dry hanging structure for the wall bricks and a dry hanging construction method for the wall bricks. The dry hanging structure for the wall bricks comprises a plurality of dry hanging assemblies transversely fixed to a building wall at intervals and the wall bricks connected to the building wall through the dry hanging assemblies, wherein each dry hanging assembly comprises a fixing piece connected to the building wall and a connecting piece connected between the fixing piece and the corresponding wall brick; a clamping groove body is formed in each fixing piece; and each connecting piece comprises a connecting piece fixedly connected to the side, facing the building wall, of the corresponding wall brick anda buckle connected to the side, facing the building wall, of the connecting piece, wherein the buckle is clamped in the clamping groove body. The dry hanging assembly for dry hanging of the wall bricks, the dry hanging structure for the wall bricks and the dry hanging construction method for the wall bricks have the advantages that the influence of the technical level of on-site workers on the engineering quality is small, the engineering quality is easy to guarantee, the overall wall surface is flat after dry hanging of the wall bricks, construction is easy, the workload is small, the construction process is easy to master, the construction period is short, and construction waste is little.

Owner:深圳市弘景装饰工程有限公司

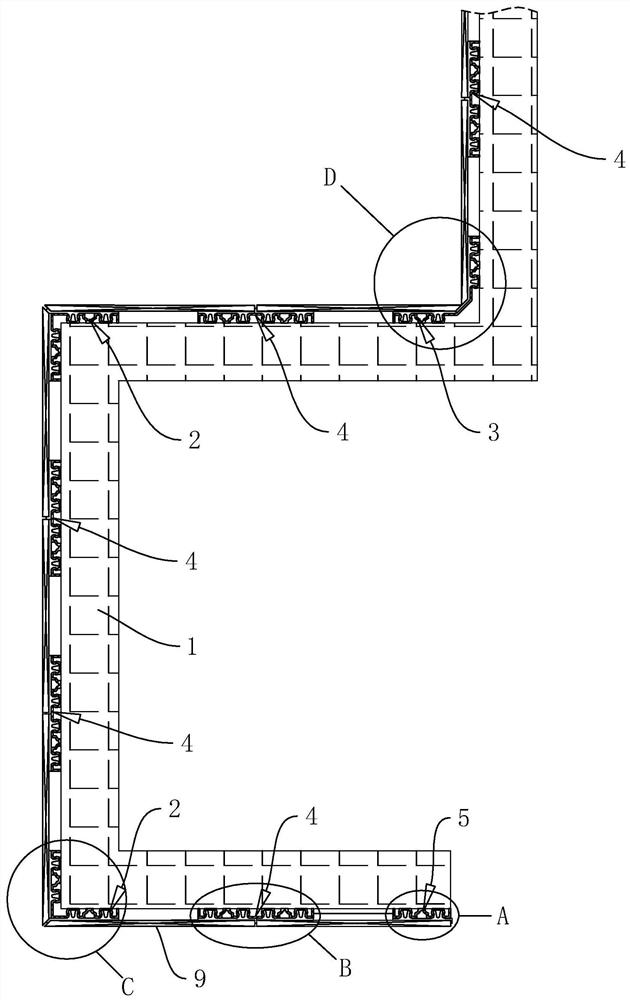

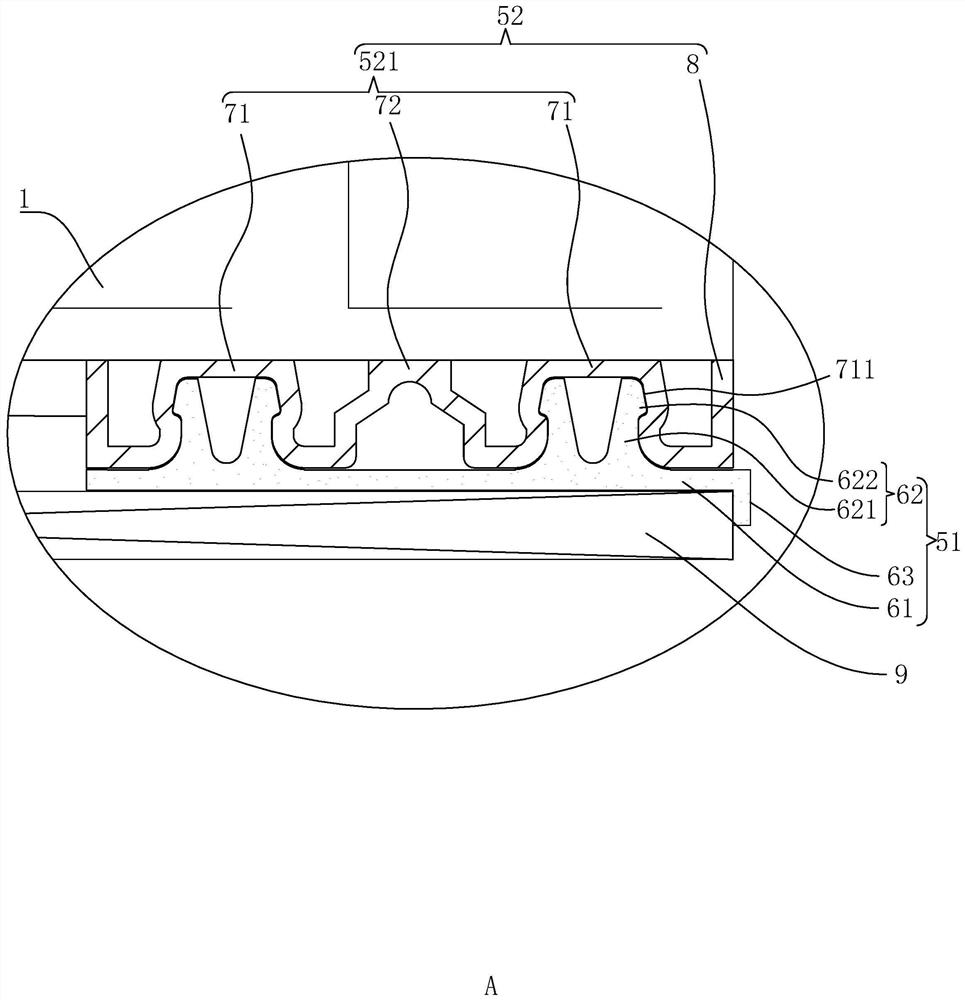

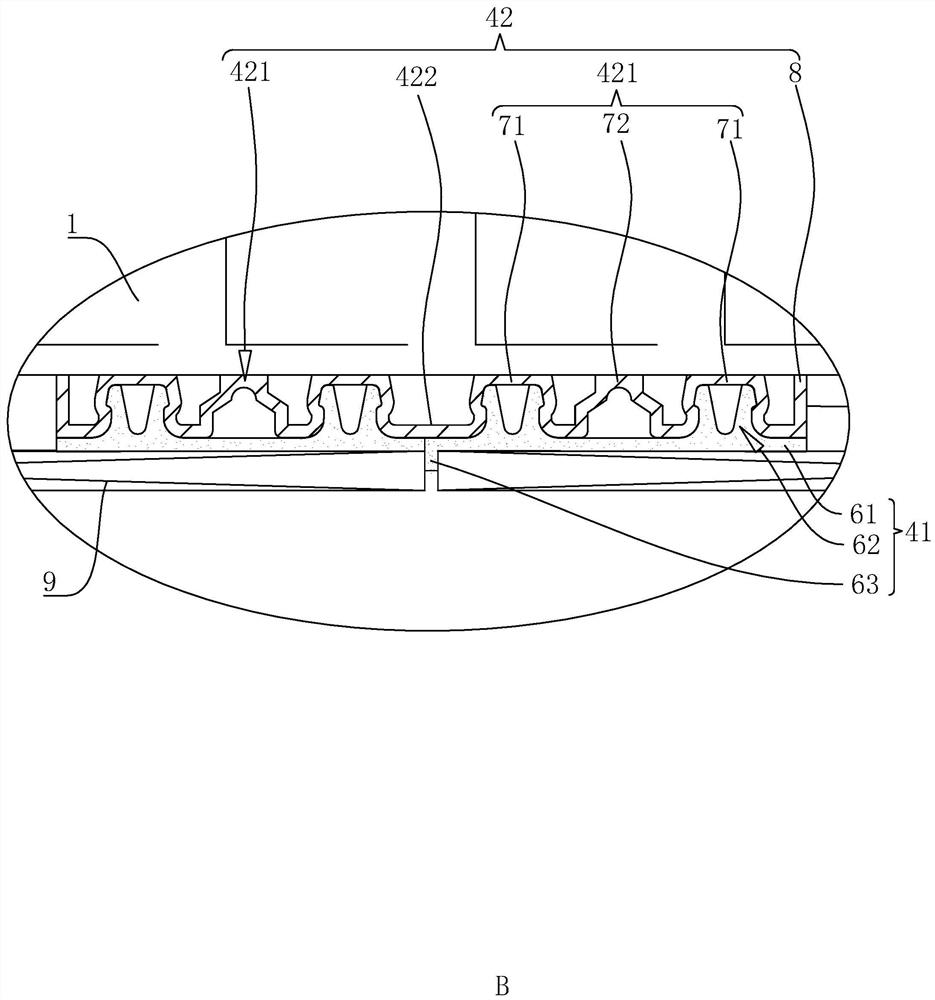

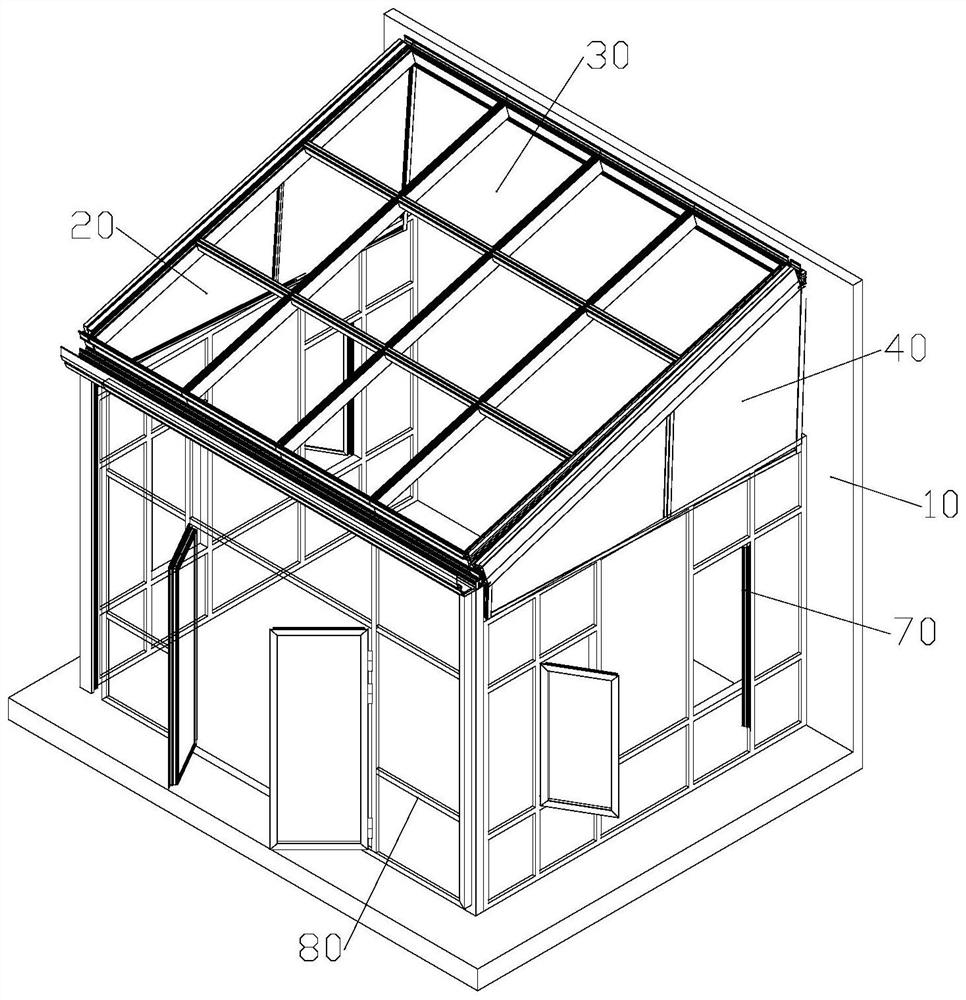

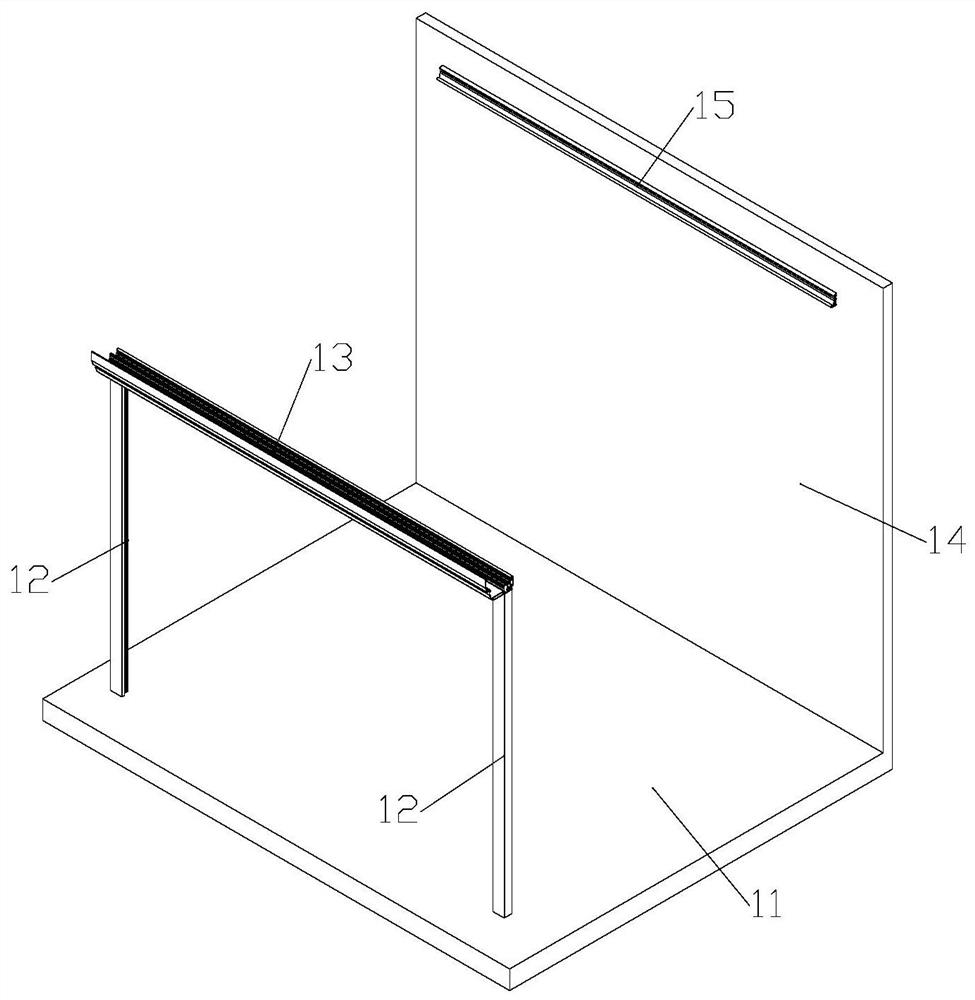

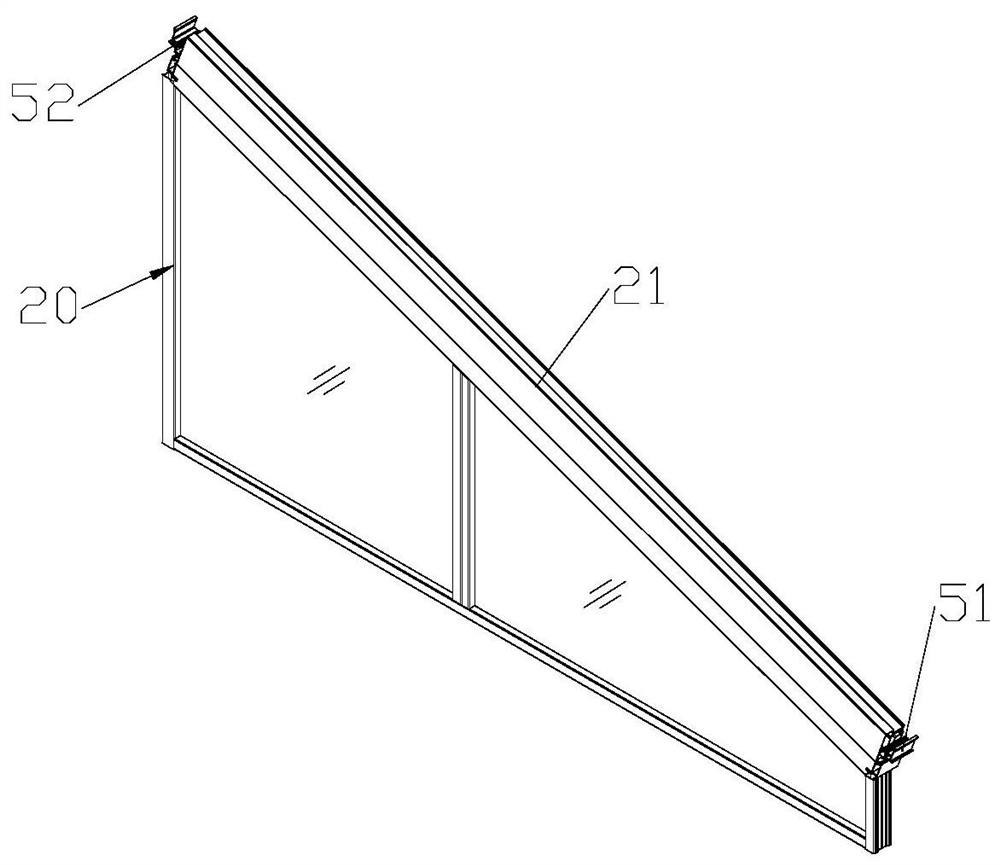

Unit-style sun room

ActiveCN111321802BReduce the difficulty of construction managementSimple tilt angleBuilding roofsRoof drainageCells panelWindow opening

Owner:汨罗振升铝业科技有限公司

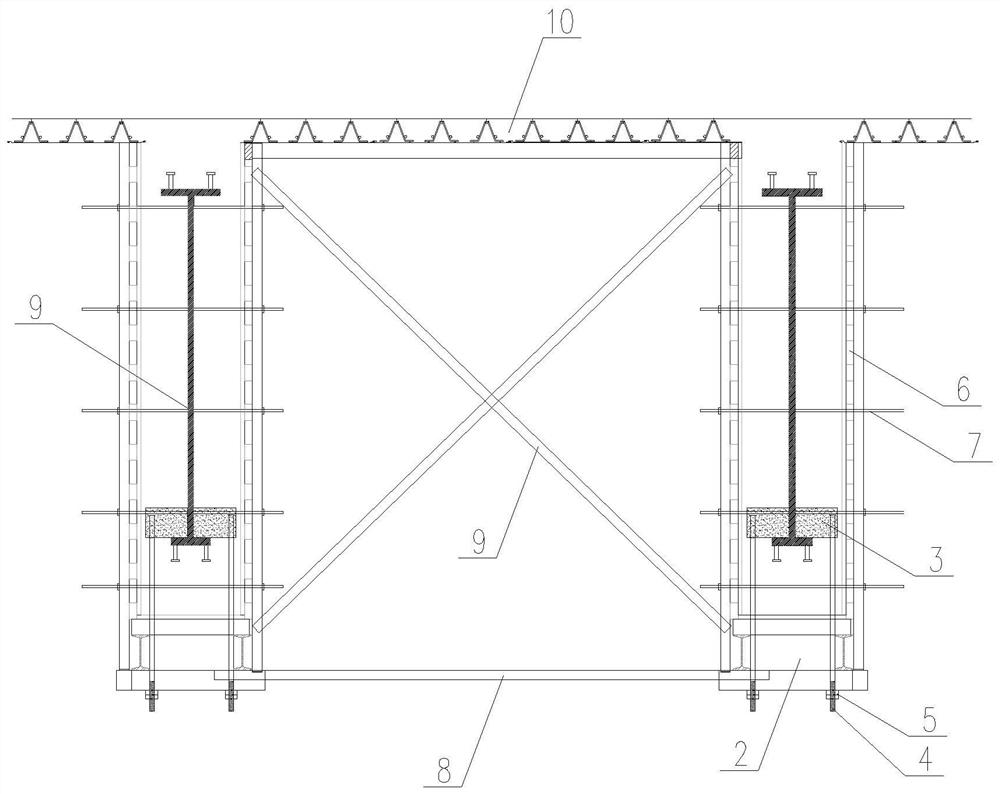

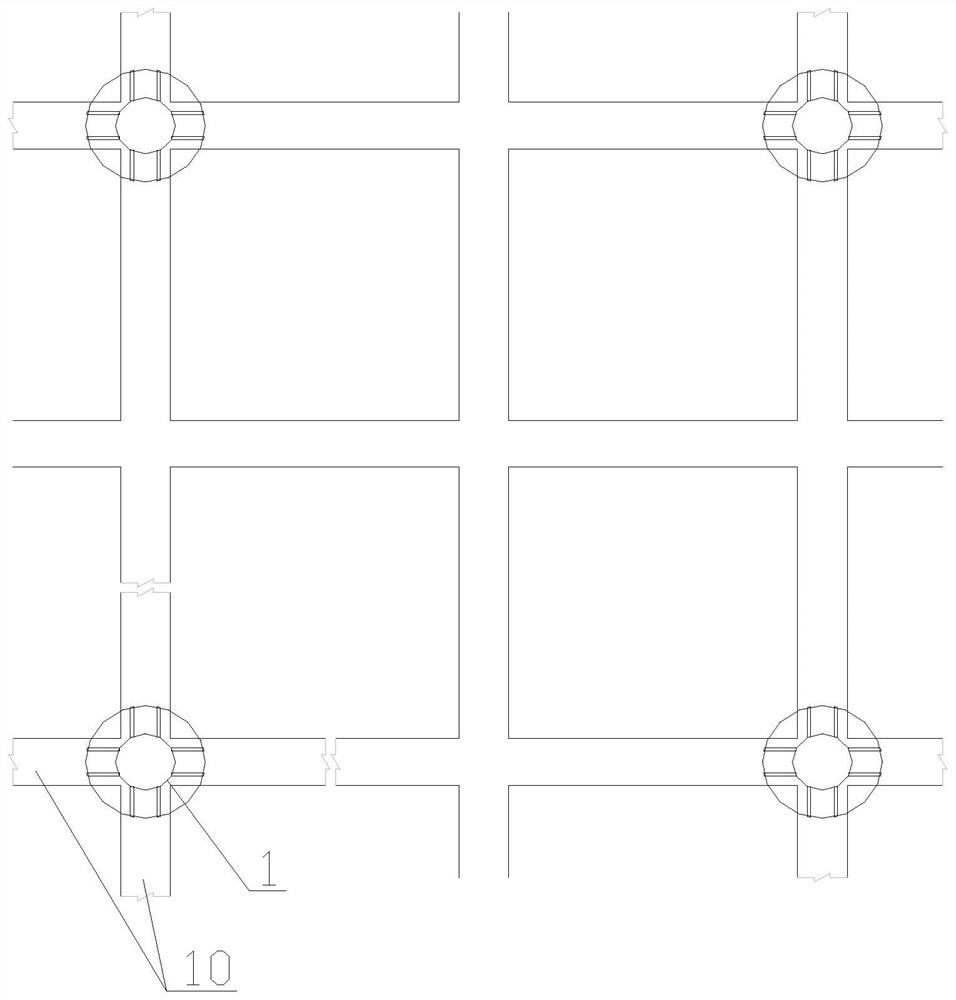

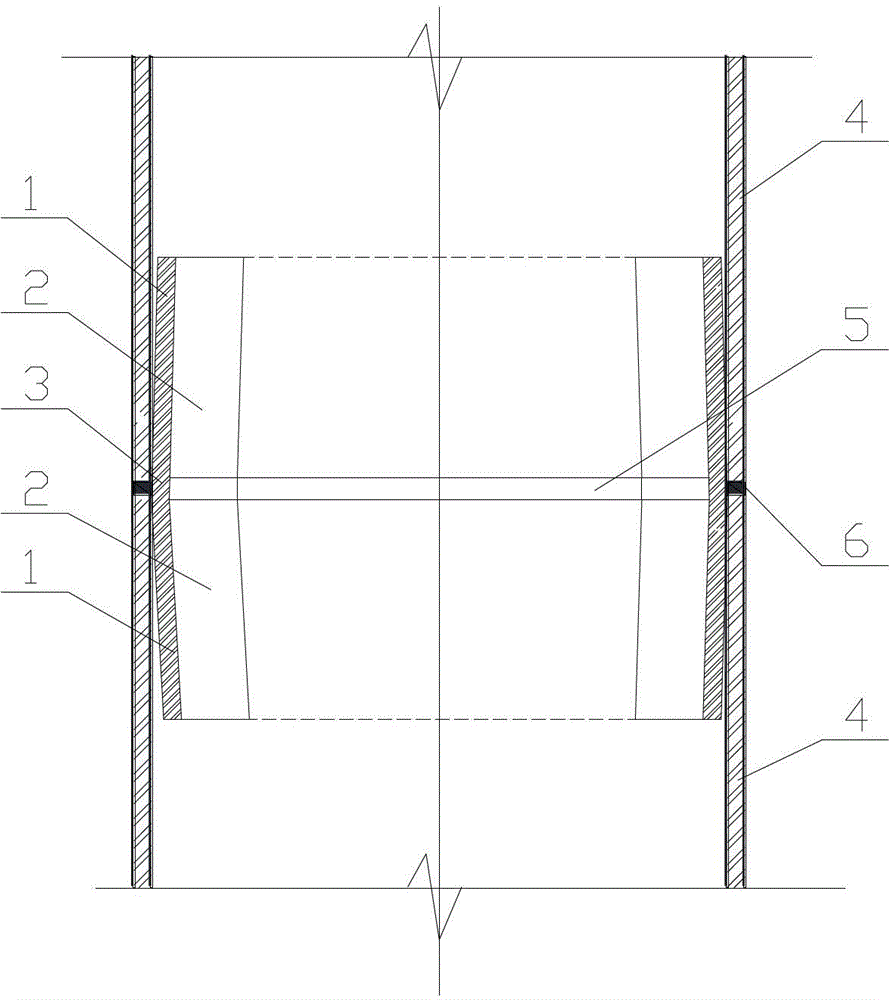

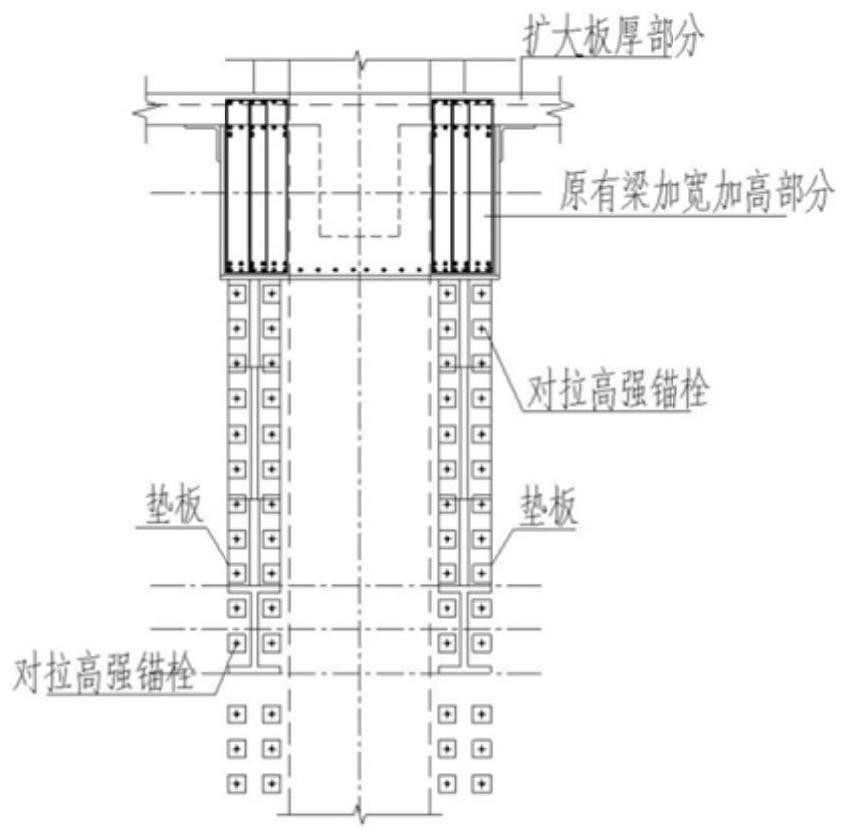

High and large space profile steel-concrete structure roof construction formwork system and method

ActiveCN112681724AHigh security riskLong construction periodForms/shuttering/falseworksSteel tubeFraming (construction)

The invention discloses a high and large space profile steel-concrete structure roof construction formwork system and method. The system comprises steel pipe columns, bottom formwork systems, lifting lug plates, lifting rods, fastening bolts, side formwork systems, opposite-pull rods, horizontal connecting rods, inclined supporting rods and the like, wherein the top ends of the steel pipe columns are supported around the lower edge of a cross-shaped joints of the high and large space profile steel-concrete composite beam through hollow bearing beams, the lifting lug plates are welded to the upper edges of H-shaped steel bottom plates of the profile steel-concrete composite beam, the top ends of the lifting rods are welded to the lifting lug plates, and the lower ends of the lifting rods are connected with the bottom die systems which are fixed and adjusted in height through the fastening bolts. The method is used for high and large space structure combined roof construction, solves the problems that in high and large space number sign-shaped profile steel-concrete composite beam and integral roof construction of theaters, venues and the like, the full framing workload is large, the cost is high, the construction period is long, and the operation environment is poor, the method greatly reduces the cost, and is safe and reliable in construction, engineering quality is easy to guarantee, benefits are remarkable, and the effect is good.

Owner:CCCC FOURTH HIGHWAY ENG

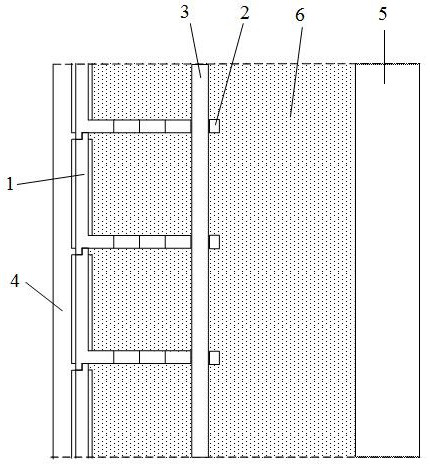

Multi-step precast concrete retaining wall

PendingCN112064669AImprove the anchoring effectImprove integrityArtificial islandsExcavationsArchitectural engineeringRebar

The invention provides a multi-step precast concrete retaining wall, and belongs to the technical field of support construction. The multi-step precast concrete retaining wall comprises a multi-step precast concrete bottom plate, a precast concrete retaining wall body, a concrete tie beam, tie steel bars and nuts, wherein an upper step base of the precast concrete retaining wall body is arranged on a wall body base of the multi-step precast concrete bottom plate, and a lower step base of the precast concrete retaining wall body is clamped on the outer side of the wall body base of the multi-step precast concrete bottom plate; and the tie steel bars are connected with the soil filling side of the precast concrete retaining wall body, and the other ends of the tie steel bars penetrate through a hole channel of the concrete tie beam and are locked through the nuts. The anchoring performance, integrity and stability of the concrete retaining wall can be improved, multi-step bayonets are adopted, sliding and overturning are effectively prevented, and the bearing capacity of the wall is remarkably improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for lifting concrete in ultrahigh reducing steel pipe column

ActiveCN103195167BReduce frictional resistanceSmooth liftBuilding constructionsCement mortarMaterials science

Owner:中建六局第一建设有限公司 +1

Composite beam frame with different strength composite column and built-in core column and its construction method

InactiveCN103967127BReduce section sizeImprove axial performanceBuilding material handlingPre stressAxial pressure

The invention relates to a special strong combination column and combination beam frame with internally-arranged core columns and a construction method of the special strong combination column and combination beam frame. The special strong combination column and combination beam frame with the internally-arranged core columns is provided with internally-arranged asymmetric steel rib or plastic rib prestressed concrete combination beams and reinforcing bar concrete combination columns with the internally-arranged core columns, the combination beams are horizontally arranged between the combination columns, and the combination beams are connected with the combination columns at intersections through joints. The core columns are formed by pouring steel ribs or plastic ribs and concrete together, longitudinal ribs are distributed around the core columns and are wrapped by stirrups, and the core columns are placed in the reinforcing bar concrete columns. Transverse stiffening ribs are arranged on the steel ribs or the plastic ribs in the combination beams, the steel ribs or the plastic ribs at the midspan positions are arranged on the lower portions of the combination beams, the steel ribs or the plastic ribs on supports are arranged on the upper portions of the combination beams, and prestressed ribs are arranged in the combined beams in the length direction. The prestressed ribs on the beam and column joints penetrate through two sides of the core columns, and are tensioned and anchored at the ends of the combination columns. The axial pressure performance of the columns can be improved, the section size of the combination columns is small, the core columns can be poured on the scene and can also be prefabricated in factories, field mounting is achieved, workloads are reduced, and the construction period is shortened.

Owner:NORTHEAST GASOLINEEUM UNIV

Reinforced inner arch concrete block retaining wall

PendingCN112031020AImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresArchitectural engineeringMesh reinforcement

The invention discloses a reinforced inner arch concrete block retaining wall. The wall is formed by building several rows of blocks, each row of blocks are formed by alternately arranging rib-penetrating soil-retaining blocks and inner clamping soil-retaining blocks, the rib-penetrating soil-retaining blocks are mutually staggered, and the inner clamping soil-retaining blocks are mutually staggered; rib-penetrating holes of upper and lower rib-penetrating soil-retaining building blocks are coincided, and tie reinforcing penetrating ribs penetrate the rib-penetrating holes; and each tie reinforcing penetrating rib is connected to a reinforcing tie reinforcing mesh. According to the wall, the anchoring performance, integrity and stability of the concrete retaining wall can be remarkably improved, due to adoption of several mutually-staggered arch structures, and combination of series reinforcing tie reinforcing meshes, the bearing capacity of a wall body is remarkably improved, the safety performance is remarkably improved, the cost is low, and the engineering quality is easy to guarantee.

Owner:SHENYANG JIANZHU UNIVERSITY

Connecting component of curtain wall system

InactiveCN104563343AEasy constructionImprove product qualityWallsArchitectural engineeringMaterial consumption

Disclosed is a connecting component used for directly assembling a curtain wall board on a curtain wall vertical frame. The connecting component comprises a hollow straight web girder and two wing beams, wherein the two wing beams are connected with the web girder through T-shaped components. A C-shaped component is arranged at one end of the web girder, flange nuts are mounted at the tops and the bottoms of the two wing beams, a wing plate of one flange nut is clamped by a groove of the C-shaped component, a web plate of the C-shaped component is provided with a hole which a threaded rod penetrates through, and when the corresponding flange nut is screwed, the threaded rod mounted on the corresponding flange nut and in the hole of the web plate of the C-shaped component can be adjusted to go in and out, so that the three-directional adjusting function is achieved. The connecting component has the advantages that the construction technology content is low, accurate adjustment of the relative position between the curtain wall board and the curtain wall vertical frame is conveniently achieved, and due to the fact that the connecting component is a finished product manufactured by a factory, quality is reliable; controllability of construction quality is good, and material consumption is low; the quantity of garbage on the construction site is small, dust pollution caused in a curtain wall board on-site cutting and hole forming process and occupational diseases of construction workers do not exist, environmental protection is better achieved, and the occupational health of the construction workers is effectively guaranteed.

Owner:邱建平 +1

Early-dismantling support of aluminum alloy top plate

InactiveCN101864835BConstruction safety is not affectedFaster turnaroundForms/shuttering/falseworksSheet steelHigh stress

The invention provides an early-dismantling support of an aluminum alloy top plate which comprises a support main body and a template support connected on the support main body, wherein the support main body consists of a vertical steel pipe, a lower connecting plate welded on the lower end of the vertical steel pipe, an upper support plate welded on the upper end of the vertical steel pipe and limit sheets welded at the middle part of the vertical steel pipe; the vertical steel pipe is sheathed with a jacking which is formed by casting cast steel; and the vertical steel pipe between the jacking and the upper support plate is also sheathed with a slide support which is formed by welding steel plates. The early-dismantling support has the advantages of fast and convenient dismantling, highworking efficiency, simple structure, high stress intensity, convenient and flexible operation, easily mastered construction process, accelerated construction progress and shortened construction period.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

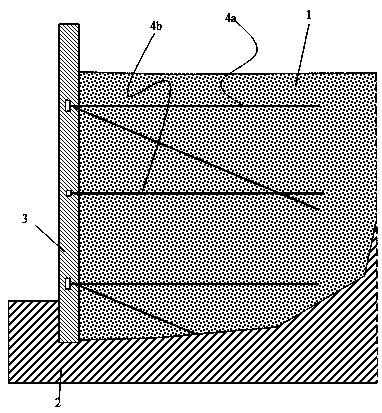

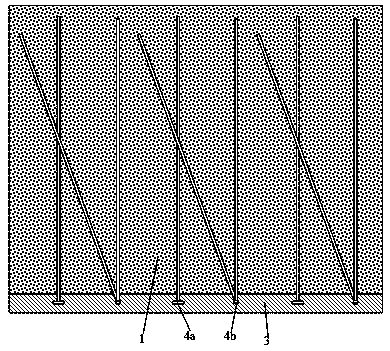

Reinforced anchoring type concrete retaining wall

InactiveCN108797635AImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresRoad engineeringEngineering

The invention provides a reinforced anchoring type concrete retaining wall, and belongs to the field of urban underground road engineering as well as the technical field of municipal facilities. According to the reinforced anchoring type concrete retaining wall, reinforcing anchoring pulling bars are horizontally arranged by rows, and the reinforcing anchoring pulling bars at the upper and lower adjacent rows are staggered with each other; the arrangement form of the reinforcing anchoring pulling bar is divided into two types, namely, vertical crossing of the reinforcing anchoring pulling barsand horizontal crossing of the reinforcing anchoring pulling bars; and the vertical crossed reinforcing anchoring pulling bars and the horizontal crossed reinforcing anchoring pulling bars on the same horizontal row are staggered with each other. The reinforced anchoring type concrete retaining wall has the beneficial effects that the anchoring performance, the integrity and the stability of theconcrete retaining wall are remarkably improved, the safety performance is remarkably improved, moreover, the cost is low, and the engineering quality is easy to guarantee.

Owner:SHENYANG JIANZHU UNIVERSITY

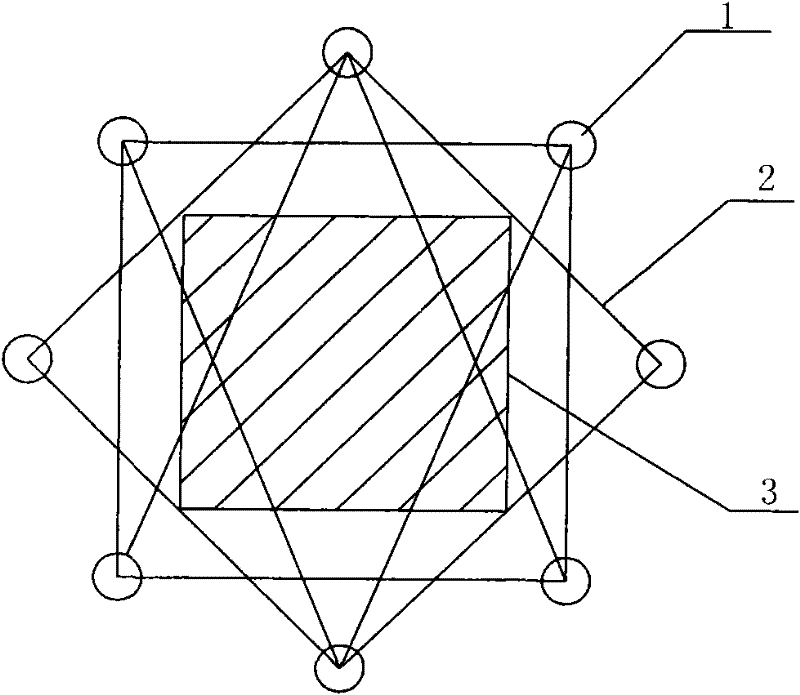

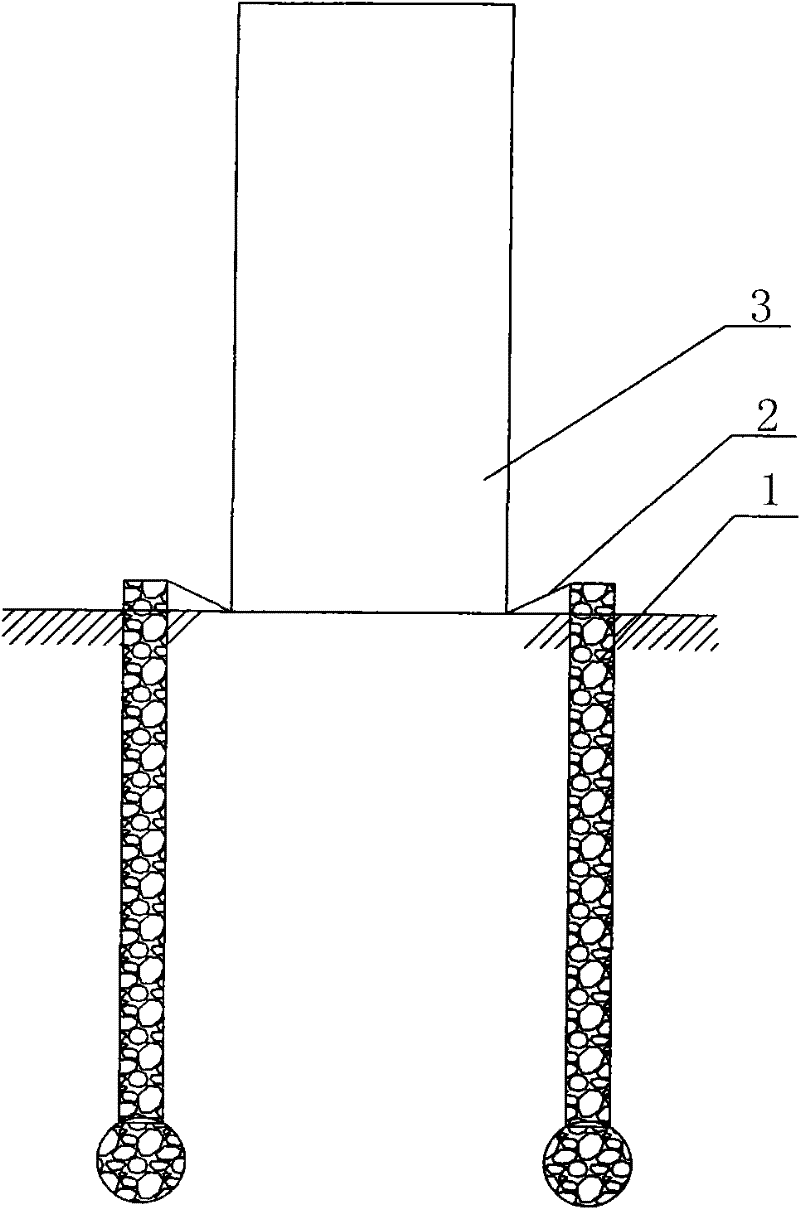

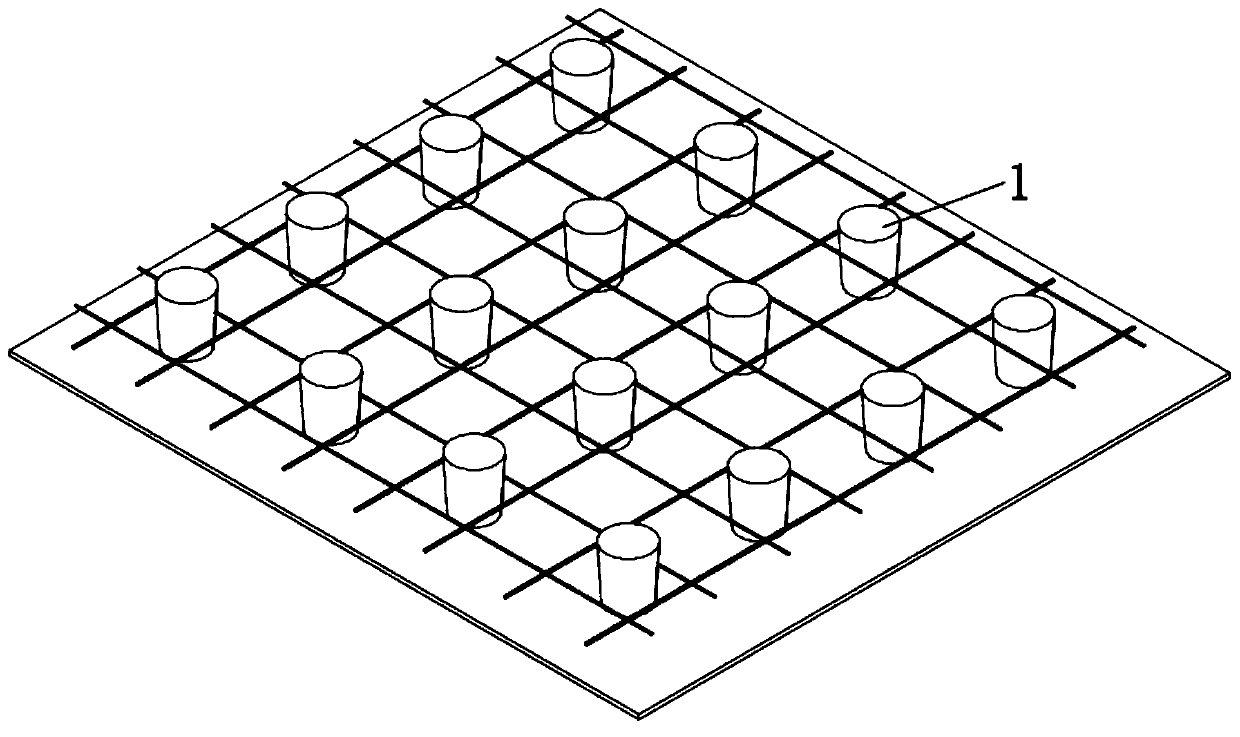

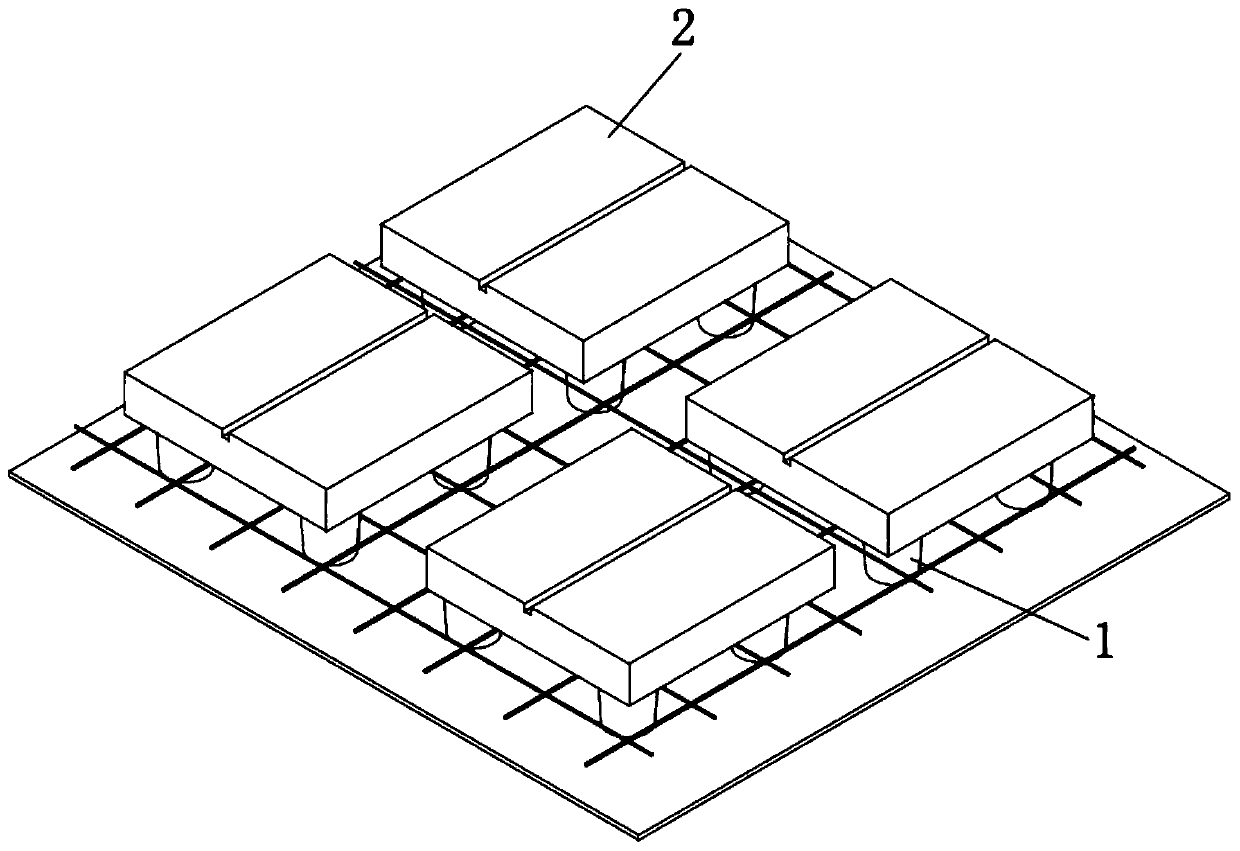

Underpinning device and method for bridge and building

InactiveCN101806040BEasy constructionEasy to operateBuilding repairsFoundation repairRebarEarth anchor

The invention provides an underpinning device and an underpinning method for a bridge and a building. The underpinning device comprises a plurality of columnar pile foundations arranged along a bridge pier of the bridge or around a building foundation, wherein flexible ropes are stretched among the tops of the pile foundations; different flexible ropes are arranged in a netlike form; and the two ends of the flexible ropes are anchored on the pile foundations or ground anchors. The method comprises the following steps: (1) piling around the bridge or the building and inserting steel pipes, wherein the top ends of the steel pipes are higher than an original foundation; (2) inserting reinforcing steel bars and pouring concrete into the steel pipes and solidifying the concrete to form the pile foundations; (3) arranging the flexible ropes on the tops of the pile foundations in the netlike form, tensioning the flexible ropes by using a tensioner, supporting the bridge or the building and anchoring the two ends of the flexible ropes; (4) treating the original foundation, detaching the original foundation, adding necessary facilities and building a new foundation; and (5) placing the bridge or the building on the new foundation. A composite rope supporting structure is used, so the bridge or the building can be underpinned, construction is performed easily and the engineering qualityis easy to ensure.

Owner:徐国彬

Self-balancing external prestressing strengthening method for bridge structure

ActiveCN102587296BImprove bearing capacityReduce the burden onBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

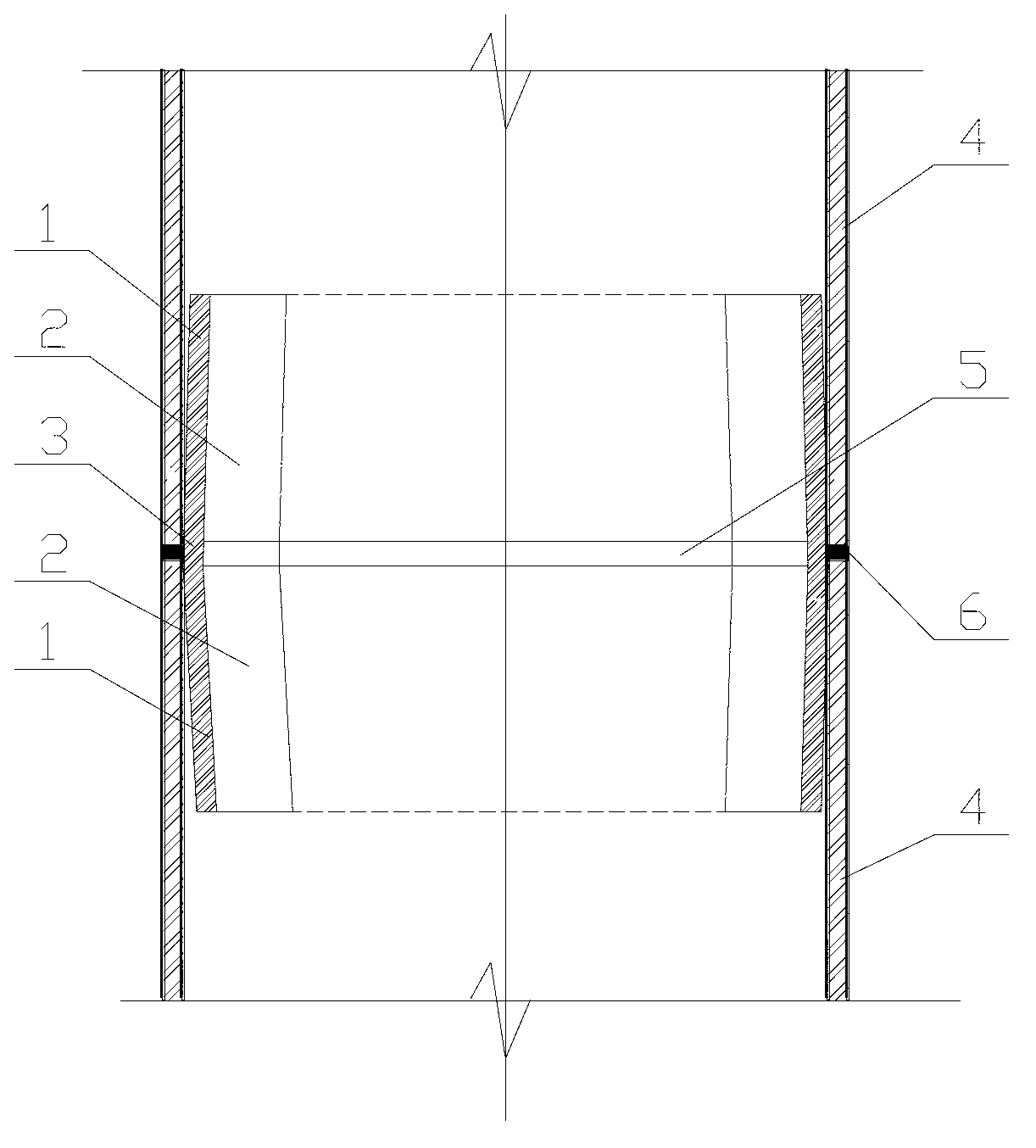

Box formwork construction method of assembly type box formwork hollow floor

The invention relates to a box formwork construction method for an assembly type box formwork hollow floor. The box formwork construction method comprises the following steps of: manufacturing concrete wedge-shaped cushion blocks according to the design thickness of a floor lower flange cast-in-place layer; mounting floor slab bottom ribs, then arranging the wedge-shaped cushion blocks at positions shown in a box formwork design diagram, arranging four wedge-shaped cushion blocks at the bottom of each box formwork, and keeping the small-head ends of the wedge-shaped cushion blocks downwards and the large-head ends of the wedge-shaped cushion blocks upwards; arranging the box formworks at positions of the box formwork design diagram, placing the box formworks on the wedge-shaped cushion blocks, and supporting and positioning the box formworks through the four wedge-shaped cushion blocks; after the box formworks are installed, mounting floor slab surface ribs and inter-box-formwork rib beam steel bars, arranging anti-floating steel bars on the box formworks while the floor slab surface ribs are installed, arranging the anti-floating steel bars in the middles of the upper surfaces ofthe box formworks, and fixing the anti-floating steel bars to a floor slab bottom formwork through iron wires. On the premise that the construction quality is guaranteed, the construction difficulty is reduced, the construction efficiency is improved, and position conflicts between the box formwork positioning structure and the structural stress ribs are avoided.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

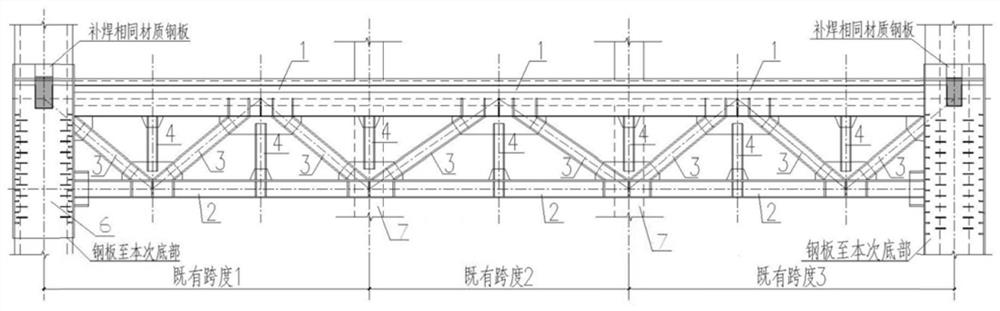

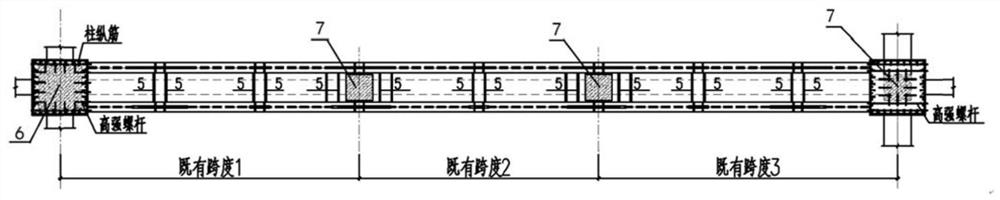

Double-truss steel-concrete combined conversion reinforcing truss

PendingCN114687577AIncreased Strength and RigidityGood reinforcement effectBuilding repairsStructural engineeringConcrete beams

The invention relates to a double-truss steel-concrete combined conversion reinforcing truss which comprises a steel member and an upper chord member formed after the section of an existing concrete beam is increased, and the steel member comprises a double-truss steel lower chord member, a double-truss steel diagonal web member, a double-truss steel straight web member, an upper chord member embedded part and a lower chord member connecting part which are arranged below the upper chord member. All the steel members are connected in an equal-strength butt welding mode, and the steel members at the two ends of the truss are connected with existing concrete frame columns with enlarged sections and additionally provided with connecting plates. Compared with the prior art, secondary stress and secondary deformation caused by unloading and load redistribution in the column extraction transformation process can be reduced or eliminated, new and old materials and components are easier to act together, deformation is easier to cooperate, rigidity and strength are greatly enhanced, the reinforcing effect is more obvious, construction operation is easier to achieve, and construction monitoring reliability is high; and the engineering quality is easier to guarantee.

Owner:SHANGHAI PUDONG ARCHITECTURAL DESIGN & RES INST

A prefabricated l-shaped concrete multi-layer multi-step retaining wall

ActiveCN112523256BImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresConcrete beamsArchitectural engineering

The invention belongs to the technical field of retaining walls, and specifically relates to a prefabricated L-shaped concrete multi-layer and multi-step retaining wall, including L-shaped stepped prefabricated concrete retaining wall panels, concrete columns, concrete beams, etc. On the soil, the connecting groove at the bottom of the L-shaped stepped precast concrete retaining wall panel fits with the tooth tenon of the bottom plate with toothed tenon; the L-shaped stepped precast concrete retaining wall panel with more than two floors is assembled from the bottom to the upper layer, and the L-shaped The stepped prefabricated concrete retaining wall panels are connected to the concrete beams, the concrete beams are connected to the concrete columns one by one, and the filling soil is filled between the L-shaped stepped prefabricated concrete retaining wall panels and the original soil. The invention can improve the anchoring performance, integrity and stability of the concrete retaining wall. The L-shaped stepped prefabricated concrete retaining wall panels, concrete columns and concrete beams form a spatially distributed retaining wall, which can improve the wall bearing capacity and safety performance. Improvement, and the cost is low, and the project quality is easy to guarantee.

Owner:沈阳促晋科技有限公司

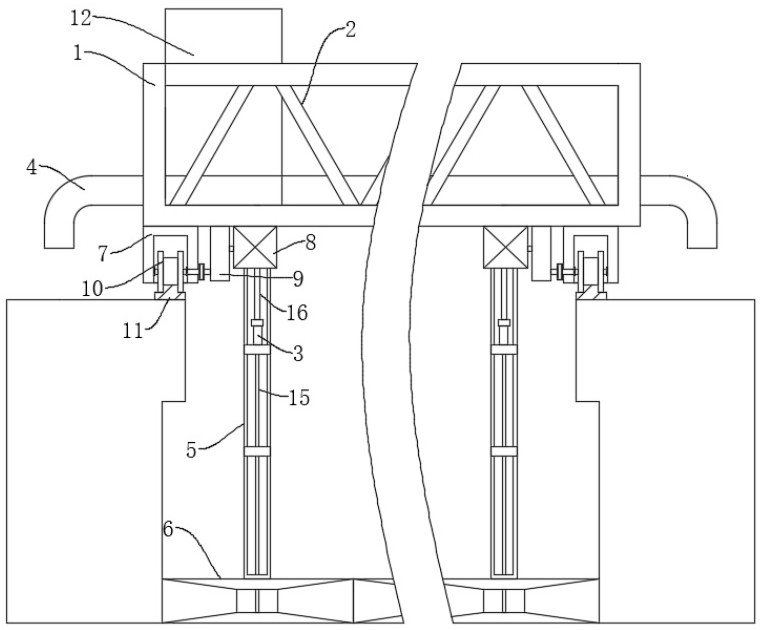

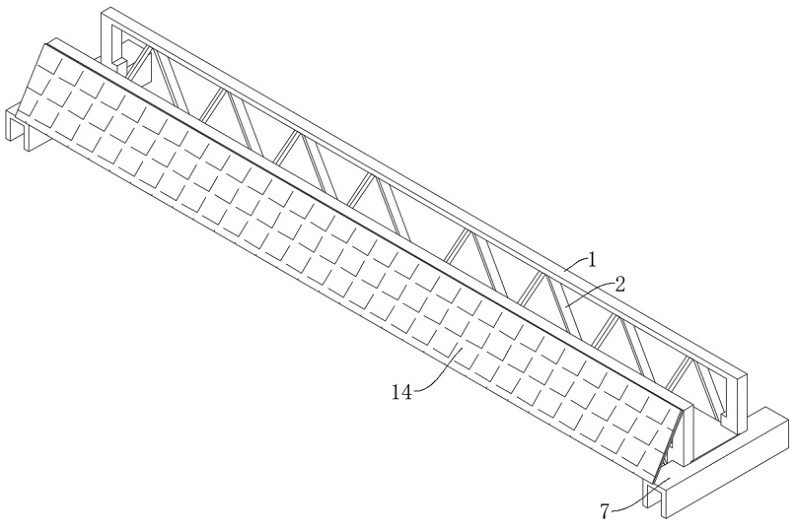

Pumping truss type suction dredger and mounting method

InactiveCN113750585APrevent spillageEasy to cleanSettling tanks feed/dischargeSludgeArchitectural engineering

The invention discloses a pumping truss type suction dredger and a mounting method, and belongs to the technical field of sewage treatment. The pumping type truss suction dredger comprises a horizontal truss, and further comprises an end beam fixedly connected to the bottom of the horizontal truss, a steel frame and a mud scraping box; and a driving part used for driving the horizontal truss to move is arranged on the end beam; the steel frame is fixed at the bottom of the horizontal truss; the sludge scraping box is fixedly connected to the bottom of the steel frame; and sludge is guided through the sludge scraping box, so that the sludge is prevented from overflowing all around, the situation that the overflowing sludge is separated from the adsorption range of the suction dredger is avoided, and the sludge treatment effect is prevented from being reduced. The key in construction, namely, the construction method of the pumping type truss type suction dredger, is researched; a set of comprehensive construction technology for mounting the pumping truss type suction dredger is formed, the engineering quality is guaranteed, the reworking phenomenon is reduced, the engineering cost is saved, the mounting technology is simple, operation is convenient, and the engineering quality is easy to guarantee.

Owner:QINGDAO INSTALLATION & CONSTR

Method for carrying out dynamic compaction treatment on complex site foundation

InactiveCN111501725AStrict requirementsMeet the use requirementsSoil preservationDynamic compactionEnergy increasing

The invention discloses a method for carrying out dynamic compaction treatment on a complex site foundation. Miscellaneous fill on the surface layer of the site is utilized, the dynamic compaction andpower consolidation function is carried out in the tampering manner of column hammer crushing, hammer flattener reinforcing and stage-by-stage energy increase, the foundation surface layer within thedepth range is effectively reinforced to form an overlying crust, and upper loads are borne by the overlying crust and are dispersed into a lower foundation. The method has the beneficial effects that the overlying crust of 3-5 m is formed on the site surface layer, the originally thin part of the overlying crust becomes thicker, the overlying crust with the thickness being relatively uniform isformed on the surface layer of the whole site, the bearing capacity can meet requirements, and meanwhile soft soil on the lower portion of the overlying crust can be enhanced.

Structure and Construction Method of Steel Anchor Pipe Reinforcing Weathered Rock Strata Reinforced Balance Weight Retaining Wall

ActiveCN109736346BImprove stabilityReduce earth pressureArtificial islandsUnderwater structuresEconomic benefitsRetaining wall

The invention discloses a structure and a construction method of a steel anchor pipe reinforcing the weathered rock layer with reinforcement and balance weight type retaining wall. The steel anchor pipe of the present invention realizes the reinforcement treatment of the weathered rock layer through grouting inside and outside the pipe, and the treated rock mass foundation bears The strength is greatly improved, fully meeting the foundation bearing requirements of the upper embankment retaining structure; at the same time, the stability of the weathered rock layer after treatment is improved, and the steel anchor pipe can also be used as a slope anti-slide structure, which realizes the anti-slip and disaster reduction of the original weathered rock layer slope The effect; the reinforced earth (counterweight type) retaining wall of the present invention has realized the breakthrough of traditional retaining wall wall thickness dimension, and the laying of geogrid has greater meaning for retaining wall stability simultaneously; The present invention The construction method is mature, the process is reasonable, and it has the advantages of rapid construction and outstanding economic benefits. The invention has broad prospects for the geological application of weathered rock formations to filling road embankments and retaining structures.

Owner:CHINA FIRST HIGHWAY ENG +1

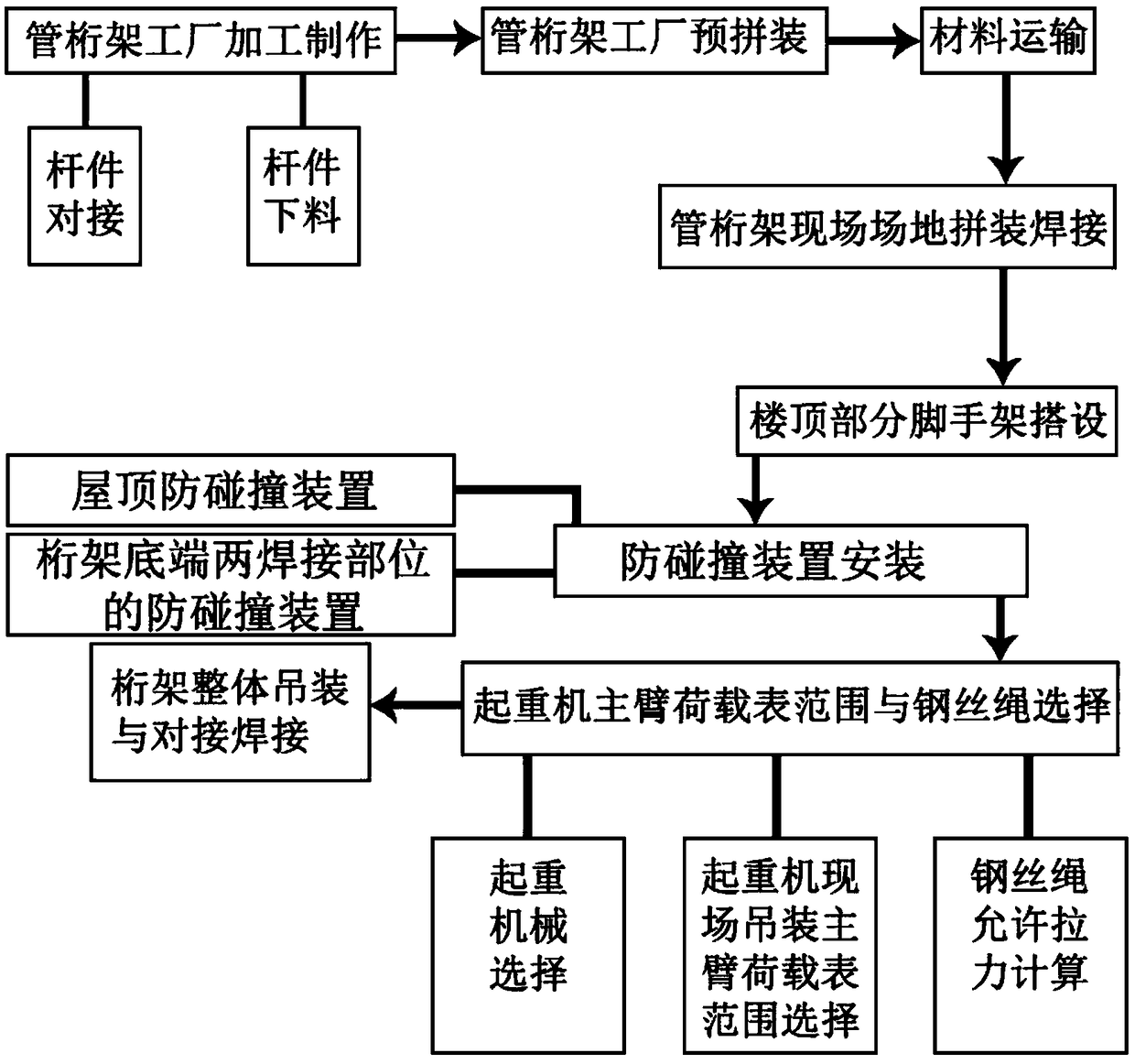

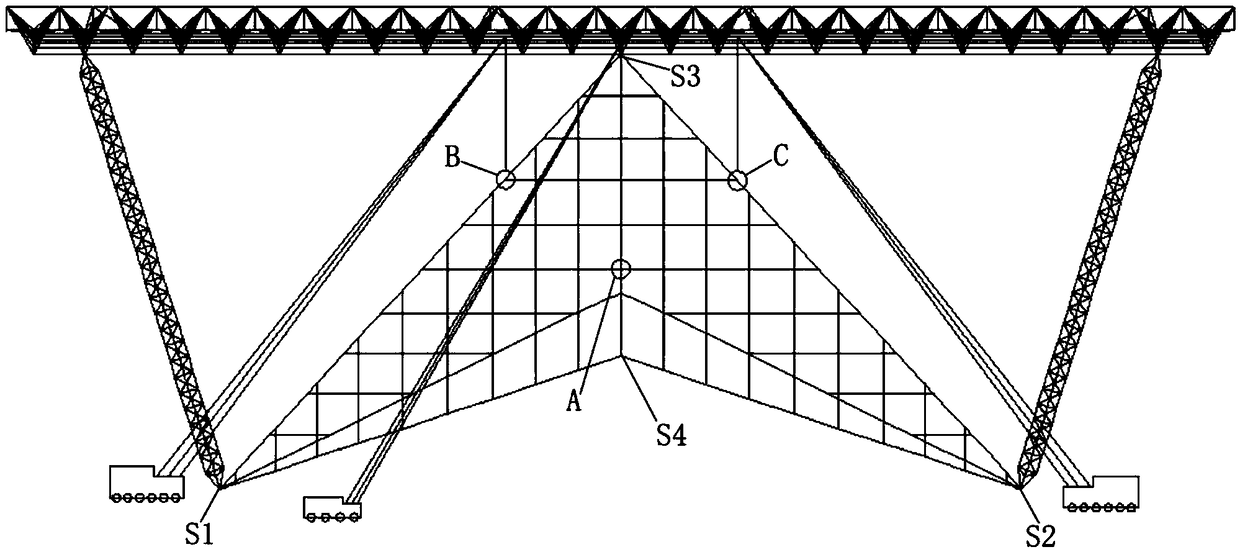

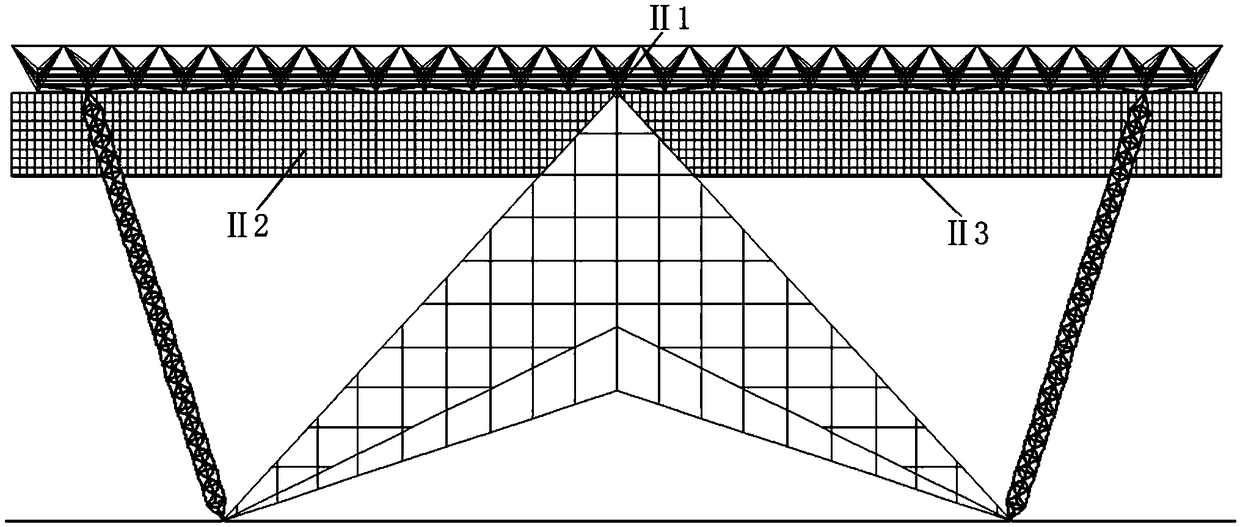

A construction method for overall hoisting of large multi-angular cantilevered trusses

ActiveCN107100309BImprove assembly efficiencyEasy constructionBuilding roofsBuilding material handlingTerrainButt welding

A construction method for integrally hoisting a large-size multi-edge-and-corner overhanging truss is disclosed. Integral assembling of a steel pipe truss is conducted on site, and integral hoisting is conducted after assembling is completed; the truss is connected with three welding positions in a butt-joint mode and then is welded firmly; two 500 t all-terrain cranes and a 350 t all-terrain crane are adopted to hoist the whole truss simultaneously, and step-by-step hoisting is conducted from south to north; the truss is totally provided with three main stress support joints which are all fixed by adopting butt welding, a third calibration point support is located at the top of the truss, a welded ball joint at the position of the third calibration point is a support point of a steel rainshed grid frame actually, a first calibration point support and a second calibration point support are located on both the left and right sides of the bottom of the truss correspondingly, and the first calibration point support and the second calibration point support are global stress supporting points of the truss. The construction method for integrally hoisting the large-size multi-edge-and-corner overhanging truss has the characteristics that the construction safety is high, the construction period is short, the engineering quality is easy to guarantee, the ground integral assembling efficiency is high, and the construction cost is reduced greatly.

Owner:FUJIAN MINNAN CONSTR ENG

Parabola-shaped lap joint assembly type channel

PendingCN107059813AFirmly connectedEasy constructionIrrigation ditchesArtificial water canalsLap jointEngineering

The invention relates to a parabola-shaped lap joint assembly type channel. The parabola-shaped lap joint assembly type channel structurally comprises a trench, and multiple trenches can be quickly connected through lap joint to form canals of different lengths; one side of the trench extends outwards to form a step-shaped connector; the other side of the trench horizontally extends to form a lap; the lap can be horizontally lapped on the connector; and a water stop strip (or water strop rod) is placed between the lap and the connector, and the purposes of water sealing and seepage prevention are achieved through gravity extrusion of the trench. According to the parabola-shaped lap joint assembly type channel, through the lap joint manner, the water sealing effect is good, construction is simple and convenient, less manpower is required, industrialized prefabrication and mechanical construction can be achieved, and product quality is easily guaranteed.

Owner:NORTHWEST A & F UNIV

Fabricated concrete double-shaped combination block retaining wall

InactiveCN113565132AImprove the anchoring effectImprove stabilityArtificial islandsExcavationsArchitectural engineeringBearing capacity

The invention provides a fabricated concrete double-shaped combination block retaining wall, and belongs to the technical field of supporting construction. In the same layer, concrete fusiform blocks and concrete I-shaped blocks are mutually alternated, fusiform block front inclined ribs and I-shaped block front inclined ribs are matched with each other, fusiform block rear inclined ribs and I-shaped block rear inclined ribs are matched with each other, groove-shaped groove-shaped ribs are arranged in second fusiform block filling holes of the concrete fusiform blocks, tie bars penetrate through first round holes and second round holes of the concrete fusiform blocks and are connected with the groove-shaped ribs, the other ends of the tie bars horizontally extend to the original soil direction, and joints of the concrete fusiform blocks and the concrete I-shaped blocks on the adjacent layers are mutually staggered. The fabricated concrete double-shaped combination block retaining wall has the beneficial effects that the anchoring performance and stability of the concrete retaining wall are remarkably improved, the anti-overturning capacity of the retaining wall is effectively improved, by adopting a series clamping and locking type design technology, the integrality is remarkably improved, the bearing capacity and safety performance of a wall body are remarkably improved, the cost is low, and the engineering quality is easy to guarantee.

Owner:吉林建筑科技学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com