Reinforced anchoring type concrete retaining wall

A concrete and retaining wall technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as restrictions on inclined piles, achieve improved safety performance, improve anchorage performance, and easily ensure project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

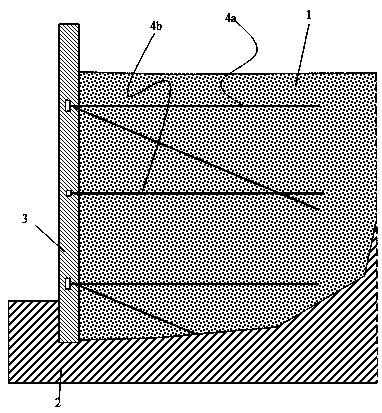

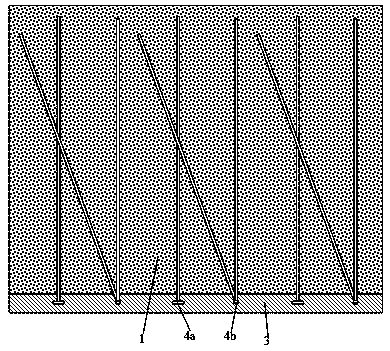

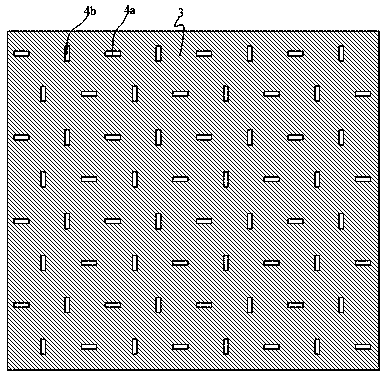

[0027] Such as Figure 1~Figure 5 As shown, a reinforced anchorage type concrete retaining wall includes filling soil 1, original soil 2, concrete retaining wall body 3 and reinforcement anchorage tie bar 4, and is characterized in that:

[0028] A part of the concrete retaining wall body 3 extends into the original soil 2, and one side thereof is filled with soil 1;

[0029] Strengthening and anchoring tie bars 4 are arranged in the concrete retaining wall 3, and the strengthening and anchoring bars 4 extend vertically out of the concrete retaining wall 3 and extend into the filling 1;

[0030] The reinforcement and anchoring ties 4 are arranged horizontally in rows, and the reinforcement and anchoring ties 4 in the upper and lower adjacent rows are interlaced;

[0031] There are two types of layouts for the reinforced anchorage ties 4: vertically crossed reinforced anchorage ties 4a and horizontally intersected reinforced anchorage ties 4b;

[0032] One of the long helical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com