Short-chain branch cross-linked water-retaining solvent layer controlled-release type polycarboxylic acid slump retaining agent and preparation method thereof

A technology of water solvent and polycarboxylate, which is applied in the field of polycarboxylate admixtures for cement-based cementitious materials, and can solve the problems of unsatisfactory initial fluidity, segregation, bleeding, settlement, and large compounding ratio of slump-retaining agents, etc. problems, to achieve the effect of enhancing anchoring capacity and water state, reducing the probability of segregation and bleeding, and increasing the initial water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

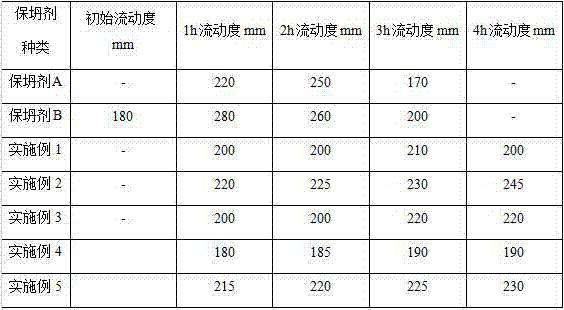

Examples

Embodiment 1

[0034] The short-chain branched cross-linked water-retaining solvent layer controlled-release polycarboxylate slump-retaining agent and its preparation method are prepared by polymerizing the following components, with a total mass part of 1000. The preparation method is as follows:

[0035] 1. The first feeding: 320 parts of 2400 molecular weight isopentenol polyoxyethylene ether, 3.0 parts of sodium hypophosphite, 2.0 parts of ethylene glycol methacrylate phosphate and 200 parts of water are added to the reactor, Continue to stir until the solution has no obvious lumps or flakes; measure the temperature in the kettle, control the temperature at 15°C, and put 0.5 parts of 27.5% industrial-grade hydrogen peroxide and 2.0 parts of ammonium persulfate at one time;

[0036] 2. The second feeding: Within 2-5 minutes of feeding, start to drop the initiator and small monomer solution in sequence; the initiator is composed of 4.0 parts of glucose monohydrate, 0.8 parts of dicyclohexyl...

Embodiment 2

[0039] The short-chain branched cross-linked water-retaining solvent layer controlled-release polycarboxylate slump-retaining agent and its preparation method are prepared by polymerizing the following components, with a total mass part of 1000. The preparation method is as follows:

[0040]1. The first feeding: Add 323 parts of vinyl butyl ether polyoxyethylene ether, 3.5 parts of sodium hypophosphite, 3.5 parts of methacryloyloxyethyl phosphate and 220 parts of water into the reaction kettle, and keep stirring , until the solution has no obvious lumps or flakes; measure the temperature in the kettle, control the temperature at 10°C, and put 1.5 parts of 27.5% industrial grade hydrogen peroxide and 1.2 parts of ammonium persulfate at one time;

[0041] 2. The second feeding: Within 2-5 minutes of feeding, start to drop the initiator and small monomer solution in sequence; the initiator consists of 3.5 parts of dextrin, 0.6 parts of N,N'-diisopropylcarbodiimide and Composed of...

Embodiment 3

[0044] The short-chain branched cross-linked water-retaining solvent layer controlled-release polycarboxylate slump-retaining agent and its preparation method are prepared by polymerizing the following components, with a total mass part of 1000. The preparation method is as follows:

[0045] 1. The first feeding: Add 325 parts of 2400 molecular weight prenol polyoxyethylene ether, 4.0 parts of sodium hypophosphite, 3.5 parts of ethylene glycol methacrylate phosphate and 200 parts of water into the reactor, Continue to stir until the solution has no obvious lumps or flakes; measure the temperature in the kettle, control the temperature at 18°C, and put 2.5 parts of 27.5% industrial grade hydrogen peroxide and 1.5 parts of ammonium persulfate at one time;

[0046] 2. The second feeding: Within 2-5 minutes of feeding, start to drop the initiator and small monomer solution in sequence; the initiator is composed of 2.5 parts of glucose monohydrate, 0.4 parts of dicyclohexylcarbodiim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com