Connecting component of curtain wall system

A technology for connecting components and curtain walls, which is applied to building components, walls, building structures, etc. It can solve the problems of small adjustable range of back bolt components, high assembly precision, and high labor costs, so as to ensure occupational health and reduce material consumption. , the effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

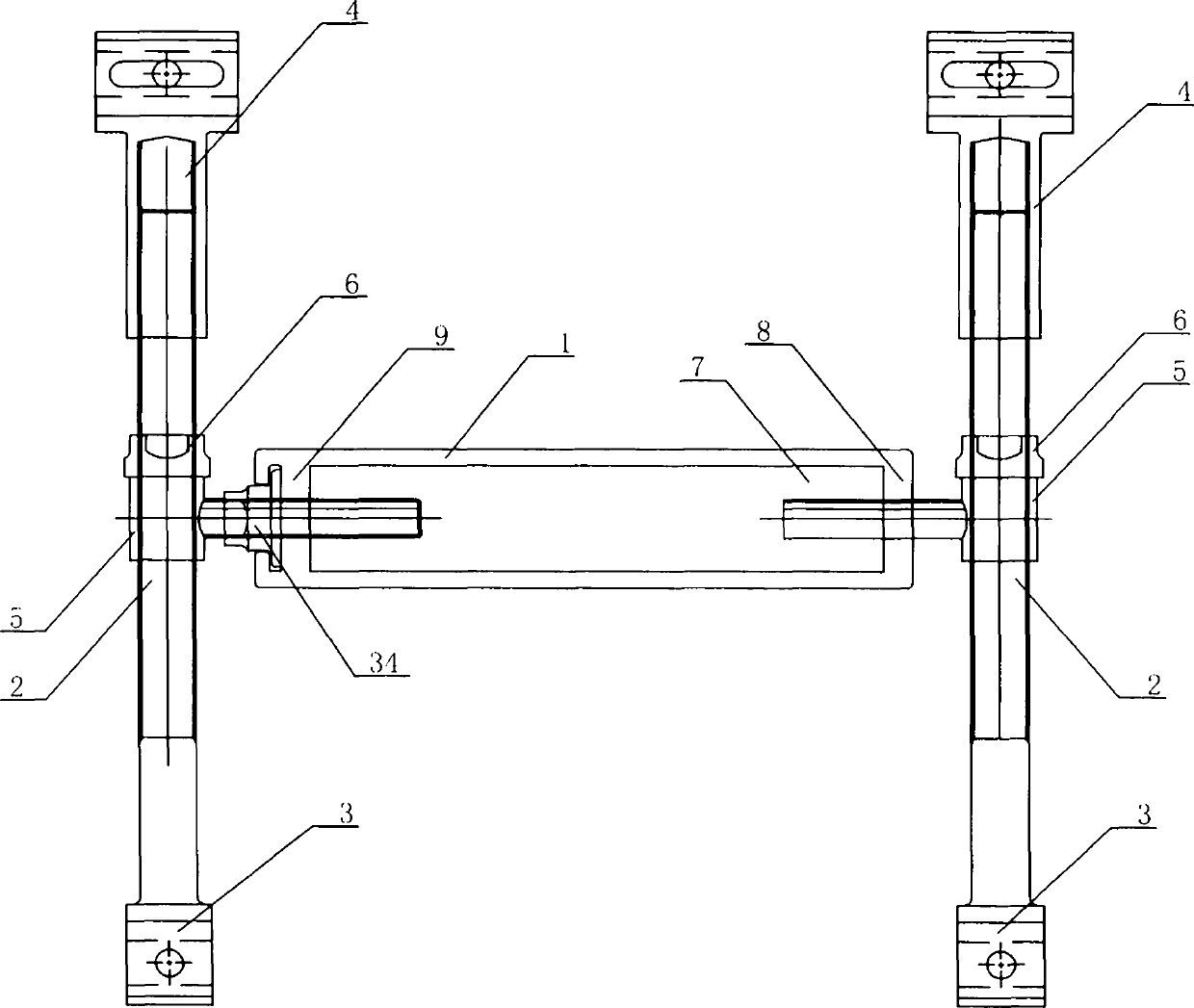

[0028] The technical characterictic of the present invention and function are described in detail below by accompanying drawing:

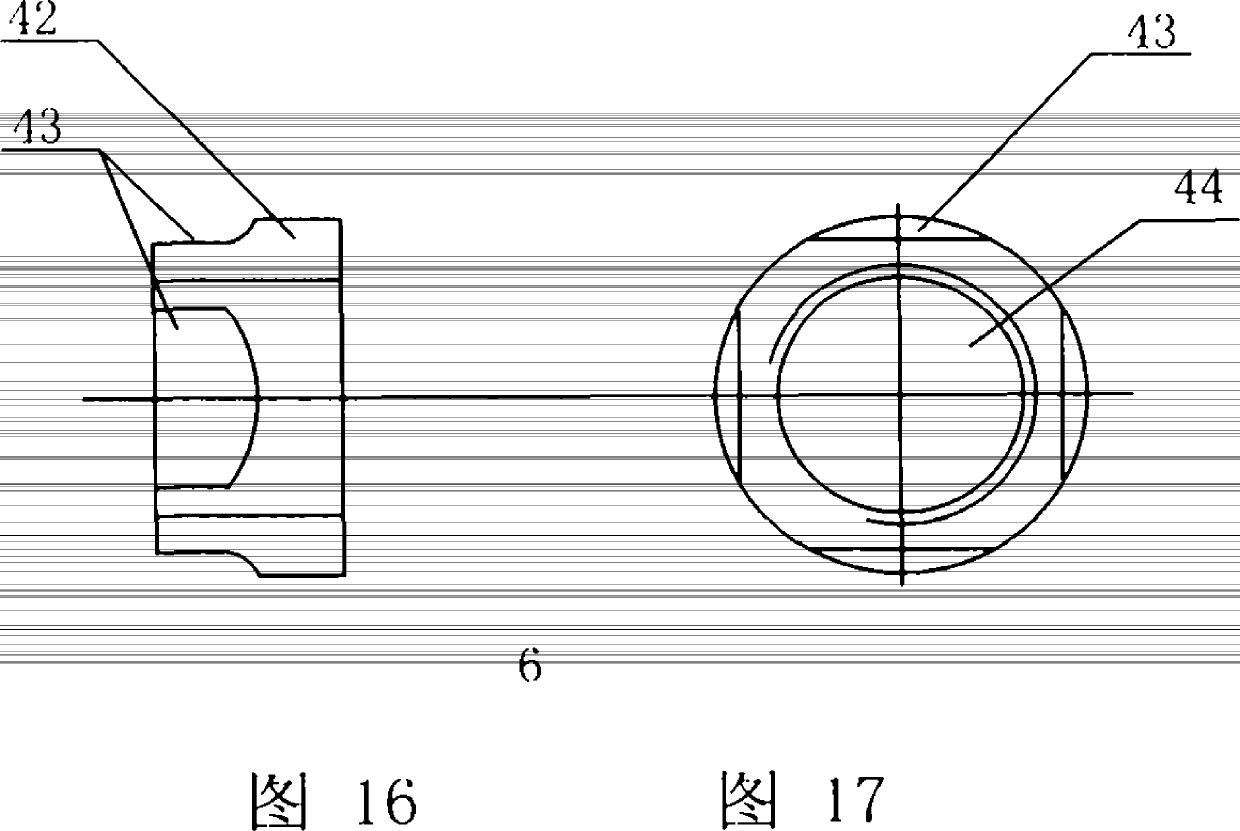

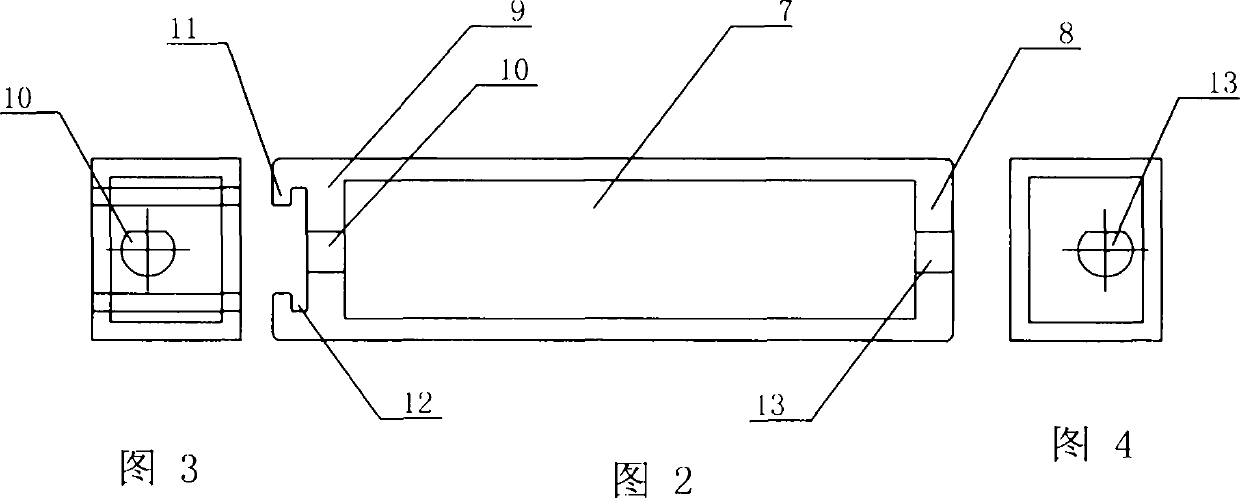

[0029] From figure 1It can be seen from the figure that the connecting member is H-shaped as a whole, with a straight web beam 1 in the middle, and the web beam 1 is a hollow member with a middle cavity of 7, and a sealing C-shaped member 9 is arranged at the left end of the web beam 1. A sealing end plate 8 is provided at the right end. A T-shaped member 5 is assembled on the left and right sides of the web beam 1, and the abdominal end screws of the T-shaped member 5 extend into the middle cavity 7 of the web beam 1, and a flange nut is assembled in the C-shaped member 9 on the left side of the web beam 1 34. The left and right spars 2 are all made up of screw rods 3 and tube nut members 4 .

[0030] control figure 1 , figure 2 , Figure 10 and Figure 12 It can be seen that an oblate hole 10 is provided on the web of the C-shaped member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com