FRP framework type rail sleeper structure

A frame-type sleeper technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of difficult to meet technical and economic comprehensive requirements, stability defects, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

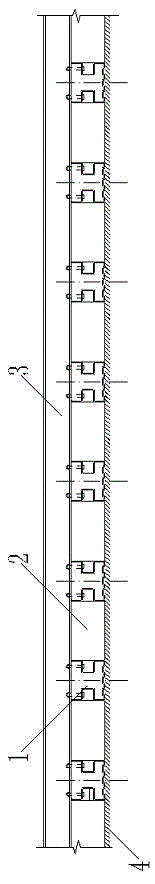

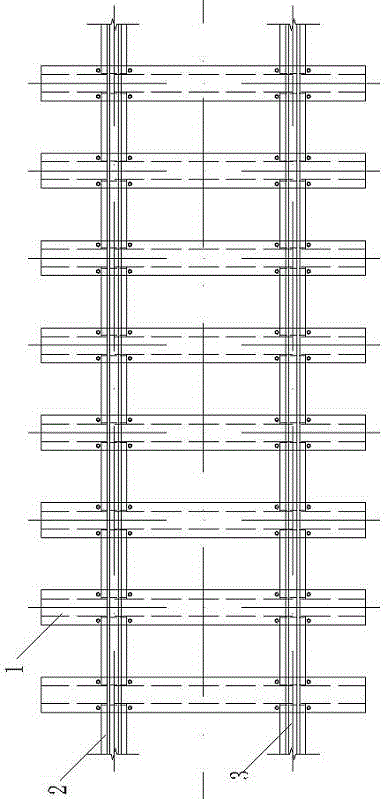

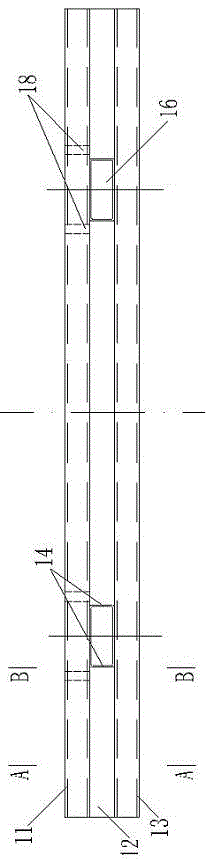

[0023] See attached figure 1 to attach Figure 8 , the FRP frame type sleeper structure in the figure, comprises the sleeper beam member 1 for fixing rail 3; It is characterized in that:

[0024] The sleeper beam member 1 is made of FRP material, and the sleeper beam member 1 further includes an upper wing plate 11 and a lower wing plate 13, and the upper wing plate 11 and the lower wing plate 13 are connected through a middle web plate 12 to become hollow. I-shaped cross-section beam member, the hollow inner cavity of the I-shaped cross-section beam member is filled with polyurethane rigid foam I15, and the two ends of the sleeper beam member 1 support the rails, and two transverse partitions 14 are symmetrically arranged , the two transverse partitions 14 and their intersecting upper and lower wings 11 and 13 enclose a hollow rectangular cross-section mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com