High and large space profile steel-concrete structure roof construction formwork system and method

A technology of concrete structure and high space, which is applied in the fields of formwork/formwork/work frame, building structure, and on-site preparation of building components. Complicated, high space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

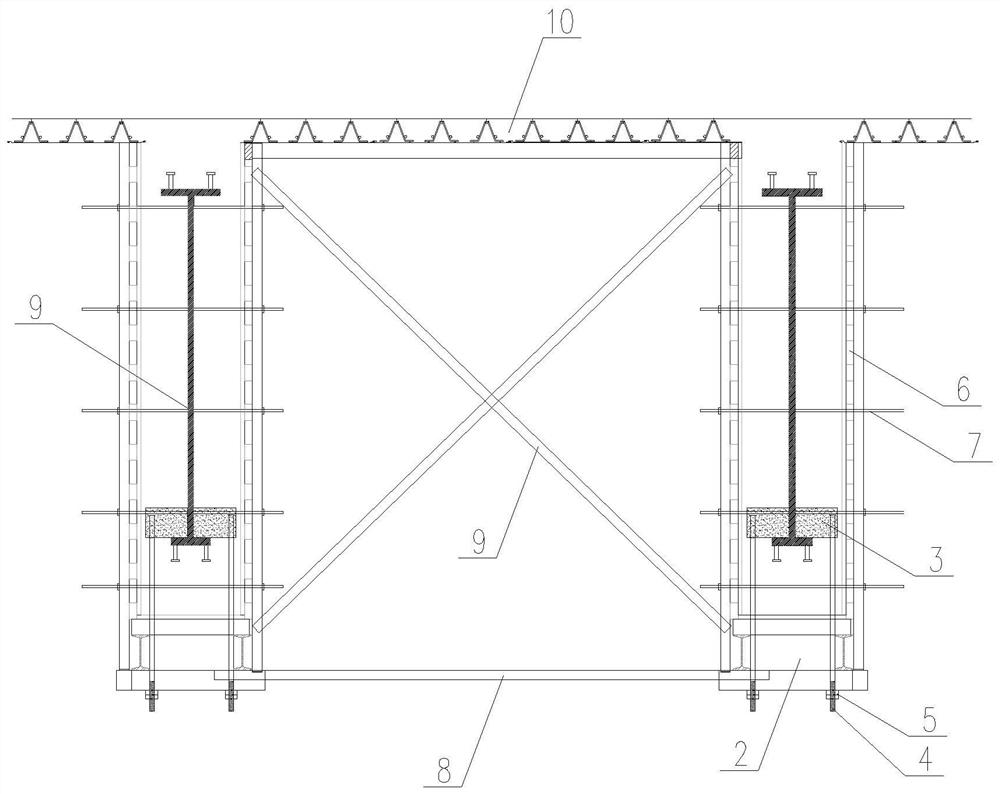

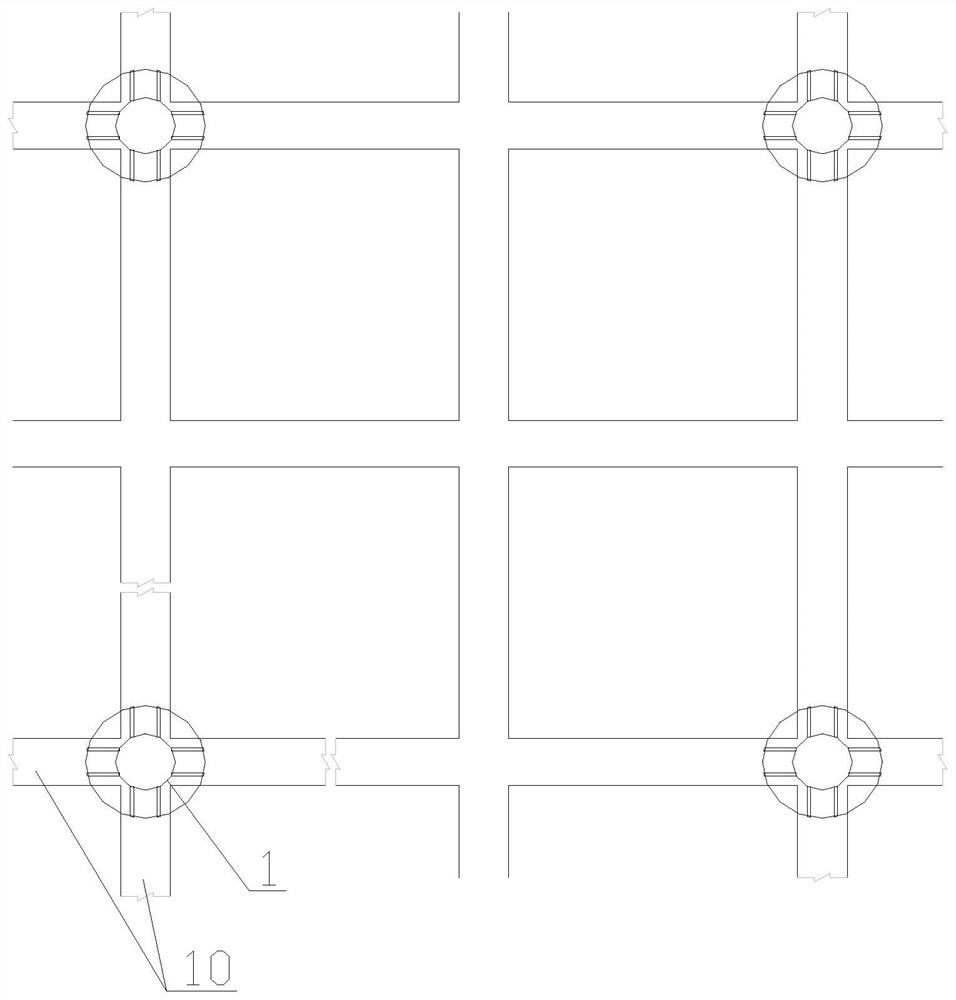

[0027] This drawing is a schematic diagram of the main components of the device, and does not represent the external dimensions, connection methods, assembly forms, positional relationships, etc. of the present invention, and some rods, etc. are omitted in the illustration.

[0028] It should be noted that the multiple solutions provided by this patent include their own basic solutions, which are independent of each other and do not restrict each other. However, they can also be combined without conflict to achieve multiple effects together.

[0029] The invention relates to the field of engineering, in particular to a formwork system and method with few brackets for the construction of a steel-concrete composite structure roof with high and large spaces. Including steel pipe column, bottom formwork system, lug plate, suspender rod, fastening bolt, side formwork system, tie rods, horizontal connecting rods and diagonal bracing rods, etc., the top of the steel pipe column is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com