Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

458results about "Truss-type bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

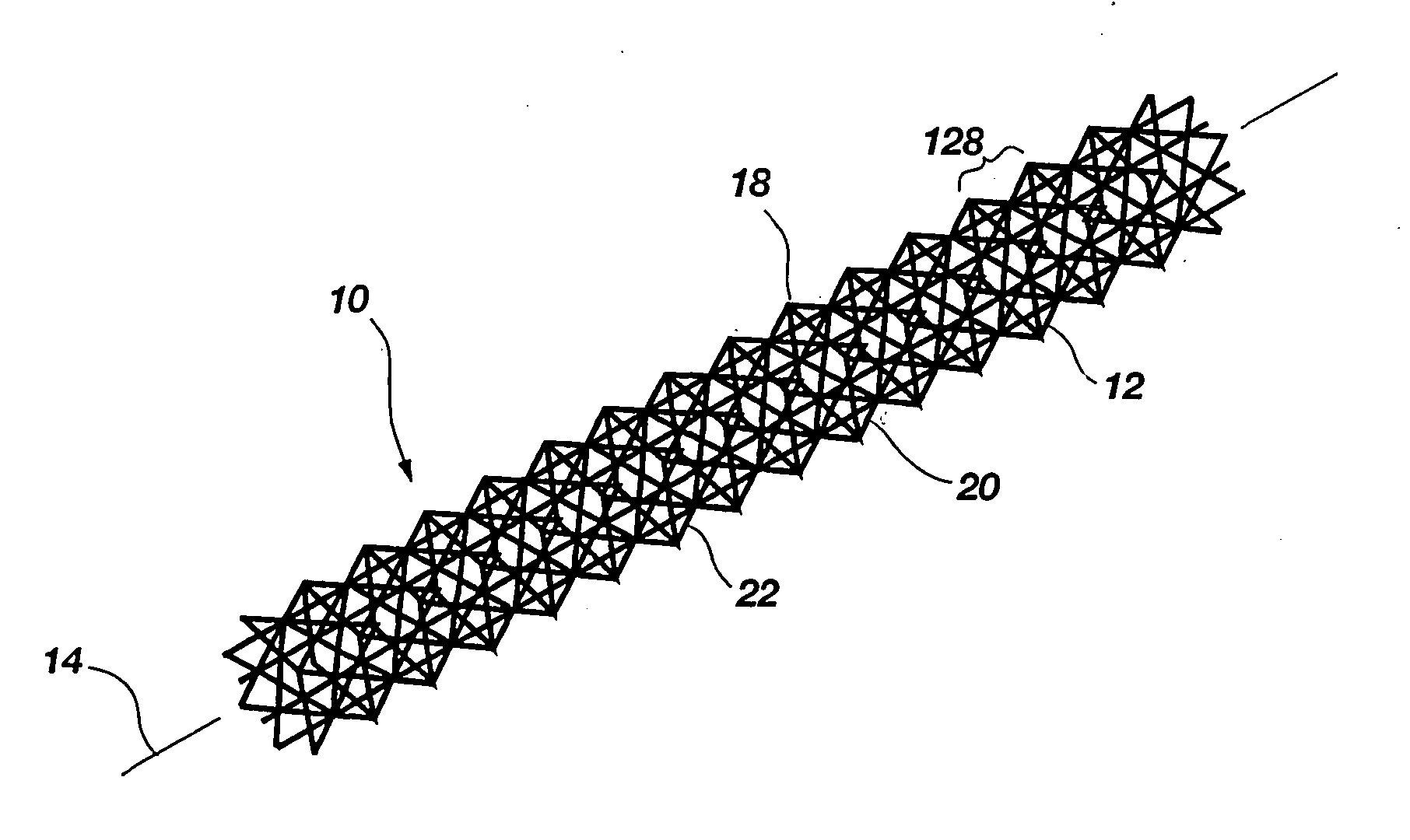

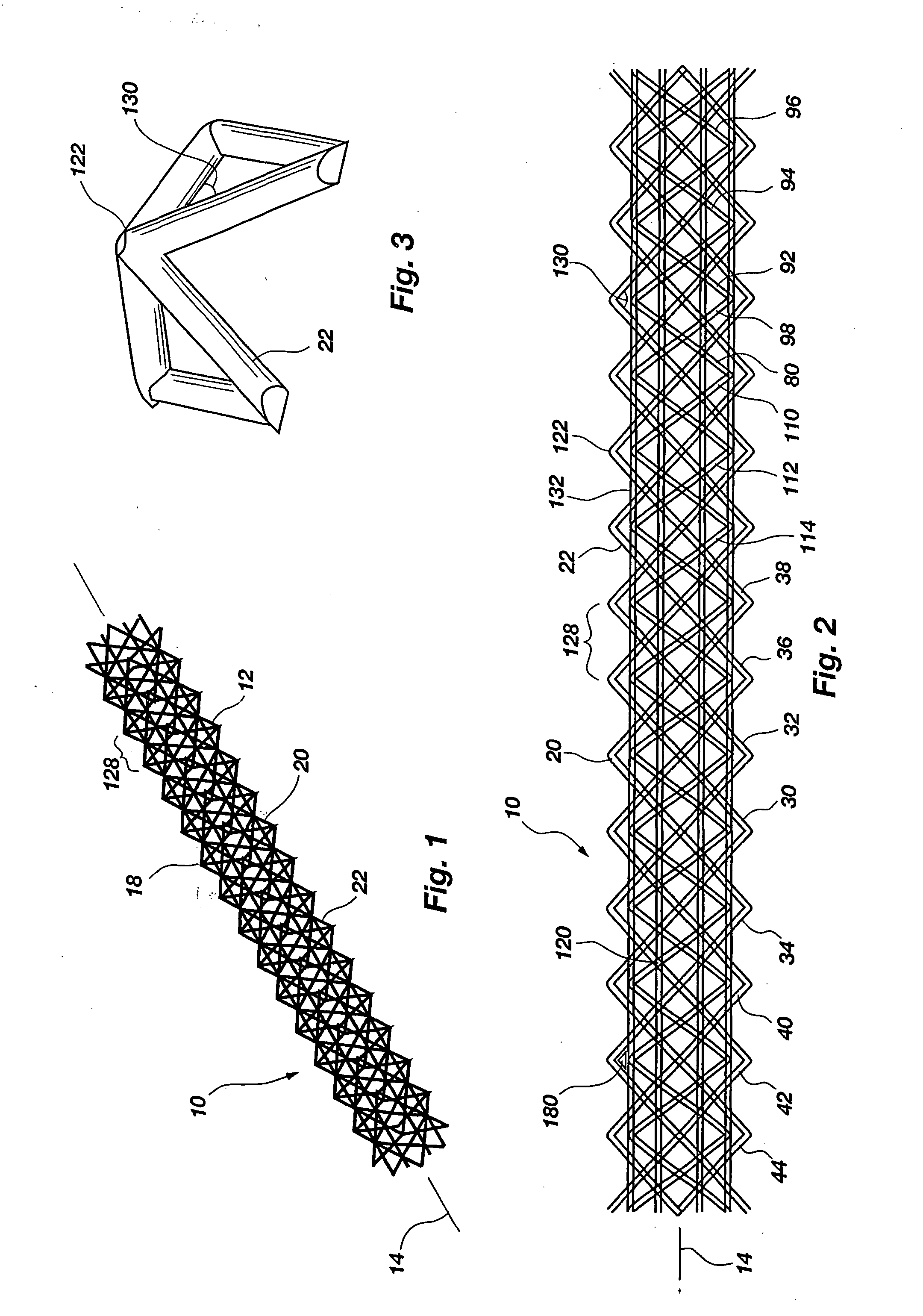

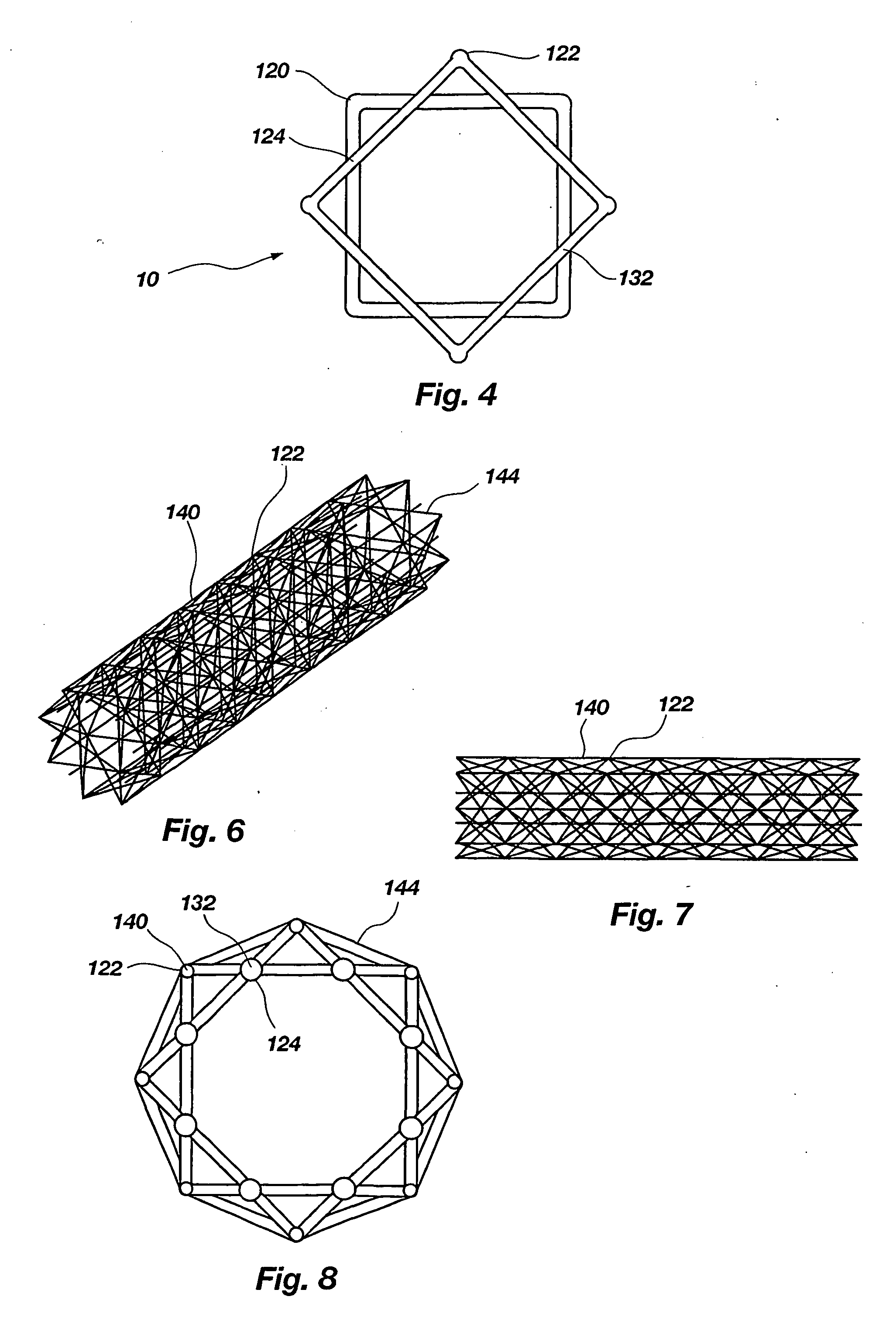

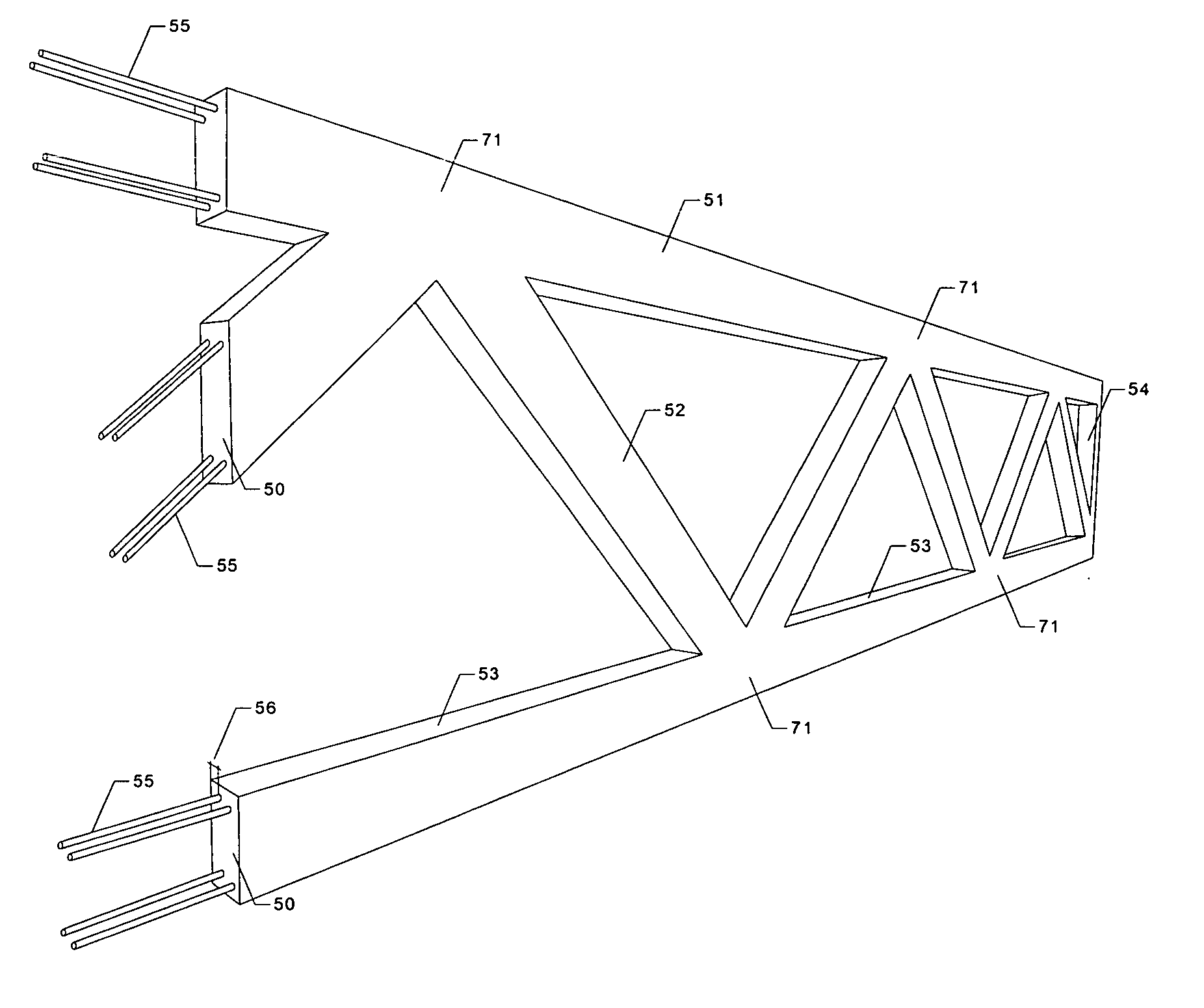

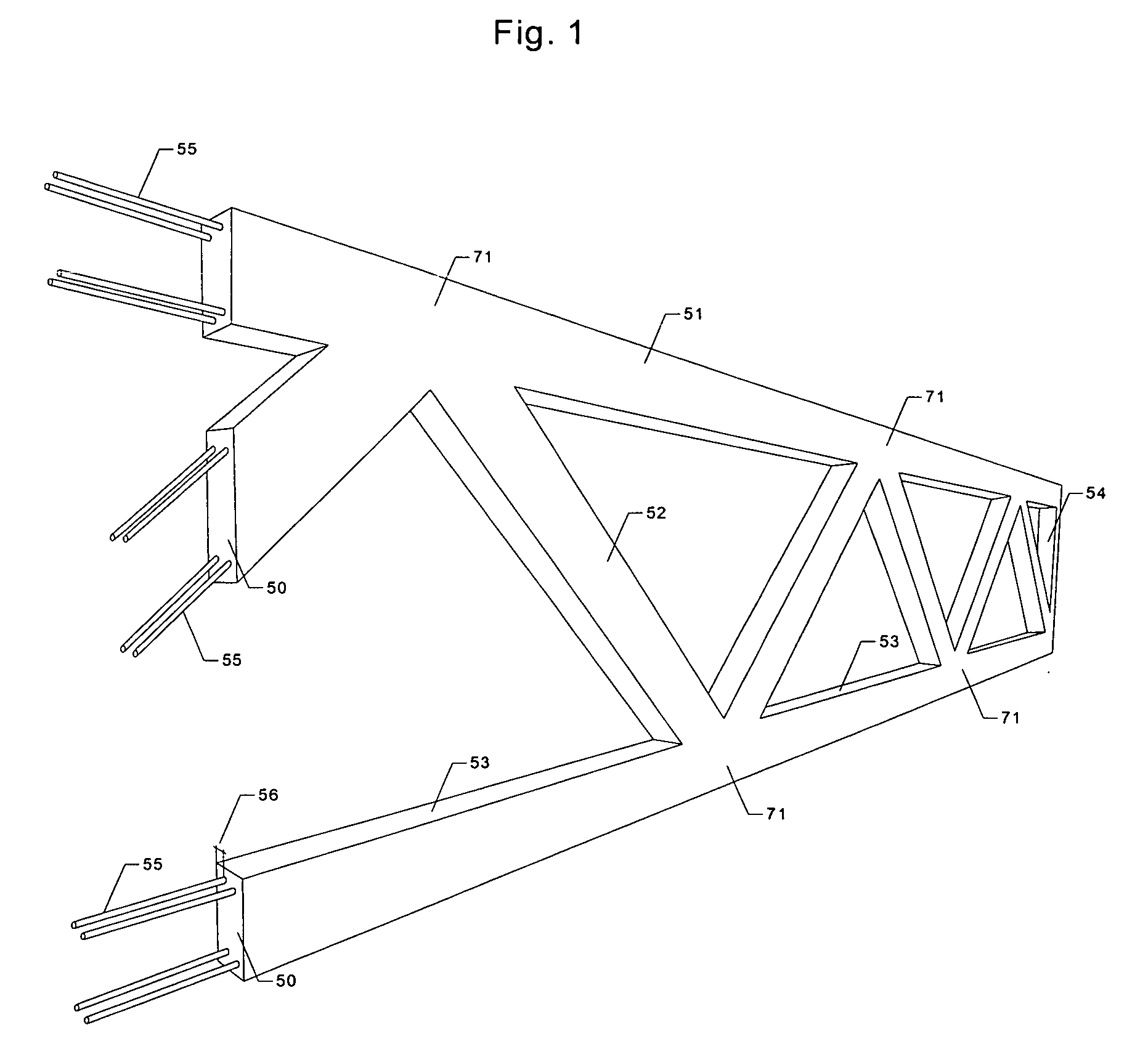

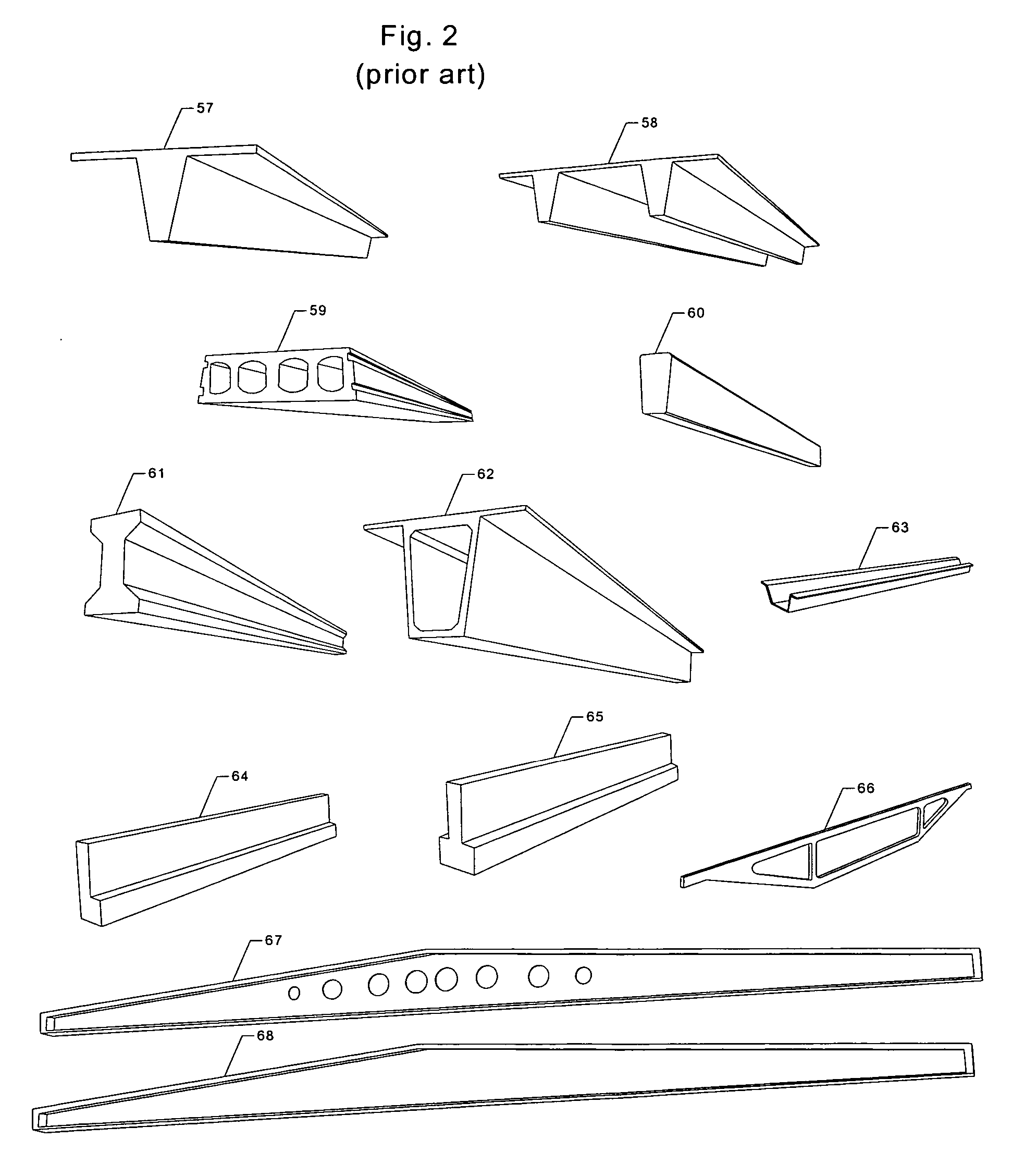

Iso-truss structure

InactiveUS20050115186A1Improved performance characteristicsReduced strengthTravelling sacksTruss-type bridgeSquare cross sectionAngular orientation

An iso-truss structure (10) includes at least two helical components (30, 32) and at least one reverse helical component (34) attached thereto with opposing angular orientations. Each helical and reverse helical component preferably includes at least four elongate, straight segments (22) rigidly connected end to end in a helical configuration forming a single, substantially complete rotation about a common axis (14) forming a first square cross section. The structure may further include at least two rotated helical components (80, 92) and at least one rotated reverse helical component (98) which are rotated with respect to the helical and reverse helical components forming a second square cross section, rotated with respect to the first. The structure may be straight, curved, flexible, or form angles.

Owner:ISOTRUSS IND LLC

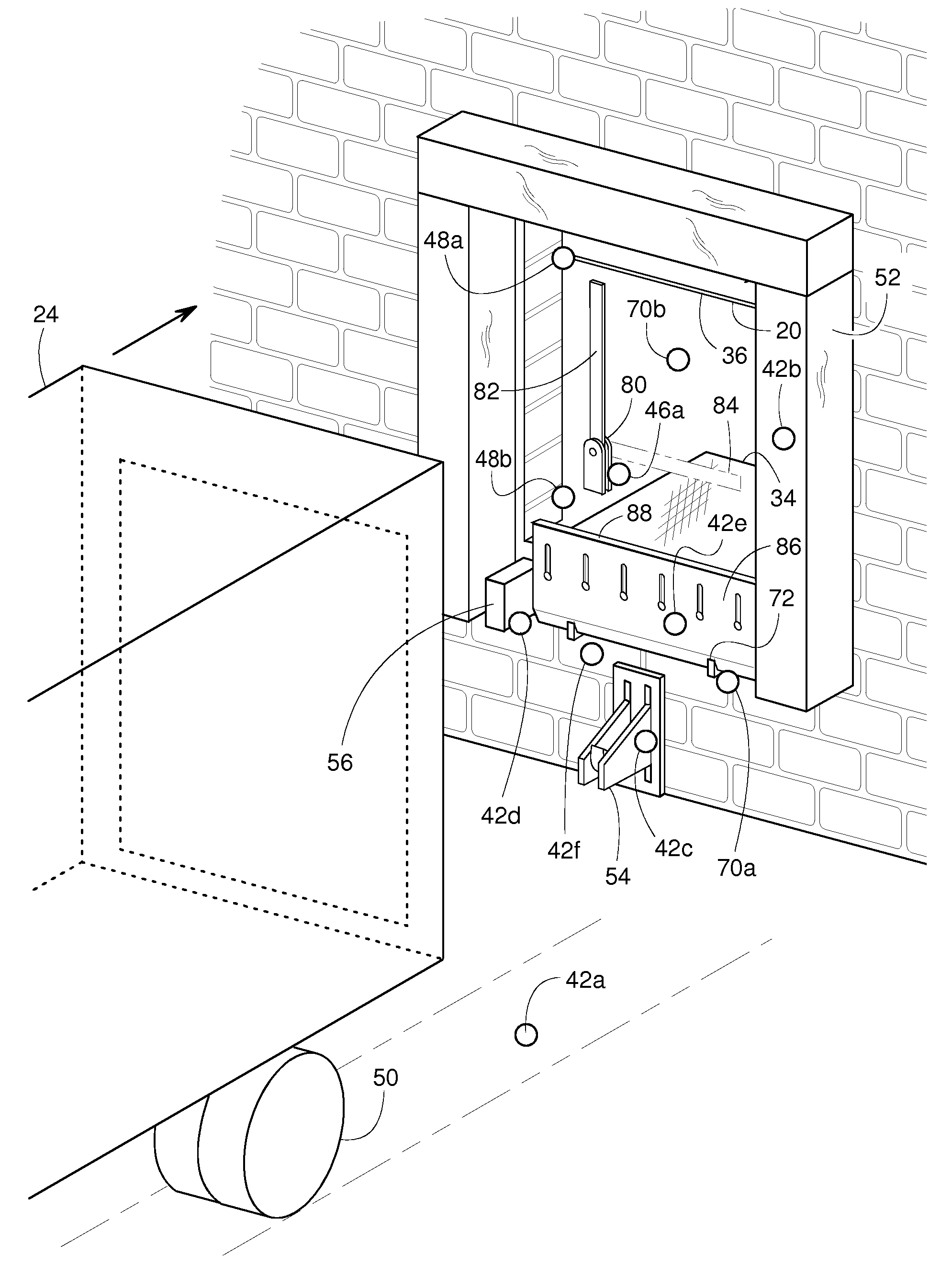

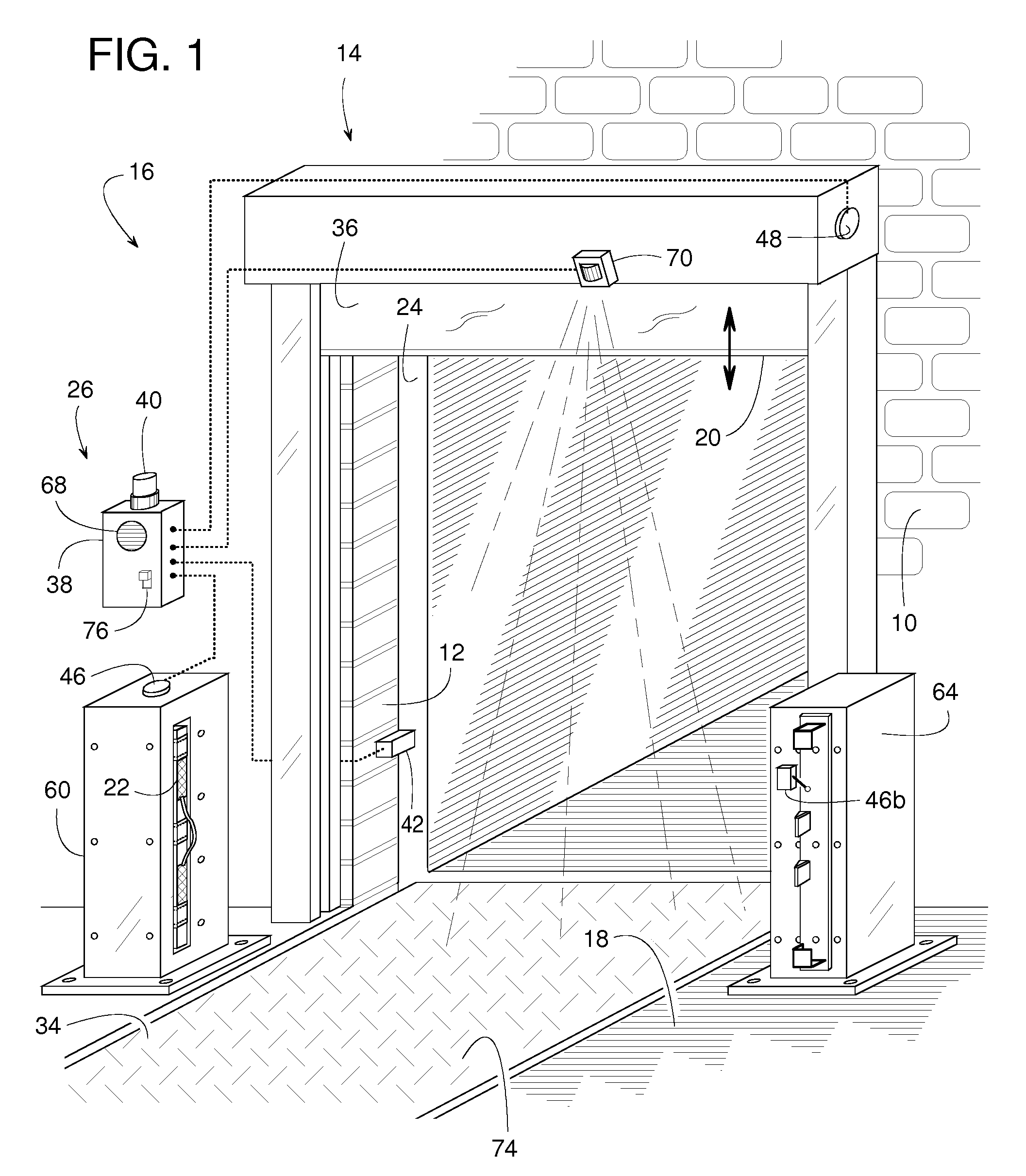

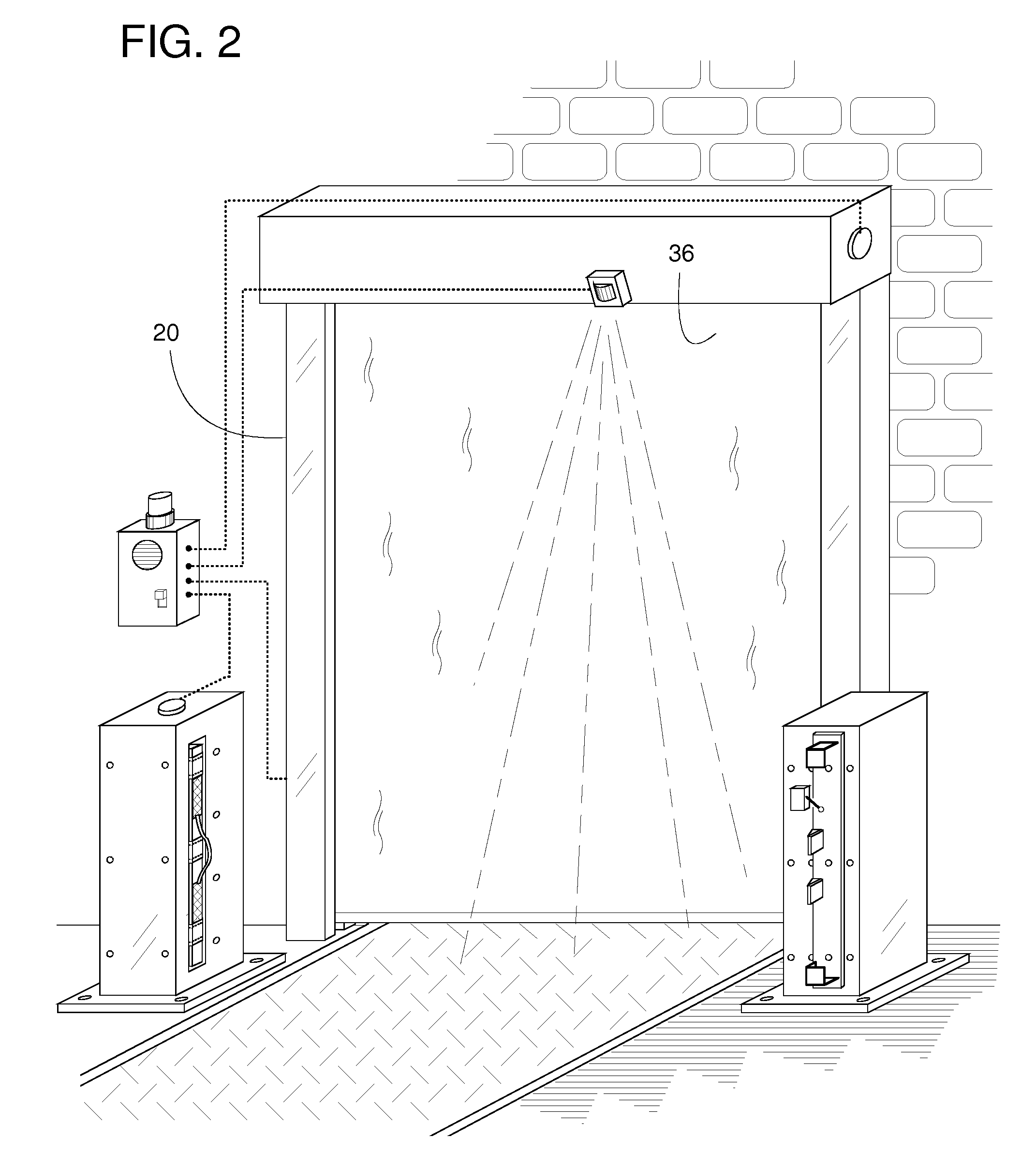

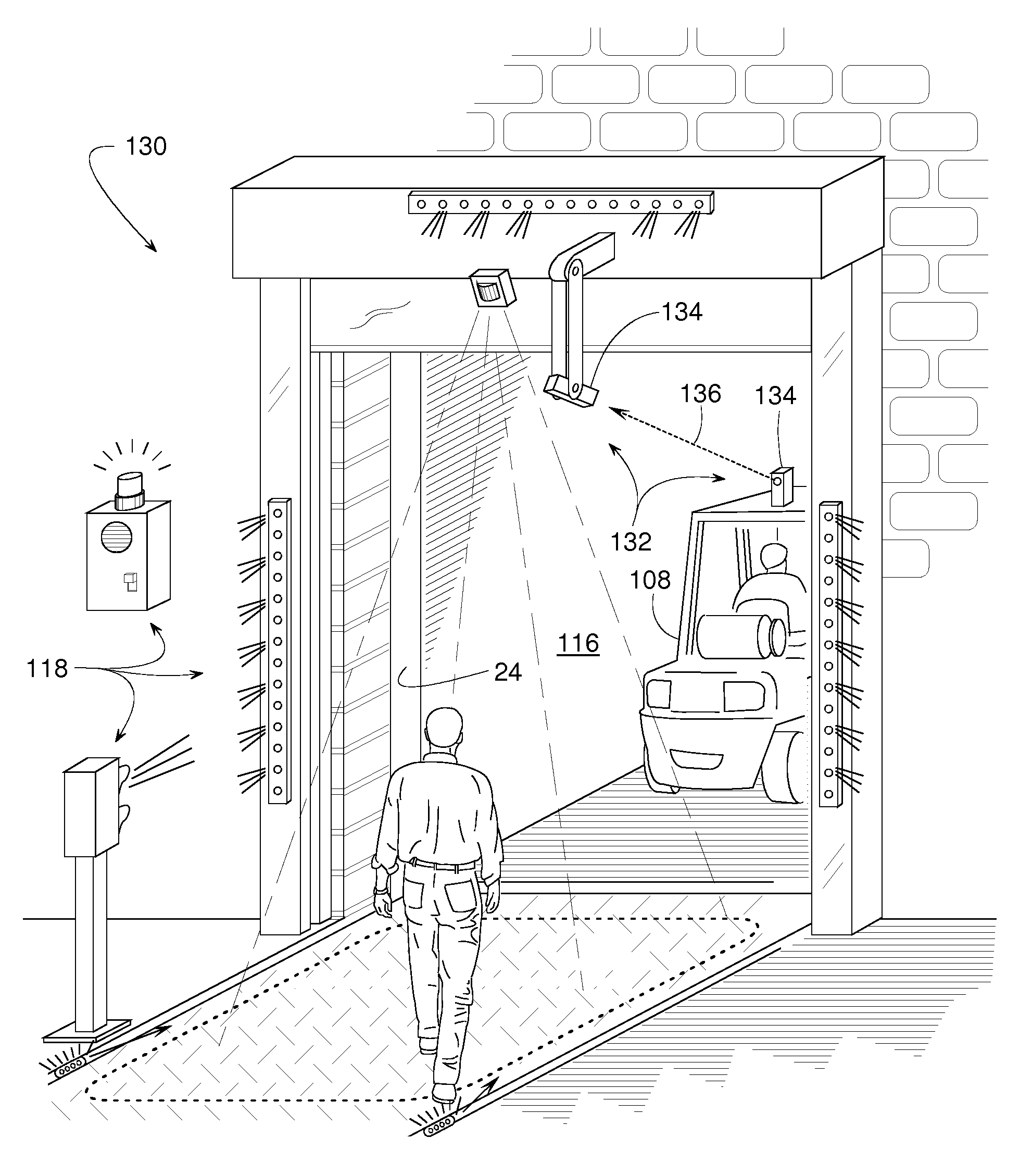

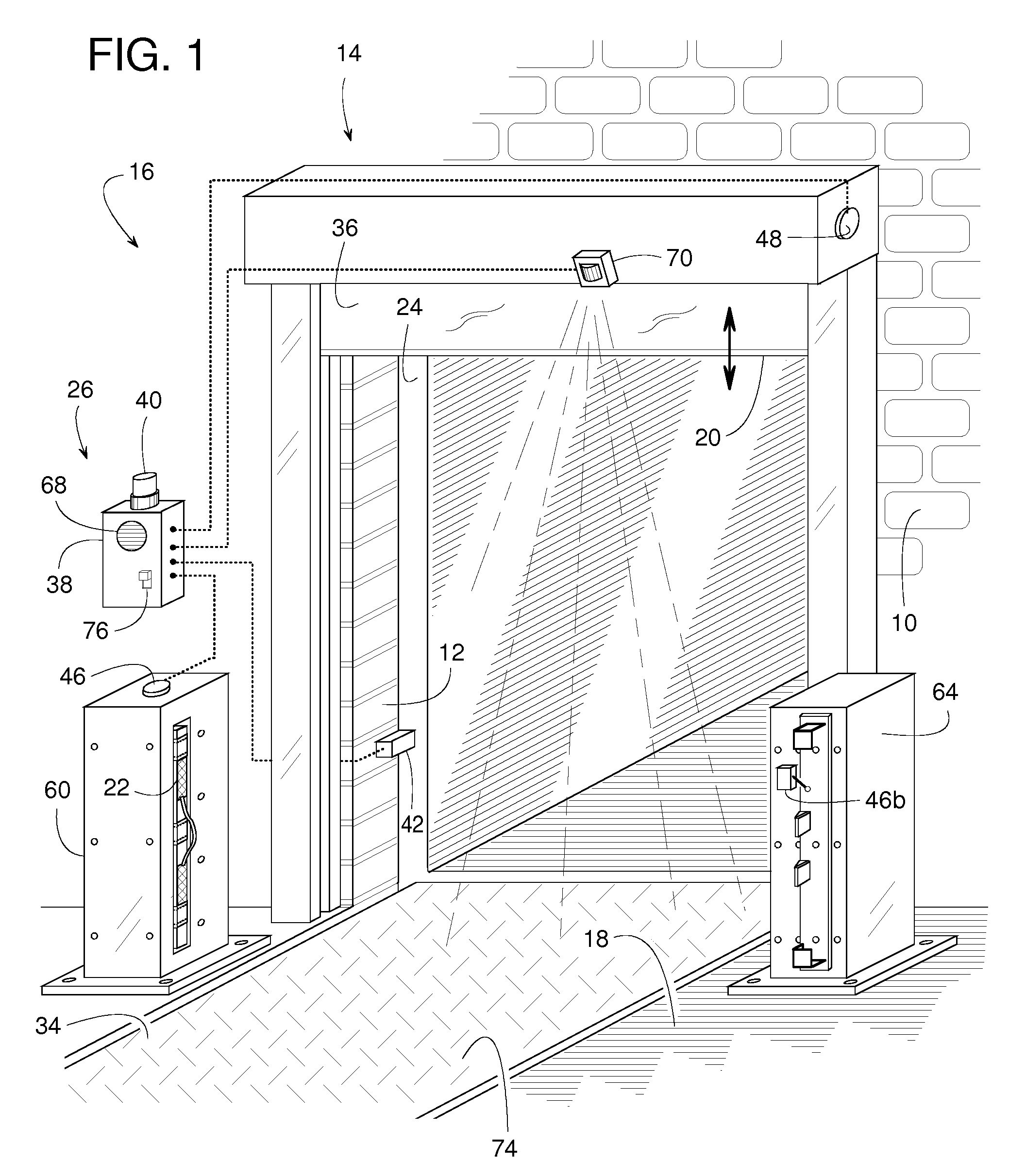

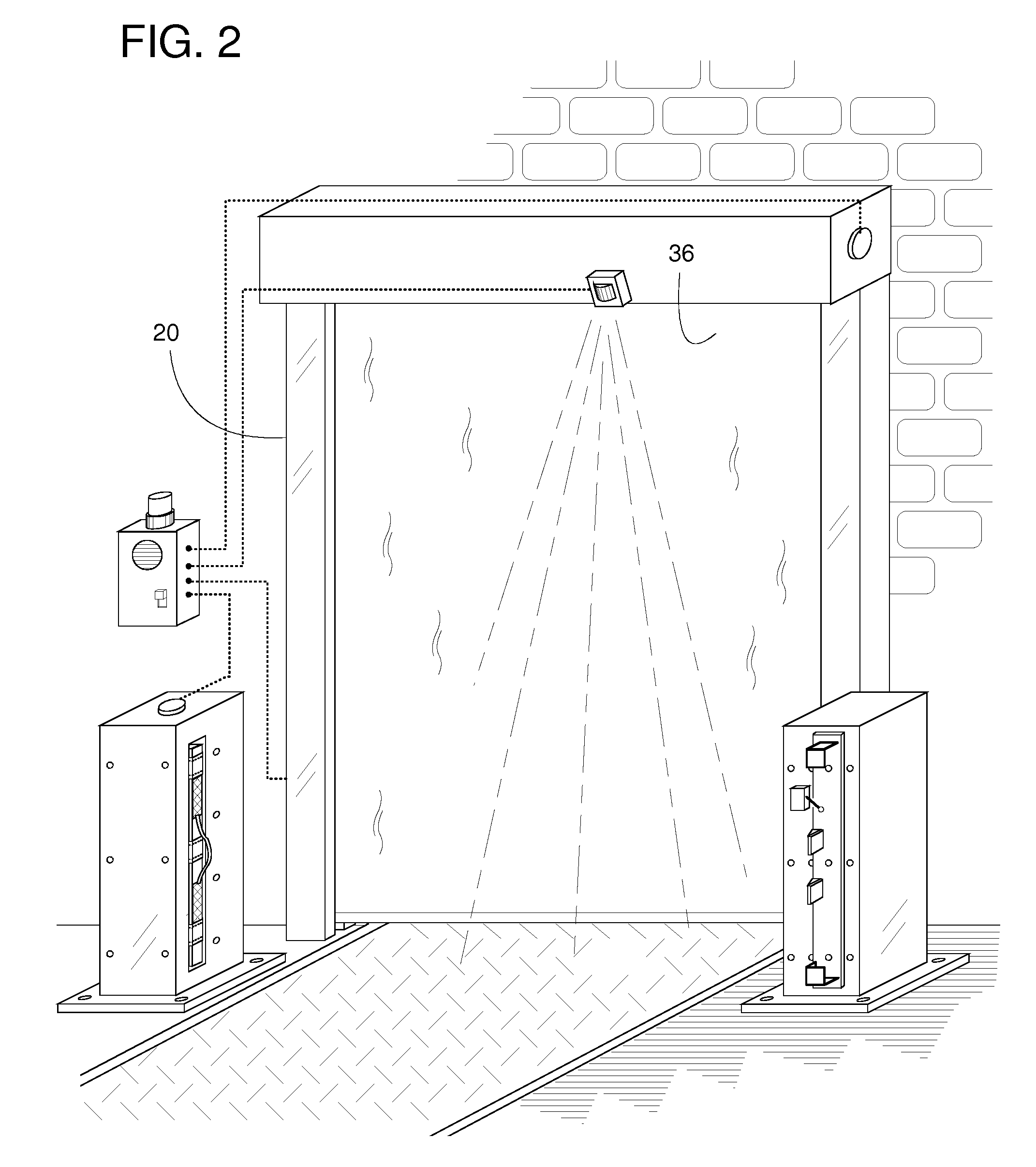

Alarm system for a loading dock

A safety system for a truck loading dock with an elevated platform provides an alarm that warns of a hazard at the loading dock such as a forklift operating inside the truck or a falling hazard that may exist due to the dock door being open while a truck is not present at the dock. In cases where a dock's open doorway is protected by a barrier that can be opened or closed, the alarm can be de-activated by closing the barrier. In some embodiments, the safety system includes a remote body sensor that detects when someone or something is near the doorway. In response to the body sensor, a second, more pronounced alarm can warn of more imminent danger where someone on the platform may be too close to an open doorway when a truck is not present.

Owner:RITE HITE HLDG CORP

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

Alarm system for a loading dock

A safety system for a truck loading dock with an elevated platform provides an alarm that warns of a hazard at the loading dock such as a forklift operating inside the truck or a falling hazard that may exist due to the dock door being open while a truck is not present at the dock. In cases where a dock's open doorway is protected by a barrier that can be opened or closed, the alarm can be de-activated by closing the barrier. In some embodiments, the safety system includes a remote body sensor that detects when someone or something is near the doorway. In response to the body sensor, a second, more pronounced alarm can warn of more imminent danger where someone on the platform may be too close to an open doorway when a truck is not present.

Owner:RITE HITE HLDG CORP

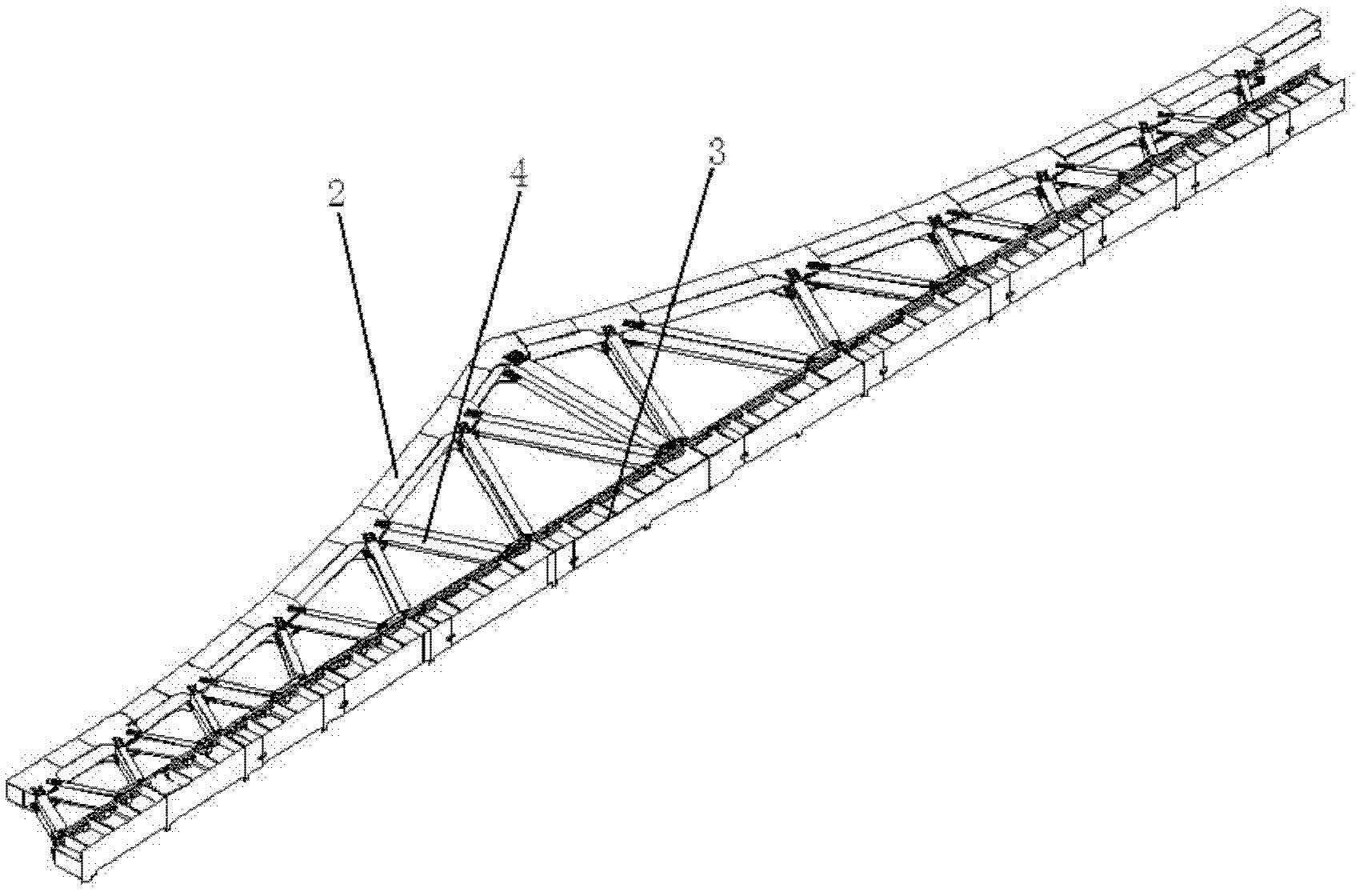

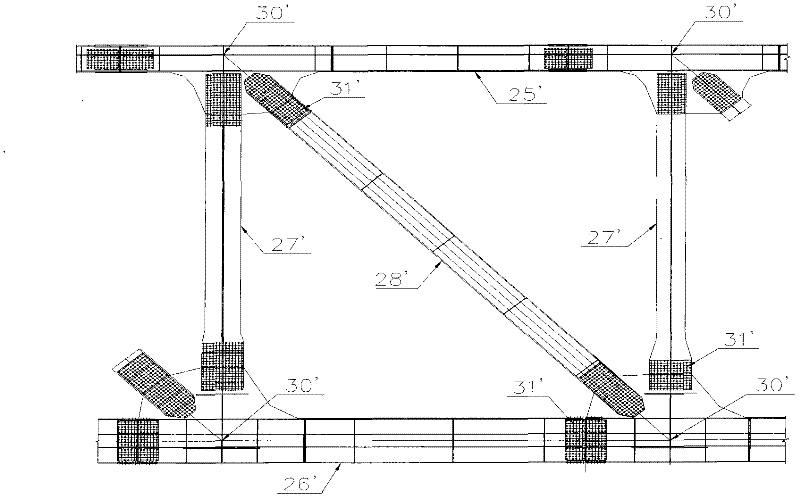

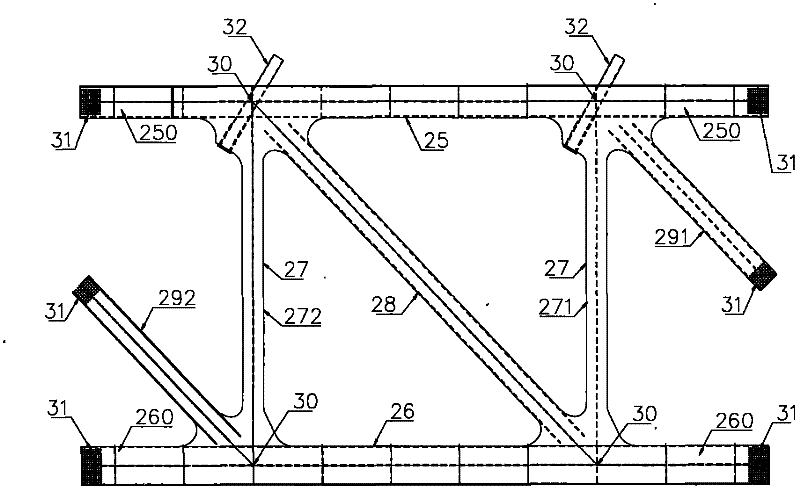

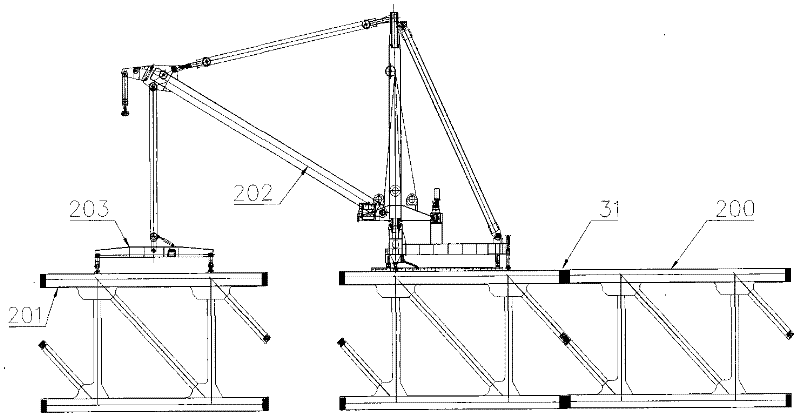

Truss sheet unit of steel truss girder, steel truss girder structure and mounting method thereof

ActiveCN102352604AImprove the quality of ex-factory productsAvoid extensive on-site constructionTruss-type bridgeBridge erection/assemblyHeavy dutySpandrel

The invention discloses a truss sheet unit of a steel truss girder, a steel truss girder structure and a mounting method thereof, relating to the design and the construction techniques of heavy-duty and large-span bridges. The steel truss girder structure consists of a plurality of the truss sheet units which are welded into a whole, wherein the truss sheet units comprise upper chord rods, low chord rods, first web rods and second web rods; the upper chord rods, the lower chord rods, the first web rods and the second web rods are welded into a rectangular frame body; two across corners of the rectangular frame body are connected by a diagonal rod; two ends of each upper chord rod further extend to form two upper connecting rods; two ends of each lower chord rod further extend to form two lower connecting rods; simultaneously, first oblique connecting rods which extend downwards are arranged among the first web rods and the upper connecting rods; and second oblique connecting rods which extend upwards are arranged among the second web rods and the lower connecting rods. When the steel truss girder is assembled, the whole truss sheet units are lifted each time; furthermore, the truss sheet units occupy two internodal lengths; the lifting times are less; the filed assembly is simple; the quantity of high-strength bolts is reduced; and the influence of the screwing of the high-strength bolts on a construction period is decreased.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

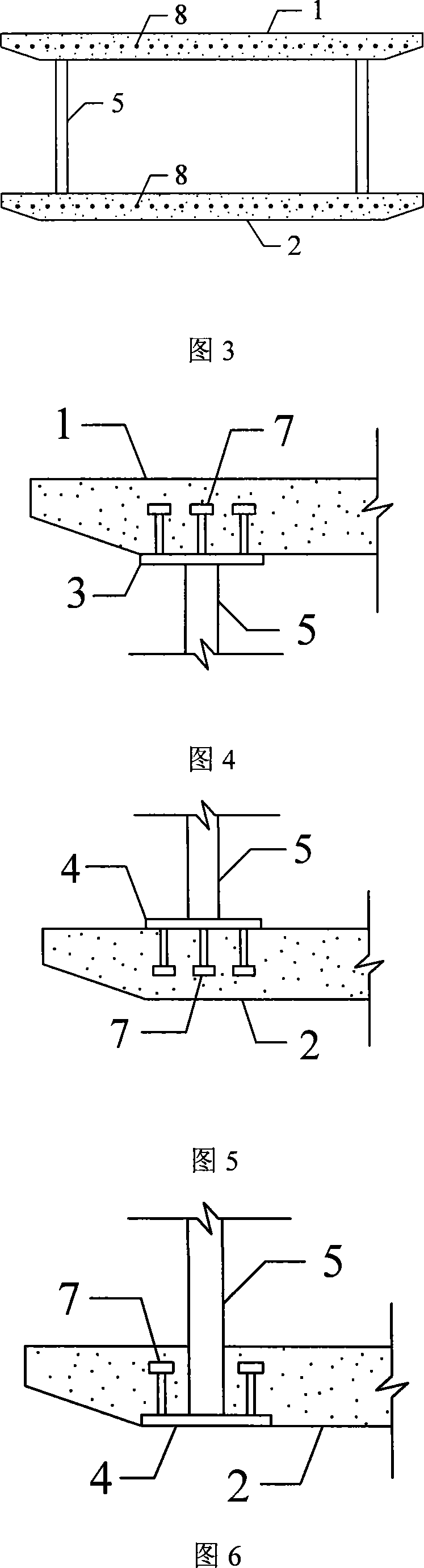

Double-deck bridge floor combined trussed girder bridge

InactiveCN101158143AIncrease capacityOpen sightTruss-type bridgeBridge structural detailsLow noiseBridge deck

A combined truss bridge of double bridge decks relates to a novel bridge structure and the combined truss bridge of double bridge decks consists of an upper concrete bridge deck, a steel structure web member and a lower concrete bridge deck. The upper and lower bridge decks are used for bearing the load of vehicles and are used as an upper chord part and a lower chord part to share the global stress with the global structure. The steel structure web member consists of a slant web member and a vertical web member, and combines the upper and the lower concrete bridge decks as a whole to be used for resisting the shearing force of the truss bridge. The upper concrete bridge deck and the lower concrete bridge deck in tensile areas are provided with vertically stressed steel bars or section steel. The invention, compared with traditional single bridge deck combined girder bridges, enjoys greater traffic capacity and higher traffic comfort; compared with steel truss bridges, the invention remarkably reduces steel consumption by using concrete bridge decks as compression chords, and has the advantages of low noise, easy maintenance, good durability and so on.

Owner:TSINGHUA UNIV

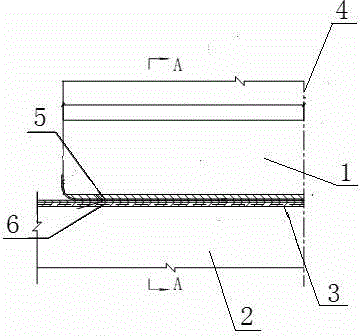

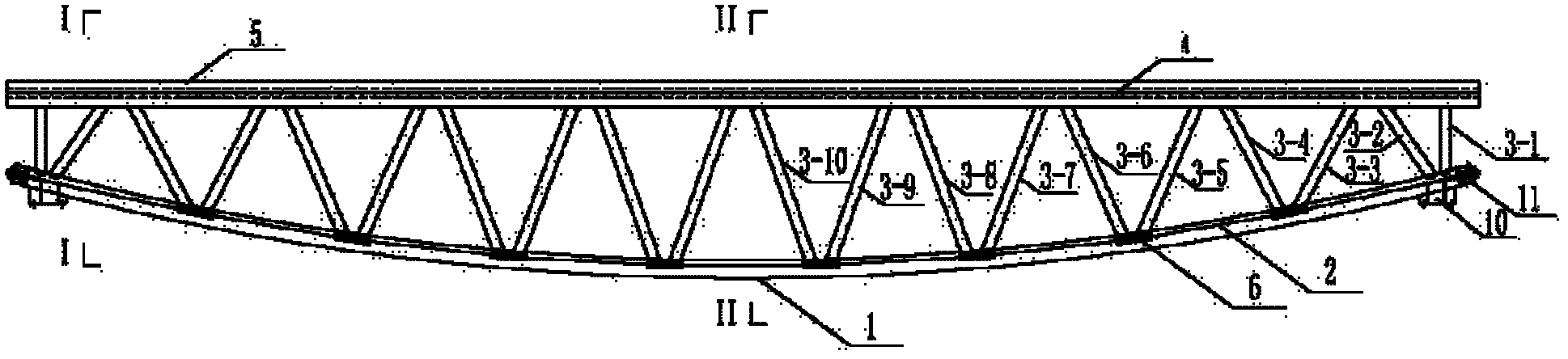

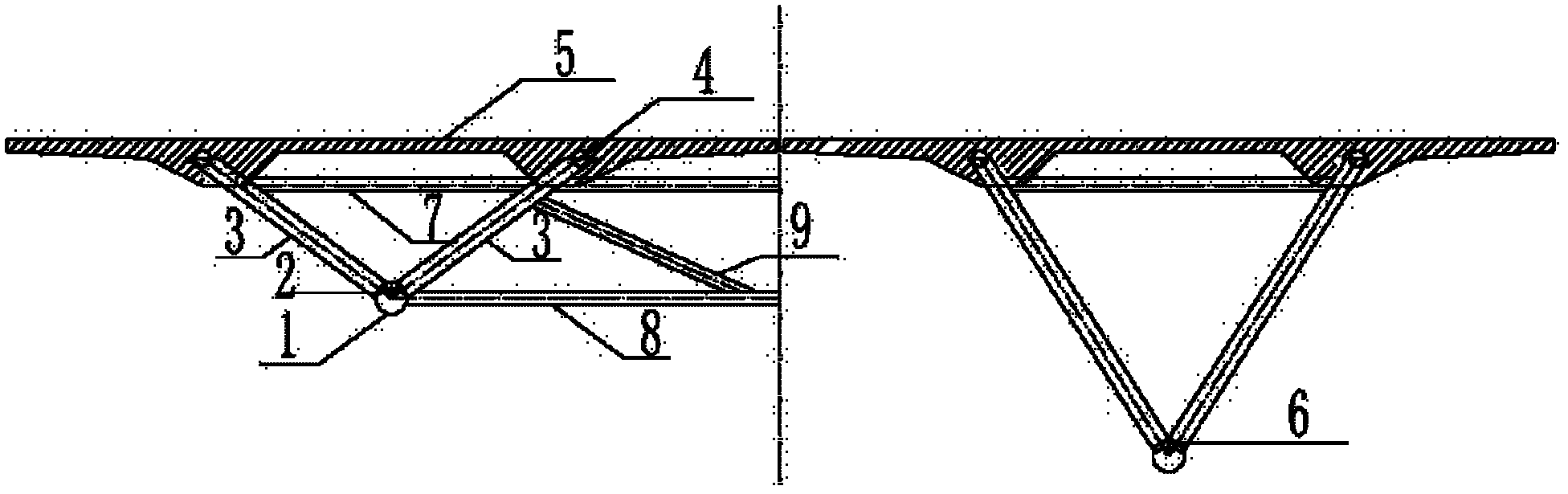

Steel truss web combined PC beam and construction method thereof

ActiveCN101936054AIncrease stiffnessAvoid crackingTruss-type bridgeLoad-supporting elementsSheet steelReinforced concrete

The invention discloses a steel truss web combined PC beam, comprising a reinforced concrete top plate and a reinforce concrete base plate as well as at least two lines of base steels; wherein the reinforced concrete top plate and / or reinforced concrete base plate are / is provided with a tensioned prestressing reinforcement, the base steels are discontinuously arranged along the length direction of the beam and are anchored on the reinforced concrete base plate, one end of steel truss web is fixedly connected with the base steel, the other end thereof is fixedly connected with a top steel, the top steel is formed with at least two lines of steel truss webs which are discontinuously arranged along the length direction of the beam and are anchored on the reinforce concrete top plate, each line of steel truss web is fixedly connected with base steel and top steel, so as to be in a shape that a plurality of continuous 'V' shapes are combined. The invention also discloses a construction method of the steel truss web combined PC beam. The invention makes the best of the advantages and properties of reinforced concrete and steel, dead weight is lighter, rigidity of web is high, steel is saved to the utmost extent, construction process is simple, footboard framework support is saved, and appearance is beautiful, thus having obvious economic benefit and wide application in the field of bridge construction.

Owner:李勇 +1

Concrete truss

A concrete structural framework comprised of a combination of reinforced steel, including pre-stressed and post-tensioned, with high performance concrete (HPC), for use in construction and other industries. This framework provides a highly fire resistant structure that is also resistant to the forces of nature and maintains a high level of structural integrity. The members of this concrete truss are joined or otherwise secured together by monolithic means, welded with badges, rivets, screws, or the like, in a triangular weblike configuration which provides the ultimate support against forces of compression and tension.

Owner:MENTADO DURAN JAVIER

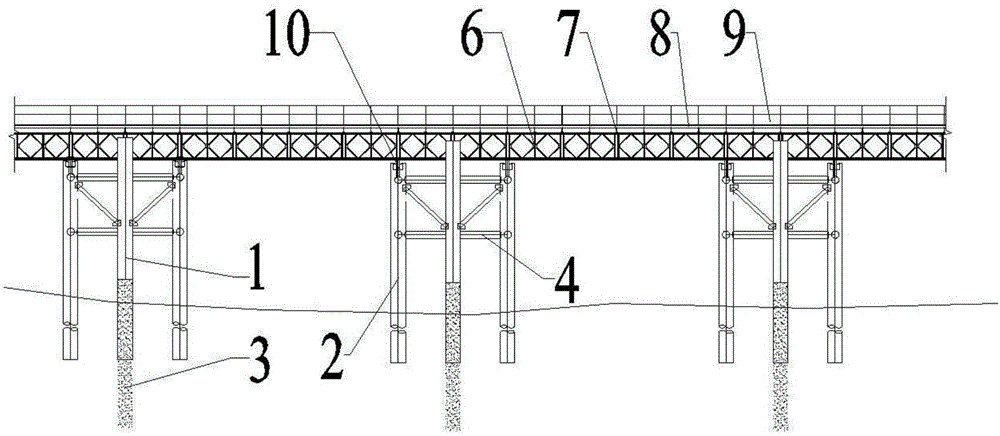

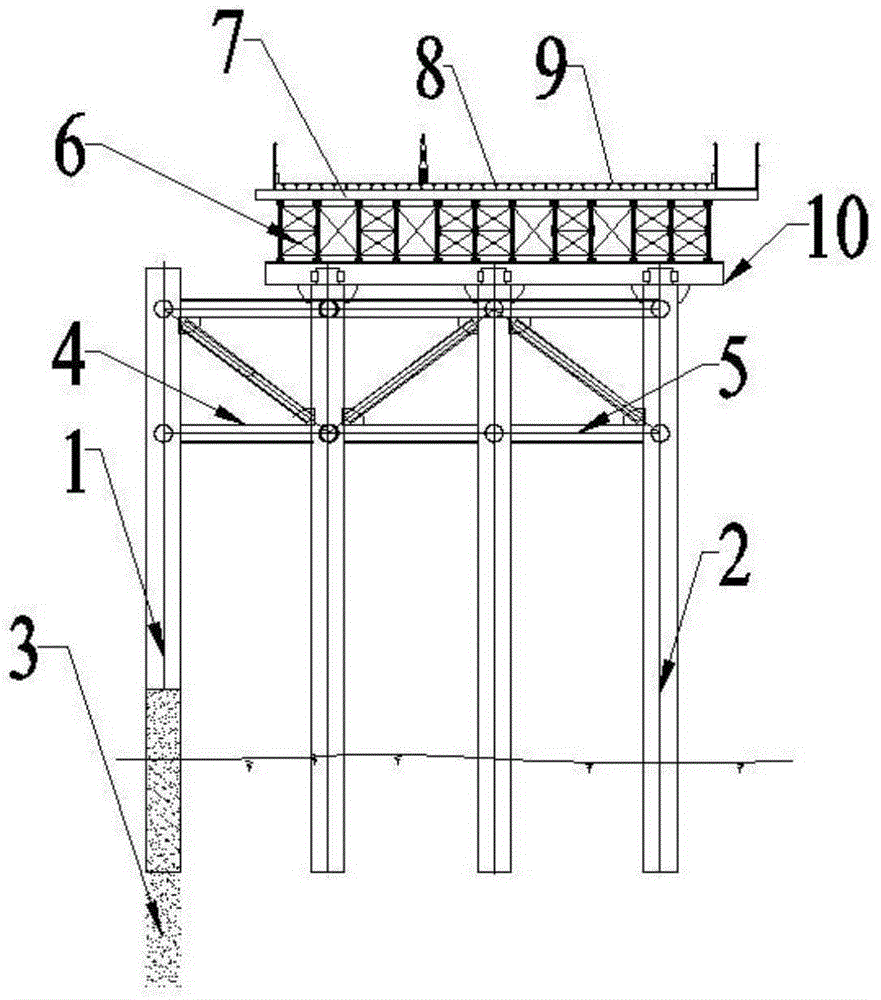

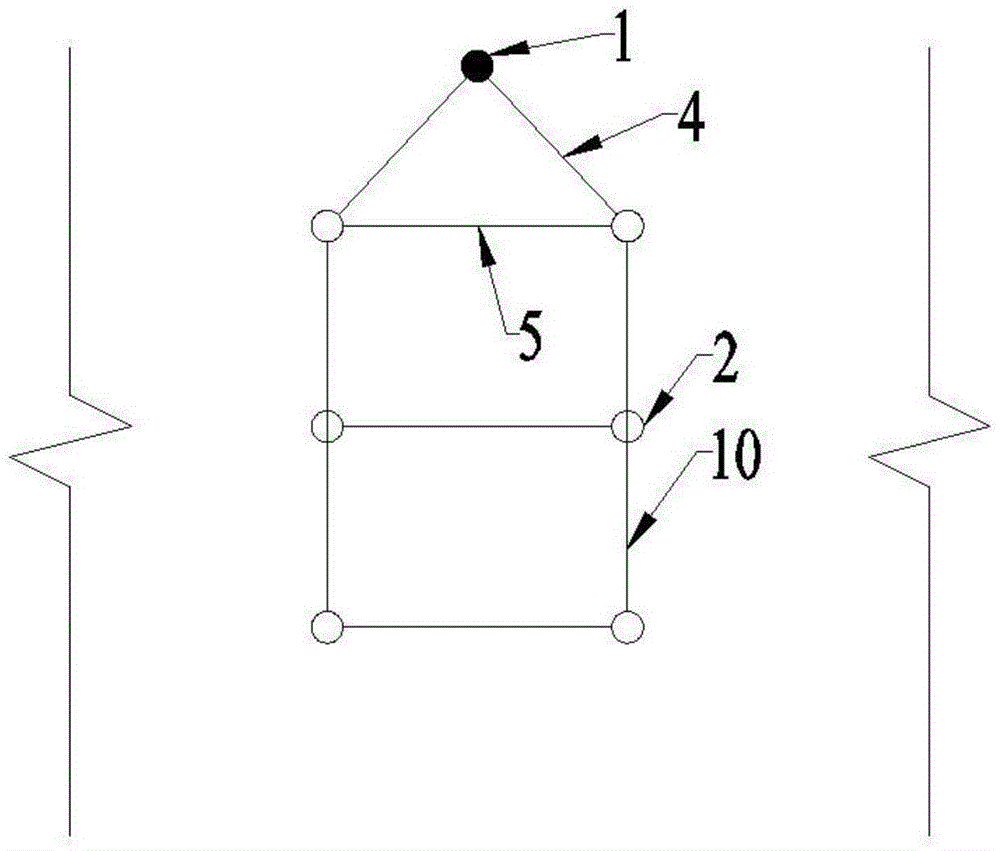

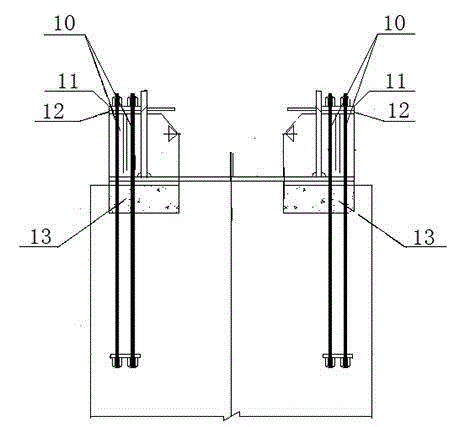

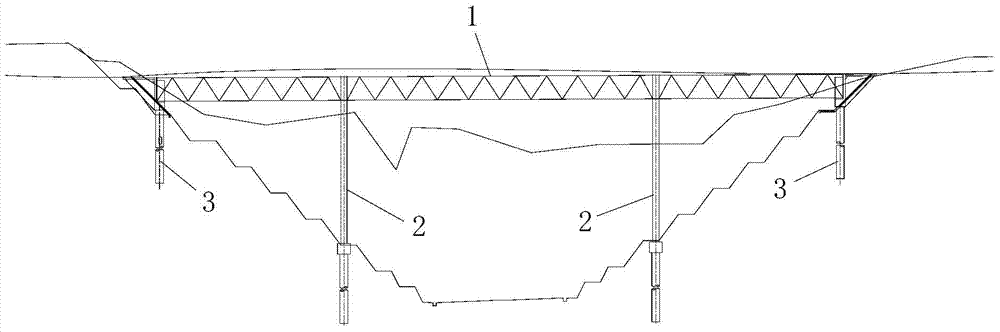

Steel trestle provided with steel anchor pile and construction method of steel trestle

InactiveCN104404861AMake up for the lack of poor stabilityImprove structural stabilityTruss-type bridgeBridge erection/assemblyHorizontal forceReinforced concrete

The invention relates to the field of bridge buildings, in particular to a steel trestle provided with a steel anchor pile and a construction method of the steel trestle. The steel trestle comprises a steel pipe support structure and the steel anchor pile, wherein the steel anchor pile is of a cylindrical and hollow tubular structure, reinforced concrete is poured in the steel anchor pile, the lower end of the reinforced concrete is fixed on a riverbed, and the steel anchor pile is connected to the steel pipe support structure through a first truss structure; a bailey truss which is arranged along the bridge direction, a transverse distributive girder which is arranged along the transverse bridge direction, and a longitudinal distributive girder and a bridge panel which are arranged along the bridge direction are fixed on the upper end of the steel pipe support structure from bottom to top in sequence. According to the steel trestle provided with the steel anchor pile and the construction method of the steel trestle, the horizontal force borne by a steel pipe pile is resisted by utilizing the steel anchor pile, so that stability of the steel pipe pile is effectively enhanced, furthermore, through drilling in the steel anchor pile, the depth for vibration sink of the steel anchor pile is reduced and the construction difficulty is reduced. The problem of difficulty in construction of the steel pipe pile with large flow speed in a cobblestone area is effectively solved, meanwhile, structural stability of the steel trestle is effectively improved, and the promotion value is great.

Owner:CCCC SECOND HARBOR ENG

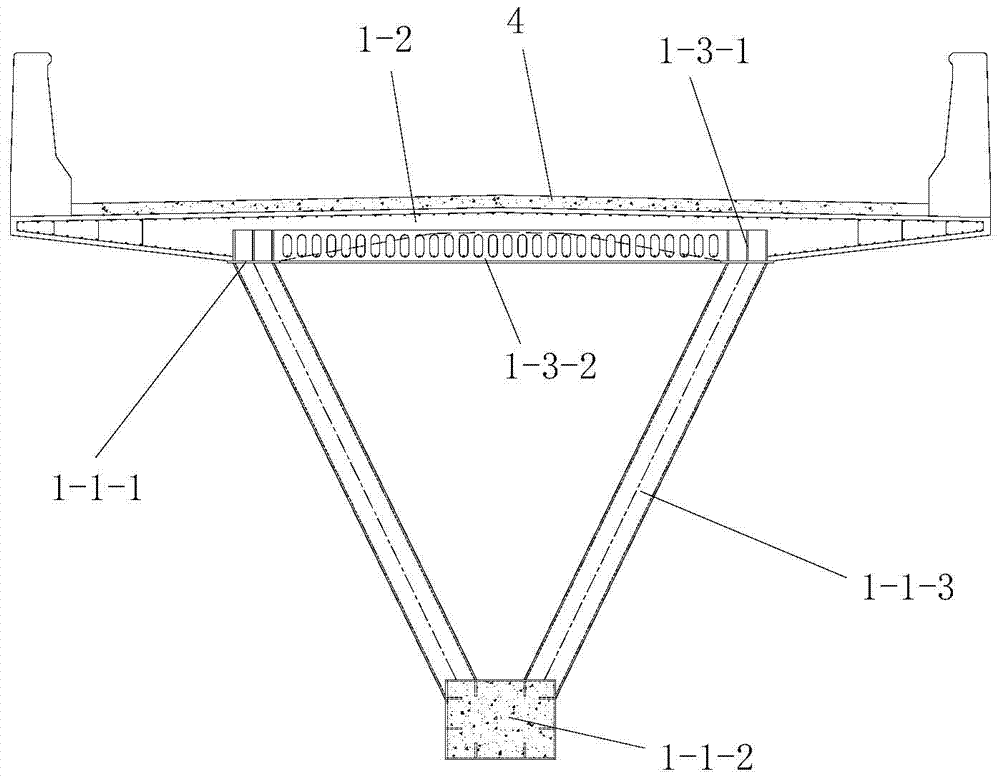

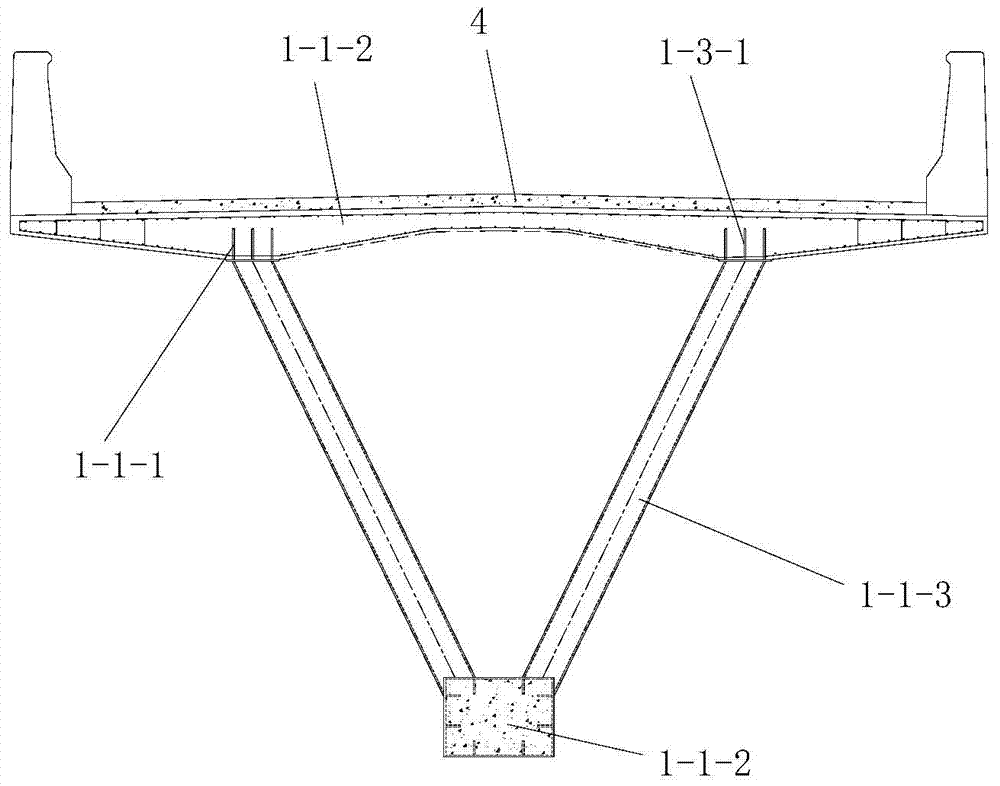

Flared leg precast concrete bridge system

InactiveUS20090183321A1Simple structureRealized benefitsGround-workTruss-type bridgeEngineeringSpandrel

A concrete building system includes a set of parallel spaced apart strip footers and one or more precast concrete sections supported by the footers in a predetermined alignment. Each precast concrete section has a top slab integrally connected to a pair of equally flared legs. Each leg depends from an end of the top slab at an effective flare angle to form a corner. The precast section includes haunch sections formed between the top slab and each leg resulting in a corner thickness greater than the uniform thickness of the angled leg to which it is integrally formed and the top member. The length of the effective span of each section varies between 60 and 90 percent of the distance between the bottom-of-leg span. The sections can be used to construct bridges, culverts, underground storage units, fluid detention units and dam structures.

Owner:COUNTY MATERIALS CORP +1

Bridge and method for manufacturing the bridge

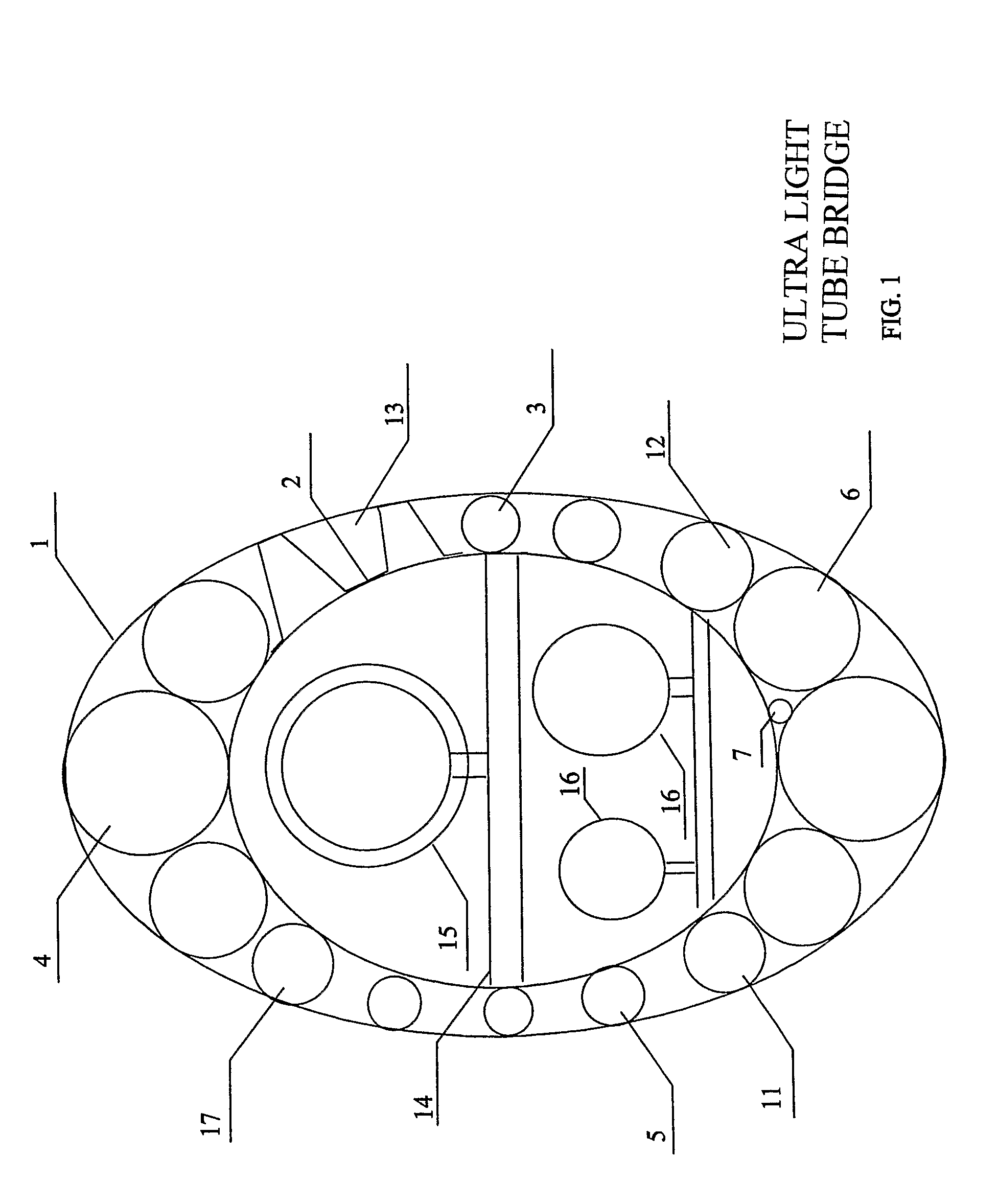

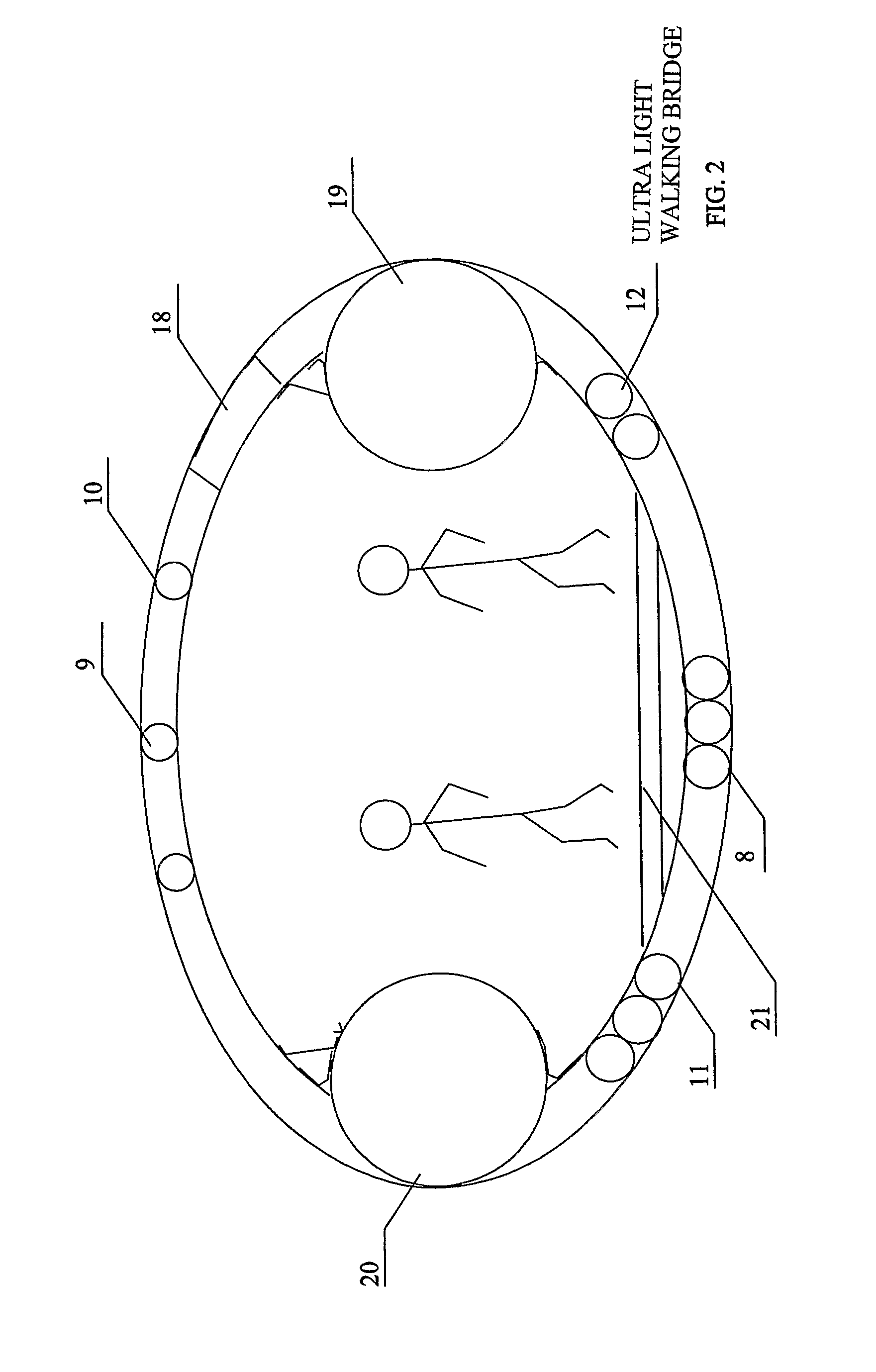

InactiveUS8214957B2Reduced footprintWeightTruss-type bridgeBridge applicationsComposite structureAerospace engineering

The bridge is constructed of one inner tube and an outer tube surrounding the inner tube. The inner and outer tube are joined to each other by connecting pipes welded to the outer surface of the inner tube and to the inner surface of the outer tube so that the inner tube and the outer tube are connected to each other through said connecting pipes whereby a rigid composite structure is formed. The tubes and pipes are preferably laser welded to each other, preferably by a continuous seam.

Owner:MIETTINEN ENSIO JOHANNES

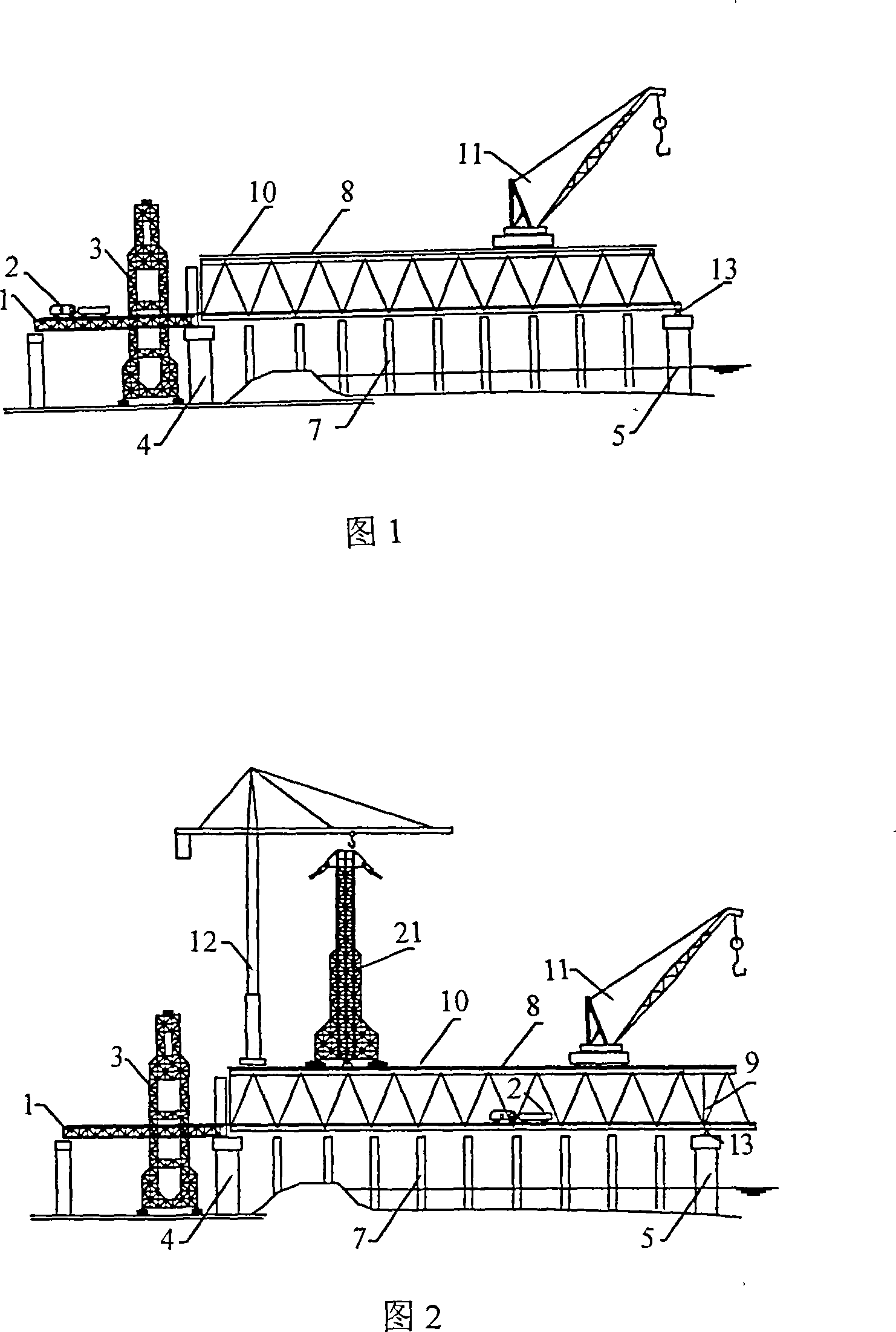

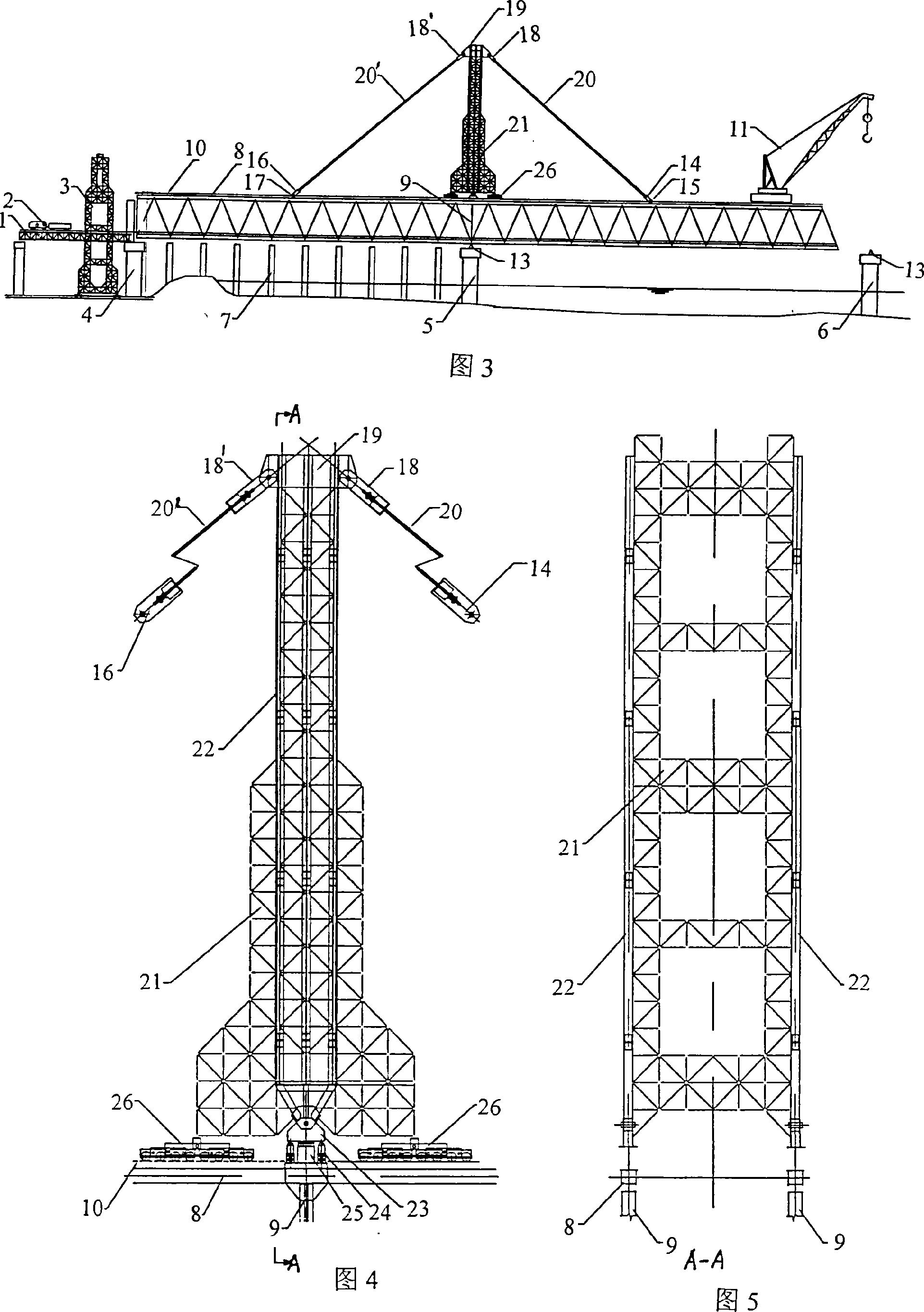

Method and system for erecting steel trusses by stay cable auxiliary complete cantilever

ActiveCN101139821AShort construction period for temporary structuresLess investmentTruss-type bridgeBridge erection/assemblyEngineeringPush ups

The invention is a method of erecting all-cantilever erected steel truss beams assisted by diagonal ropes, as well as a relevant system. The method utilizes a bearer cable tower combined with a steel structure center tower column with diagonal ropes; install a tower-type crane on the top face of the steel truss beam end at the first hole with an overhead bridge crane in a ground craning station; anchor cases below the front and rear diagonal ropes are connected with side plates at steel beam nodes, and after that, directly lift the tower to apply pre-tension on the diagonal ropes; perform all-cantilever erection for the front steel truss beam. After finishing erection of the orifice steel beam, complet load removal from the diagonal ropes with a method of pushing up the temporary seat for the front pier and lowering back a pushing and craning device between upper and lower seats of the bearer cable tower. The system comprises an auxiliary tower truss, a tower center vertical column, the upper and lower support seats, the front and rear diagonal ropes, the upper and lower anchor cases for diagonal ropes, a tower top anchor beam and a walking mechanism. The invention has the following advantages: For large-span continuous steel truss beams, utilize a special device additionally to erect multi-span steel truss beams, so as to reduce internal stress in installation of steel truss beam members, lower end deflection of the front extension arm, and increase the inclination stability of a steel truss beam on the extension arm. Meanwhile, the invention can low investment and short construction period and provide very convenient operation.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

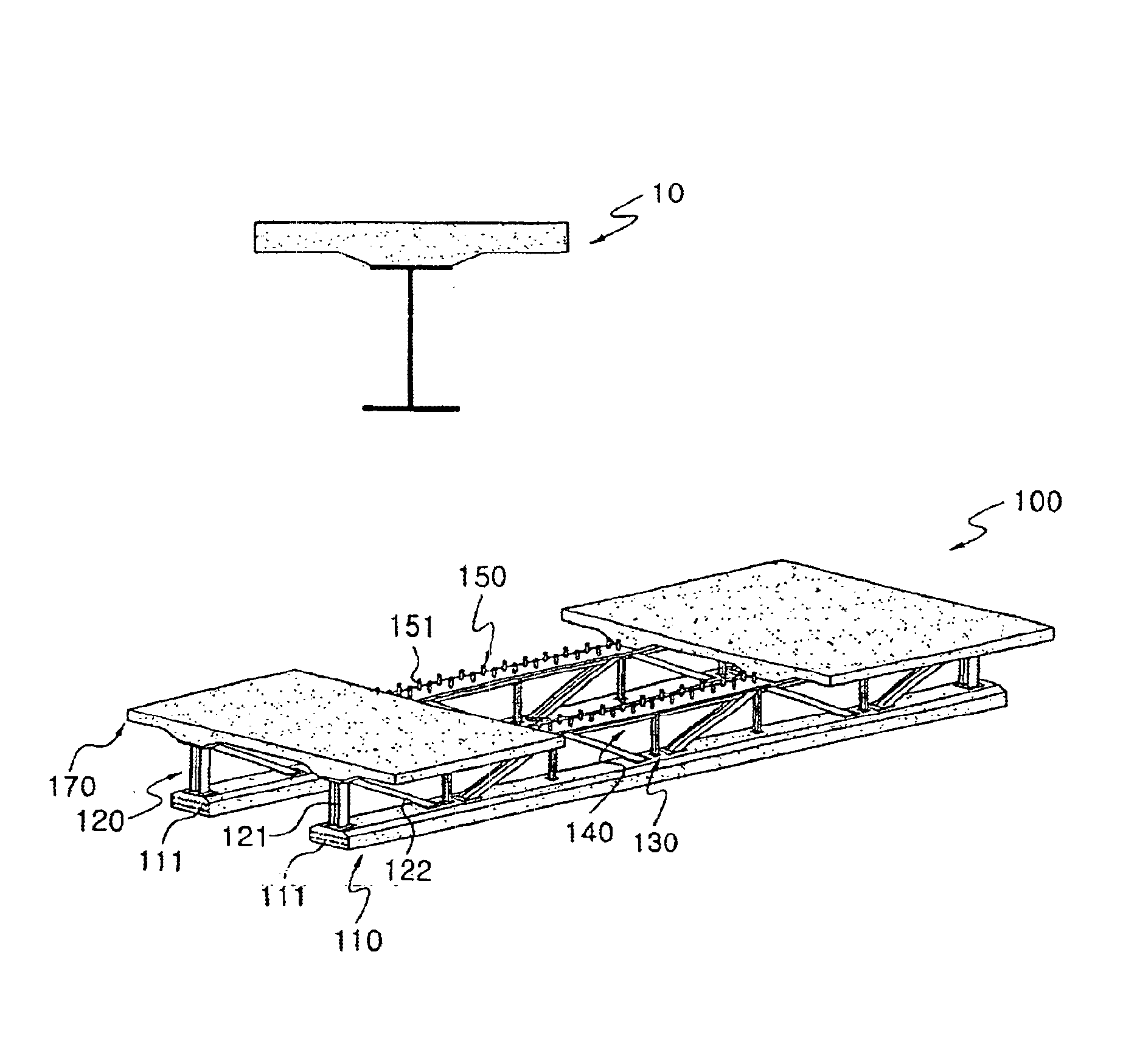

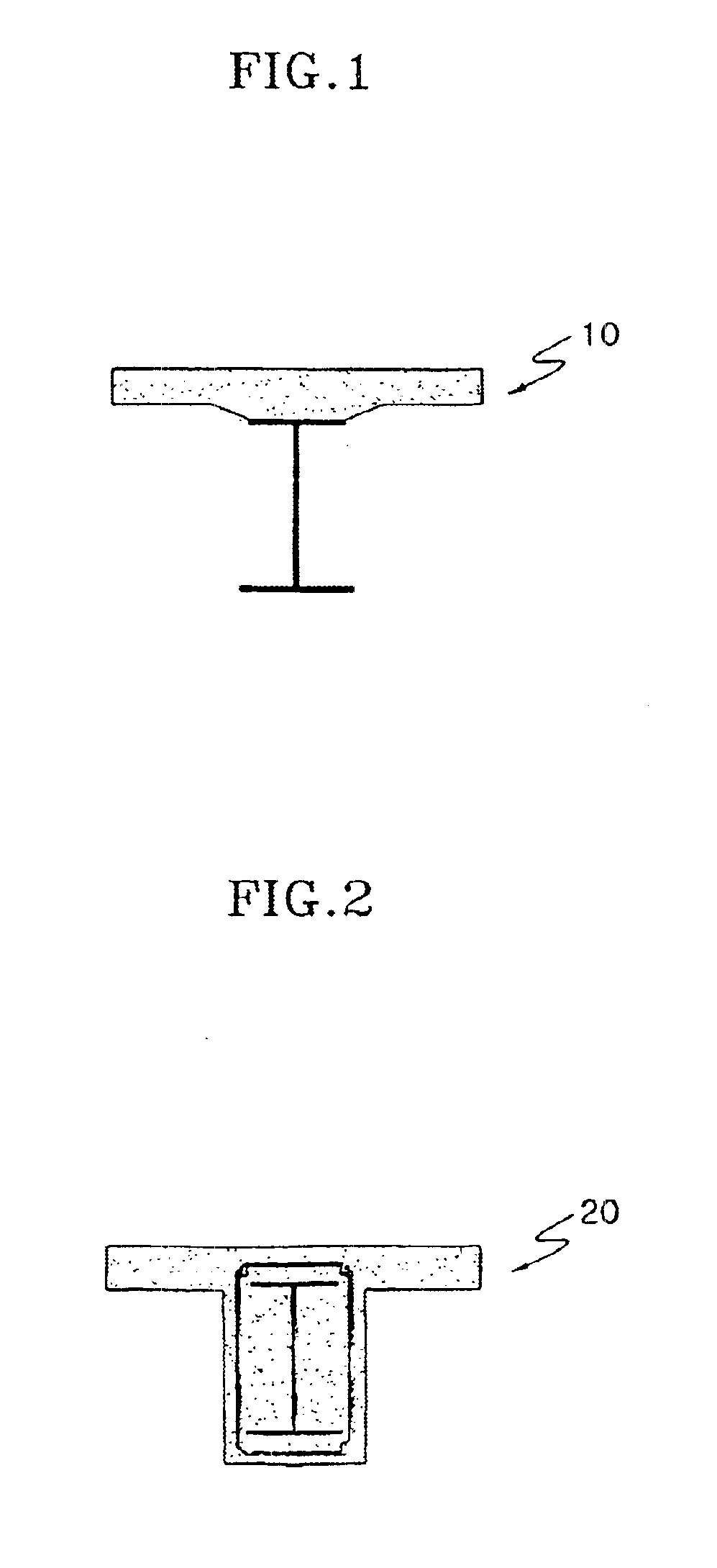

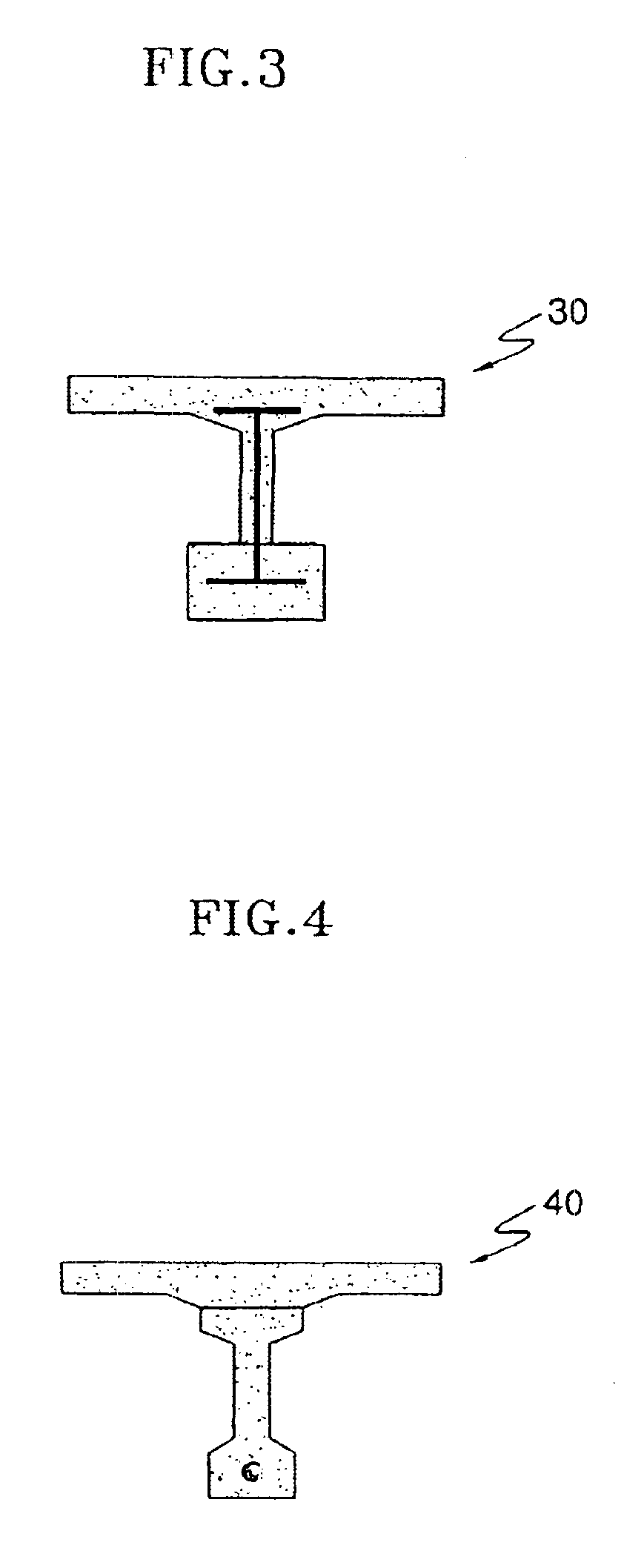

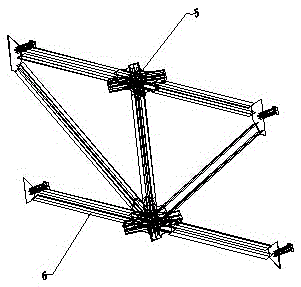

Prestressed composite truss girder and construction method of the same

InactiveUS6915615B2Maximizing material use efficiencyMaximize efficiencyTruss-type bridgeFloorsPre stressUltimate tensile strength

The present invention relates to prestressed composite truss girder and construction method of the same. The prestressed composite truss girder of the present invention comprises a concrete bottom plate having structure of composite truss; a lower-chord member being composed of prestressed concrete wherein prestress is induced to resist against the elongation strength generated when composing and not composing and to reduce the droop occurred at the state of composition and having perpendicular and horizontal cross-section of certain shape and certain length; web members wherein vertical chords and diagnal chords composed of rolled steel to upper plate of said lower-chord member; and upper-chord member combined with said web members along the longitudinal direction of said lower-chord member to resist against the compressive force generated before said concrete bottom plate being composed.

Owner:WON DAE YON

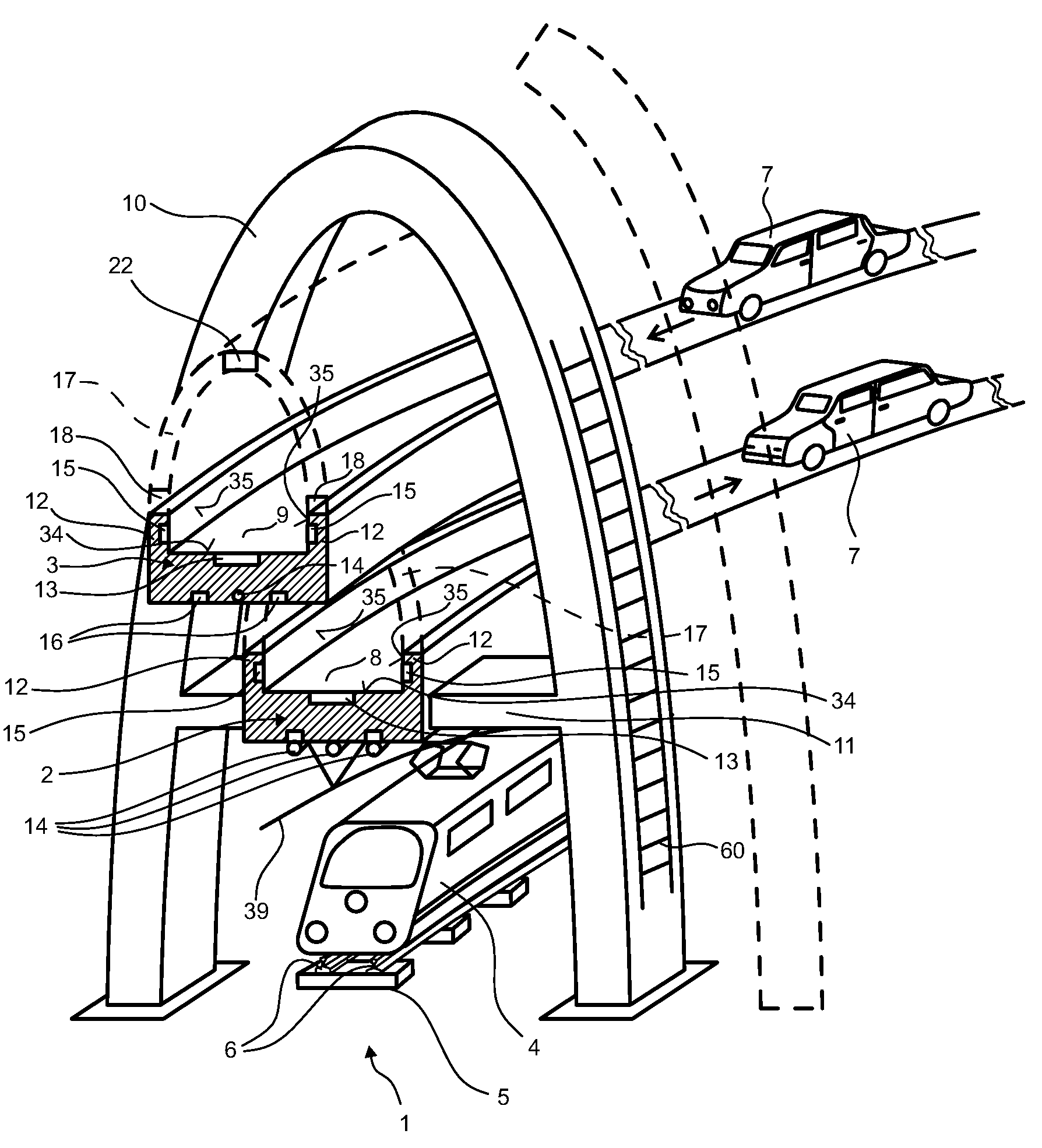

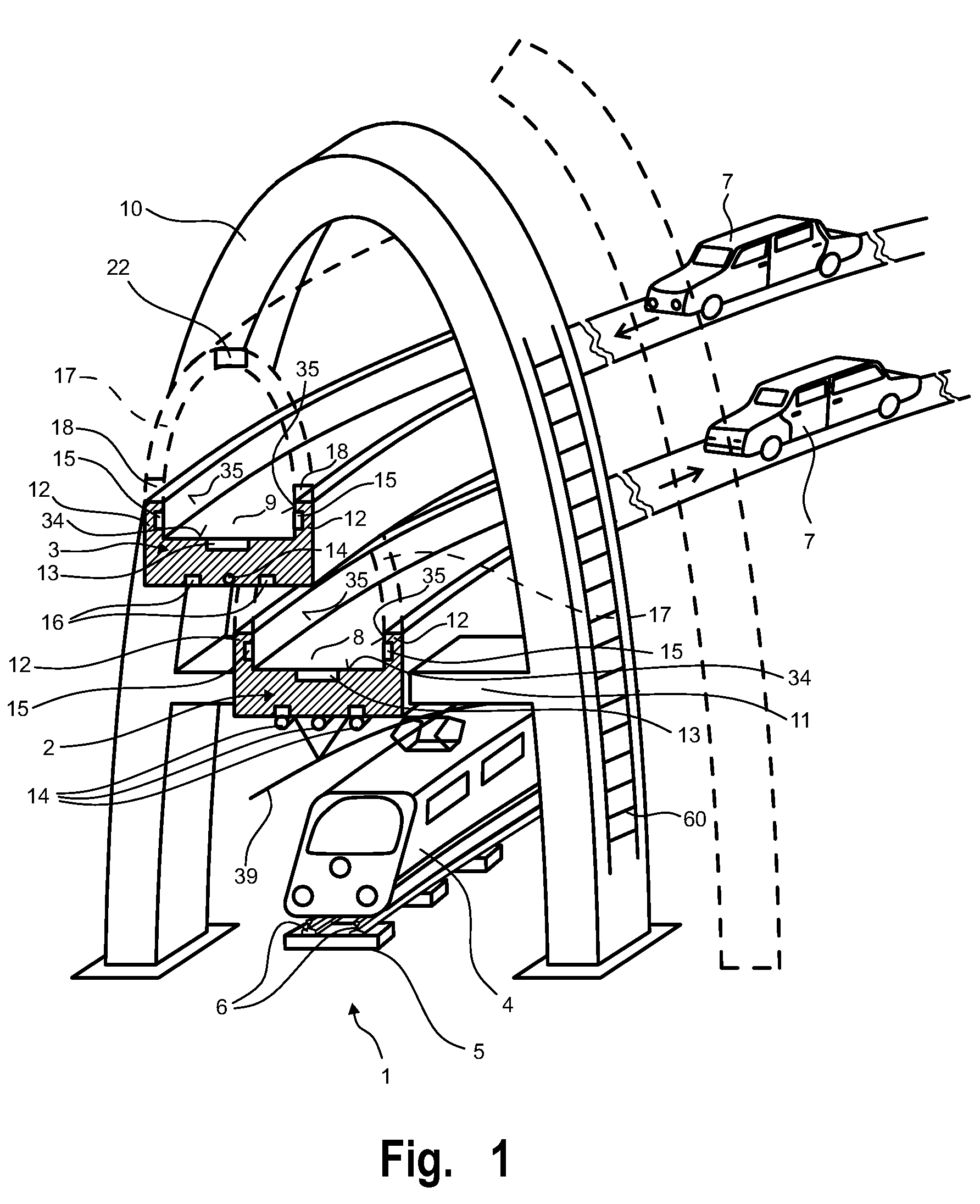

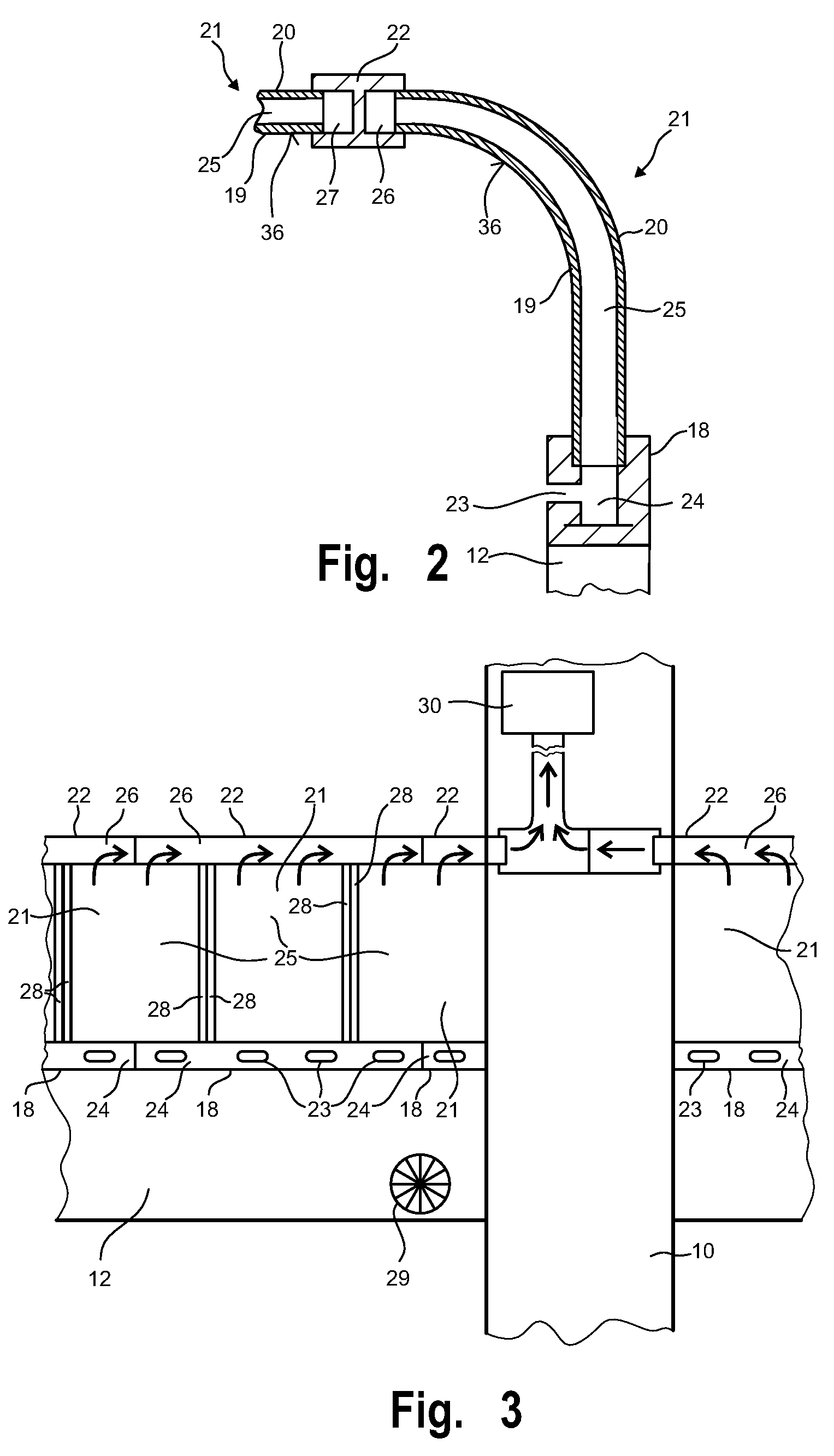

Traffic installation

InactiveUS7857543B2Easy to adaptSmall surface areaIn situ pavingsPortable bridgeSimulationTraffic routing

The invention relates to a traffic installation having at least two traffic routes arranged one above the other, which each comprise at least one traffic area, which traffic area is completely enclosed at least over a certain length, the enclosure having at least one transparent element allowing a view out of the enclosure.

Owner:TROSTER GUNTHER

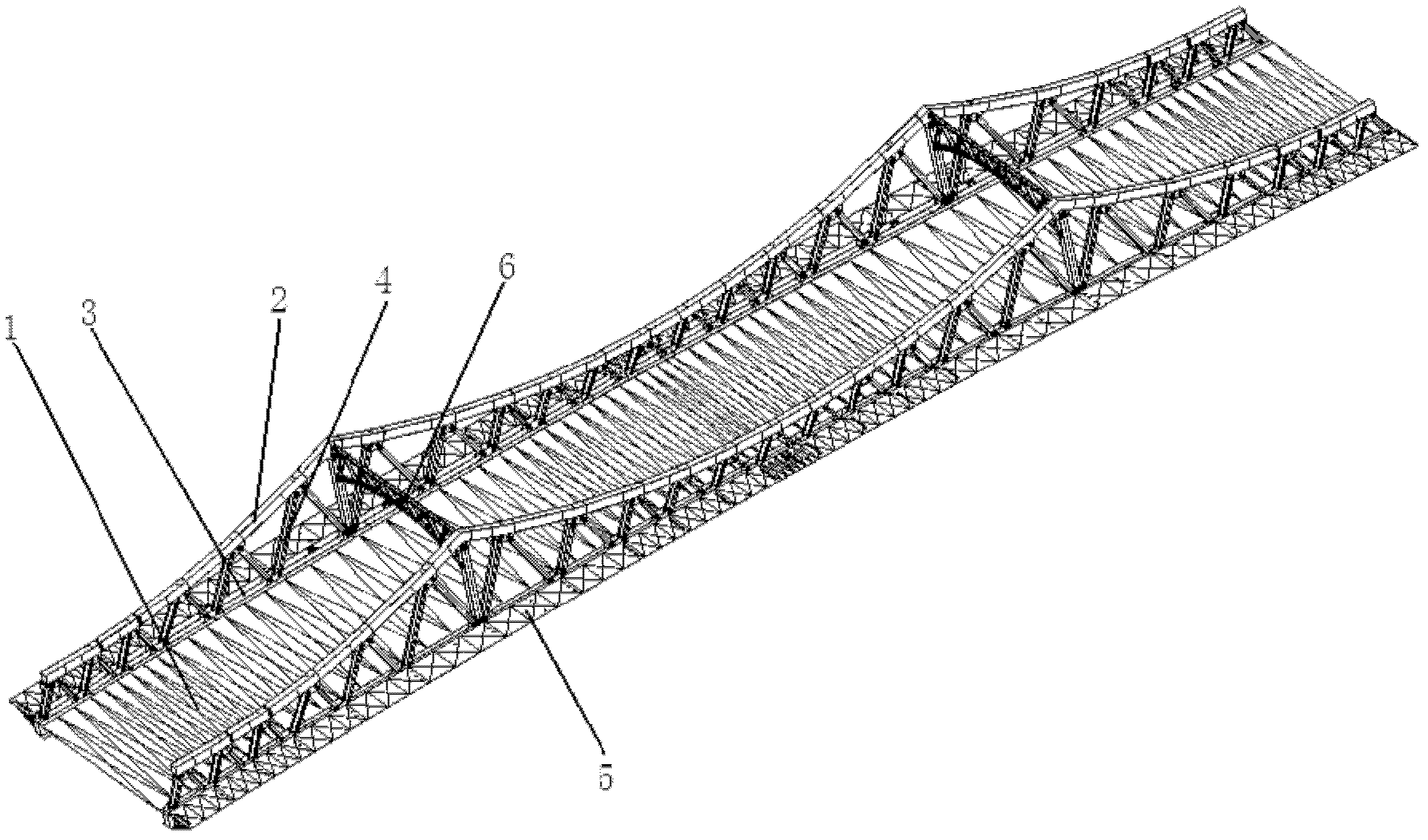

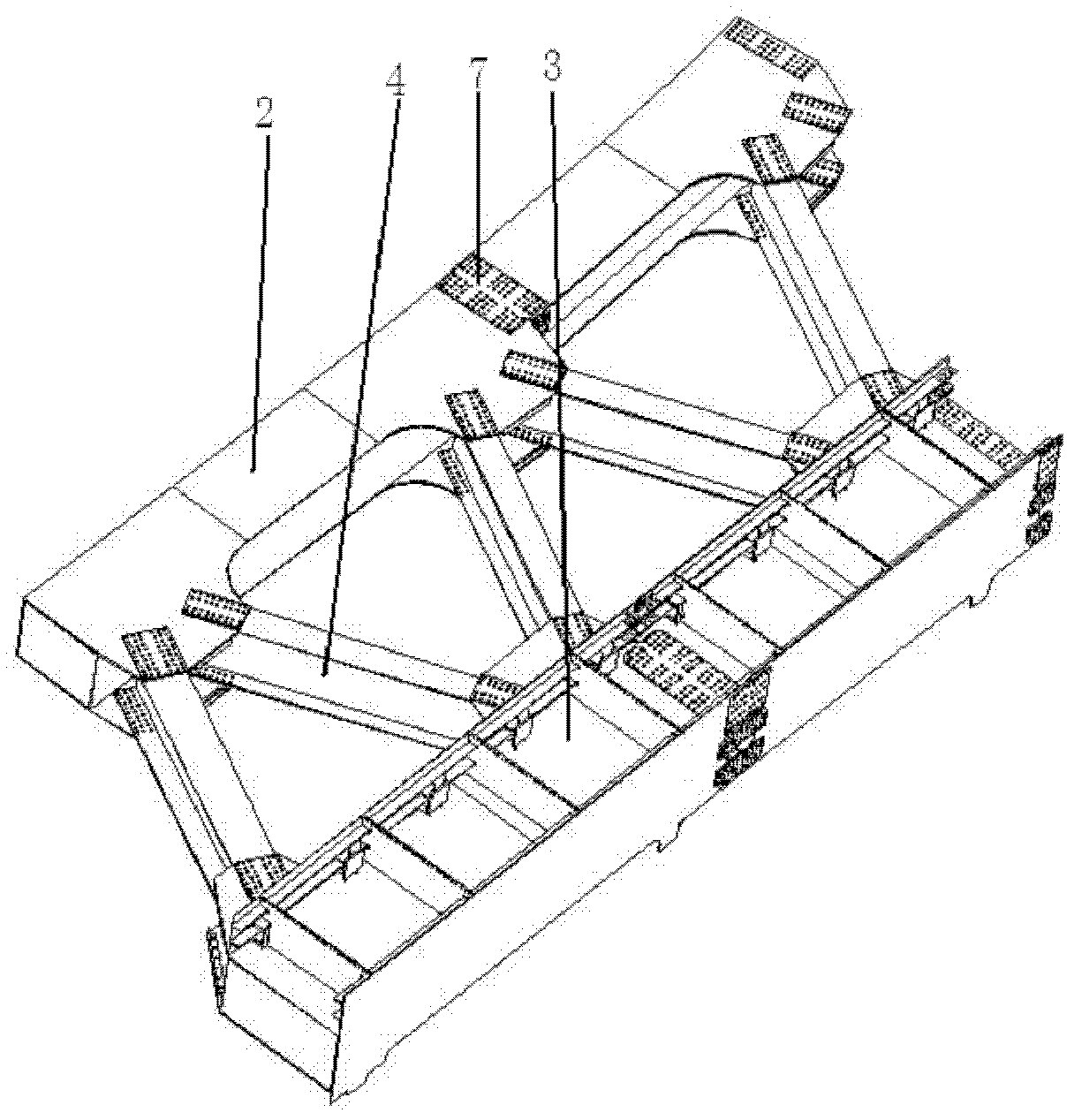

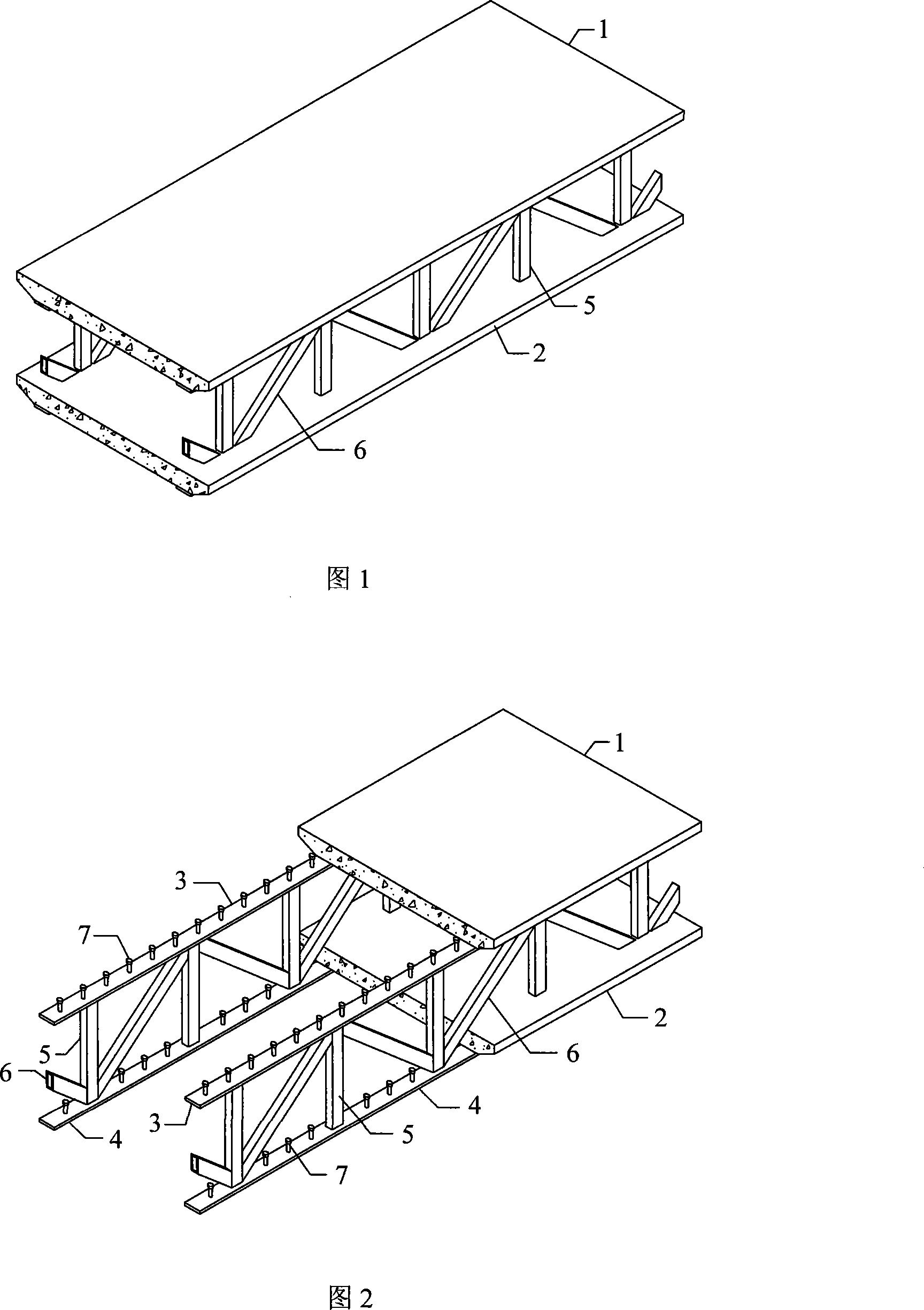

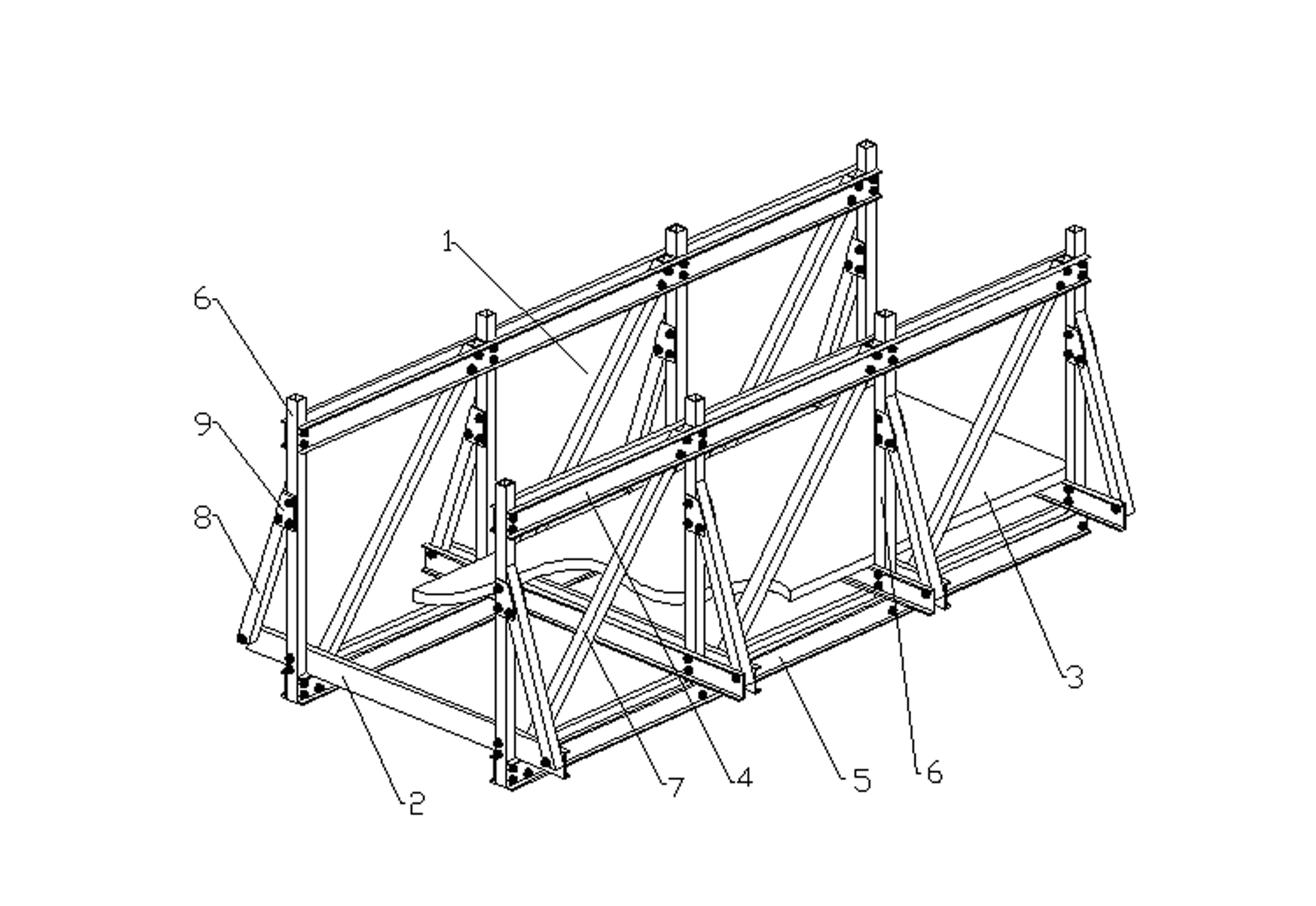

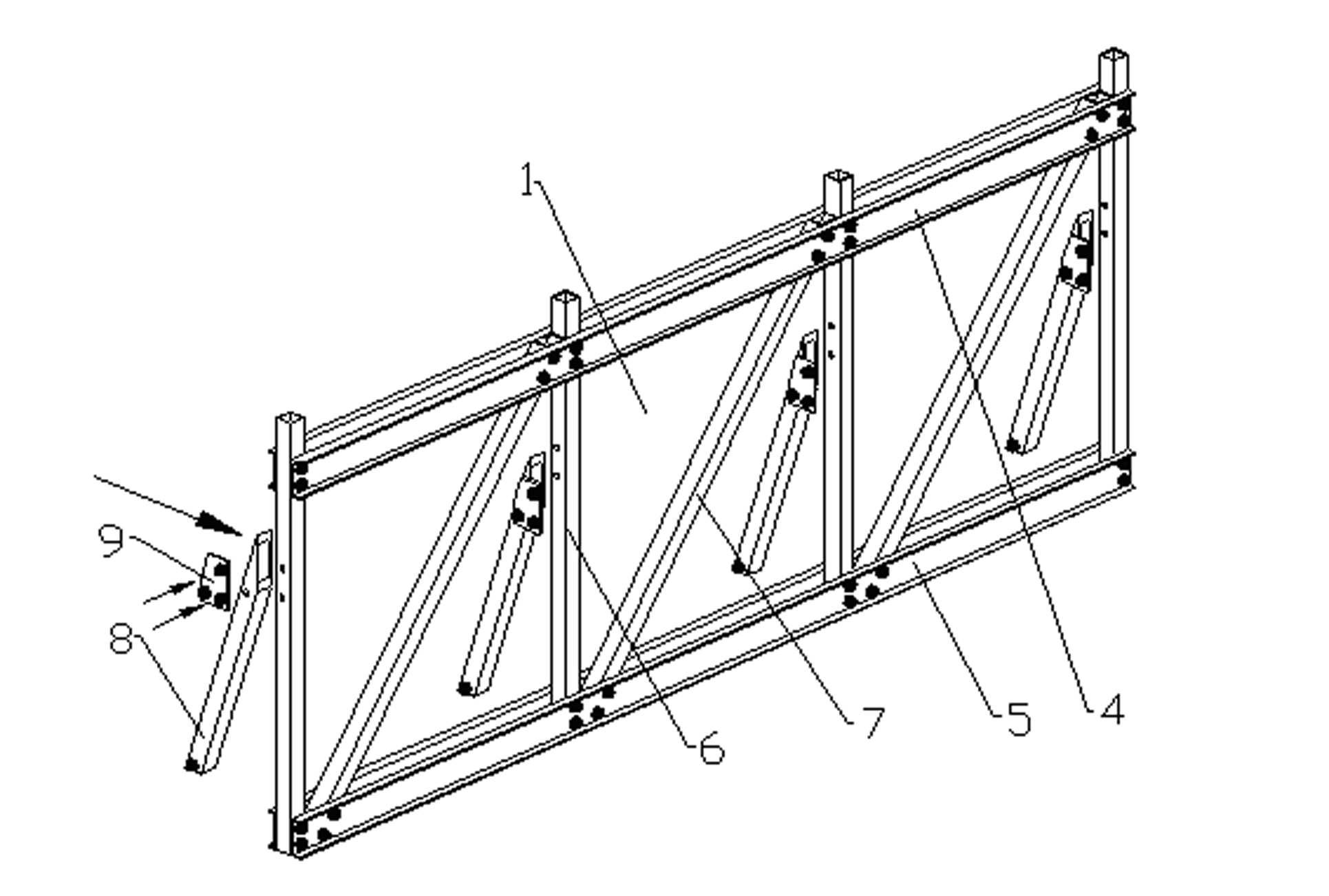

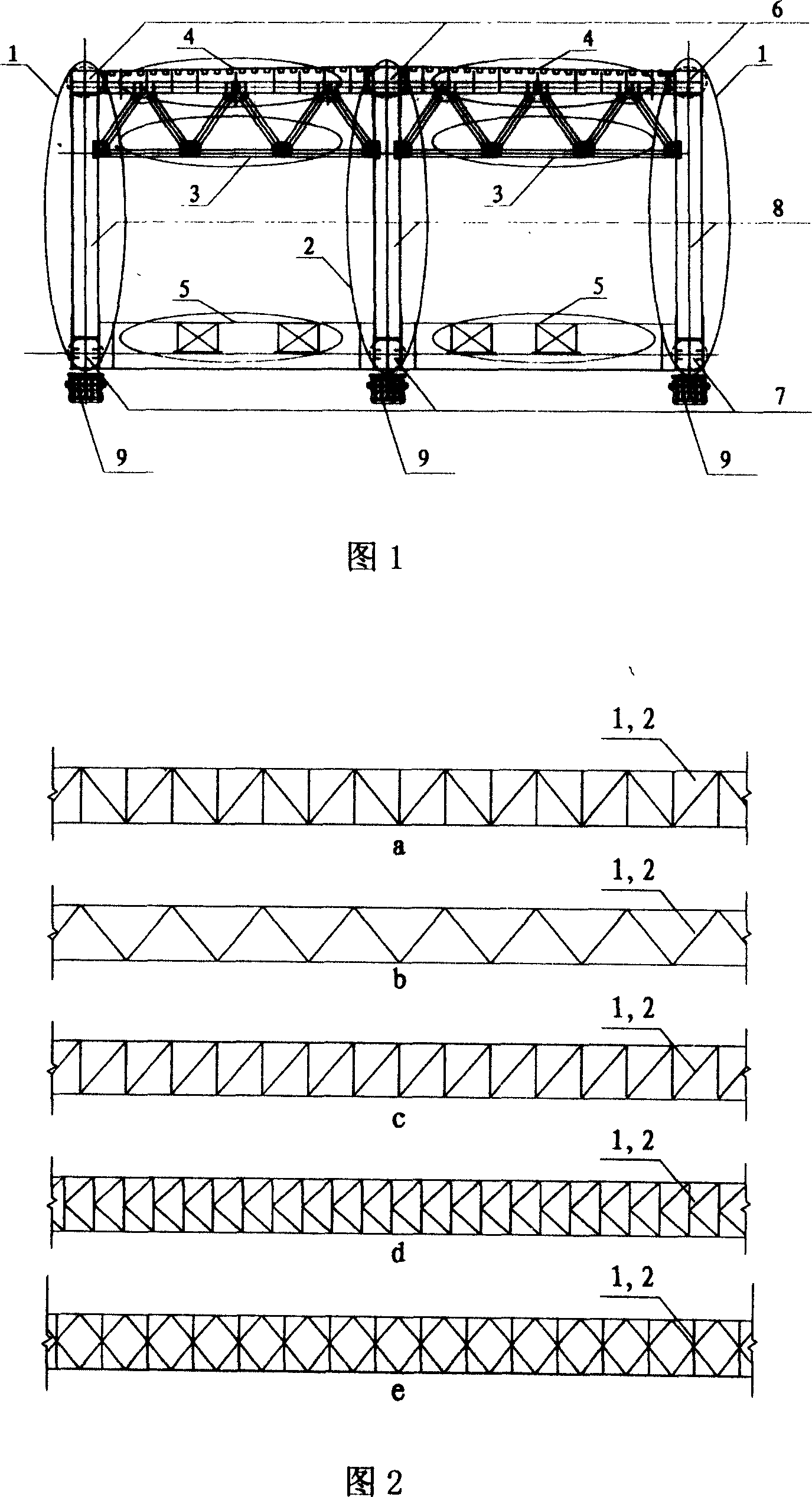

Quick-spliced sectional type composite material truss bridge

InactiveCN101967793AEliminate cracking, steel corrosion and other problemsLight in massTruss-type bridgeEmergency rescueBridge deck

The invention relates to a quick-spliced sectional type composite material truss bridge which comprises facade trusses (1), cross beams (2) and bridge decks (3), wherein each facade truss (1) is composed of an upper chord beam (4), a lower chord beam (5), vertical web girders (6) and inclined web girders (7); the upper chord beam (4) and the lower chord beam are arranged in parallel on the facade and respectively fixed with the upper and lower ends of each vertical web girder (6); each inclined web girder (7) is slantly arranged between every two adjacent vertical web girders (6), and the upper and lower ends of each inclined web girder (7) are respectively fixed with the upper chord beam (4) and the lower chord beam (5); both ends of each cross beam (2) are respectively fixed with two vertical web girders (6) parallel to the facade trusses (1) on the corresponding sides; and each bridge deck (3) is arranged on each cross beam (2) to constitute a truss bridge unit. The invention applies fiberglass reinforced plastics to the entire truss bridge and adopts flexible sectional type design, thus, the invention has the advantages of light weight, shock resistance, corrosion resistance, and convenient and quick transportation and assembly, and has wide application prospects in emergency rescue.

Owner:NANJING UNIV OF TECH

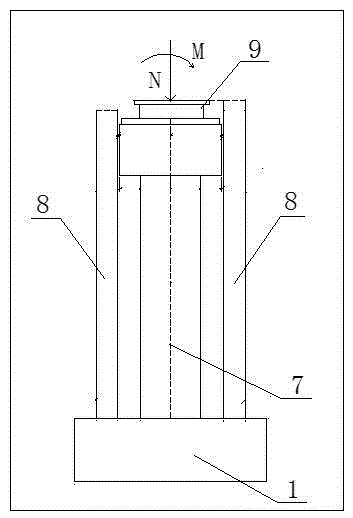

Three plates or multiple plates truss structure main girder

A three / multiple truss main beam of bridge uses a transverse connector 3 to connect a edge main truss 2 and a middle main truss 2, wherein the edge main truss 1 and the middle main truss 2 are arranged with an upper bridge or horizontal connector 4, with a lower bridge or a transverse connector 5 under, the edge main truss 2 and the middle main truss 2 are formed by an upper chord member 6, a lower chord member 7 and a middle web member 8, the middle main truss 2 can be one or several sheets. And nearby two main trusses are connected by the transverse connector 3, to transmit the force between main trusses. The invention uses at least two trusses to bear together, to reduce the force on rod, reduce rod section, reduce the thickness demand and reduce the counter force of base 9. The invention can be used in continuous beam and arc bridge, or the like.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

Bridge beam arch rib section manufacturing process

ActiveCN105586834AEasy to transportEasy to installTruss-type bridgeBridge erection/assemblyStructural engineering

The invention relates to a bridge beam arch rib section manufacturing process. The manufacturing process comprises the three steps of truss piece splicing, wind bracing transverse combination splicing and integral section splicing. The bridge beam arch rib section manufacturing process has the advantages that multi-section matching and splicing are adopted, and for each section, related components can be matched and spliced by means of specific jig frames, so that line-type precision of arch rib sections is ensured; labor amount of integral pre-assembly of the bridge beam arch rib sections is reduced, the splicing period is shortened, and working efficiency is promoted.

Owner:中铁山桥(南通)有限公司

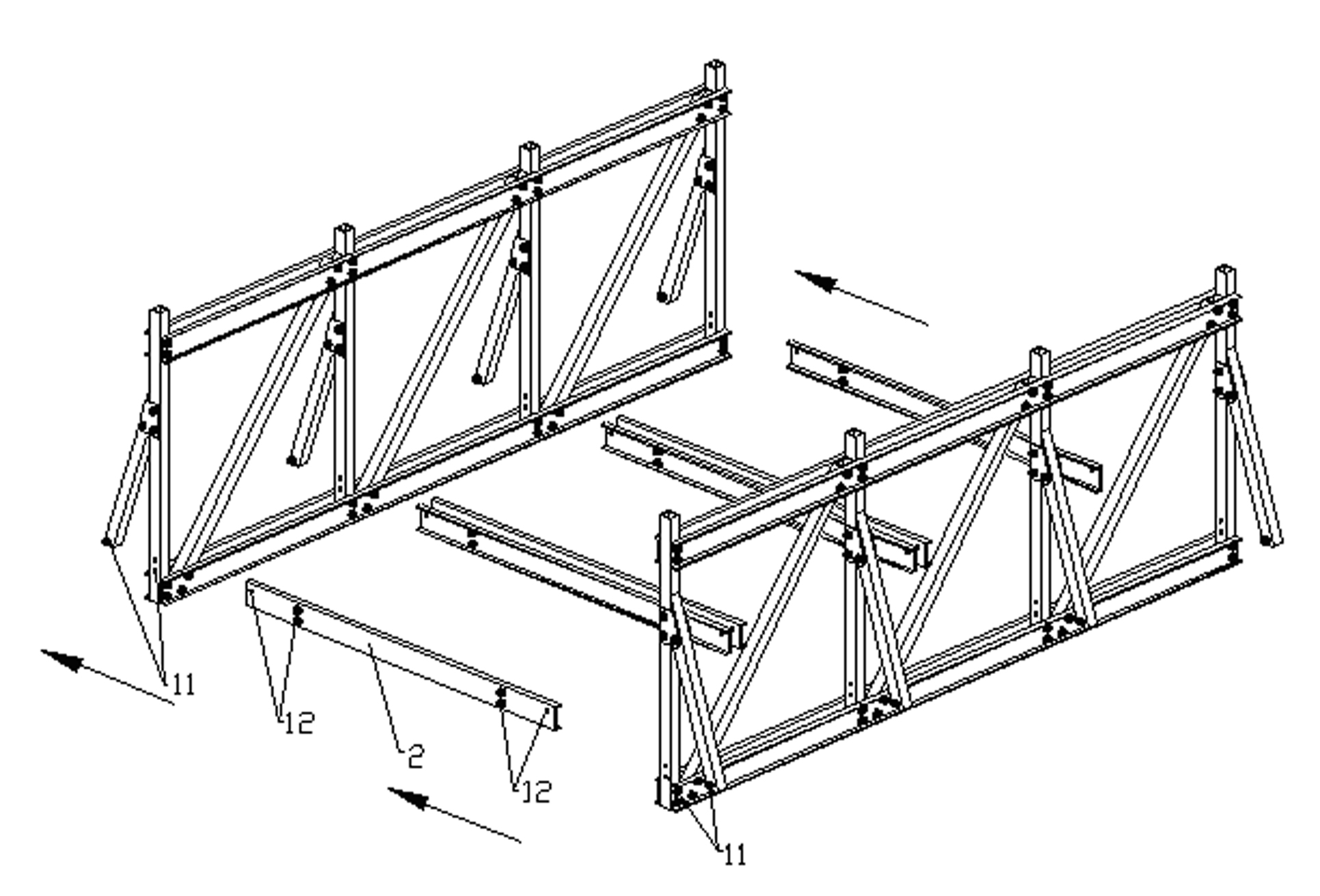

Full-welding truss section modularized splicing method

ActiveCN105735129AReduce laborShorten the timeTruss-type bridgeBridge erection/assemblyModularityStructural engineering

The invention relates to a full-welding truss section modularized splicing method. According to the method, each assembly of each truss section is divided into multiple modules, and each module is independently spliced. The method includes firstly, a truss sheet module splicing method, secondly, a transverse connecting sheet module splicing method, thirdly, an upper-layer road bridge face module splicing method, fourthly, a lower-layer railway bridge face module splicing method, fifthly, a road combination section longitudinal and transverse beam splicing method and sixthly, a truss whole section module splicing method. A bridge is spliced in a modularized manner, part of the modules of the bridge can be spliced on a bridge production site, the difficulty of constructing the bridge on the site is lowered, the labor amount for manufacturing the bridge is reduced, the manufacturing time of the bridge is shortened, and the working efficiency is improved.

Owner:中铁山桥(南通)有限公司

In-pipe prestressed steel-pipe truss composite simply-supported beam structure

The invention discloses an in-pipe prestressed steel-pipe truss composite simply-supported beam structure, which comprises a main beam framework and a bridge deck. The main beam framework is in a steel-pipe truss structure, and the bridge desk is in a concrete structure. The main beam framework comprises a lower chord and an upper chord, the upper chord is connected with the lower chord through a plurality of web tubes, each two adjacent web tubes and the upper chord or lower chord form a triangle, and the cross section of the main beam framework is in the shape of an inverted triangle. The lower chord is in an arc structure with the middle arched down, and the lateral side of the main beam framework is in a fish belly structure. A prestressed tendon is arranged in the lower chord. The in-pipe prestressed steel-pipe truss composite simply-supported beam structure is reasonable in stress, light in weight, convenient in construction, and applicable to single-span simply-supported bridges and multi-span simply supported bridges.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194ALight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

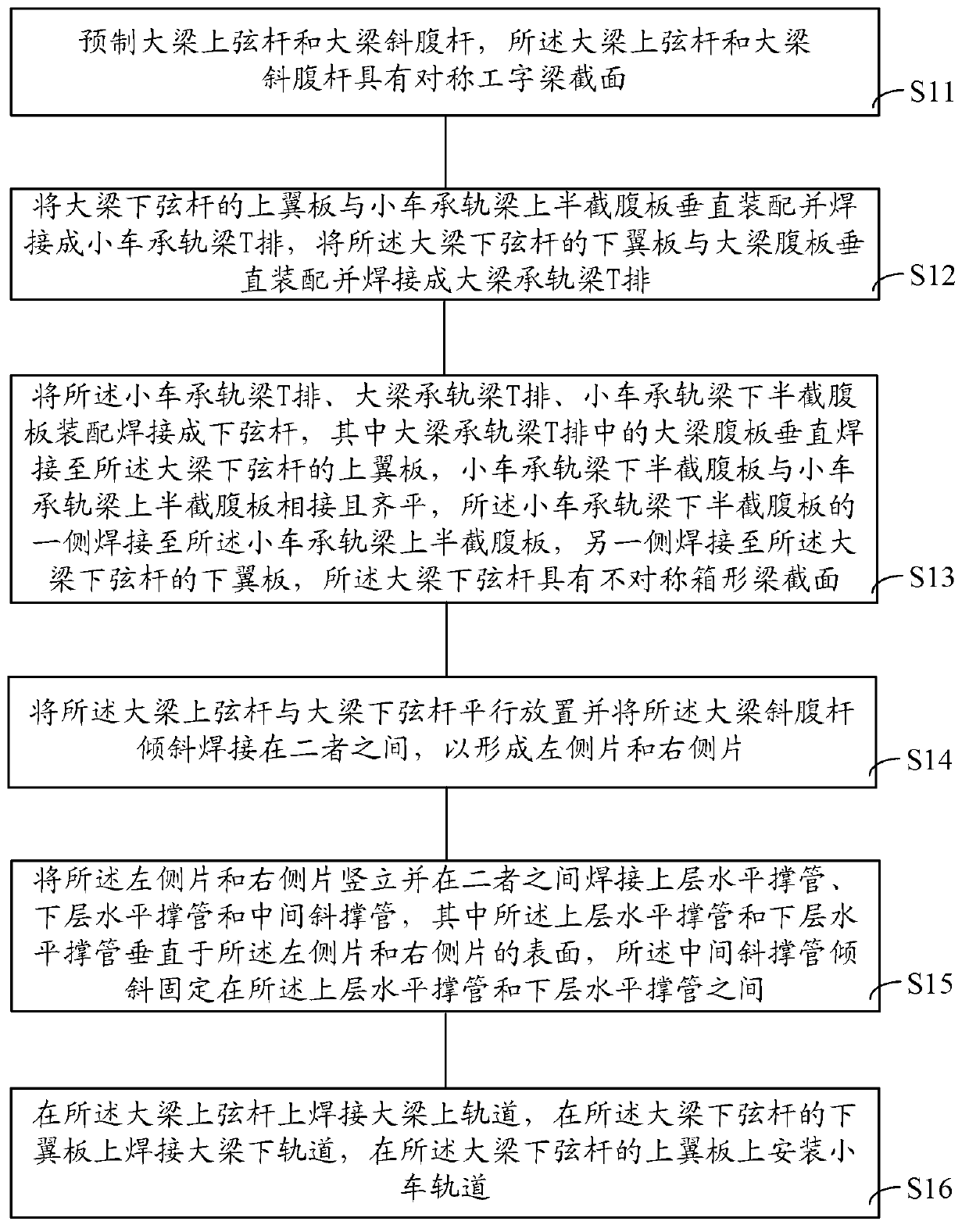

Telescopic truss crossbeam and manufacture method thereof

ActiveCN103321152AMeet the installation technical requirementsAvoid errorsTruss-type bridgeBridge erection/assemblyEngineeringLower wing

The invention provides a telescopic truss crossbeam and a manufacture method thereof. The manufacture method comprises the following steps: a crossbeam upper chord and a crossbeam diagonal web member are prefabricated; T-shaped trolley support rail beams and T-shaped crossbeam support rail beam are assembled and welded; a crossbeam lower chord is formed through the assembly and welding of the T-shaped trolley support rail beams, the T-shaped crossbeam support rail beams and a section of web member at the lower parts of the trolley support rail beams; the crossbeam upper chord and the crossbeam lower chord are placed parallelly, and the crossbeam diagonal web member is obliquely welded between the crossbeam upper chord and the crossbeam lower chord, so that a left lateral plate and a right lateral plate are formed; the left lateral plate and the right lateral plate are erected, and an upper-layer horizontal bracing tube and a lower-layer horizontal bracing tube and a middle inclined bracing tube are welded between the left lateral plate and the right lateral plate; crossbeam upper rails are welded on the crossbeam upper chord, crossbeam lower rails are welded on a lower wing plate of the crossbeam lower chord, and trolley rails are mounted on an upper wing plate of the crossbeam lower chord. According to the method, the sidewise bending and flatness of the crossbeam, the new game start of the rail and the like can be controlled in a precision range.

Owner:SHANGHAI ZHENHUA HEAVY IND

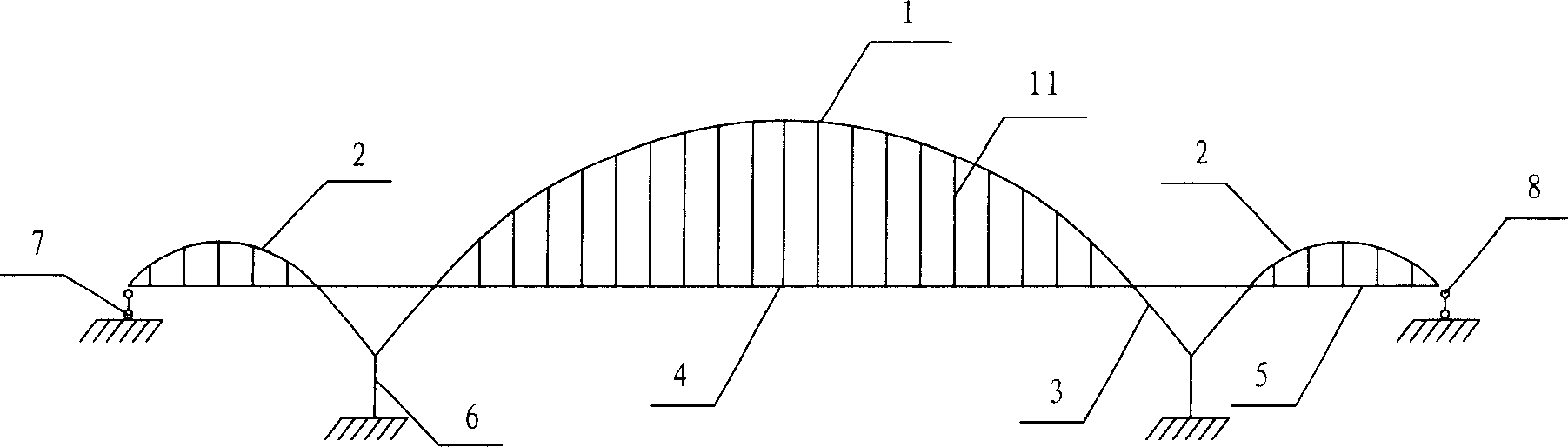

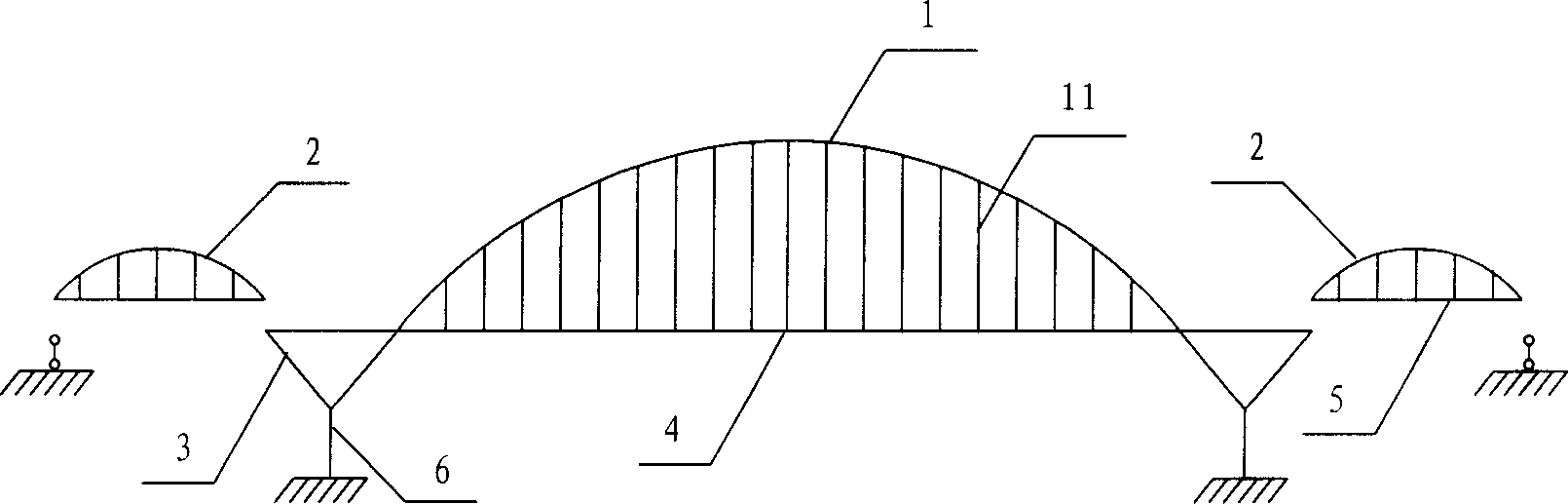

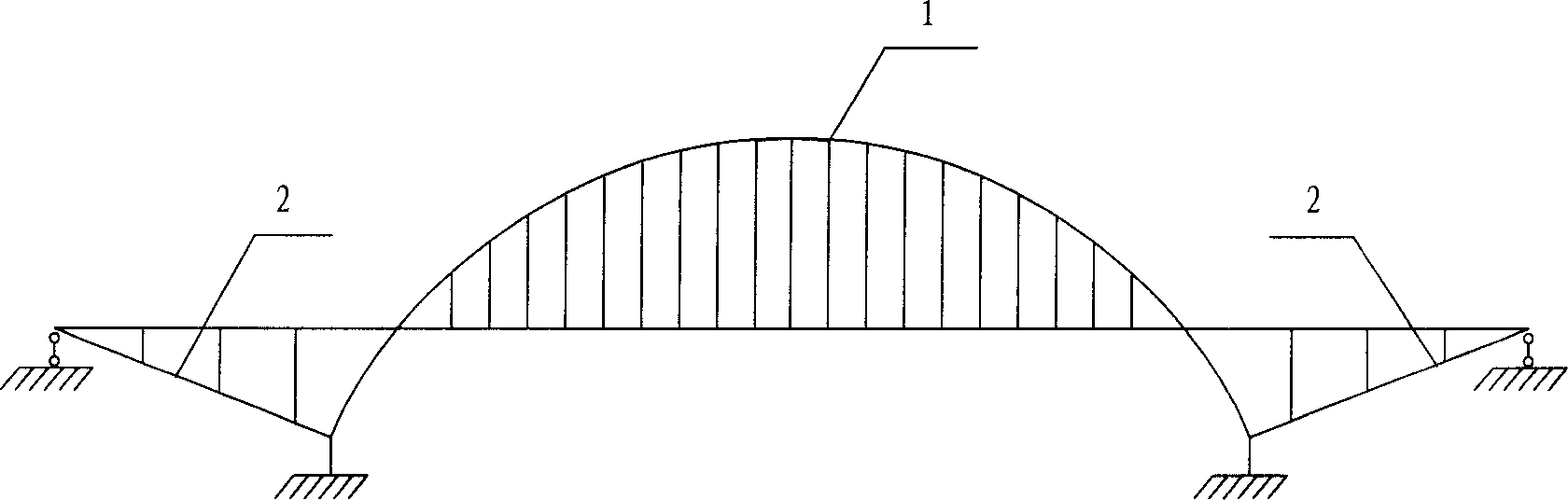

Three span continuous rigid structure steel arched bridge

This invention relates to a kind of three strides serial rigid steel arched bridge. It includes the medium bear main arch rib, the main arch deck which connects with the main arch rib through suspender and the medium bear side arch rib which is on both sides of main arch rib, the side arch deck which connects with the side arch rib and fixes it through the suspender. The main arch rib connects with the side arch rib's inner side arch springing through the triangular rigid structure on main frusta. The side arch rib's outer side arch springing connects with side frusta through support abutment. On both sides of side arch deck there is flexible tie bar, the side arch rib's outer side arch springing and the side frusta's connecting support abutment are portrait glide support abutments. The main arch deck is steel structure or steel mixture combination structure. The side arch deck is the concrete structure. This invention improves the whole bridge's rigidness by optimizing the structure. It makes the main frusta's imbalance flexural torque and level force become small. It lowers the base design difficulty and saves the bridge's steel usage. It also saves the investing cost. Its three strides serial rigid steel arch becomes more beautiful and harmony on appearance.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

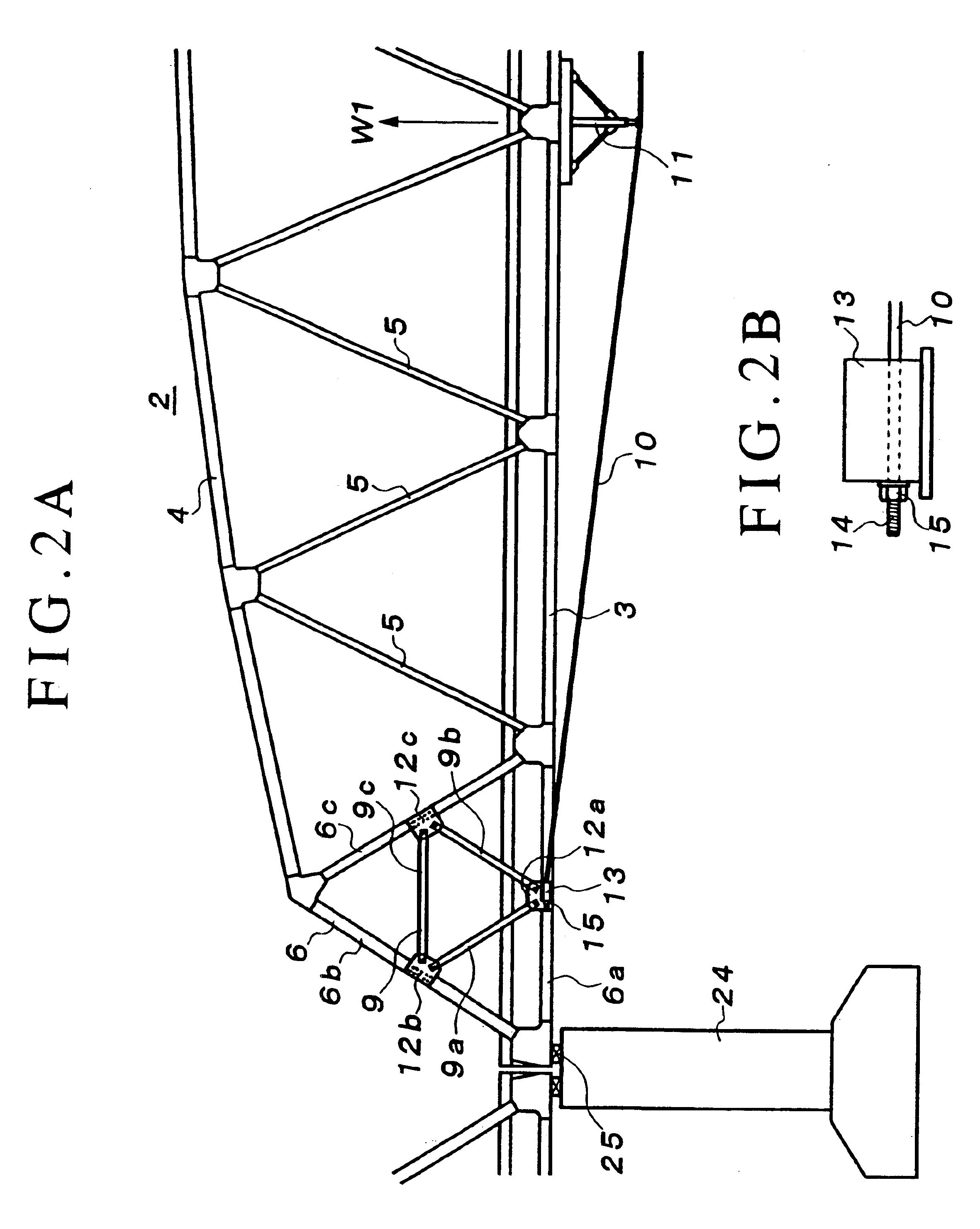

Reinforcement structure of truss bridge or arch bridge

InactiveUS6892410B2Efficient inductionTruss-type bridgeBridge structural detailsArch bridgeStructural element

Through co-action between auxiliary triangular structural frames, which are each constructed at opposite ends of a truss girder or arch girder, and a cable stretched between the auxiliary triangular structural frames, an upwardly directed force is exerted to the truss girder or arch girder, thereby effectively inducing a load resisting force. A reinforcement structure of a truss bridge or arch bridge is comprised of a truss girder or arch girder, a first and a second end of which are each provided with a main triangular structural frame. The main triangular structural frame is provided at an inner side thereof with an auxiliary triangular structural frame. The auxiliary triangular structural frame is joined at vertexes thereof with frame structural elements at respective sides of the main triangular structural frame. A cable extends in a longitudinal direction of the truss bridge, being stretched between a nearby part of a joined part at one of the vertexes of the auxiliary triangular structural frame on a side of the first end of the truss girder or arch girder and a nearby part of a joined part at a corresponding one of the vertexes of the auxiliary triangular structural frame on a side of the second end of the truss girder or arch girder. Deflecting structure, adapted to exert a downwardly directed force to the cable, is inserted between the cable and a lower chord of the truss girder or arch girder so as to tension the cable, and an upwardly directed force is exerted to the lower chord by a reaction force attributable to tension of the cable via the deflecting structure.

Owner:ASAHI ENG CO LTD +2

Multi-connection and multi-span continuous steel truss girder bridge and construction method thereof

InactiveCN104328734AEasy Connection HandlingSolve the problem of tight construction scheduleTruss-type bridgeBridge erection/assemblyEngineeringStructural engineering

The invention relates to a multi-connection and multi-span continuous steel truss girder bridge and a construction method thereof. The multi-connection and multi-span continuous steel truss girder bridge comprises a plurality of height-variable trusses, wherein the tail parts and head parts of the height-variable trusses are connected into a row, the upper part and lower part of each height-variable truss are respectively connected with an upper horizontal and longitudinal connection and a bridge surface, and the lower end of the bridge surface is fixedly connected with a plurality of bridge piers. The construction method comprises the following steps of preliminary work, building of the bridge piers, building of a top pushing splicing platform, jacking and pushing of the height-variable trusses, suspension and splicing of the height-variable trusses, paving of a worker walkway, cleaning of site, and completion. The multi-connection and multi-span continuous steel truss girder bridge and the construction method have the beneficial effects that the structure stress of the height-variable trusses is reasonable, and the steel consumption amount is reduced; by adopting the integral and splicing type node mixing structure, the splicing is simple; by adopting multiple main trusses, the transverse stress is reasonable; by arranging the worker walkway and a refuge platform in a gap between the main truss components, the truss width is effectively reduced, and the steel consumption amount is reduced; by adopting the multi-connection synchronous jacking, pushing, suspension and splicing combined construction method, the influence on the spliced jacking and pushing process of original connection caused by the new connection of splicing is avoided, the jacking and pushing quality is improved, the difficulty in synchronizing is decreased, the efficiency is improved, and the cost is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

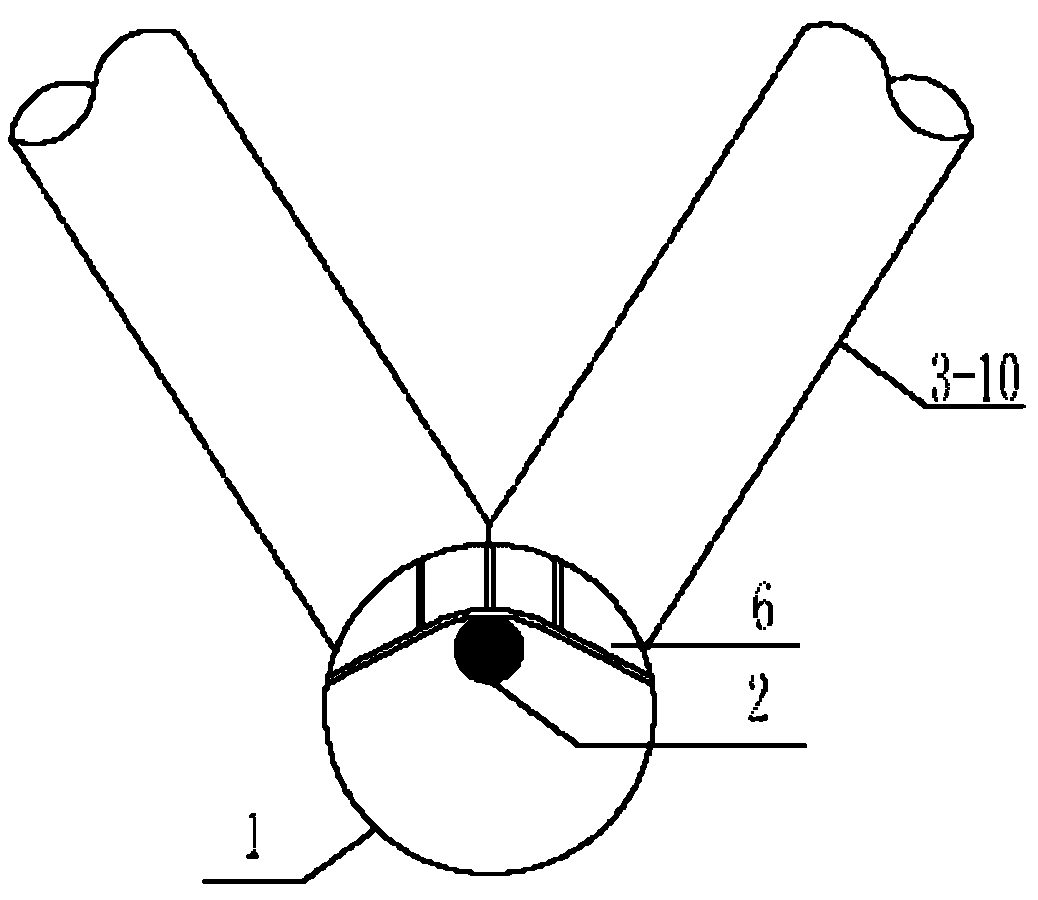

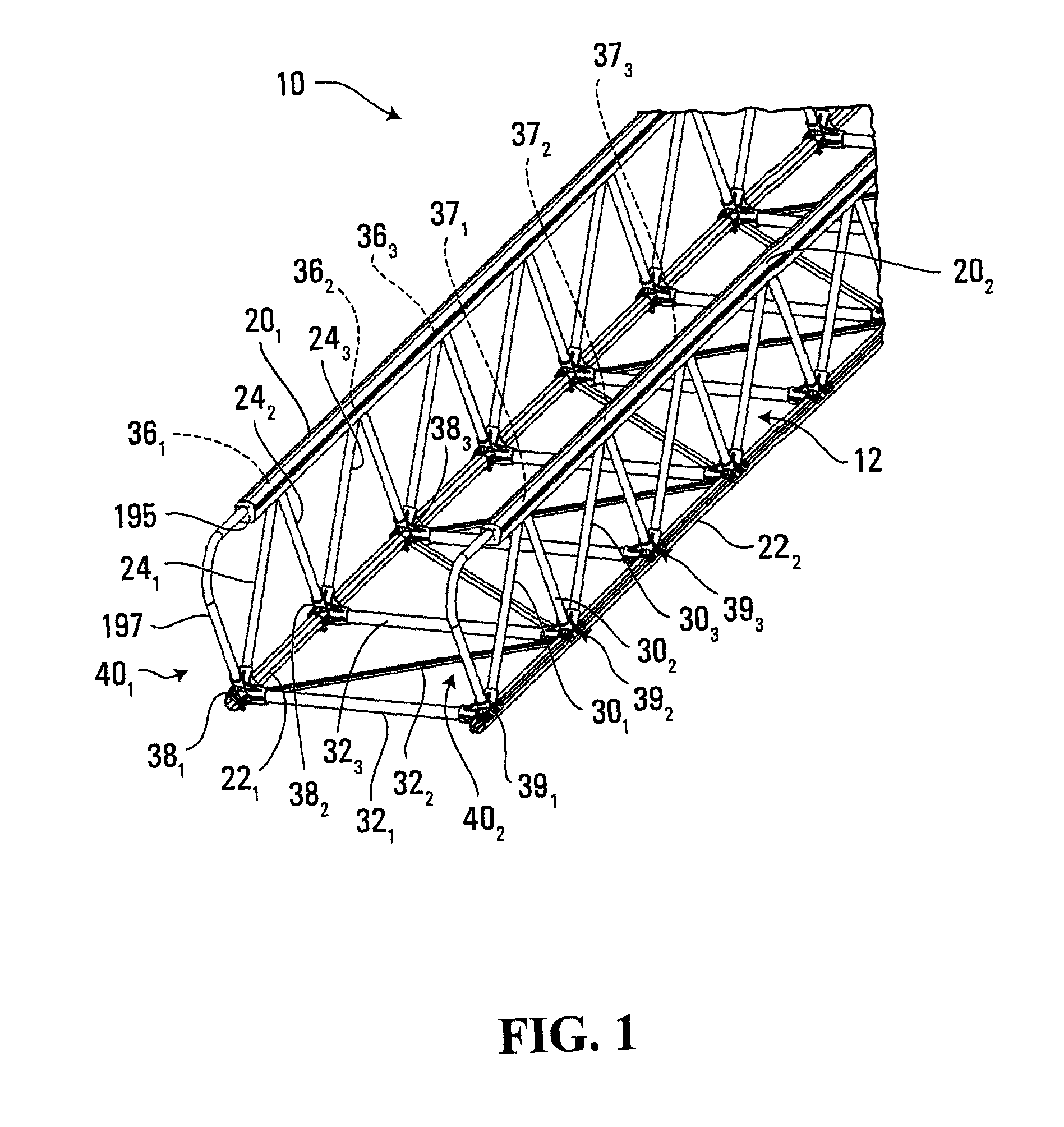

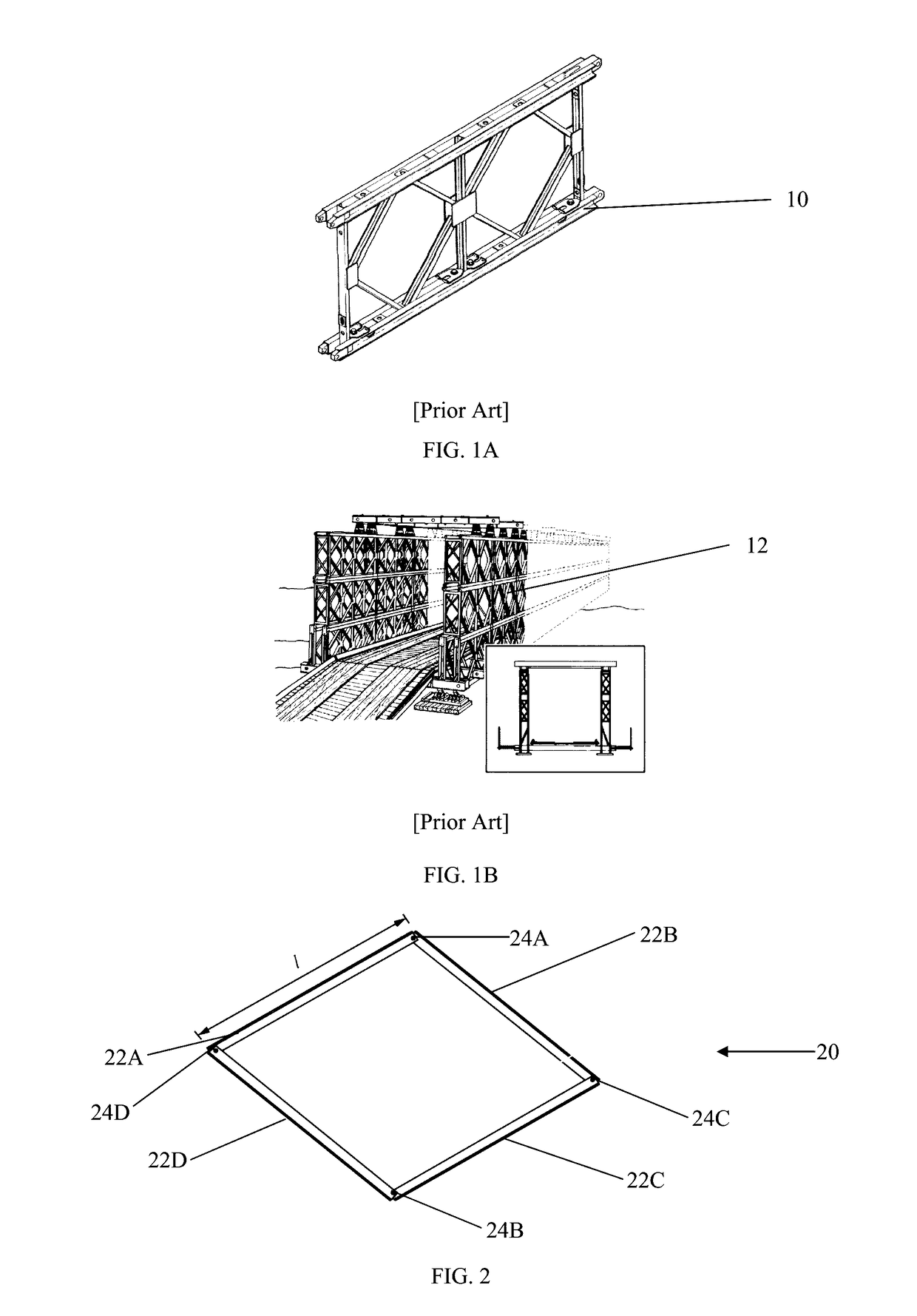

Structural assemblies for constructing bridges and other structures

ActiveUS20110197378A1Roof covering using slabs/sheetsRoof covering using tiles/slatesBiomedical engineeringStructural component

Structural assemblies for constructing bridges and other structures. A structural assembly may comprise an elongated member defining an internal space. The structural assembly may also comprise a plurality of framing members connected to the elongated member at a plurality of pin connection nodes, each pin connection node comprising a pin interconnecting the elongated member, a first one of the framing members, and a second one of the framing members, the pin having a first longitudinal end and a second longitudinal end, at least one of the first longitudinal end and the second longitudinal end of the pin being located in the internal space of the elongated member.

Owner:DE LA CHEVROTIERE ALEXANDRE

Batter brace bridge

InactiveCN101545242AOptimize construction detailsShorten the cantilever lengthTruss-type bridgeBridge deckEngineering

The invention discloses a batter brace bridge comprising steel truss composed of upper chord, lower chord and web member; the lower chord is installed at two sides of lower layer bridge deck; breadth of the lower chord adapts to breadth of lower layer bridge deck; the upper chord is installed at two sides of upper layer bridge deck; breadth between the upper chords is larger than that of lower chord; the web member top is installed slant outward. The batter brace bridge of the invention has character of broad upper layer of road deck and narrow lower layer of railway deck, which can reduce cantilever length of bridge deck and enable transversal arrangement of road bridge deck more reasonable. The cantilever of the road bridge deck can not be installed with bracket, which results in smooth line, harmonic proportion, good economic effect and saving steel material. The invention solves problem of truss type and bridge construction scale when double decks of the bridge has excessively different breadth, largely improves mechanical performance of truss structure, optimizes detail of truss structure, thereby the bridge has merits of reasonable mechanical performance, simple structure, beautiful appearance and economy.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Through prestress steel truss and concrete combined continuous steel structure bridge and construction method thereof

InactiveCN102535327ALight weightGive full play to the advantages of tensile strengthTruss-type bridgeBridge structural detailsButt jointPre stress

Owner:CCCC CIVIL ENG SCI & TECH +1

Structural assemblies for constructing bridges and other structures

Structural assemblies for constructing bridges and other structures. A structural assembly may comprise an elongated member defining an internal space. The structural assembly may also comprise a plurality of framing members connected to the elongated member at a plurality of pin connection nodes, each pin connection node comprising a pin interconnecting the elongated member, a first one of the framing members, and a second one of the framing members, the pin having a first longitudinal end and a second longitudinal end, at least one of the first longitudinal end and the second longitudinal end of the pin being located in the internal space of the elongated member.

Owner:DE LA CHEVROTIERE ALEXANDRE

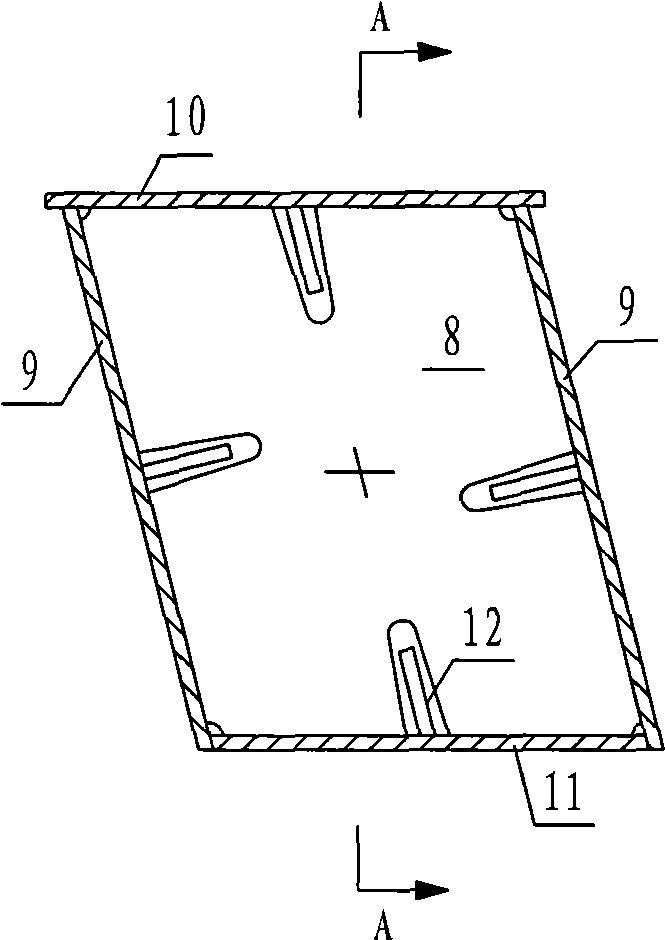

Adjustable Modules for Variable Depth Structures

This disclosure presents a new strategy for modular construction: an adjustable module. This disclosure develops a new adjustable module comprised of a four-bar linkage which can form more efficient variable depth structures. Applications can include rapidly erectable bridges, roofs, buildings, and grid shells, among others. This disclosure provides specific detail related to rapidly erectable bridge applications for variable depth arch forms. Existing rapidly erectable, steel panelized bridge systems have limited material efficiency as they are comprised of rigid modules in a girder-type configuration. This disclosure shows that the module can form variable depth three- and two-hinged arches which increase the material efficiency. The module and other arch components can be made of standard rolled steel sections, thereby forming a versatile, kit-of-parts systems.

Owner:UNIV OF NOTRE DAME DU LAC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com