In-pipe prestressed steel-pipe truss composite simply-supported beam structure

A steel tube truss and simply supported beam technology is applied in the field of in-pipe prestressed steel tube truss composite simply supported beam structures, which can solve problems such as insufficient mechanical properties, limited spanning capacity of ordinary composite structure simply supported beams, etc. Lightweight structure and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The preferred embodiment of the composite simply supported beam structure of the prestressed steel pipe truss in the present invention is as follows:

[0019] It includes a main girder skeleton, on which a bridge deck is arranged, the main girder skeleton is a steel pipe truss structure, and the bridge deck is a concrete structure;

[0020] The main beam skeleton includes a lower chord and an upper chord, the lower chord and the upper chord are connected by multiple web tubes, two adjacent webs form a triangular structure with the upper chord or the lower chord, and the main beam skeleton The cross-sectional shape is an inverted triangle structure;

[0021] The lower chord is an arc-shaped structure that bends downward in the middle, and the side shape of the main beam skeleton is a fish-belly structure;

[0022] Prestressed tendons are arranged in the lower chord.

[0023] An anchoring device is provided at both ends of the lower chord, and the anchoring device inclu...

specific Embodiment

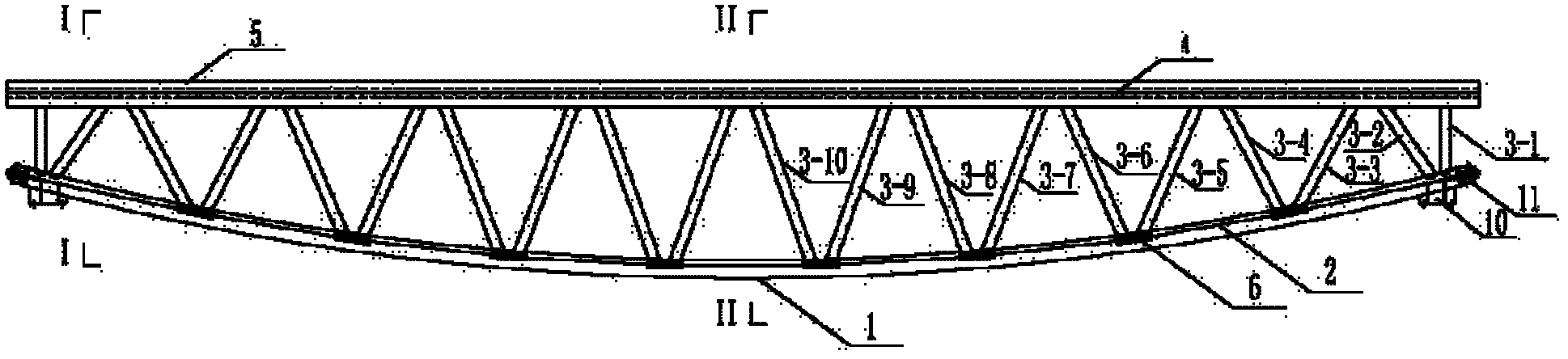

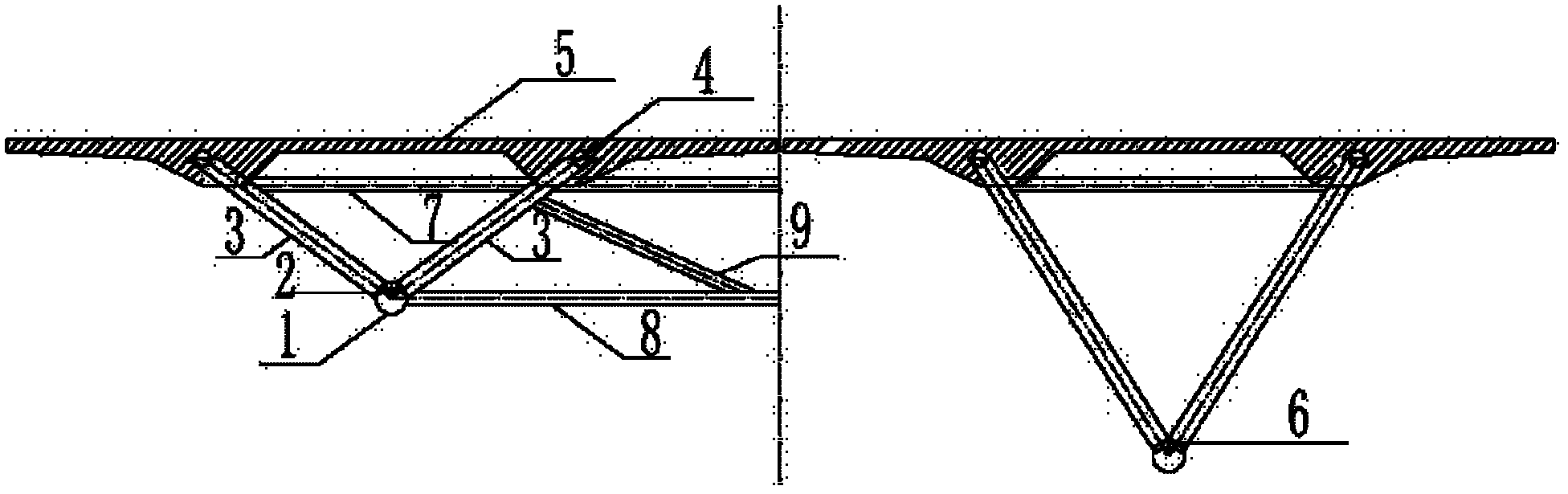

[0034] Such as figure 1 , figure 2 As shown, the main girder skeleton is a fish-belly structure, which can be single or double, and the middle of the two beams is connected into one body through transverse connecting rods 7, 8, and 9.

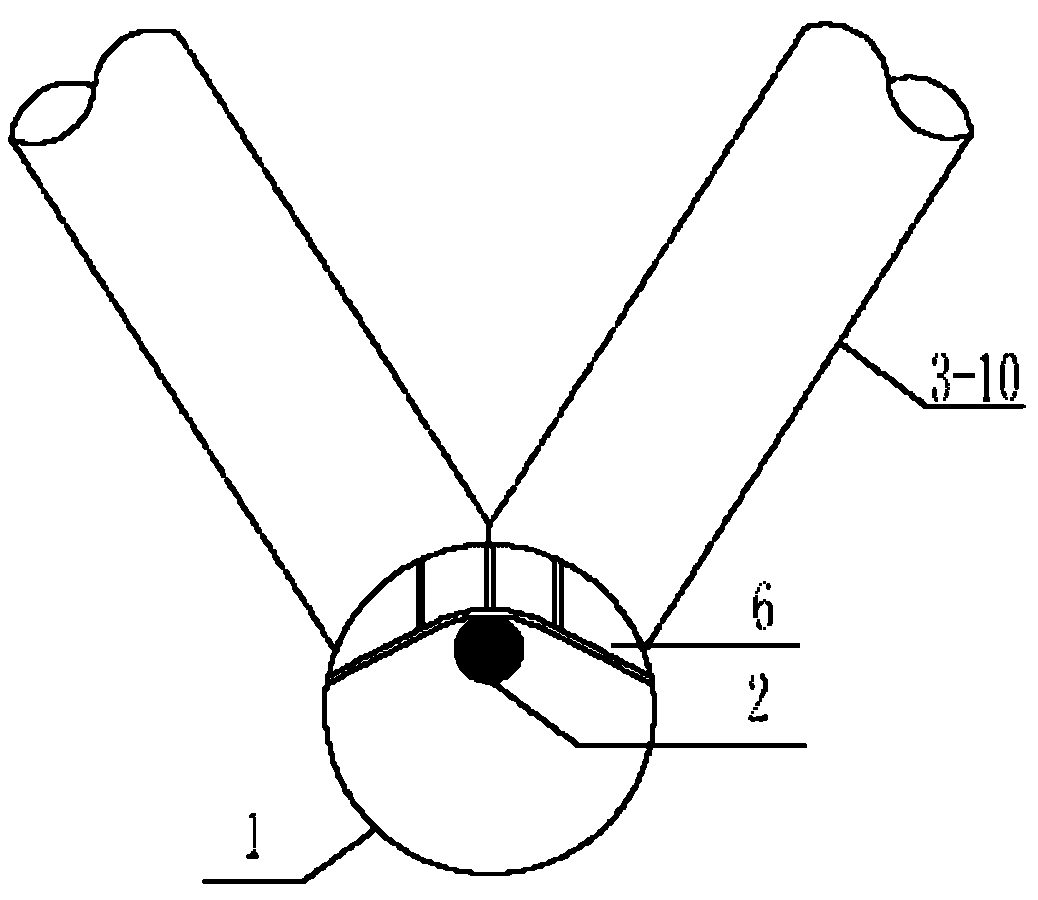

[0035] Such as figure 1 As shown, specifically, the main beam skeleton can be composed of the lower chord 1, the upper chord 4, and the 3 series of webs (including the webs 3-1 to 3-10). Or the transverse connecting rods form a triangle. The 3 series of abdominal tubes (including 3-1 to 3-10 abdominal tubes) are fixedly connected with the upper chord 4 and the lower chord 1 respectively. The cross-section is an inverted triangle, and the overall skeleton is a fish-belly structure.

[0036] Such as figure 2 As shown, it is a cross-sectional view of a double-width beam structure, and the left half of the bridge axis (double dotted line) is the cross-sectional structure at the support ( figure 1 I-I direction 1 / 2 sectional view), the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com