Quick-spliced sectional type composite material truss bridge

A composite material and truss bridge technology is applied in the field of rapid assembly of segmented composite material truss bridges. , Broad application prospects, the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

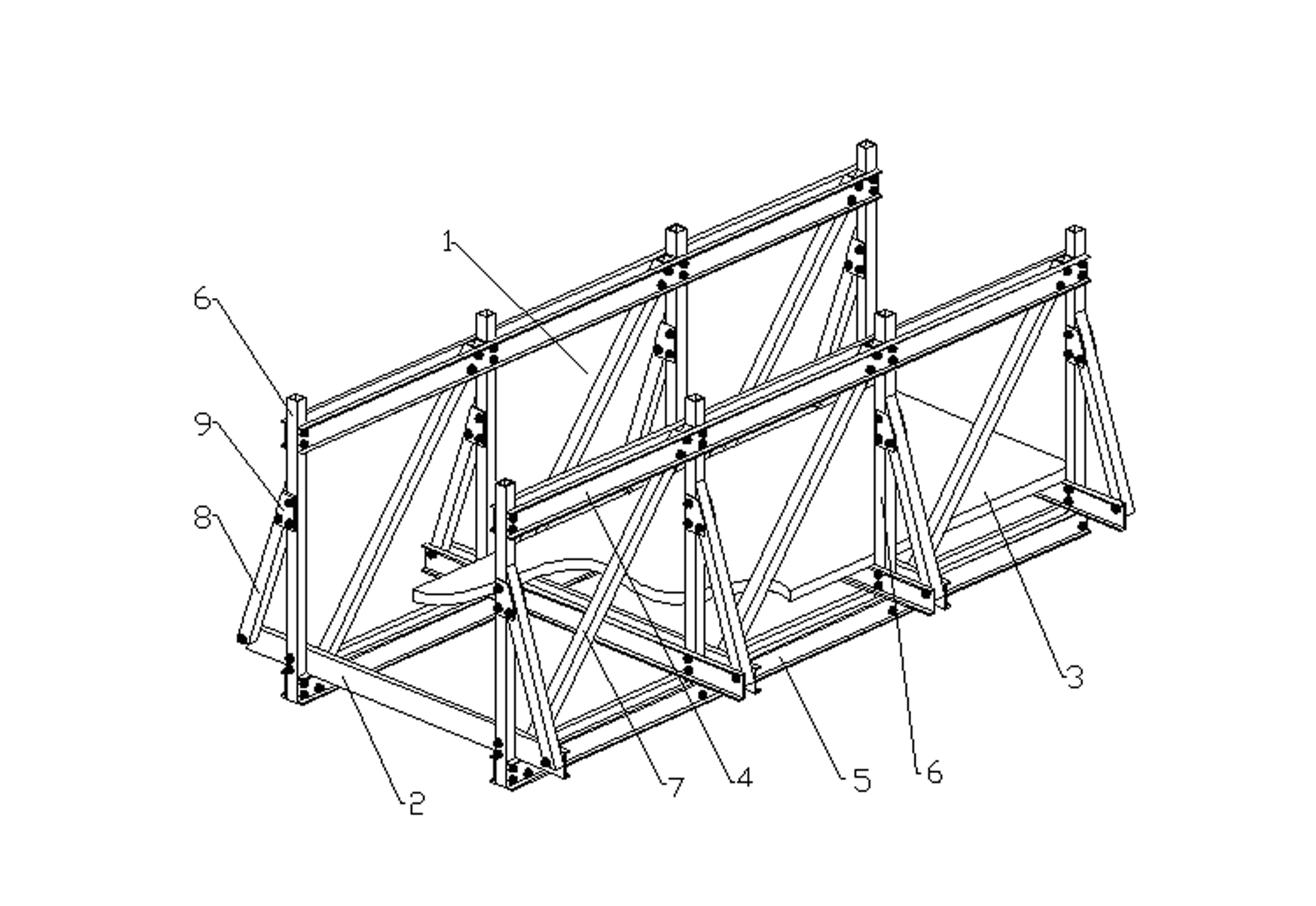

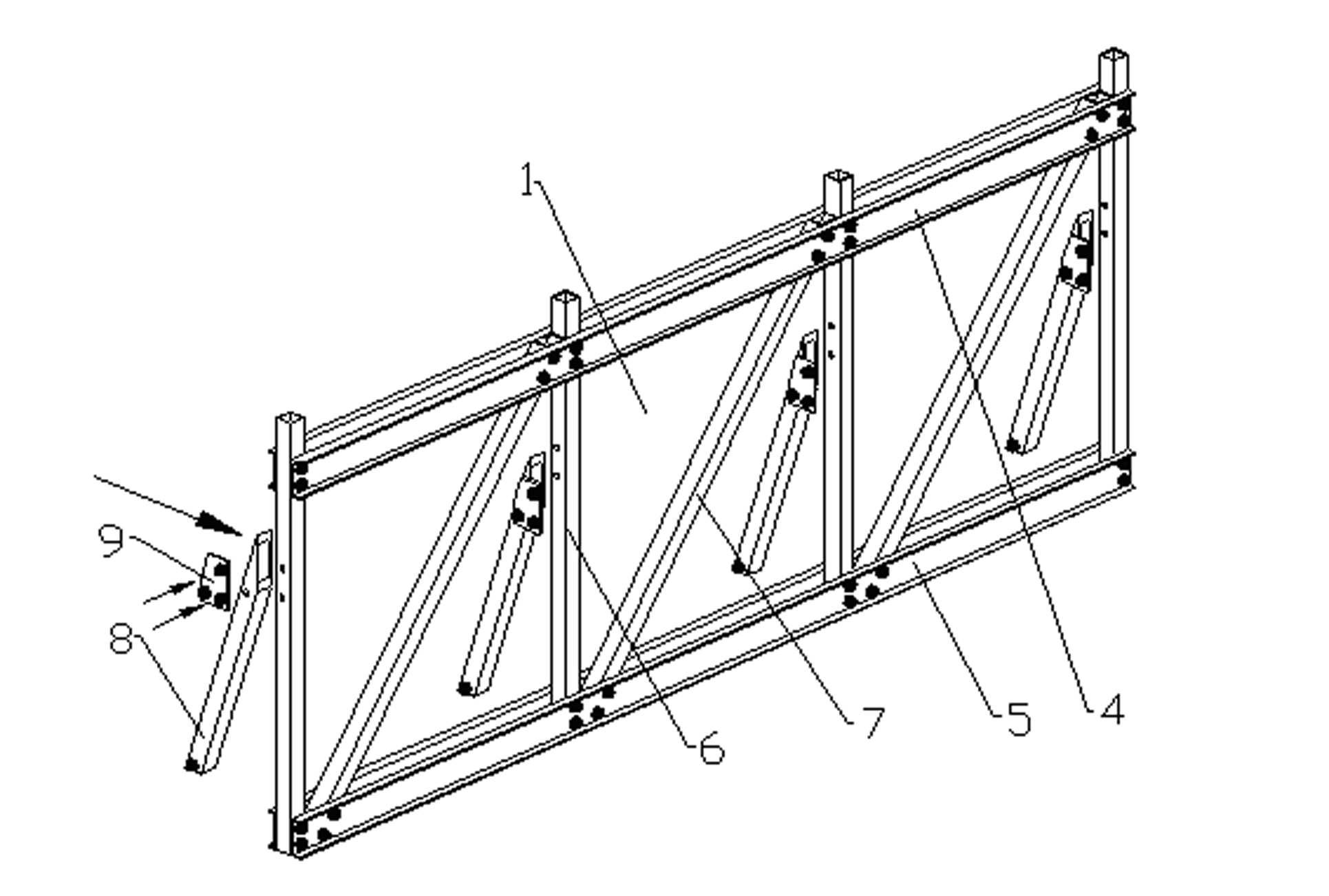

[0033] Depend on Figure 1-5 As shown, the rapid assembly segmented composite truss bridge of the present invention is made up of a facade truss 1, a beam 2 and a bridge deck 3, consisting of figure 2 It can be seen that the upper string girder 4, the lower string girder 5, the vertical web girder 6 and the inclined web girder 7 are fixed by bolts to form a facade truss 1. The two ends are fixedly connected, the inclined web beams 7 are obliquely placed between two adjacent vertical web beams 6 and the upper and lower ends of the inclined web beams 7 are respectively fixedly connected with the upper string beam 4 and the lower string beam 5; The structural strength is fixedly connected with the outer support beam 8 through the outer gusset plate 9 on the outer side of the vertical web beam 6 . Depend on image 3 It can be seen that by figure 2 As shown, two mutually symmetrical façade trusses 1 and beams 2 are assembled, and the beams 2 are installed on the bottom chord 5...

Embodiment 2

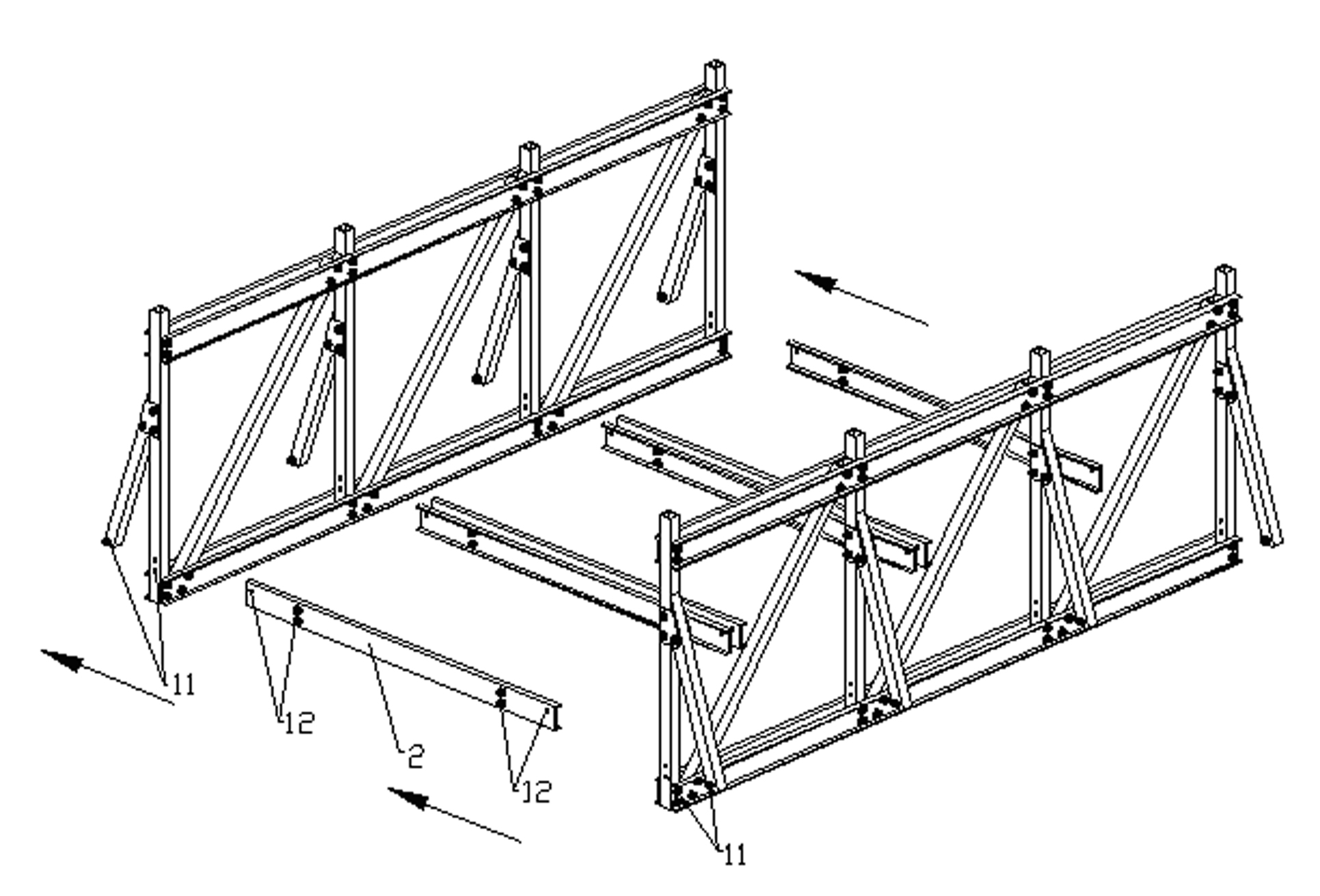

[0036] Depend on Figure 6-7 As shown, when the rapid assembly segmented composite truss bridge of the present invention needs to bear the vehicle load, a slightly shorter beam 2 can be used to replace the beam shown in Embodiment 1 with both ends exceeding a part of the width of the façade truss 1 2. Remove the outer support beam 8 and outer gusset plate 9 provided on the truss bridge unit in Example 1, and fix the bolts 11 on the vertical web beam 6 to the bolt holes 12 on the crossbeam 2 on the upper chord 4 connected to form a box truss bridge unit. In practical applications, the Figure 6The bridge deck 3 is laid on the box-shaped upper surface of the box-shaped truss bridge unit shown and spliced together in the transverse direction to form Figure 7 The above-supported vehicle-mounted bridge shown. The length and width of the above-supported vehicle-mounted bridge can be assembled according to actual needs.

Embodiment 3

[0038] Depend on Figure 8 As shown, when some places only need pedestrian bridges as common bridges or emergency bridges, it can be used Figure 6 Based on the box-shaped truss bridge unit shown, an oblique support beam 13 is added between the beams 2 on the upper surface of the truss bridge unit to form a closed box-shaped structure, and the bridge deck 3 is laid on the lower surface of the truss bridge unit. On the crossbeam 2, a down-bearing pedestrian bridge is formed, and an awning can be laid on the closed box-shaped top surface to form a Figure 8 As shown in the through-type footbridge, the length of the under-type footbridge can be assembled according to actual needs. In addition, it is also possible to use figure 1 The truss bridge element shown, in figure 1 In the shown truss bridge unit, a crossbeam 2 and an oblique support beam 13 are added above the upper chord 4, and the crossbeam 2 on the upper chord 4 should be slightly shorter than the crossbeam 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com