A kind of steel truss bridge and its manufacturing method

A technology of steel truss bridge and manufacturing method, applied in the direction of truss bridge, erection/assembly bridge, bridge, etc., can solve the problems of increasing safety risk, difficult to guarantee positioning accuracy, etc., to reduce risk, ensure processing quality, and improve stability and the effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

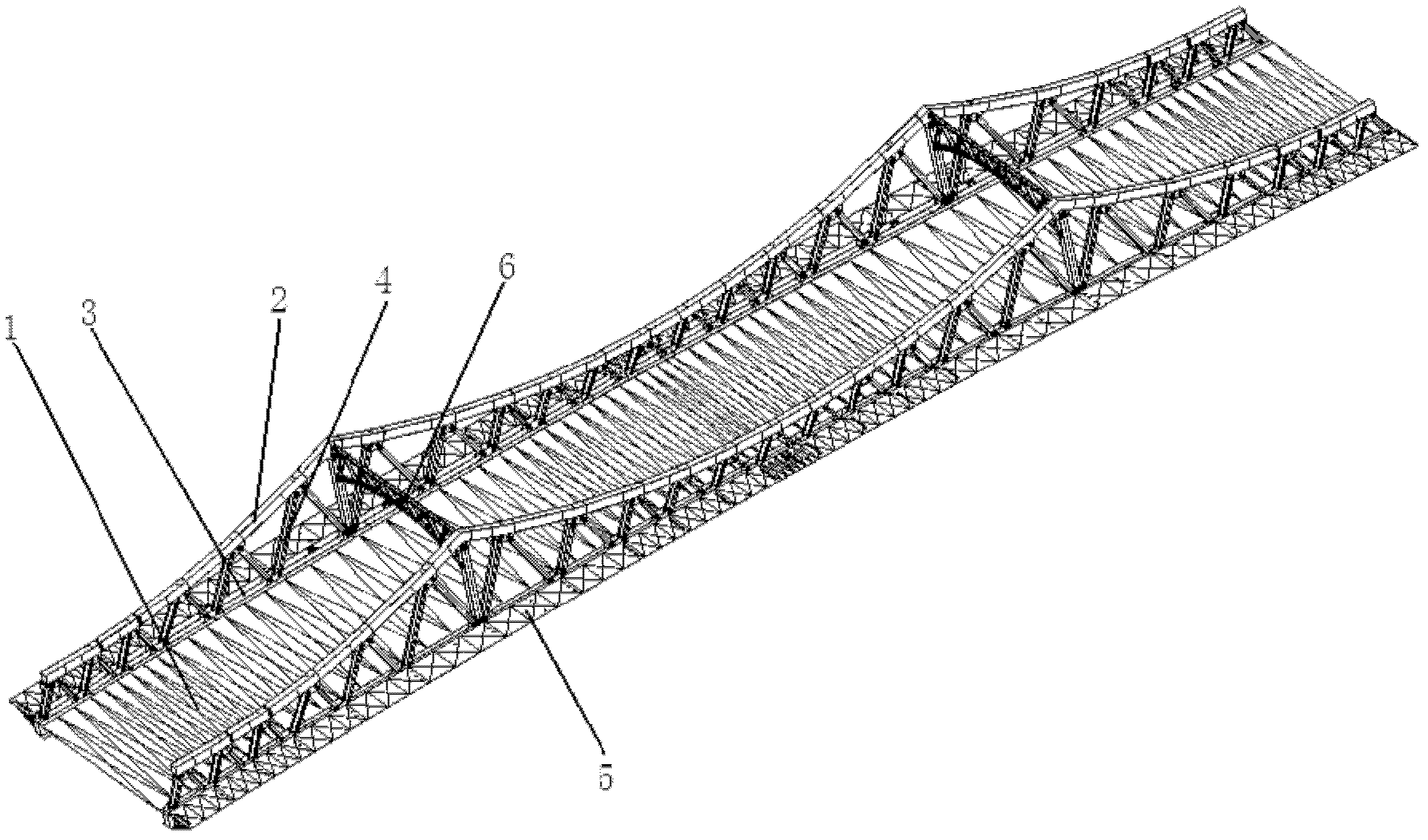

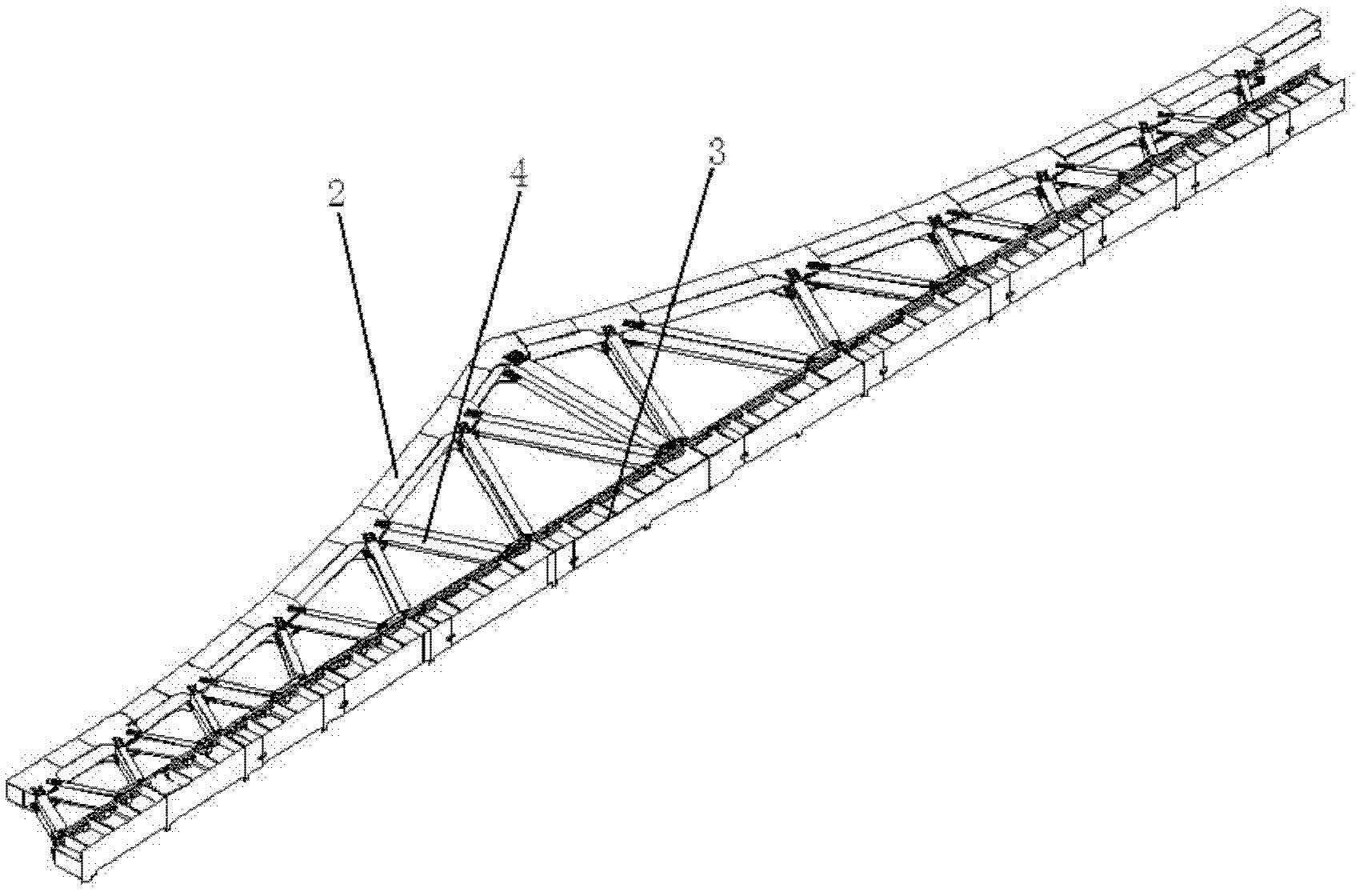

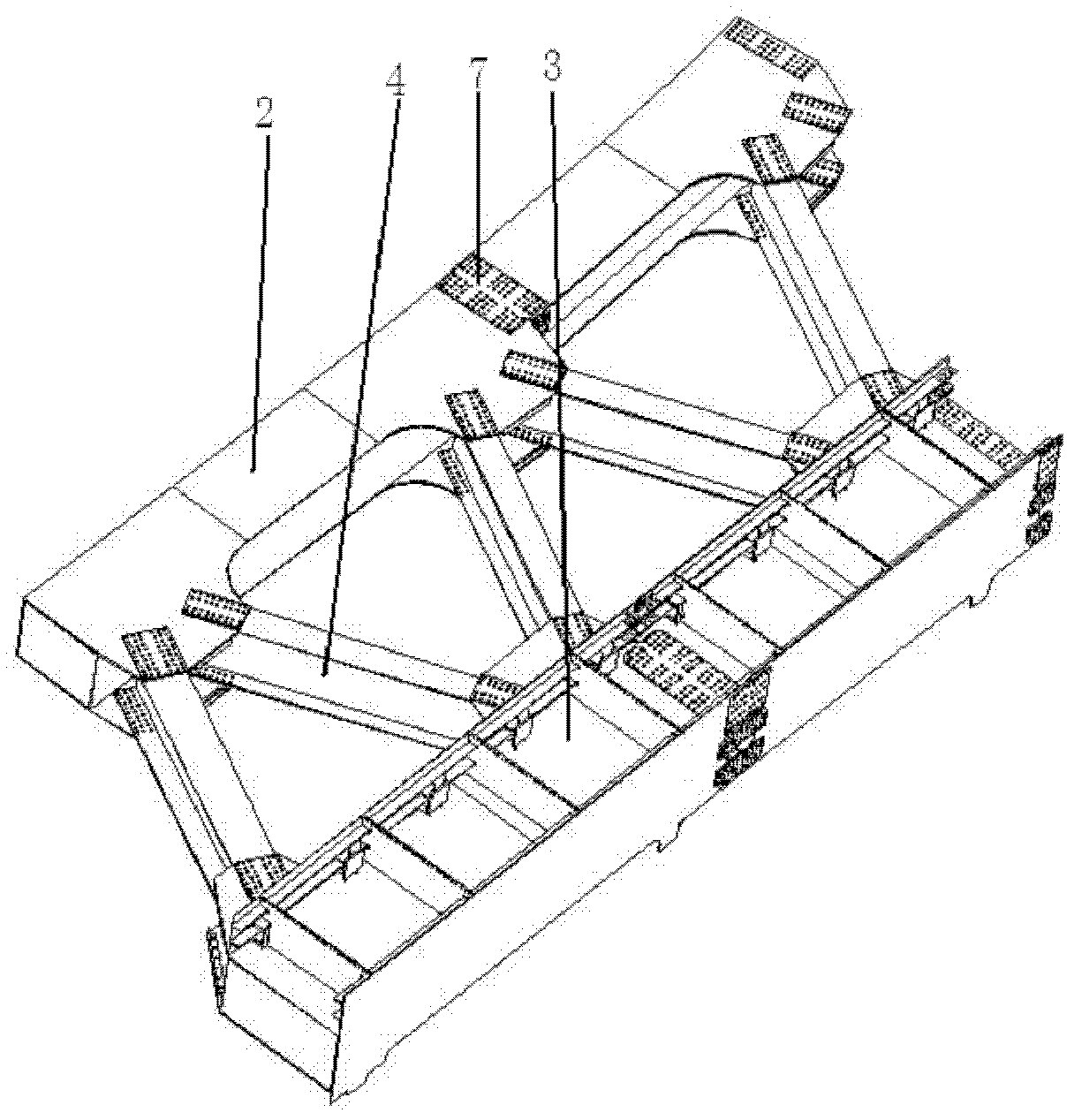

[0032] like Figure 1 to Figure 8 As shown, a steel truss bridge includes a steel box girder deck 1, a main truss composed of two steel trusses, and a steel gantry 6. The height of each steel truss adopts a quadratic parabolic variation form, and the span height on both sides is 3m , the mid-span height is 10.5m, and the mid-pivot height is 17m; the steel truss includes upper chord 2, lower chord 3 and web 4, and the two ends of web 4 are respectively inserted in upper chord 2 and lower chord 3 and passed through bolts Connection; sidewalk brackets 5 are provided on the outside of each steel truss; the lower chords 3 are respectively connected to the steel box girder deck 1 and the sidewalk brackets 5 through bolt welding. Wherein the steel door frame 6 includes a horizontal upper chord, a mid-web rod, and an arc-shaped lower chord, each of which is connected by a bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com