Pumping truss type suction dredger and mounting method

A dredging machine and truss-type technology, applied in separation methods, chemical instruments and methods, feeding/discharging devices of settling tanks, etc., can solve the problems of low sludge cleaning efficiency, reduce rework, and prevent sludge The effect of overflowing and ensuring the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

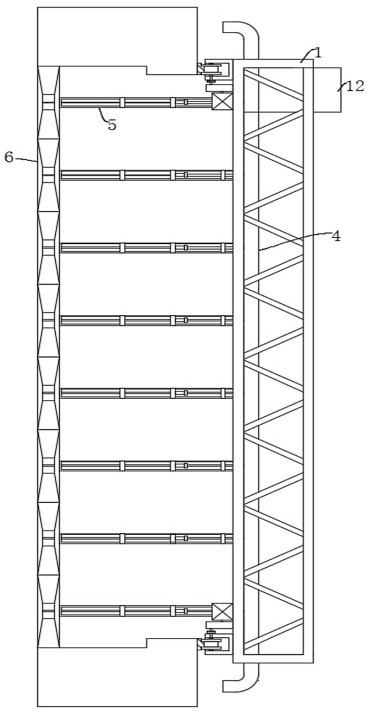

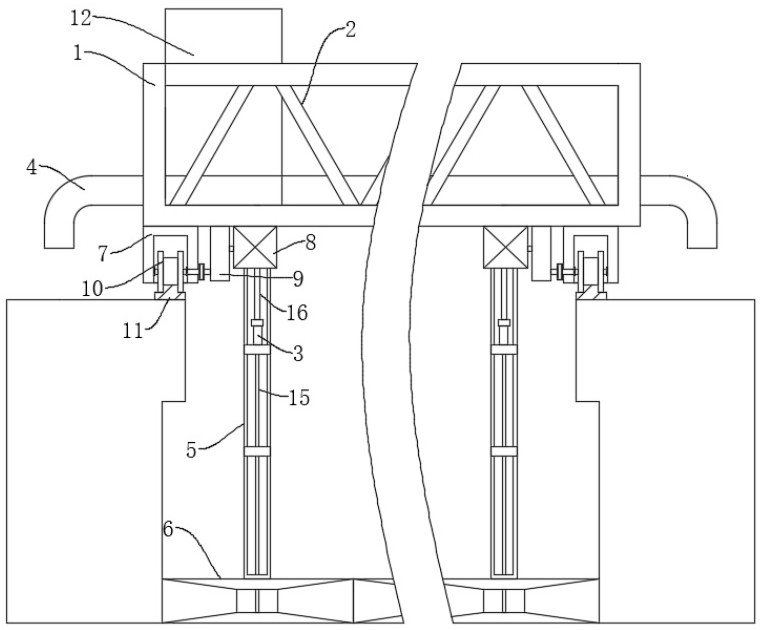

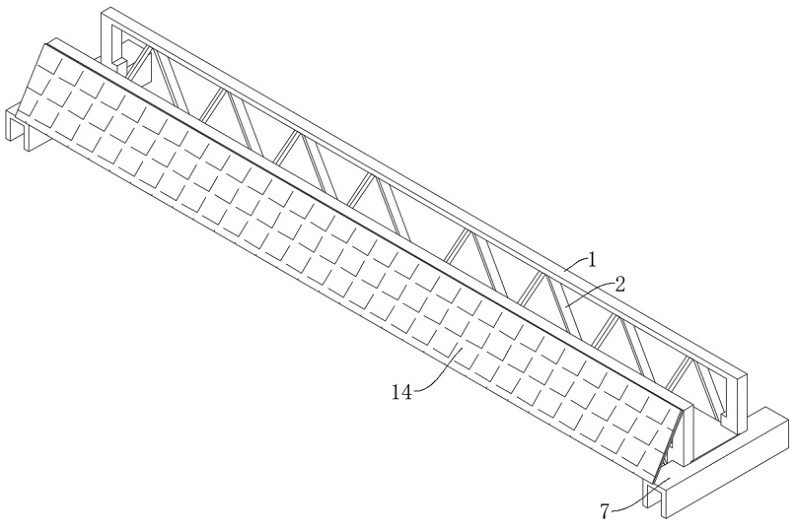

[0037] Embodiment one: refer to Figure 1-Figure 6 , a pump-suction truss-type dredger, including a horizontal truss 1, also includes: an end beam 7 fixedly connected to the bottom of the horizontal truss 1, the end beam 7 is provided with a driving part for driving the horizontal truss 1 to move; fixed on The steel frame 5 at the bottom of the horizontal truss 1; the mud scraping box 6 fixedly connected to the bottom of the steel frame 5, the mud scraping box 6 is provided with two connected trapezoidal grooves 602, and the mud scraping box 6 is provided with a mud collecting groove 601, The steel frame 5 is provided with a dredge pump 3, the input end of the dredge pump 3 is fixedly connected with a first pipeline 15, and the end of the first pipeline 15 away from the dredge pump 3 runs through the top of the mud scraping box 6 and extends to the mud collection tank 601 Inside: the mud discharge pipe 4 fixedly connected to the horizontal truss 1, the output end of the dredge...

Embodiment 2

[0045] Embodiment 2: An installation method of a pump-suction truss-type dredger adopts the following steps: Step 1: Take safety measures and environmental protection measures: Participating construction personnel must be familiar with safe operating procedures, and technical personnel shall carry out technical Safety disclosure; safety signs and warning signs are set up in the construction area, fences are set up around the filter pool, and signs are pasted on the equipment pipelines to prevent misuse; personal labor protection articles and safety protection measures are used correctly; special types of work must be certified; hoisting operations During the hoisting process, no one is allowed to stand under the jib and within the turning radius of the crane; temporarily use electricity on the construction site The relevant provisions of the JGJ "Technical Specifications for Temporary Electricity Use at Construction Sites" should be strictly followed. The installation, maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com