Method for lifting concrete in ultrahigh reducing steel pipe column

A construction method and technology of concrete roof, applied in the direction of architecture and building structure, can solve problems such as jacking failure and low success rate, and achieve the effects of high construction efficiency, reduced frictional resistance, and easy guarantee of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following examples are hereby described in detail as follows:

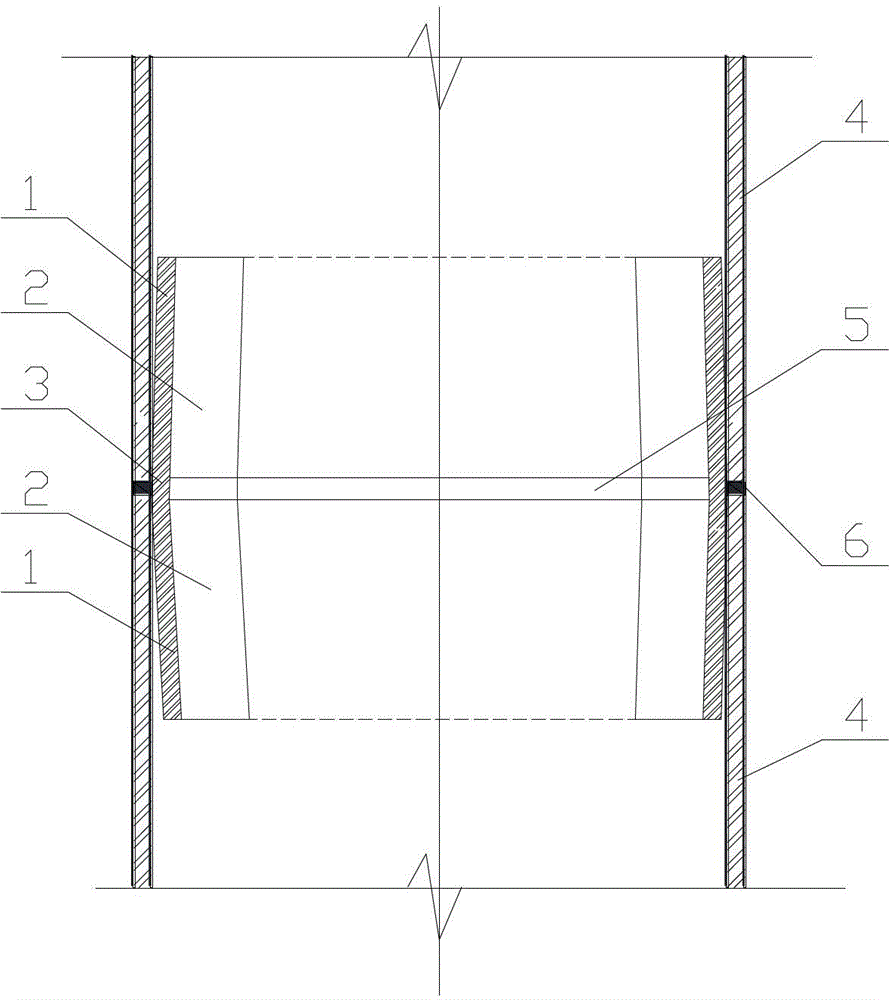

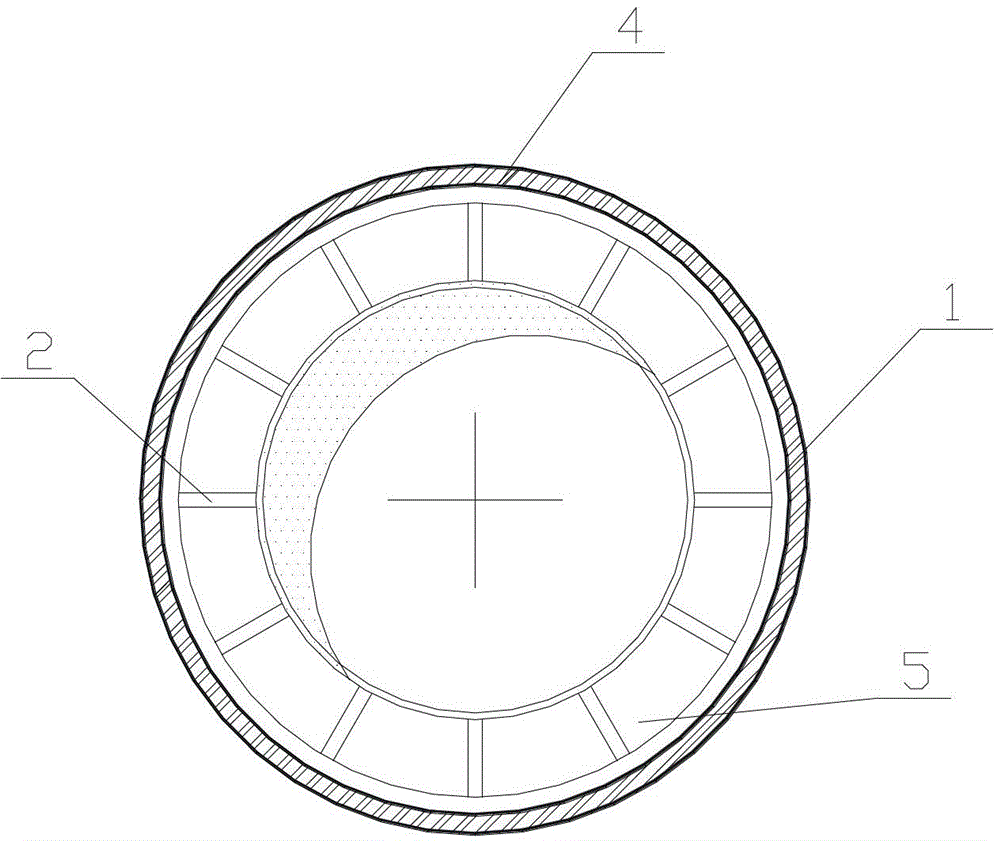

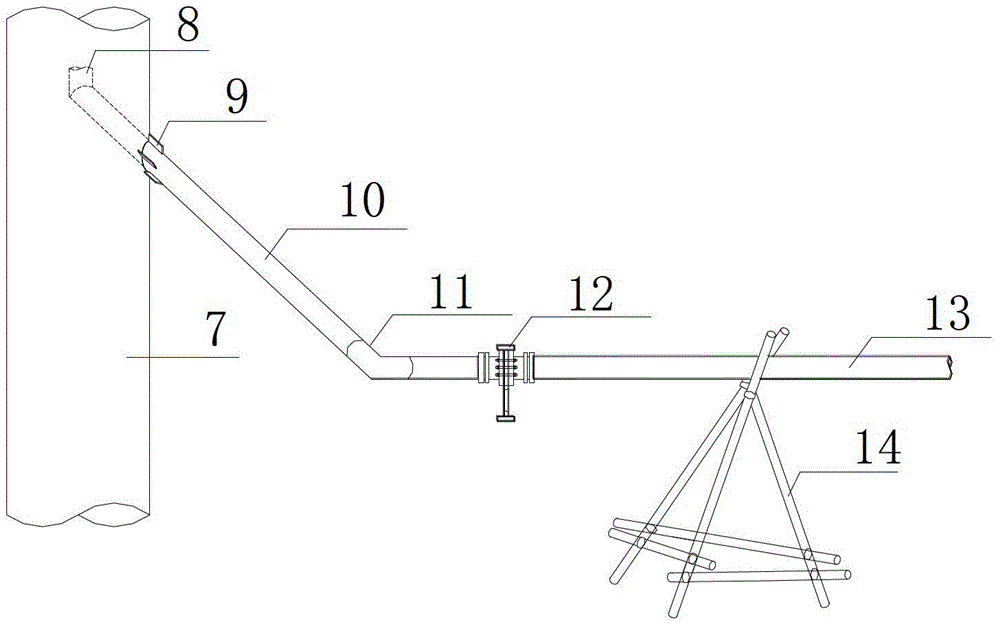

[0022] See Figure 1 to Figure 5 , the height of the concrete steel pipe column 7 of a certain project is greater than 33m, which belongs to the ultra-high variable-diameter steel pipe column. The middle section of the pipe fitting is a cylindrical section 3, and the outer diameter of the cylindrical section 3 is the same as the inner diameter of the steel pipe 4 forming the steel pipe column. The two ends of the cylindrical section 3 are tapered connecting sections 1 that gradually shrink. The annular reinforced flat plate 5 has a plurality of evenly distributed reinforced vertical plates 2 above and below the annular reinforced flat plate 5, and each reinforced vertical plate 2 is integrally formed on the inner wall of the pipe fitting along the radial direction of the inner circle of the pipe f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com