Parabola-shaped lap joint assembly type channel

A parabolic, prefabricated technology, applied in artificial waterways, irrigation pipelines, water conservancy projects, etc., can solve the problems of poor stress and frost heave resistance of prefabricated components, poor deformation ability of canal foundations, and poor connection and water-stop effect. Achieve the effect of easy assurance of engineering quality, fast installation speed and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

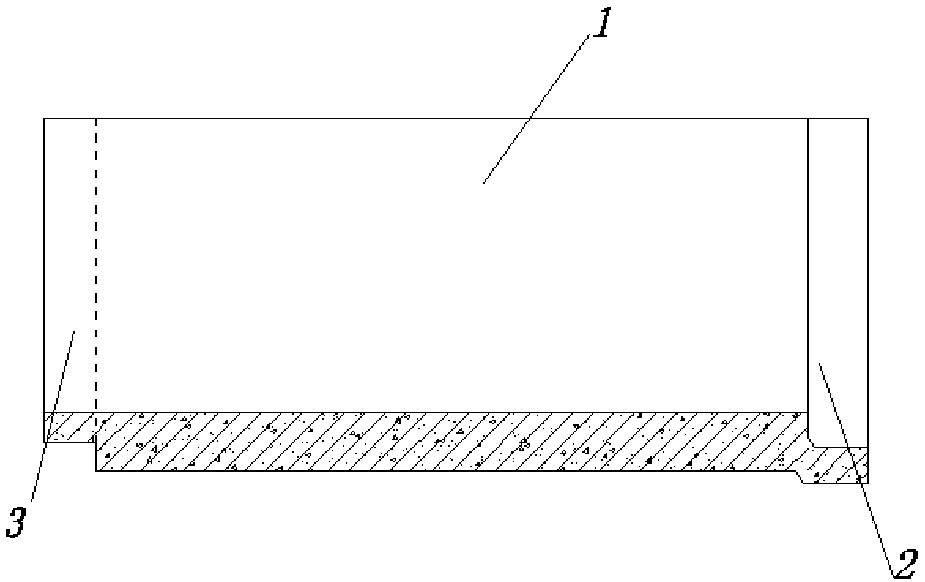

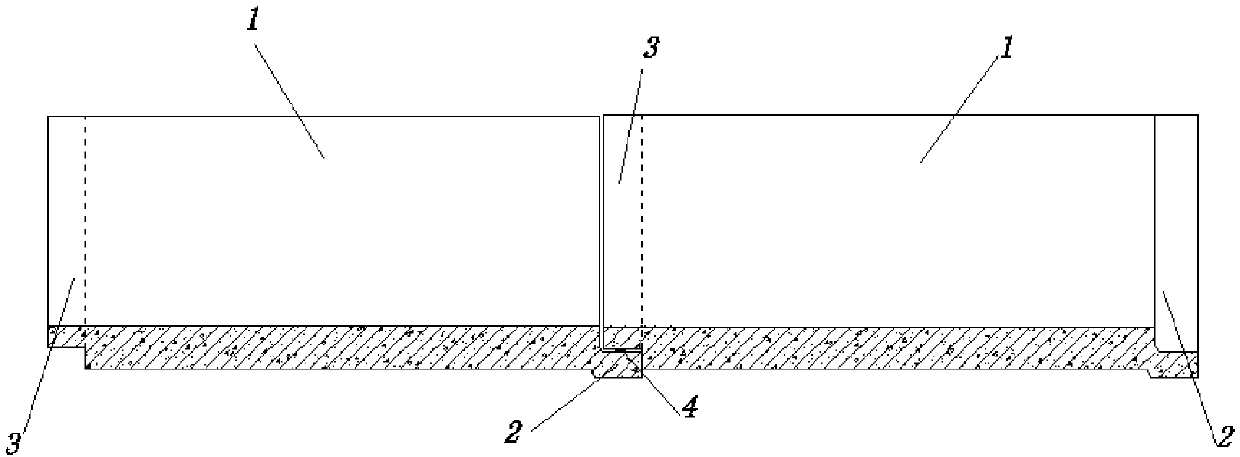

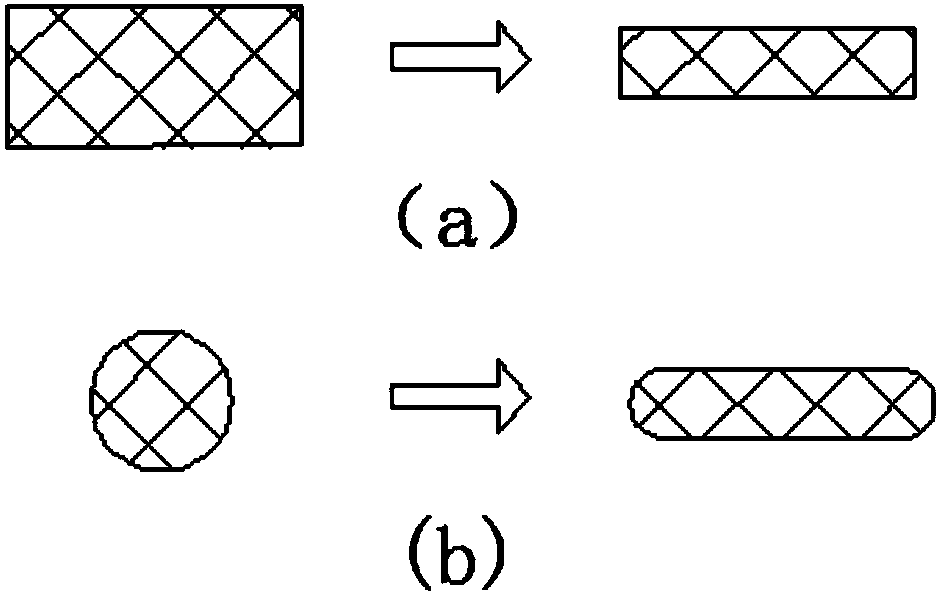

[0024] figure 1 Among them, the parabola-shaped overlapping assembled channel includes a single channel 1, and the plurality of individual channels 1 are overlapped together to form channels of different lengths, and one side of the single channel 1 extends outward. A stepped joint 2; or the other side of the trench 1 extends outwards a horizontal joint 3, of course, both sides of a single trench 1 in the present invention can also be respectively provided with a horizontal joint 3 and a stepped joint 2. The bottom of the lap 3 is higher than the bottom of the groove 1, so that a space for the joint 2 is formed, and the lap 3 and the lap joint 2 can cooperate with each other; the main function of the lap 3 and the joint 2 is to form a lap The connection structure enables multiple independent trenches 1 to be quickly connected together, and the setting of the overlap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com