Structure and Construction Method of Steel Anchor Pipe Reinforcing Weathered Rock Strata Reinforced Balance Weight Retaining Wall

A technology of steel anchor pipes and retaining walls, which is applied in the direction of foundation structure engineering, underwater structures, artificial islands, etc., can solve the problems of pile growth, long digging and drilling construction period, unfavorable construction cost control, etc., and achieve wall thickness Reduced, easy to guarantee engineering quality, good effect of reinforcement and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

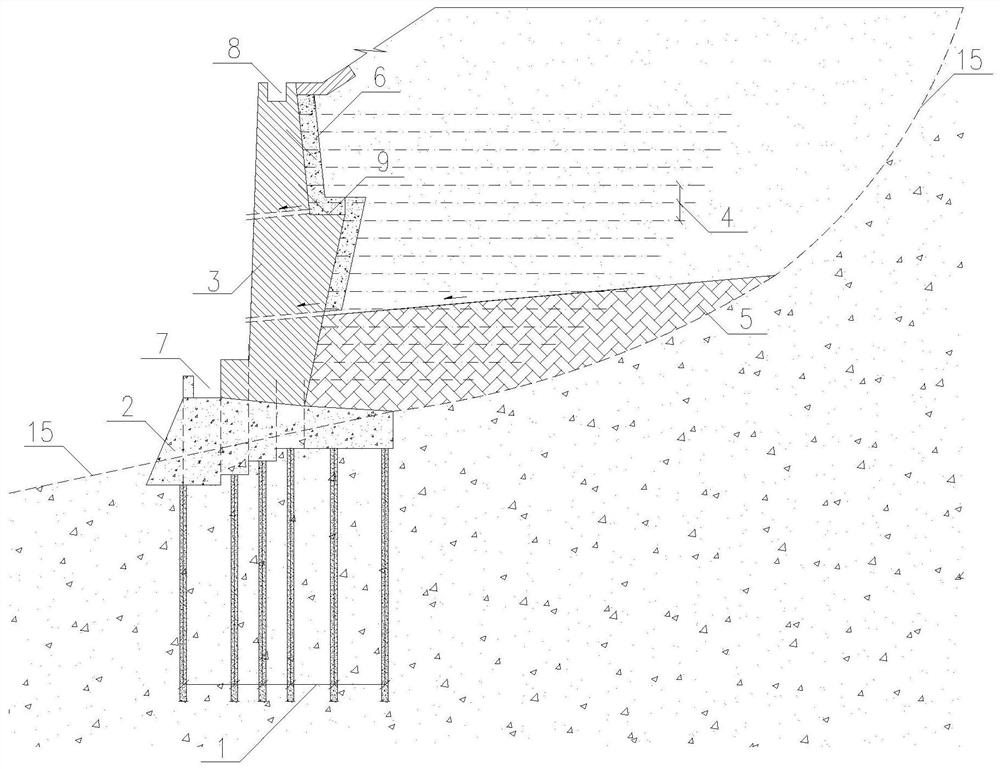

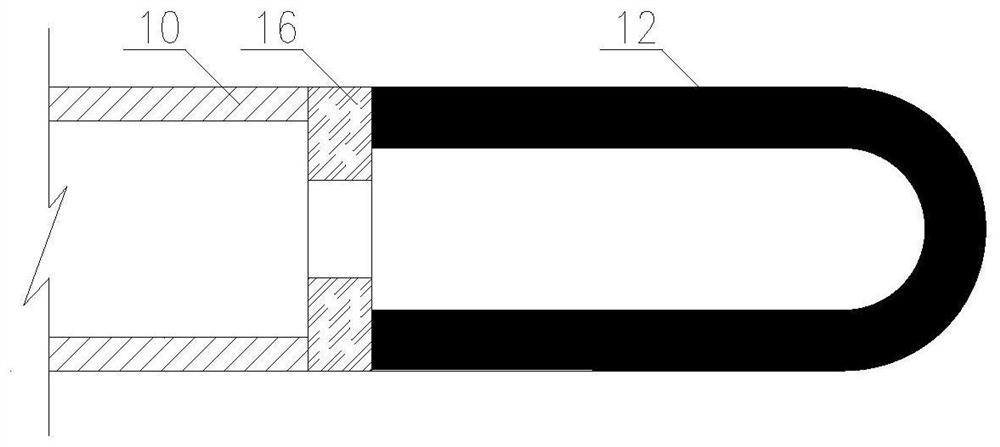

[0030] like figure 1 As shown, the steel anchor pipe of the present invention strengthens the weathered rock layer foundation and the joist foundation reinforced balance type retaining wall structure is composed of a steel anchor pipe 1, a step concrete base 2, a balance type retaining wall 3, a geogrid 4, The clay lower seal layer 5, the gravel filter layer 6, the drainage ditch 7 at the bottom of the wall, and the drainage ditch 8 at the top of the wall. The steel anchor pipe 1 is obtained by secondary grouting to the inside and outside of the steel pipe 10, wherein the outer grouting body of the steel pipe 10 and the weathered rock and soil around the steel pipe 10 form a composite soil around the pipe to reinforce the weathered rock formation. The whole steel anchor pipe 1 is located in the geology of the weathered rock stratum, and the lower ends of each steel anchor pipe 1 are at the same horizontal line, while the heights of the upper ends show step-like differences; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com