Prefabricated L-shaped concrete multilayer multi-step retaining wall

A prefabricated concrete and retaining wall technology, applied in the field of retaining walls, can solve problems such as restrictions on inclined piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

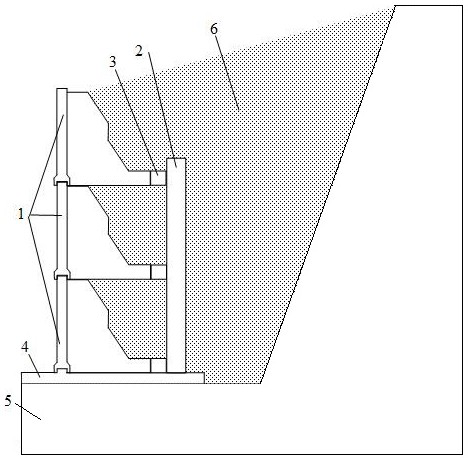

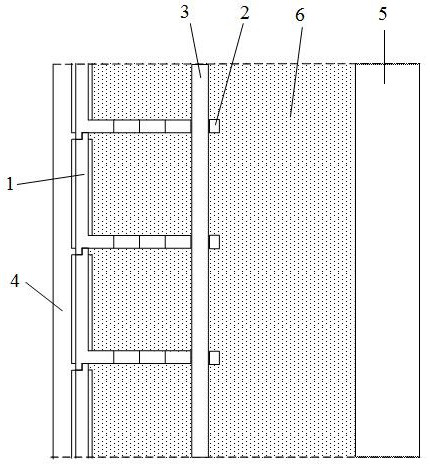

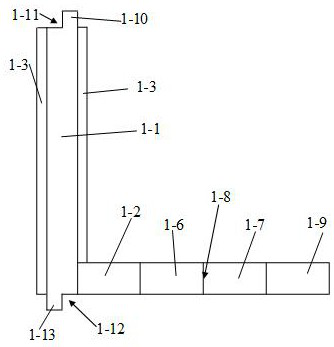

[0018] A prefabricated L-shaped concrete multi-layer multi-step retaining wall, comprising L-shaped stepped prefabricated concrete retaining wall panels 1, concrete columns 2, concrete beams 3, toothed tenon bottom plates 4, original soil 5, and filled soil 6, the The toothed tenon bottom plate 4 is located on the original soil 5, and the toothed tenon bottom plate 4 is provided with an L-shaped stepped precast concrete retaining wall panel 1, and the bottom of the L-shaped stepped precast concrete retaining wall panel 1 is provided with a joint with the toothed tenon bottom plate 4. The connecting grooves 1-4 where the teeth and tenons fit together; the L-shaped stepped precast concrete retaining wall panels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com