Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Meet layout requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

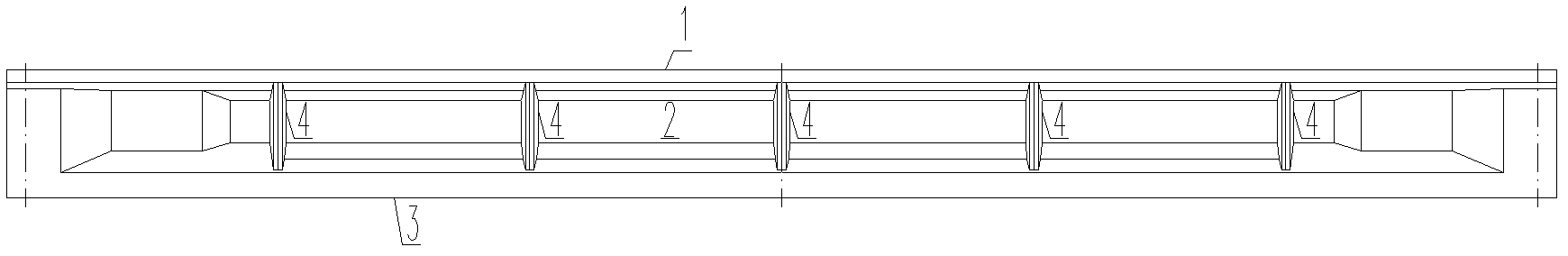

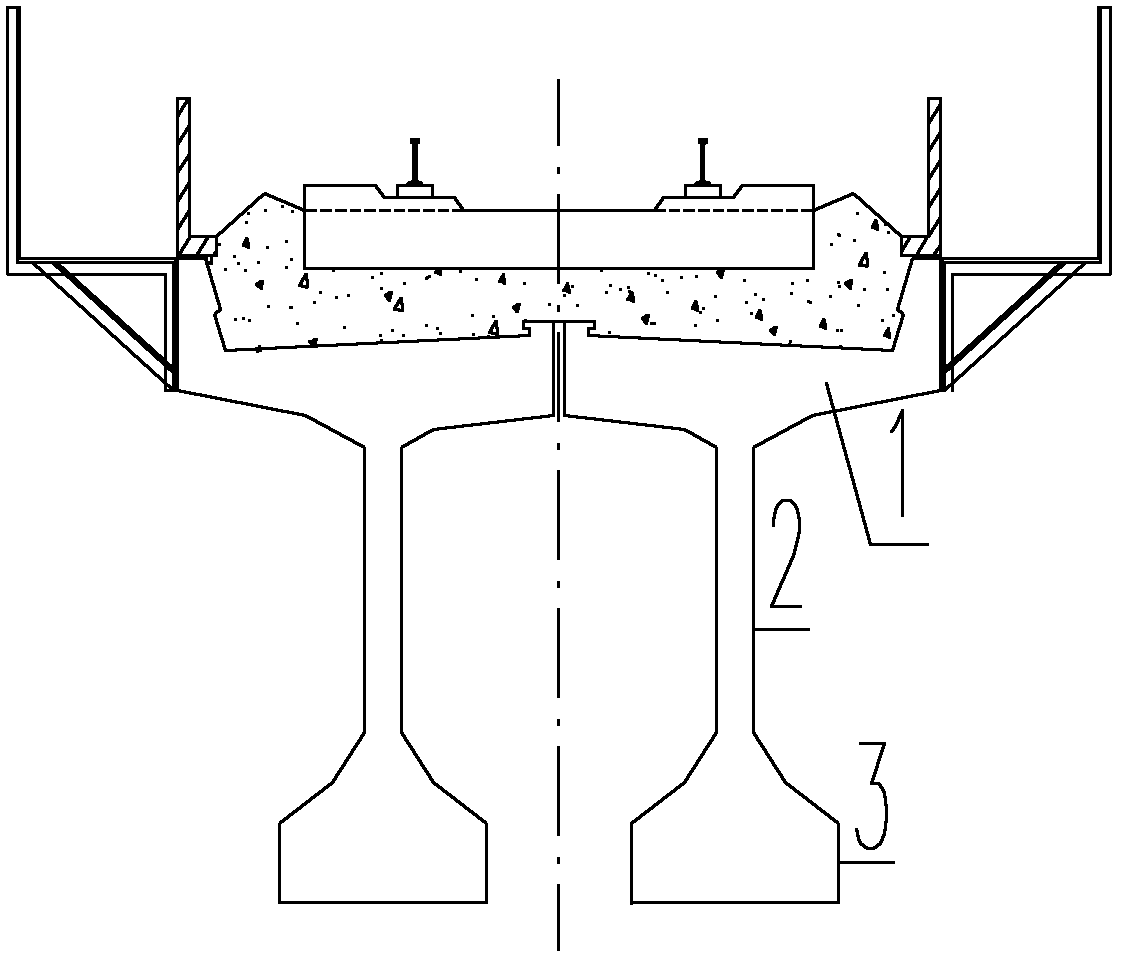

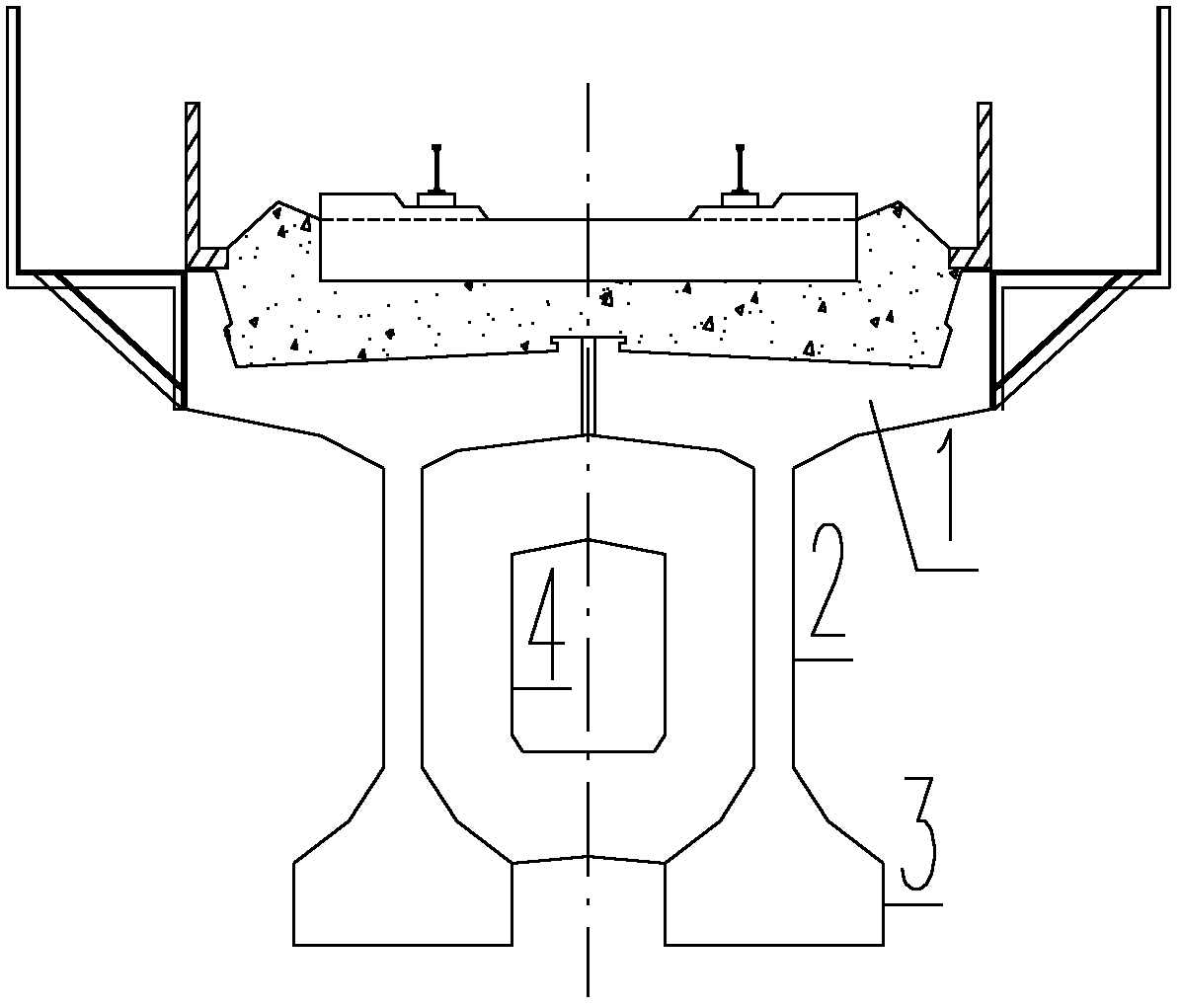

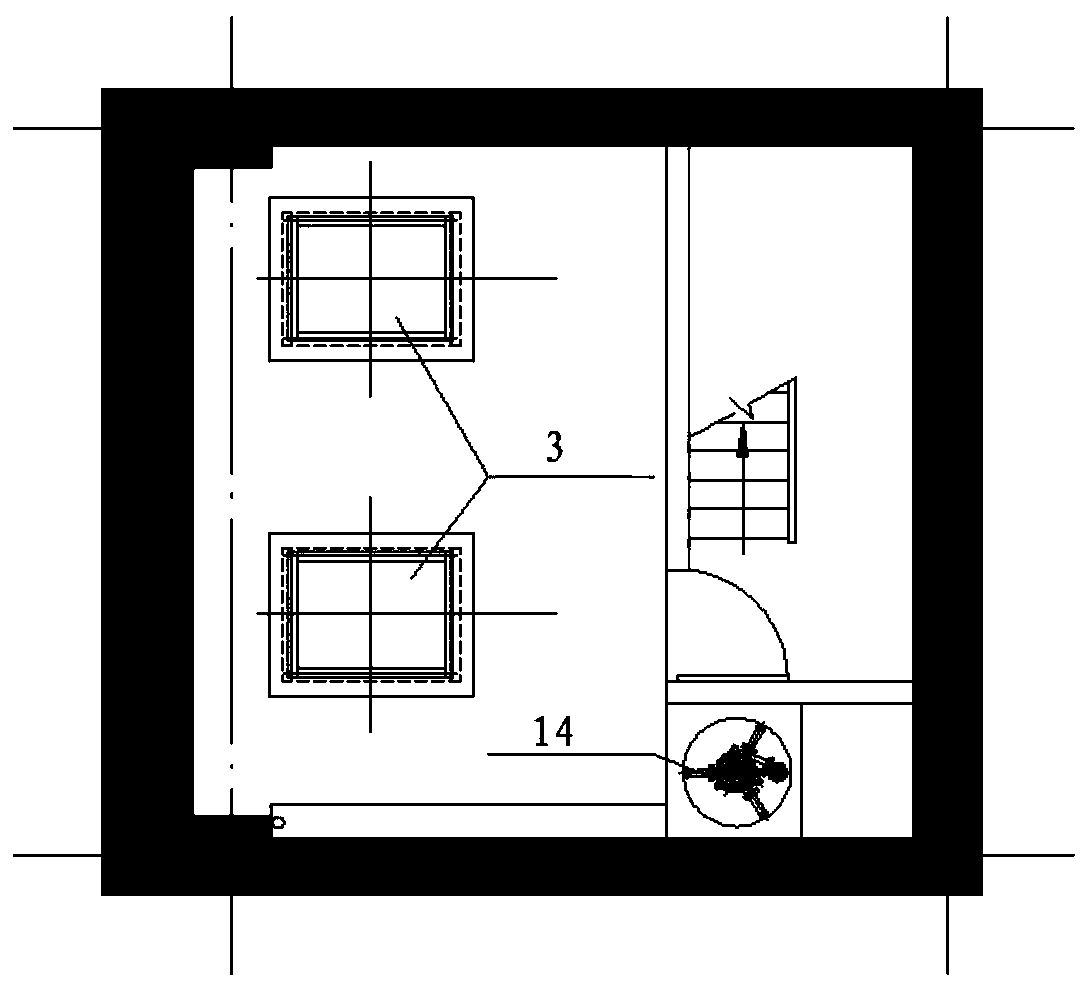

Self-balancing external prestressing strengthening method for bridge structure

ActiveCN102587296AReduce the burden onGive full play to the role of reinforcementBridge erection/assemblyBridge strengtheningConcrete beamsT-beam

The invention relates to a self-balancing external prestressing strengthening method for a bridge structure. The self-balancing external prestressing strengthening method is characterized by comprising the following steps of: carrying out interface processing at a connecting place (5) of a top flange of a concrete beam; (2) inserting reinforced bars at the connecting place (5) of the top flange of the concrete beam; (3) installing the reinforced bars at the connecting place (5) of the top flange of the concrete beam; (4) installing the reinforced bar of a steering block (6) and a diverter (9) at the bottom of the beam; (5) symmetrically adding diaphragm plates at a place far away from the end of the beam by 2-3m, and installing an anchorage device (10); (6) concreting the connecting place (5) of the top flange of the beam, the steering block (6) and the newly added diaphragm plates (8); and (7) installing and tensioning an anchoring external cable, thus obtaining a self-balancing external prestressing strengthening structure. An external prestressing system can be used for detecting and adjusting the stress of the cable at any time, inspecting the corrosion condition of the cable and can also be used for maintaining and replacing the cable when necessary. The self-compacting concrete solves the problems of dense reinforcement assembly, complex structure, narrow space of formworks and traditional structural members, cavities caused by the blocking of aggregates and the like, effectively ensures the dense degree of placing concrete and increases the strengthening effect. The self-balancing external prestressing strengthening method can be used for strengthening heavy railroad brides, concrete box girders and T beams.

Owner:SHUOHUANG RAILWAY DEV +3

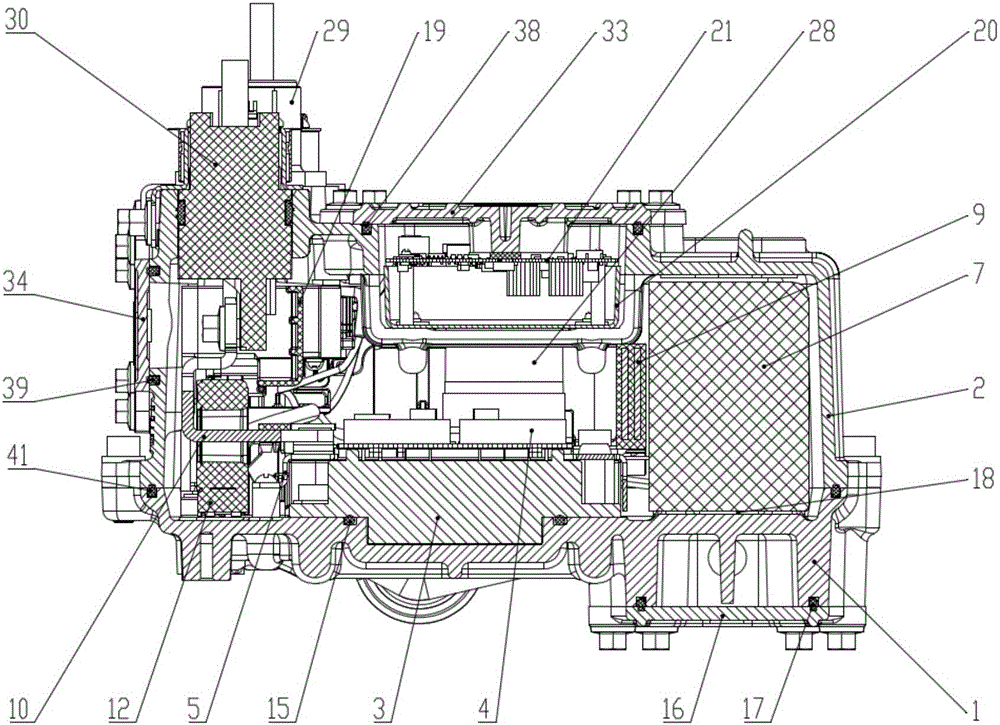

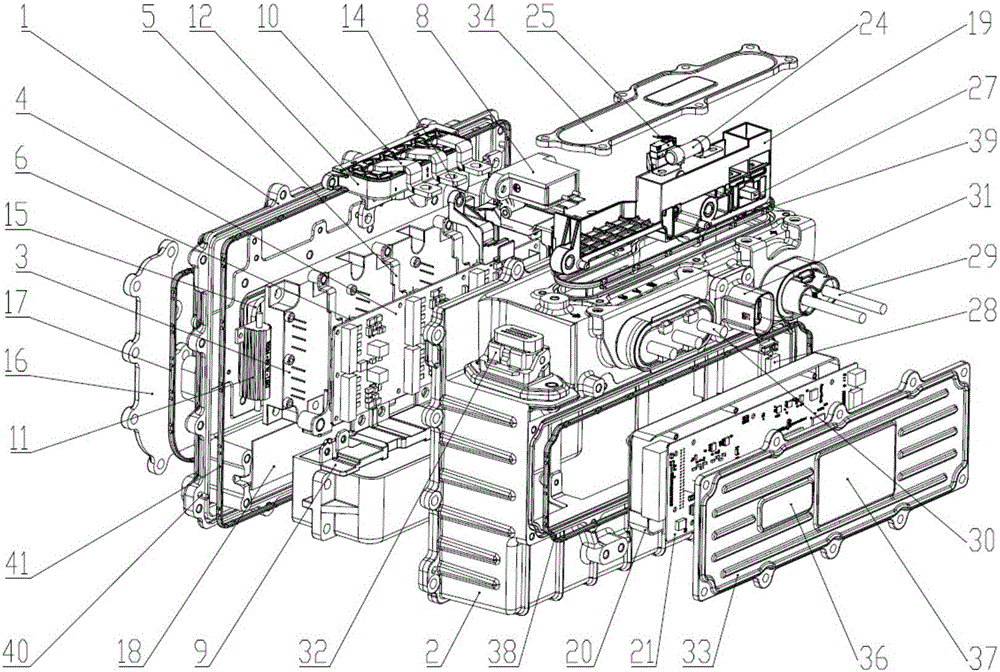

Electric car motor controller

ActiveCN105846750AReduce volumeAchieve mutual complementarityAC motor controlCooling/ventilation/heating modificationsCapacitanceLow voltage

The invention relates to an electric car motor controller. The controller comprises a direct current bus capacitor, an IGBT module, a metal support, a driving board, a current sensor, an AC busbar, a DC busbar assembly and a Y capacitor which are arranged in a main box body. An upper box body is also included. An internal portion of the upper box body is provided with a wire connection seat assembly, a shielding board, a control board, a cathode change over busbar, an anode change over busbar, an air conditioning connector, a microswitch, an air conditioning insurance and a direct-current high-voltage interlock connector. A direct current connector, an alternating current connector, an air conditioning connector, a low voltage connector, a control board cover and a junction box cover are fixed to an external portion of the upper box body. When the motor controller provided in the invention works, an IGBT and the direct current bus capacitor are vertically placed so that the controller can flexibly adapt to whole car arrangement. And simultaneously the controller possesses advantages that the structure is compact; power density is high; a heat dissipation effect is good; electromagnetic compatibility is good; operation safety is high and so on.

Owner:CHINA FIRST AUTOMOBILE

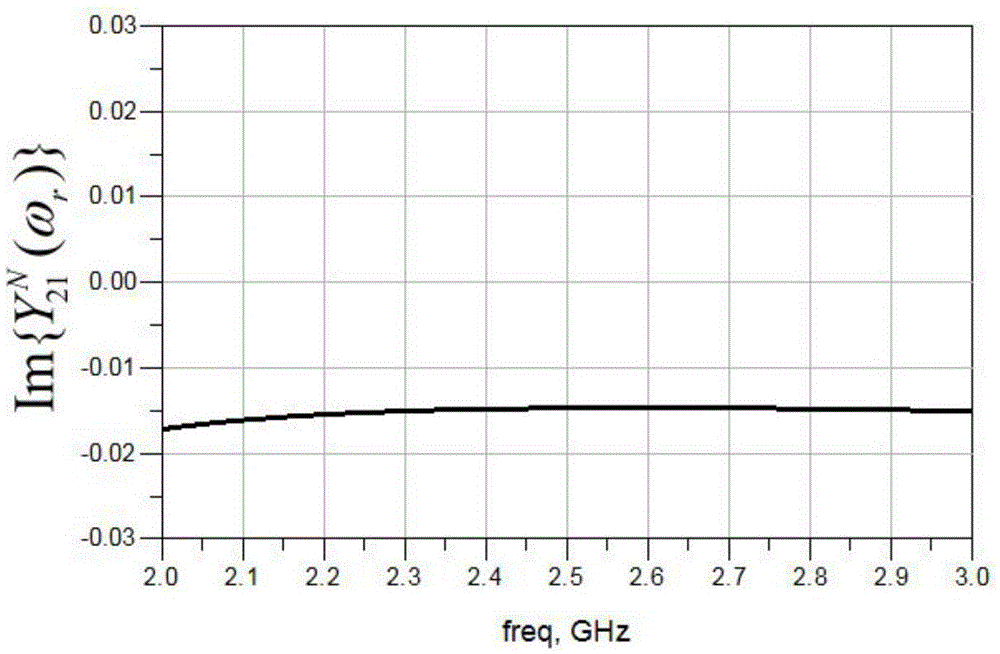

Antenna mutual-coupling elimination device and method and wire communication device

InactiveCN105633575AMatch does not affectImprove isolationAntenna couplingsFrequency spectrumPhased array

The invention discloses an antenna mutual-coupling elimination device and method and a wire communication device. The antenna mutual-coupling elimination device comprises an interference elimination circuit, wherein the interference elimination circuit is arranged between a pair of coupling antennas, and the interference elimination circuit and a matching circuit of the antenna form a decoupling network. In the antenna mutual-coupling elimination device, the decoupling network jointly formed from the interference elimination circuit and the matching circuit can be used for effectively reducing interference and influence caused by antenna coupling, the antenna radiation efficiency is improved, a far-field pattern of the antenna is changed, the spatial correlation of the antenna is reduced, the demands of a new-generation wireless communication system on channel capacity, data throughput rate and reliability are met, and the spectrum efficiency utilization ratio of the communication system can be improved. Meanwhile, the coupling elimination technology can be suitable for various types of multi-antenna wireless communication terminals, base stations, phased array radars, transceivering assemblies and other communication systems.

Owner:SHENZHEN WEIYINGZHI TECH CO LTD

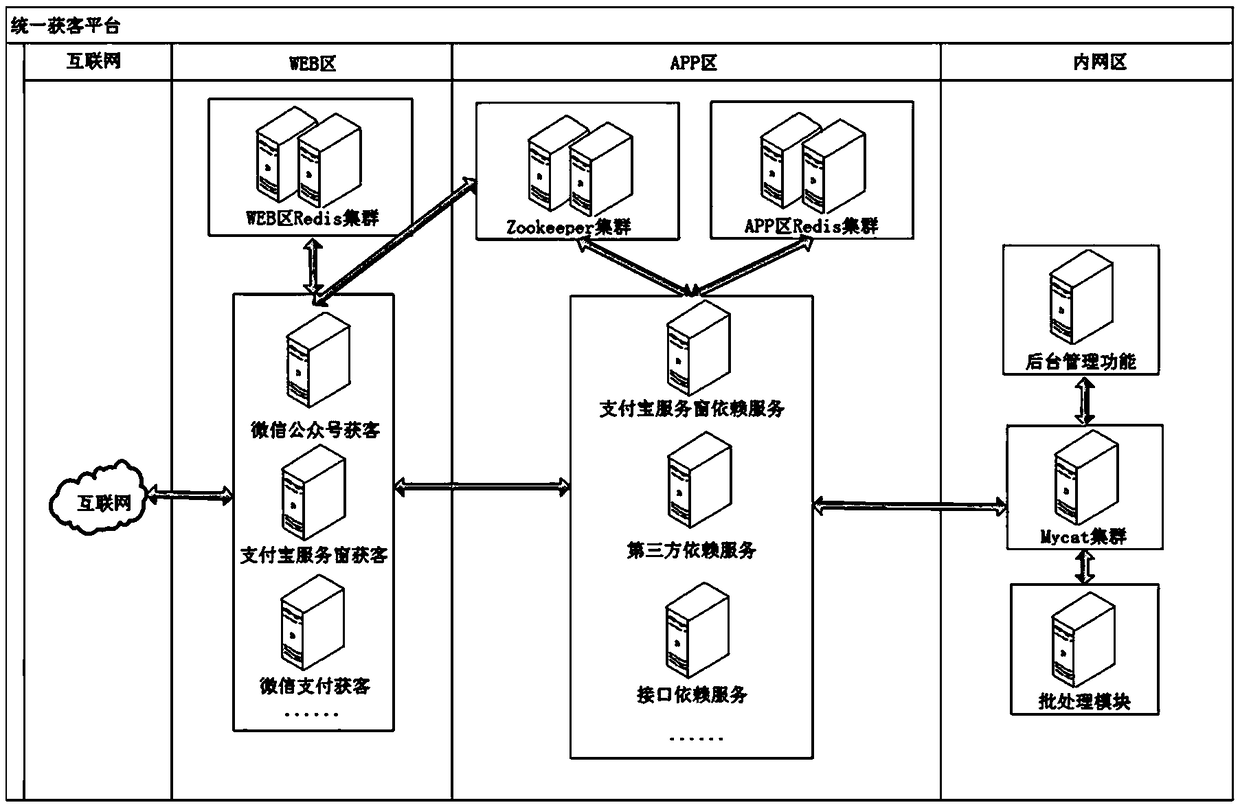

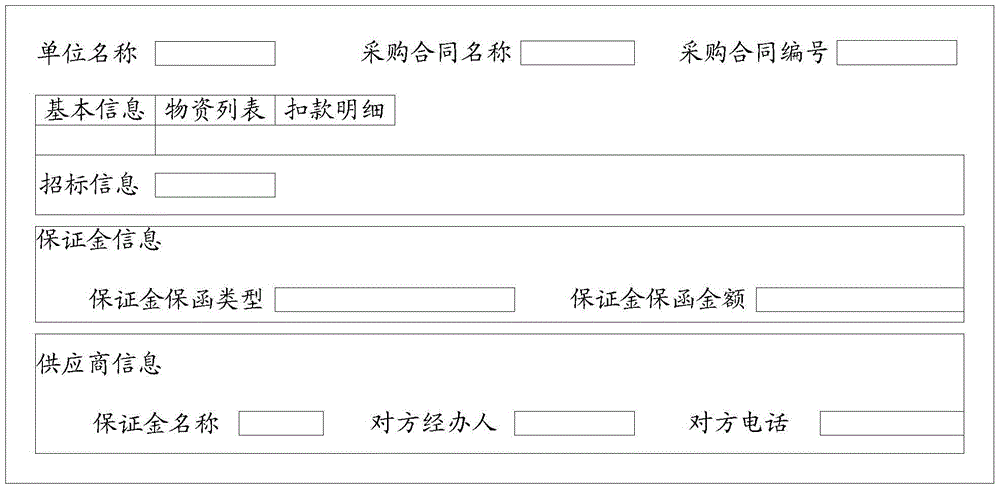

A multi-channel customized credit card intelligent application system

ActiveCN109377321AConvenient and efficient online card application experienceReduce manpower and material costsFinanceBuying/selling/leasing transactionsFingerprintData monitoring

The invention relates to a multi-channel customized credit card intelligent application system. The system comprises an information channel subsystem, which is used for providing customers with card handling channel and payment channel, and supporting customers to realize electronic contract signature. A unified guest receiving platform is used for realizing information exchange with the information channel subsystem and carrying out data processing and data monitoring on the credit card business; An internal subsystem for storing, managing and publishing the data processed by the unified guest receiving platform; Dependency subsystem is used to provide log library, behavior analysis and user fingerprint information collection functions for the unified guest platform. Compared with the prior art, the invention has the advantages of rich service handling channels, flexible customization, low human and material resources cost, strong management ability, strong expansibility and the like.

Owner:上海浦东发展银行股份有限公司信用卡中心

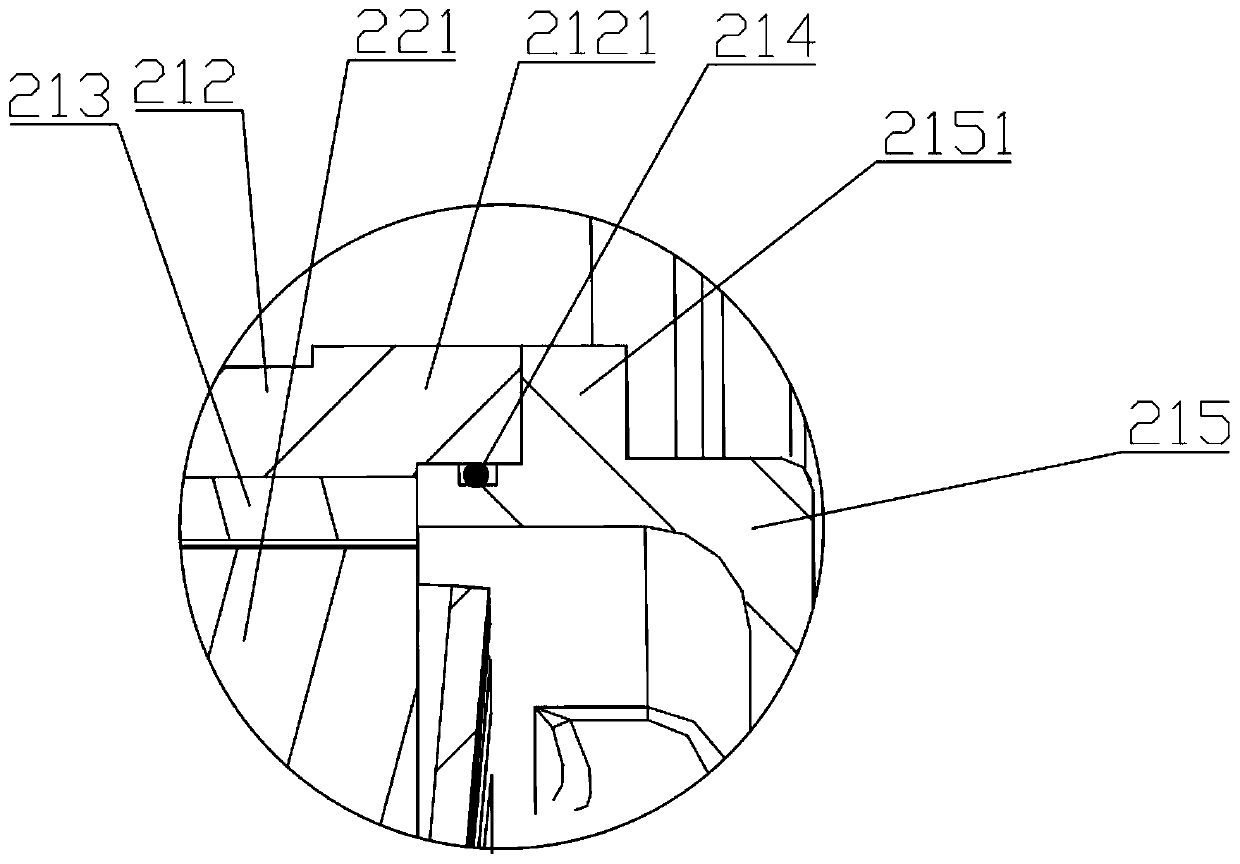

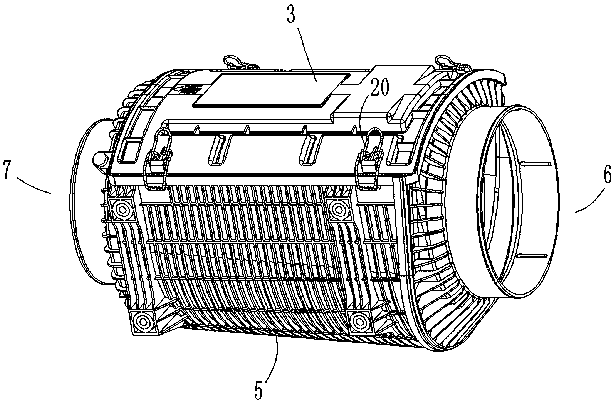

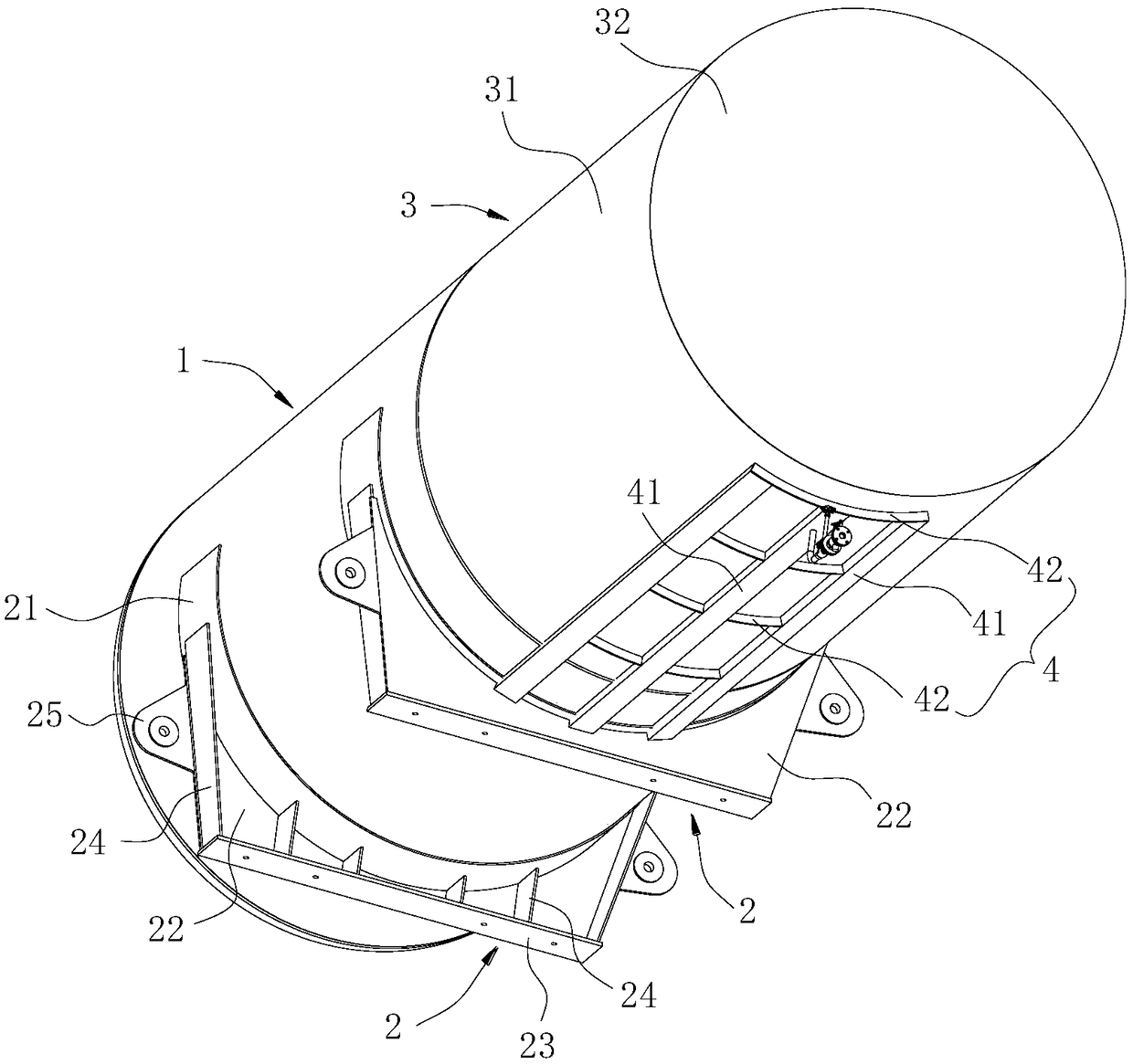

External rotor hub motor driving assembly

InactiveCN110022029ASmall structure sizeStable structureMagnetic circuit rotating partsMagnetic circuit stationary partsMotor driveEngineering

The invention provides an external rotor hub motor driving assembly. The external rotor hub motor driving assembly comprises a hub, a motor and a brake, wherein the motor is installed in the hub, andthe motor comprises a rotor assembly and a stator assembly; the rotor assembly is arranged outside the stator assembly; the stator assembly is connected with the power supply to drive the rotor assembly to drive the hub to rotate; the motor is further connected with the brake, and the rotor assembly is braked to enable the hub to stop rotating through the brake. The cooling structure and the supporting structure of the hub motor assembly are both integrated in the hub, so that the structure size of the motor is greatly shortened, and the cooling performance is high; two bearings are adopted for supporting the rotor assembly and the stator assembly, so that the positioning precision is high, and the structure is more reliable; and meanwhile, the structure of the driving assembly is simplified, the universality is high, and the arrangement requirements of various vehicle types on the driving assembly can be met. In addition, a brake disc is directly fixedly connected with the rotor assembly, so that the brake performance is better, and the reliability is higher.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

Riser column group vibration anti-collision and power generation device and method

InactiveCN106522853AMeet layout requirementsDrilling rodsPiezoelectric/electrostriction/magnetostriction machinesElectricityRotation function

The invention relates to a rotatable device and a method, and the device and the method can achieve piezoelectric power generation and vibration suppression synchronously. The device is composed of a rotation assembly, a piezoelectric assembly and a current guide assembly. The rotation assembly is responsible for achieving the rotation function of the whole device. Both the piezoelectric assembly and the current guide assembly are arranged in an asymmetrical mode. The piezoelectric assembly achieves power generation through deformation of piezoelectric patches. The current guide assembly generates torque needed by rotation through asymmetrical pore plates of different densities of pores. When seawater passes through cylindrical attached columns at the ends of the piezoelectric patches, the piezoelectric patches are induced to vibrate and deformed continuously, and a steady stream of currents is generated. A rotary current guide pate and the piezoelectric patches damage a streaming boundary layer on the surfaces of marine risers, formation of streaming vortexes is affected, and vibration suppression is achieved. By means of the marine risers, the device achieves piezoelectric power generation and vibration suppression synchronously.

Owner:SOUTHWEST PETROLEUM UNIV

Printed circuit board and wireless terminal adopting multiple-input multiple-output antenna technology

InactiveCN104218317AImprove isolationResolve interferenceRadiating elements structural formsAntenna couplingsMiniaturizationEngineering

Owner:ZTE CORP

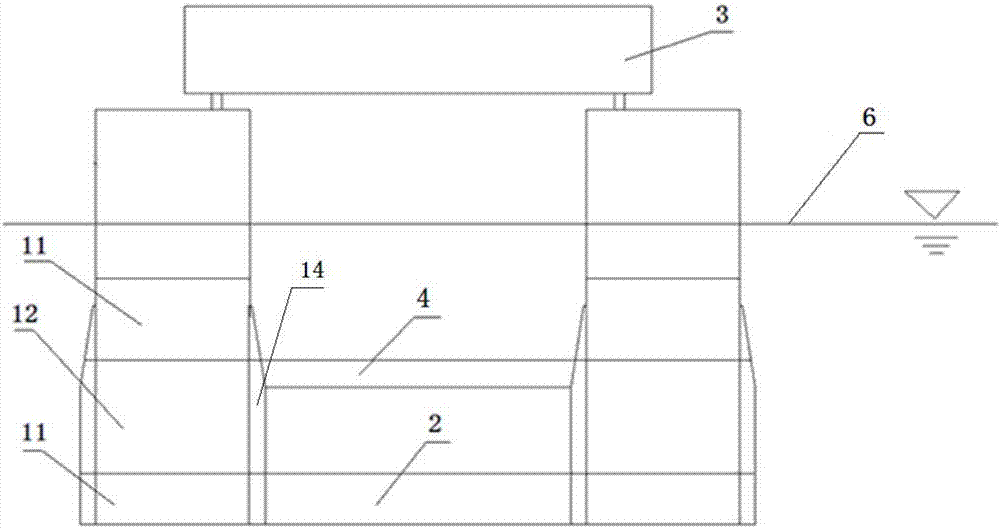

Deep draft dry-tree oil storage semisubmersible production platform

ActiveCN107140138ASmall range of motionSmall heave amplitudeFloating buildingsBallast tankBuoyancy function

The invention discloses a deep draft dry-tree oil storage semisubmersible production platform characterized by comprising columns, buoyancy tanks, and a topside module; the four buoyancy tanks are arranged on the bottom periphery of the semisubmersible production platform; the break angle between two adjacent buoyancy tanks is provided with the column; the top surfaces of the four columns support and are connected with the topside module; an oil tank is arranged in each column; a first ballast tank is respectively arranged on and below the oil tank in each column; the top of each column is provided with an equipment chamber; a void chamber is formed between the first ballast tank on the oil tank and the equipment chamber; a second ballast tank is arranged in each the buoyancy tank. The semisubmersible production platform uses the first ballast tanks to balance the oil tank crude oil amount changes, uses the second ballast tanks to ensure the whole production platform to have the draft depth at 50-60m, thus ensuring the whole platform to keep small moving amplitude and small heaving amplitude, satisfying SCR and dry-tree oil extraction requirements, and reducing engineering investments.

Owner:CHINA NAT OFFSHORE OIL CORP +1

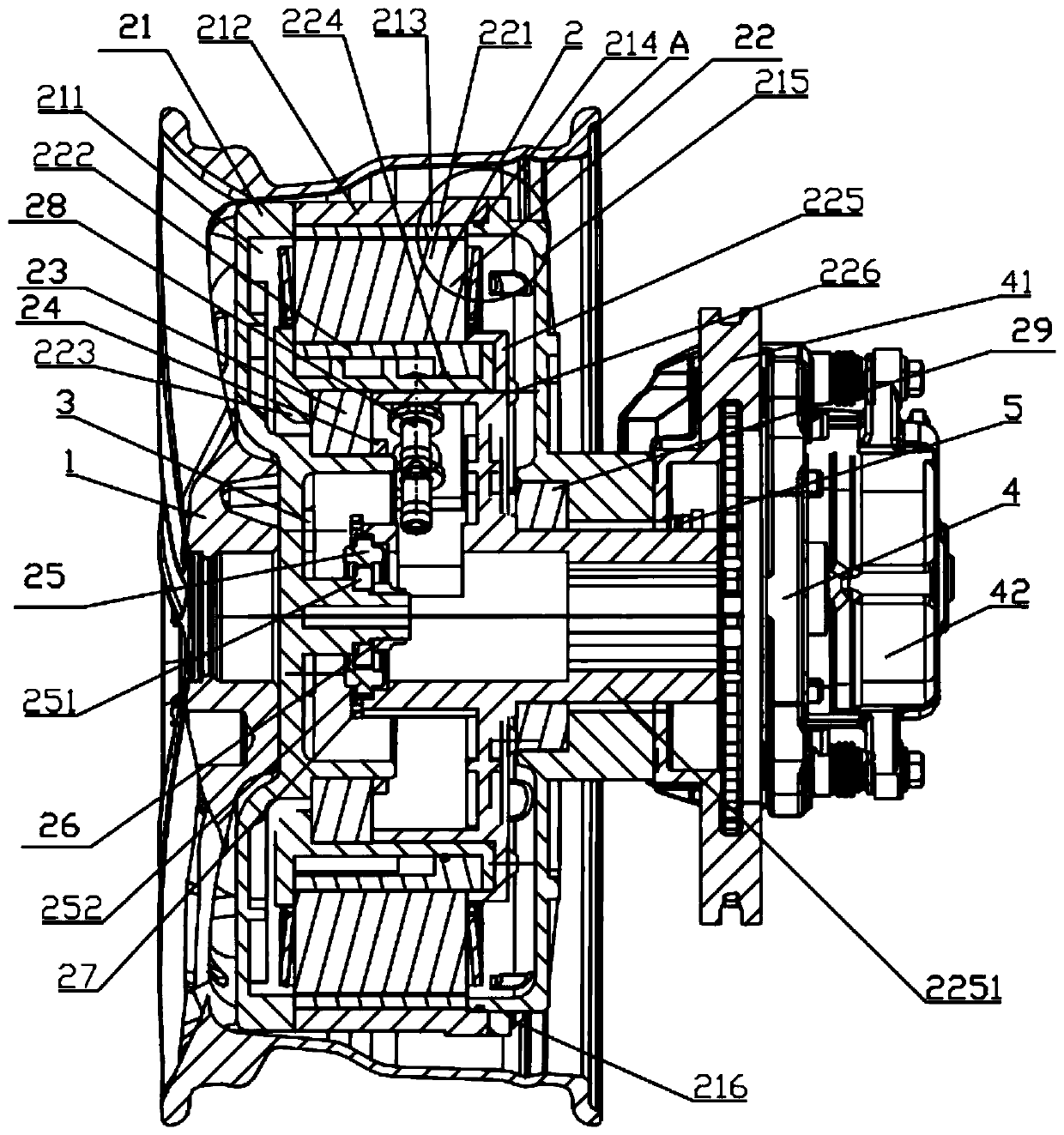

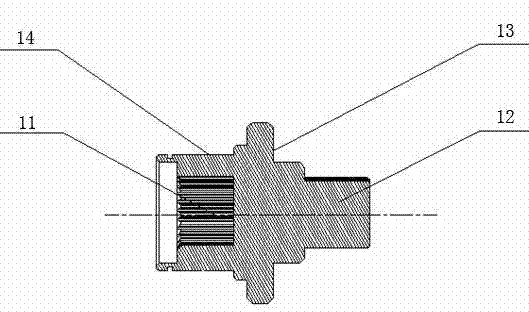

Motor integrated structure of hybrid electric vehicle

InactiveCN102358157AReduce axial sizeMeet layout requirementsHybrid vehiclesGas pressure propulsion mountingMotor driveElectric vehicle

The invention aims at providing a motor integrated structure of a hybrid electric vehicle, which comprises a motor drive shaft, a motor stator assembly, a motor rotor assembly, a motor revolver stator and a motor revolver rotor, wherein the motor drive shaft, the motor stator assembly, the motor rotor assembly, the motor revolver stator and a motor revolver rotor are integrated and assembled in an integrated shell and are respectively connected with a vehicle engine cylinder and a transmission installation shell through installation terminal surfaces at two sides of the integrated shell, one end of the motor drive shaft is connected with an engine through a vehicle dual-mass flywheel by adopting an external spline, and the other end of the motor drive shaft is connected with a transmission by adopting an internal spline. The motor integrated structure has the advantages of compact structure, convenience for installation, small arrangement space and the like, and solves the problem that motor assemblies are arranged in a limited space of an integral vehicle forecabin.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

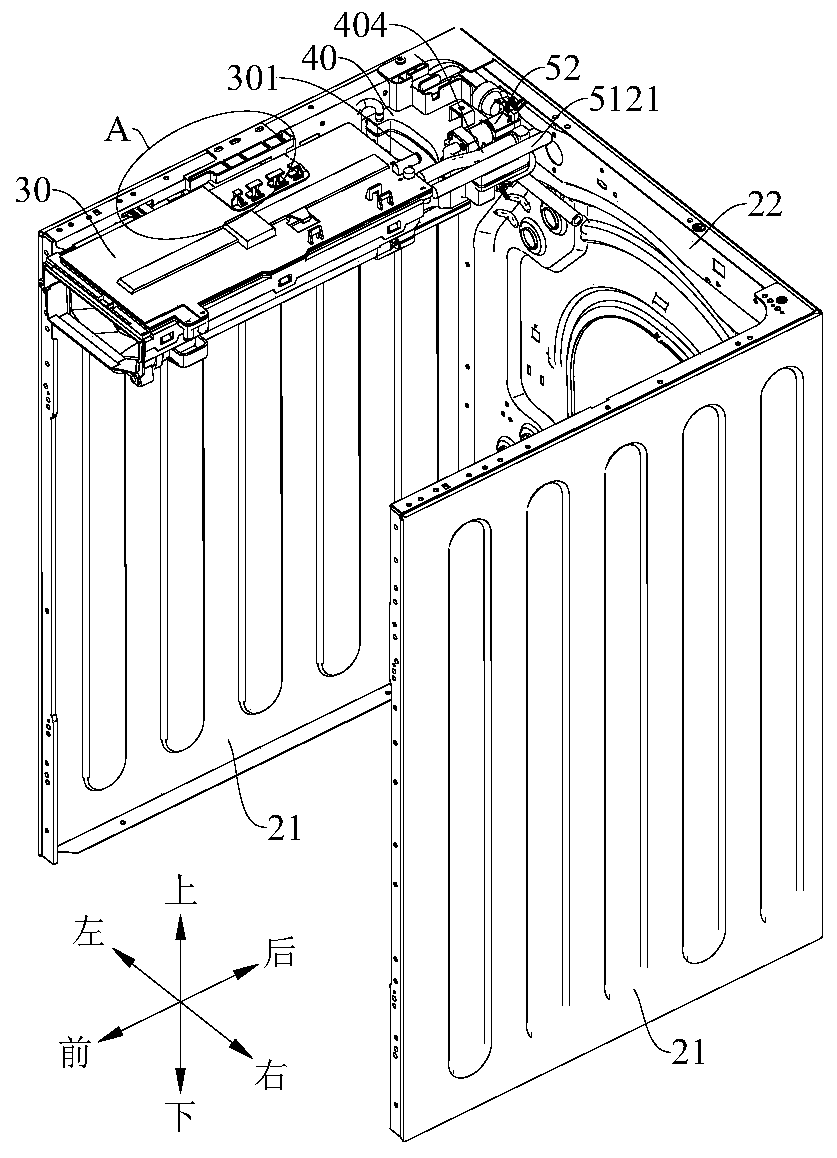

Garment treating device

ActiveCN109881443AReduce hardnessImprove experienceWater contaminantsOther washing machinesSaline waterWater softening

The invention discloses a garment treating device. The garment treating device comprises a base assembly and a garment processing module, wherein a regeneration processor is arranged in the base assembly; the garment processing module is arranged at the top of the base assembly, and a water softener is arranged in the garment processing module, and is communicated with the regeneration processor,wherein the water softener comprises a water softening piece for softening water, and the regeneration processor is suitable for reducing the water softening performance of the water softening piece.Compared with the technical scheme that a soft water cavity and a saline water cavity are integrally formed in the related technology, in the garment treating device in the embodiment, the water softener and the regeneration processor are separately arranged, the water softener and the regeneration processor can be assembled, disassembled, maintained and used respectively, diversification of product layout can be achieved, and different layout requirements are met.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

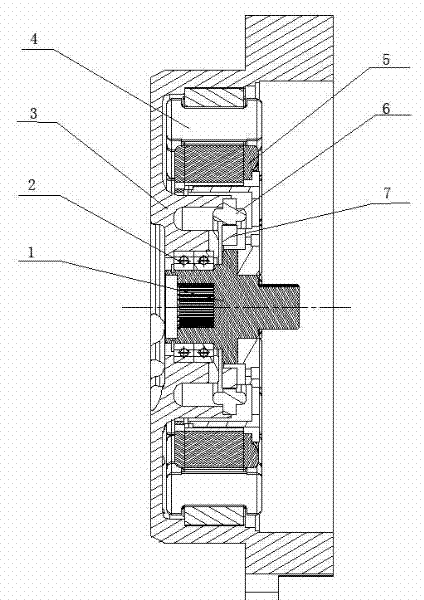

Electronic parking actuator capable of assisting and replacing hydraulic braking and parking device

PendingCN113236693AControlled clampingControllable releaseBrake actuating mechanismsActuatorsRotational axisRotation - action

The invention belongs to the technical field of motor vehicle parking systems, and particularly relates to an electronic parking actuator capable of assisting and replacing hydraulic braking and a parking device. The electronic parking actuator comprises a shell, a motor, a speed reduction transmission assembly and a threaded shaft; the motor is arranged in the shell and provides a source of driving force; the speed reduction transmission assembly is arranged in the shell and transmits the rotation action of the motor to the threaded shaft after speed reduction and torque increase; and the direction of the threaded shaft is perpendicular to the direction of a rotating shaft of the motor, and the threaded shaft rotates and acts outwards. According to the electronic parking actuator provided by the invention, a brand new layout mode and a brand new transmission mode are adopted, the arrangement requirement of a high-power motor can be met, a large reduction ratio can be achieved at the front section of transmission, and therefore vibration and noise are reduced; a coded disc and a detection device are matched, so that the braking force can be accurately controlled; and the basic condition that one set of electronic parking actuator is used for replacing the combination of two sets of traditional hydraulic braking and electronic braking execution driving mechanisms is met.

Owner:OECHSLER PLASTIC PROD TAICANG

Calculation method for controlling electric furnace smelting cost

ActiveCN110490672AMeet layout requirementsFast operationMarket predictionsForecastingAlloy elementScrap

The invention provides a calculation method for controlling the smelting cost of an electric furnace. The method comprises the following steps of: according to requirements of target components of a finished product, scrap steel bulk density, scrap steel element oxidation rate, alloy element yield, metal rate of metal materials and scrap steel bulk density, a finished product target component constraint equation, a scrap steel target bulk density constraint equation, a scrap steel and alloy quality constraint equation and an optimized batching target function are constructed, a linear programming mathematical model is constructed according to the equations, and the addition amount of scrap steel and alloy when the smelting cost is minimum are obtained through calculation. According to themethod, factors such as the burning loss rate of elements in the scrap steel, the alloy yield, the scrap steel density and the metal rate of metal raw materials in the smelting process are comprehensively considered; meanwhile, factor coefficients of different scrap steel types to electric energy consumption are introduced into an optimized batching objective function of the smelting cost, a comprehensive optimized batching model of the total cost of scrap steel, alloy and electric energy consumption is constructed, better applicability is achieved for a multi-element raw material structure, and the smelting cost of the electric furnace is effectively reduced.

Owner:WISDRI ENG & RES INC LTD

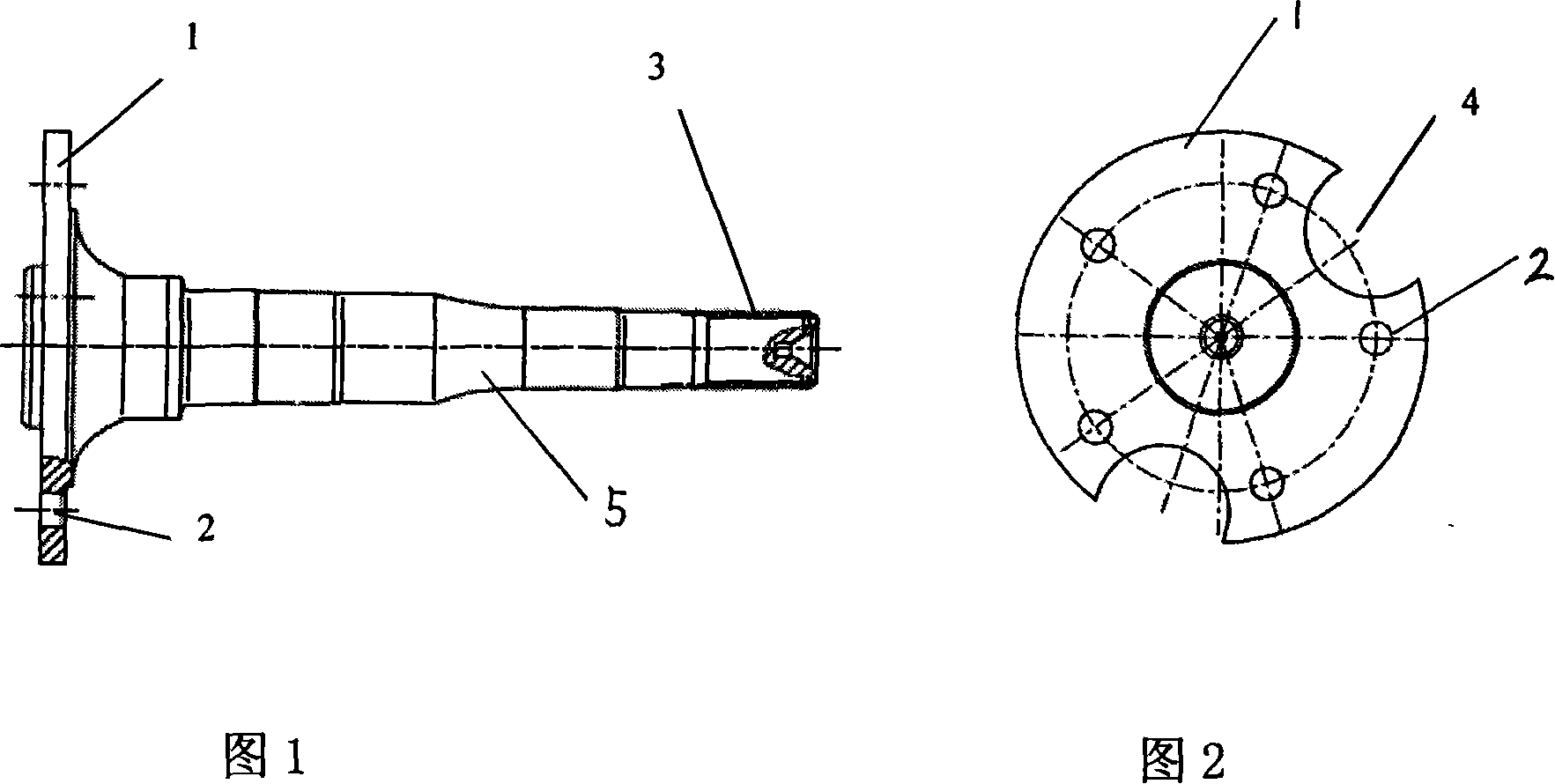

Car rear axle semi-axis structure

The invention relates to a half-shaft structure of an automobile rear axle, comprising a half-shaft and a half-shaft flange disc at the end; five vehicle wheel bolt holes are uniformly distributed on the half-shaft flange disc; meanwhile, the half-shaft flange is cut with a demising gap which gives a place to a brake soleplate; the invention is better provided with two demising gaps which are semiround gaps. By adopting the arrangement type of five bolts, the invention leads the driving force to be uniformly distributed on the five bolts, thus reducing the bearing force of each bolt, improving the service life of the vehicle wheel bolt and meeting the requirement of large load of the whole vehicle; furthermore, the invention is provided with two semiround troughs on the half-shaft flange, which provide assembly space for the installation of the brake soleplate, thus meeting the arrangement requirement of the braking system. Compared with other proposals, the invention has the advantage of low cost.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

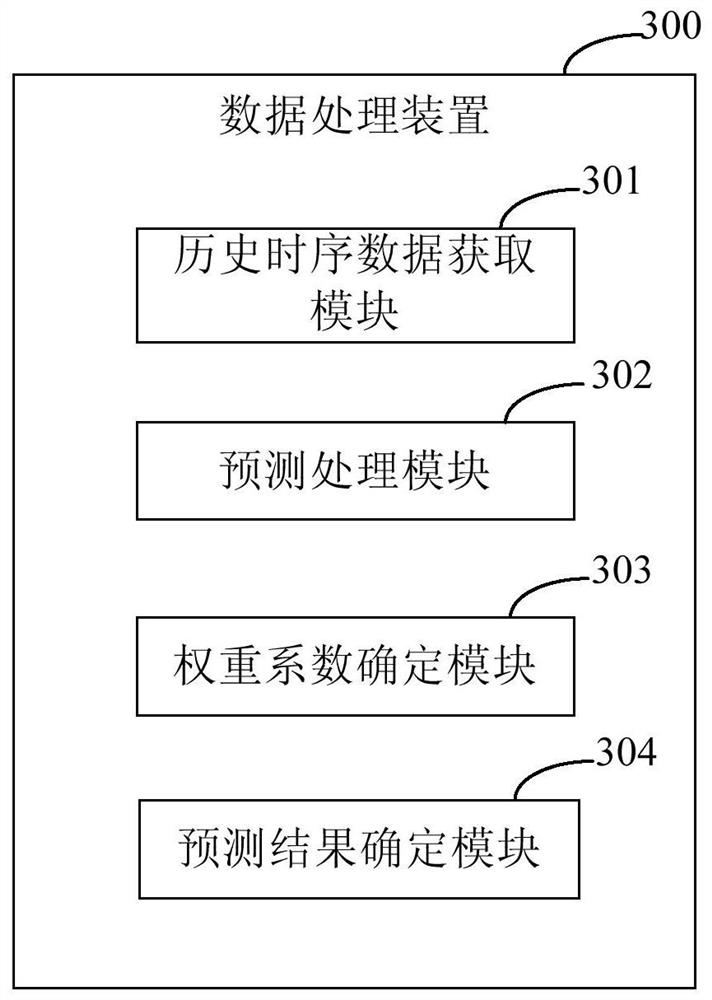

Data processing method and device

PendingCN113743971AReduce volatilityImprove accuracyNeural architecturesMarketingAlgorithmEngineering

The invention discloses a data processing method and device, and relates to the technical field of computers. According to one specific embodiment, the method comprises the steps: obtaining historical time sequence data, wherein the historical time sequence data indicates task order amount information; performing prediction processing on the historical time series data by using multiple time series models, and determining target time series data and a time series model set corresponding to the target time series data according to a prediction value obtained after the prediction processing; according to the target time sequence data and the time sequence features corresponding to the target time sequence data, training each time sequence model in the time sequence model set by using a deep learning algorithm to determine a weight coefficient corresponding to each time sequence model; and determining a prediction result corresponding to the target time sequence data according to the prediction value and the weight coefficient corresponding to each time sequence model. According to the embodiment, the volatility of the prediction result is reduced, the accuracy and interpretability of the prediction result are improved, and the prediction result can meet the layout requirement of the supply chain.

Owner:BEIJING WODONG TIANJUN INFORMATION TECH CO LTD +1

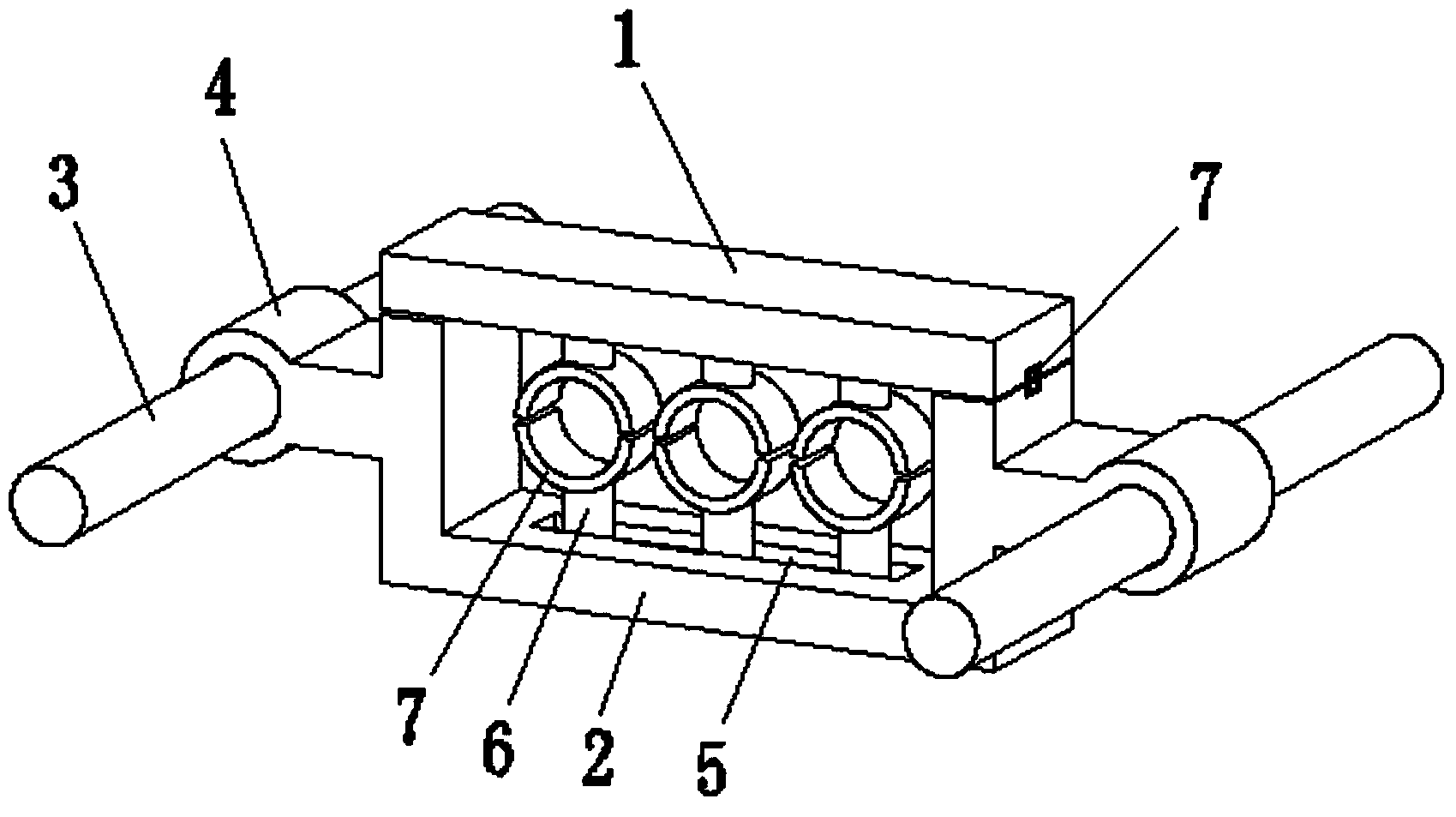

Movable opening and closing wire arranging fixer

InactiveCN104377617AMeet layout requirementsAvoid wear and tearElectrical apparatusMechanical equipmentIndustrial engineering

The invention discloses a movable opening and closing wire arranging fixer. The wire arranging fixer comprises a movable part, a fixed part and fixing rods. The movable part and the fixed part are movably connected, and fixing arms are arranged on the fixed part and arranged on the fixed rods in a sliding mode; the movable part and the fixed part are each provided with a sliding groove and a plurality of wire arranging assemblies; each wire arranging assembly comprises a connecting arm and an arc clamping arm arranged on the connecting arm, wherein the connecting arm is arranged in the corresponding sliding groove in a sliding mode; when the movable part and the fixed part are clamped together, the arc clamping arms on the movable part and the corresponding arc clamping arms on the fixed part form whole circles in a combined mode. According to the movable opening and closing wire arranging fixer, the movable part and the fixed part can be clamped together after arranging a line on the arc clamping arms, and the wire arranging fixer is suitable for arranging line wires connected already; the wires can move along the sliding grooves along with the wire arranging assemblies and are prevented from abrasion after being stuck; the direction of the line is fixed in the direction of the fixing rods, and the requirement for line arrangement of mechanical equipment is met.

Owner:SUZHOU MINGYUAN STAMPING PARTS FACTORY

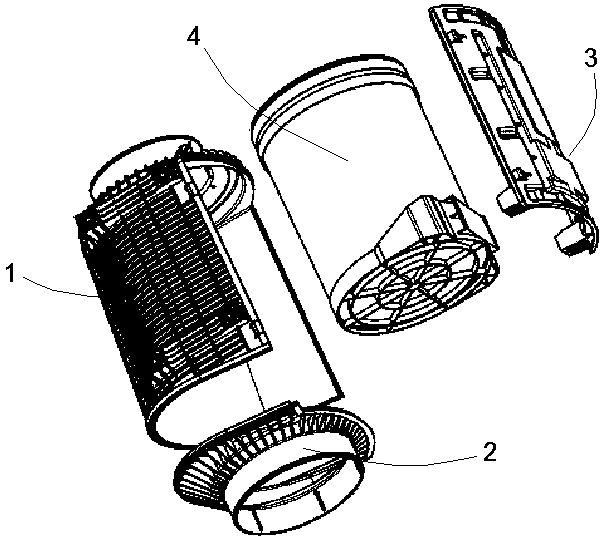

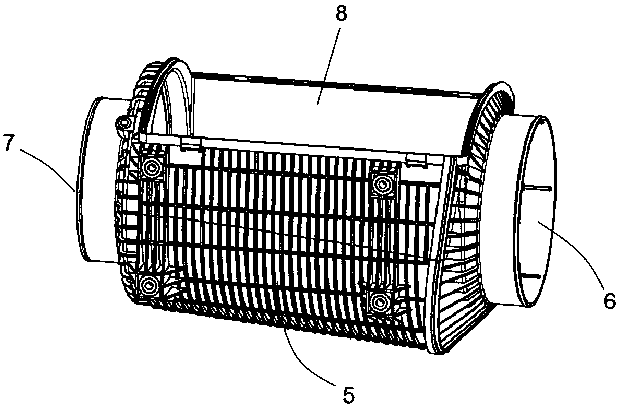

Straight-through type air filter

PendingCN107939564AGood filtration performanceSmall footprintCombustion-air/fuel-air treatmentMachines/enginesAir cleanersEngineering

The invention discloses a straight-through type air filter. The straight-through type air filter comprises a shell, an air inlet cover, a side cover and a filter element and is characterized in that the shell and the air inlet cover are fixedly connected in a welded mode, and accordingly, a shell assembly is formed and provided with an air inlet, an air outlet and a mounting opening formed in theside face; the filter element is mounted inside the shell assembly and is in sealing connection in a radial interference fit mode; the side cover is connected with the shell assembly and seals the mounting opening; the filter element comprises an air inlet end, an air outlet end, a plurality of air inlet channels and a plurality of air outlet channels; a plurality of small air inlet holes are formed in the air inlet end face at intervals, and each small air inlet hole extends in the axial direction to form the corresponding air inlet channel and is sealed near the air outlet end; and a plurality of small air outlet holes are formed in the air outlet end face at intervals, and each small air outlet hole extends in the axial direction to form the corresponding air outlet channel and is sealed near the air inlet end. The air filter can occupy small space so as to meet the arrangement requirement of a compact space or a special-shaped space of a vehicle.

Owner:广西华原过滤系统股份有限公司

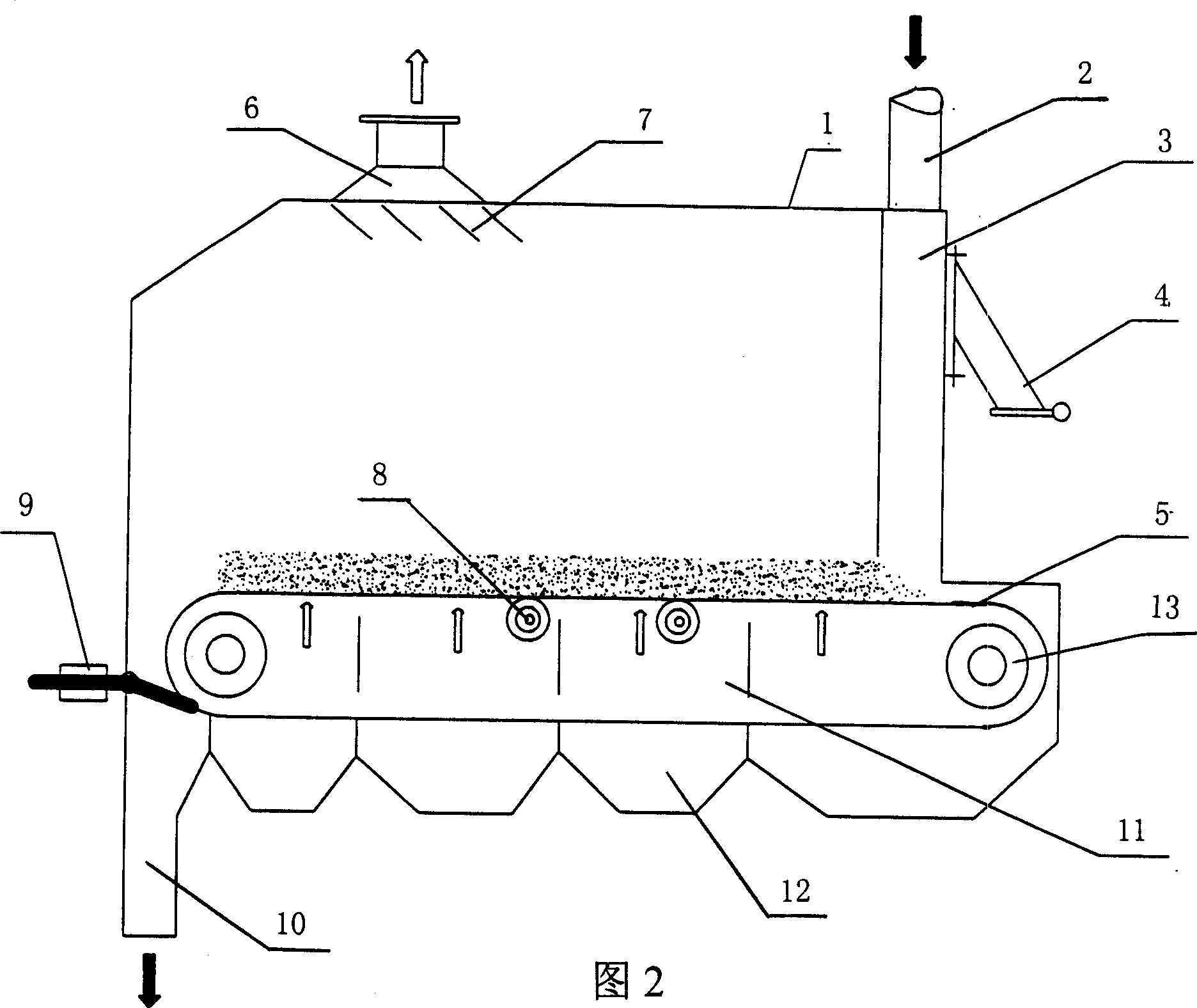

Chain-type slag-off controlling cooler for fluidized bed boiler

InactiveCN1403738AContinuous slaggingStable slaggingFluidized bed combustionApparatus for fluidised bed combustionAir volumeSlag

The chain-type slag-off controlling cooler for flouidized bed boiler has inside the casing one slag-off flow equalizing channel communicated with the slag inlet, one speed regulating chain type grate below the slag-off flow equalizing channel, one cold draft separating chamber, one hot draft outlet and one slag outlet communicated with the casing below the chain type grate. The speed regulating chain type grate is used as draft distributor and slag-off controller, the boiler may exhaust slag continuously stable and controllably. Separating air blowing is favorable to the sectional regulation of cooling draft, reasonable distribution of draft amount and high cooling efficiency of the slag-off controlling cooler.

Owner:XIAN THERMAL POWER RES INST CO LTD

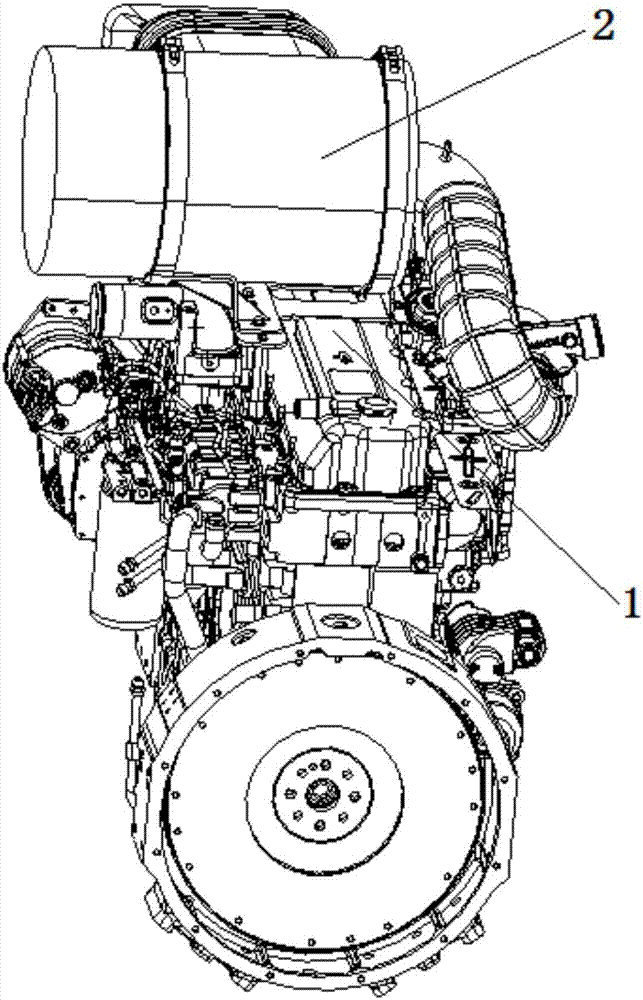

Device for supporting air filter

ActiveCN106917705AImprove adaptabilityMeet the installation layout requirementsMachines/enginesAir cleaners for fuelAxial displacementAir filter

The invention discloses a device for supporting an air filter. The device comprises a plurality of connecting parts which are connected with an engine cylinder cover to install the air filter on an engine room, wherein a connecting plate is arranged above the connecting parts and connected with all the connecting parts to enable the connecting parts to form an integrated device, a bracket which is connected with the connecting plate and used for supporting the air filter is detachably arranged above one end of the connecting plate, a limiting frame which is connected with the connecting plate and used for limiting axial displacement of the air filter is detachably arranged above the other end of the connecting plate, annular locking devices are arranged on the bracket and the limiting frame, and the diameters of the annular locking devices can be adjusted to change tightness degree of the air filter. The device disclosed by the invention has a simple structure, achieves the purpose of quickly installing the air filter on the engine room, has strong suitability, reduces a requirement for the whole automobile space, avoids the problem of designing and distributing an air filter support for many times, effectively improves production efficiency and reduces production cost.

Owner:GUANGXI YUCHAI MASCH CO LTD

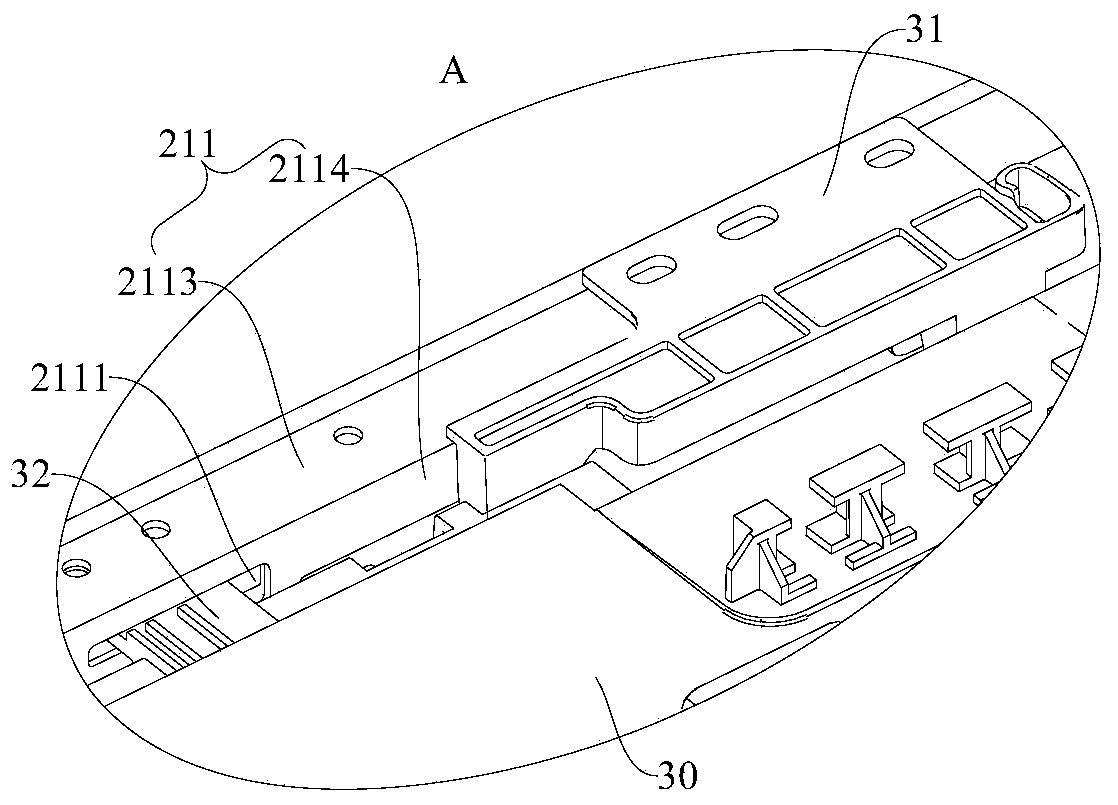

Automobile middle door lock mainbody

The invention relates to a main body of door lock of vehicle, which comprises a lock frame, a cover plate, a clamp plate with return spring, a pallet, a pallet spring and a unlock arm. Wherein, the clamp plate is mounted on the rotation axle, while it has claw groove matched with pallet; the pallet is mounted on the rotation axle of pallet; the end of one arm of pallet has the convex claw matched with the claw groove, to compress one end of pallet spring above said arm; another arm of pallet is contacted with unlock arm; when locking, the function force of pallet spring can contact the clamp plate to avoid its rotation; when unlocking, the unlocking arm rotates the pallet, to overcome the force of pallet spring, to release the clamp plate; then the clamp plate will rotate back by the return spring, to unlock. The invention avoids the lock element, internal handle unlocking element, external handle unlocking device and lock pin unlocking element, to simplify the structure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

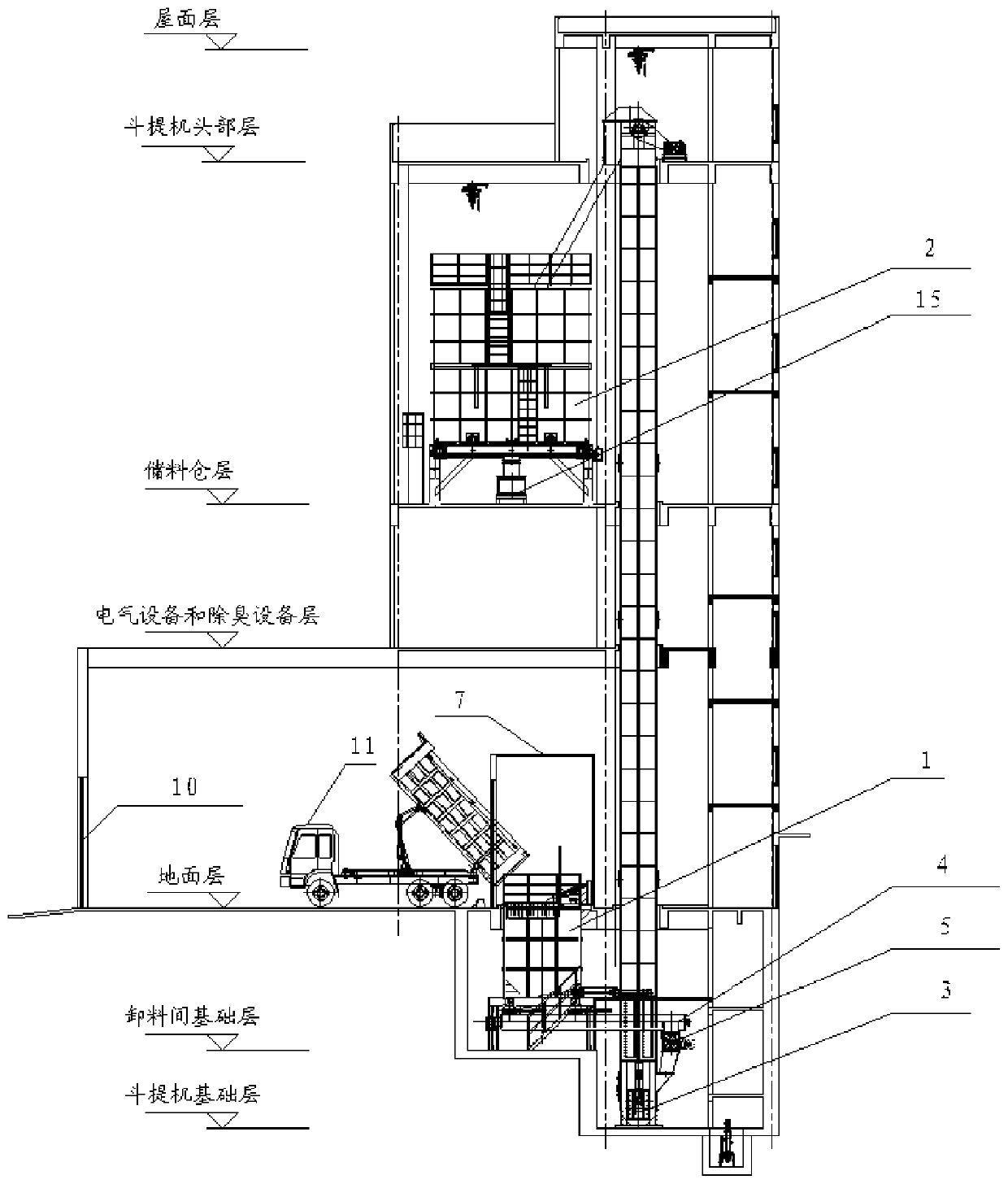

Coal-fired power plant sludge blending combustion system

InactiveCN111023115AMeet layout requirementsTake advantage ofIncinerator apparatusCombined combustion mitigationCombustion systemSludge

The invention relates to the technical field of sludge blending combustion. The invention discloses a coal-fired power plant sludge blending combustion system, which is characterized in that the system comprises a hopper used for collecting sludge conveyed by an unloading vehicle, a storage bin used for storing the sludge, and a bucket elevator used for lifting the sludge from the hopper to the storage bin. The bucket elevator is vertically arranged; the storage bin is positioned above the hopper; the storage bin and the hopper are located on the same side of the bucket elevator, so that the arrangement requirement that the storage bin needs to have a certain height is met, the installation characteristic that the bucket elevator has a certain height is met, the space is fully utilized, the space under the storage bin is prevented from being left unused, the space is effectively utilized, the occupied area is reduced, and workshop configuration is optimized.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

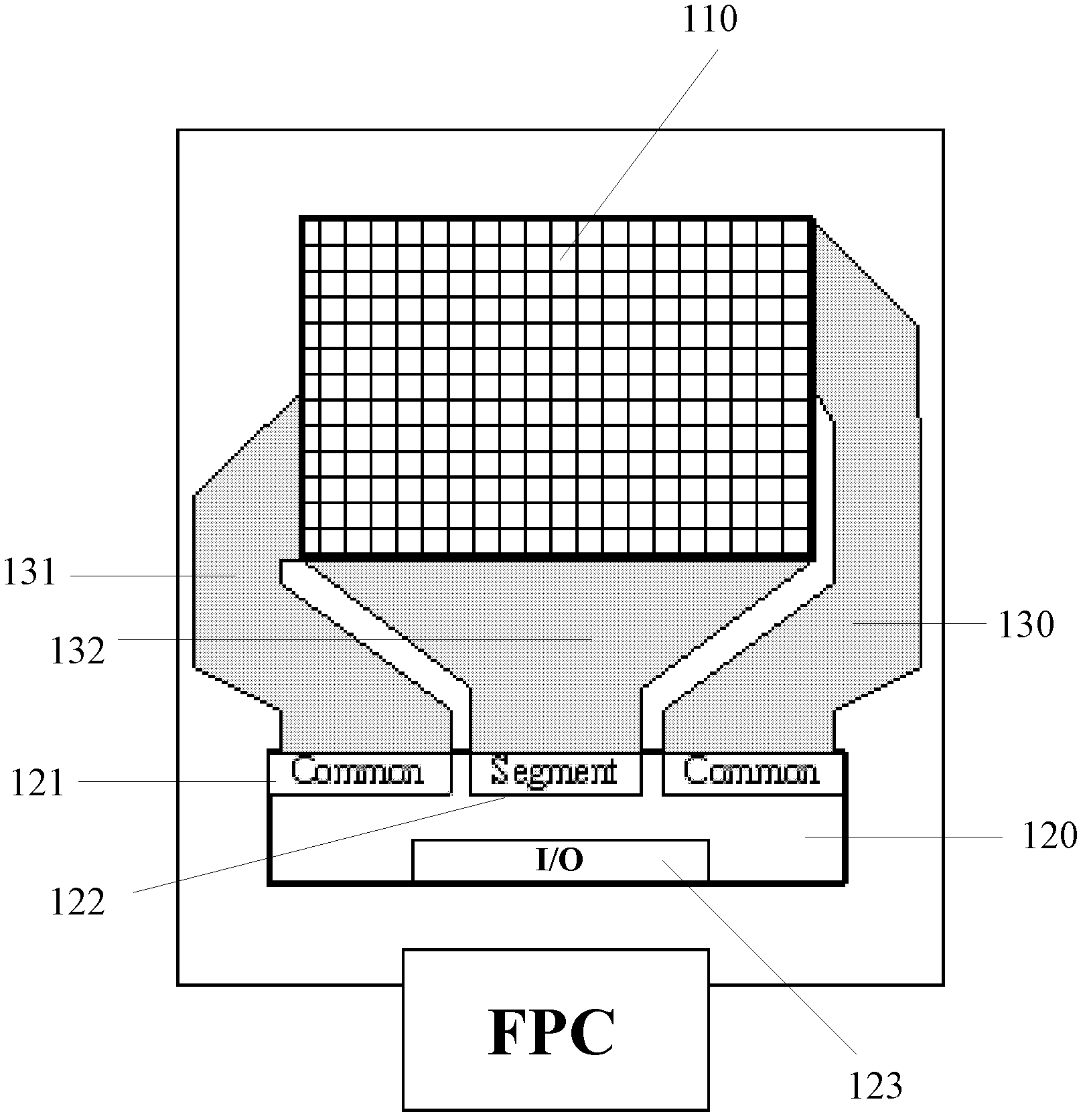

Organic light emitting diode (OLED) display driving chip and display

InactiveCN102254512AMeet layout requirementsStatic indicating devicesSolid-state devicesOLEDDisplay device

The invention discloses an organic light emitting diode (OLED) display driving chip, comprising a first common drive port, as well as a second common drive port and a third common drive port positioned at two sides of the first common drive port, and a first-segment drive port and a second-segment drive port which are arranged to space the first common drive port, the second common drive port and the third common drive port. Thus, a drive output port of the OLED display driving chip additionally provides a group of COM ports with repeat functions, which can be selected for use to meet different layout requirements, therefore, the layout requirements of different OLED screens can be met through the way that drive chips in the same type can use different COM ports.

Owner:SINO WEALTH ELECTRONICS

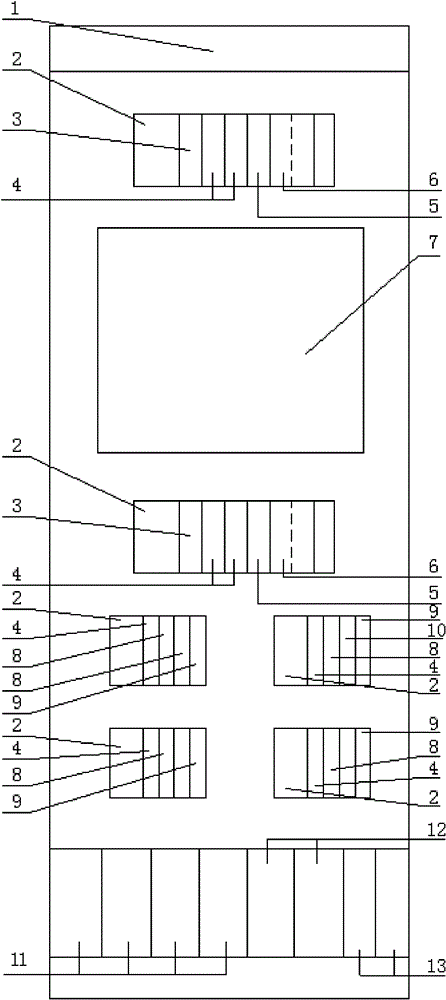

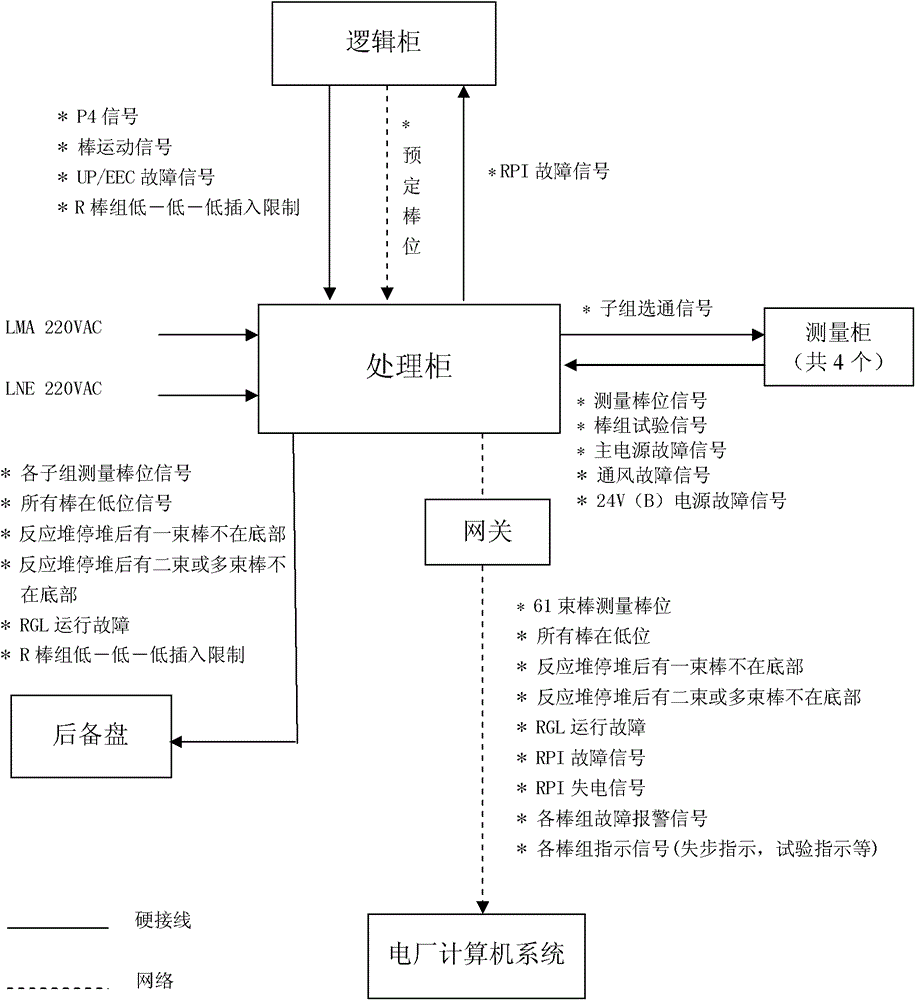

Rod position processing device of nuclear power station control rod based on PLC (Programmable Logic Controller) platform

ActiveCN101877250BReal-time monitoring of input signalsImprove stabilityNuclear energy generationNuclear monitoringNuclear powerEmbedded system

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Adjustable annular movable wire arranging fixator

InactiveCN104393541AAvoid wear and tearExtended service lifeElectrical apparatusMechanical equipmentEngineering

The invention discloses an adjustable annular movable wire arranging fixator. The fixator comprises a housing, a main wire ring, auxiliary wire rings and a fixing rod, wherein an inner matching groove is formed in the housing, while an outer matching groove is formed in the main wire ring; an annular lug is arranged on each auxiliary wire ring and located in the inner matching groove and the outer matching groove; a fixing arm corresponding to the fixing rod is arranged on the housing and fixed on the fixing rod; a positioning groove is formed in the fixed rod; a positioning screw matched with the positioning groove is arranged on the fixing arm. The adjustable annular movable wire arranging fixator enables a wire to move to a certain extent and avoids the abrasion of the wire after being locked due to the running fit of the main wire ring and a plurality of auxiliary rings; the two ends of the positioning rod can be fixed according to the desired direction, the trend of the line is fixed in the direction of the positioning rod, and the fixing housing also can be matched and locked with the positioning groove by use of the positioning screw after being glided to a specific position on the fixing rod according to requirements, and therefore, the requirements of mechanical equipment on the arrangement of the line are met.

Owner:SUZHOU MINGYUAN STAMPING PARTS FACTORY

Terminal antenna and terminal

ActiveCN108470972ASmall sizeSmall footprintAntenna supports/mountingsRadiating elements structural formsAntenna radiationElectrical and Electronics engineering

The invention discloses a terminal antenna and a terminal and belongs to the wireless communication technology field. The terminal antenna comprises a grounding floor, an antenna support and an antenna radiation structure. The grounding floor is connected to the antenna support. The antenna radiation structure is connected to the grounding floor and the antenna support respectively. The antenna support has anisotropy. Because the antenna support has the anisotropy, the component of the constitutive parameter of the antenna support in a certain direction is numerically different from the components in any other directions so that an electromagnetic wave can radiate in different directions and the antenna support achieves an auxiliary radiation effect. In the invention, through the antenna support having the anisotropy, under the condition that the size of the terminal antenna is not increased, the bandwidth and the efficiency of the terminal antenna can satisfy a design requirement, andthe antenna is used for the terminal.

Owner:HUAWEI TECH CO LTD

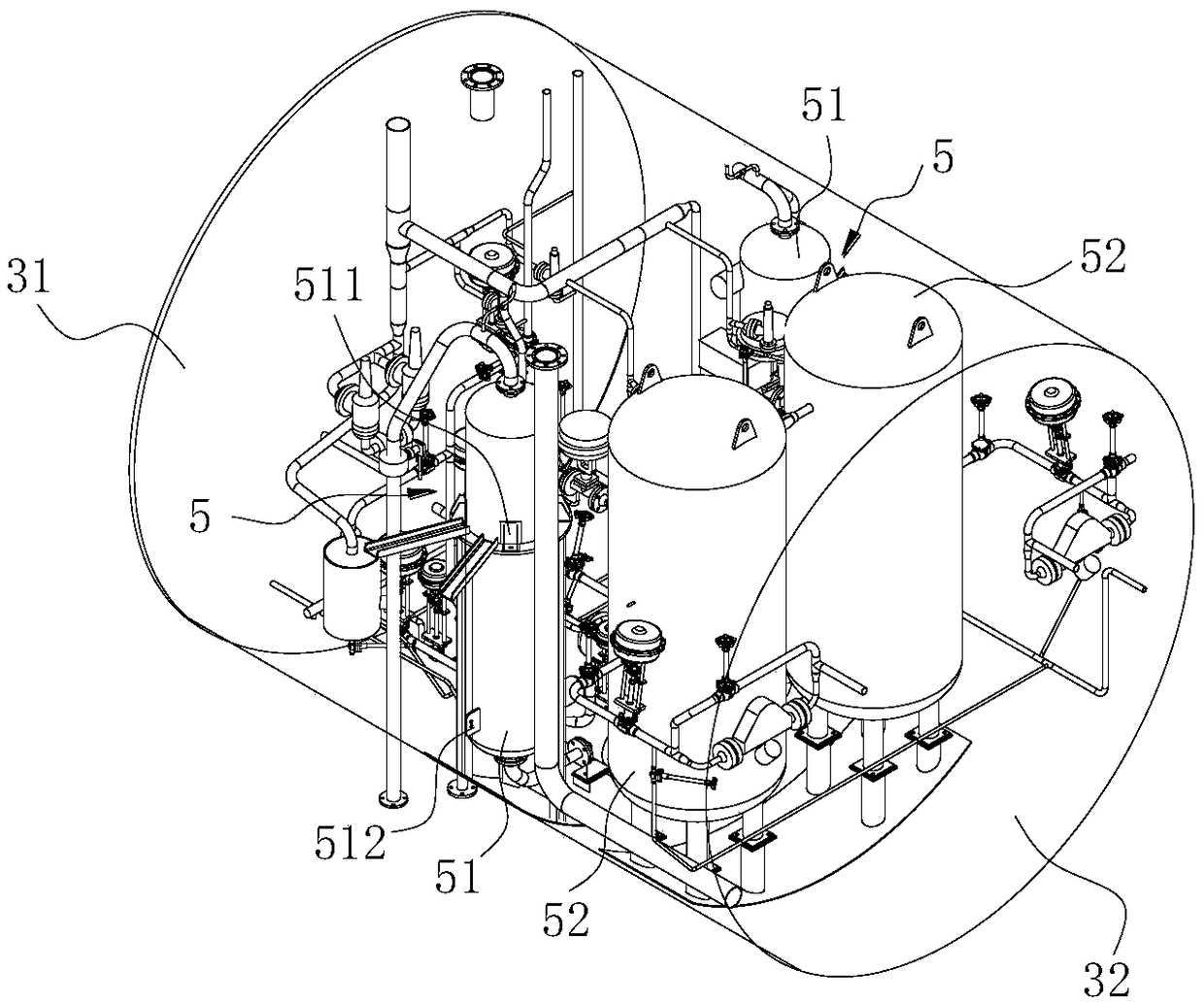

LNG fuel supply system for ship

ActiveCN109000148AHigh strengthIncrease stiffnessVessel mounting detailsWaterborne vesselsFuel tankEngineering

The invention provides an LNG fuel supply system for a ship. The LNG fuel supply system for the ship comprises a fuel tank and a gas supply unit, wherein the fuel tank is used for storing LNG, and thegas supply unit is arranged at one end of the fuel tank and used for supplying gas to the outside; the LNG fuel supply system for the ship further comprises an enclosure device, a reinforcing deviceand at least two supports; the supports are arranged at the bottom of the fuel tank in the axis direction of the fuel tank in a spaced manner to support the fuel tank; the enclosure device covers theexterior of the gas supply unit and supports the gas supply unit; the enclosure device is fixedly connected with the fuel tank and extends outwards from one end of the fuel tank in an impending manner; the reinforcing device is arranged at the bottom of the enclosure device, extends to the bottom of the fuel tank and is connected and fixed to a neighbouring support; and the bottom surface of the reinforcing device is higher than the bottom surface of the support. The LNG fuel supply system for the ship, provided by the invention, has the advantages that good strength and rigidity are realizedbecause the fuel tank, the enclosure device and the supports are connected by using the reinforcing device to form an integrated structure, the enclosure device is placed in an impending manner to reduce the cost of a hull base placed on the ship, and the layout requirement of a ship form with compact space is satisfied.

Owner:CIMC JINGMEN HONGTU SPECIAL AIRCRAFT MFG +2

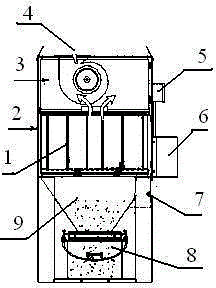

Novel flat bag type dust remover

InactiveCN104436909AExtended service lifeReduce noiseDispersed particle filtrationProduct gasEngineering

The invention relates to a novel flat bag type dust remover which comprises a dust collection device, a pollution gas impact pressure chamber and a fan room, wherein the dust collection device comprises an air inlet and an ash bucket; an air inlet baffle is arranged between the air inlet and the ash bucket; the pollution gas impact pressure chamber is formed above the dust collection device; a vibrating motor is arranged on the side surface of the pollution gas impact pressure chamber; a flat cloth bag and a metal insertion plate are arranged inside the pollution gas impact pressure chamber; the flat cloth bag is communicated with the ash bucket in a closed mode and is supported by virtue of the metal insertion plate; the fan room is positioned above the pollution gas impact pressure chamber and is communicated with the pollution gas impact pressure chamber in the closed mode; and a fan is arranged in the fan room. The novel flat bag type dust remover disclosed by the invention is complete in ash removal, and low in noise, and the service life of filter bag is long.

Owner:QINGDAO HOSEN HEAVY IND

Double-rear-axle truck frame

InactiveCN104648477AMeet layout requirementsGuaranteed UniversalUnderstructuresVehicle frameManufacturing technology

The invention discloses a double-rear-axle truck frame and relates to the technical field of automobile manufacture. The truck frame is divided into a front section, a transition section and a left vertical beam and a right vertical beam which are arranged on the rear section. The outside distance between the left vertical beam and the right vertical beam in the front section is 1080 mm, and the outside distance between the left vertical beam and the right vertical beam in the rear section is 850 mm. A front cover plate and an engine front suspension bend beam are sequentially arranged on the front section, and a first middle beam, a second middle beam, a balance suspension beam and a rear beam are sequentially arranged on the rear section. Two ends of the engine front suspension bend beam are connected with a middle support to be further connected with the left vertical beam and the right vertical beam through plate spring seats. Two ends of the first middle beam, the second middle beam, the balance suspension beam and the rear beam are connected with the left vertical beam and the right vertical beam through connection plates. The truck frame solves the problem that the existing frame is high in mass, low in loading mass and poor in whole truck fuel economy.

Owner:DONGFENG LIUZHOU MOTOR

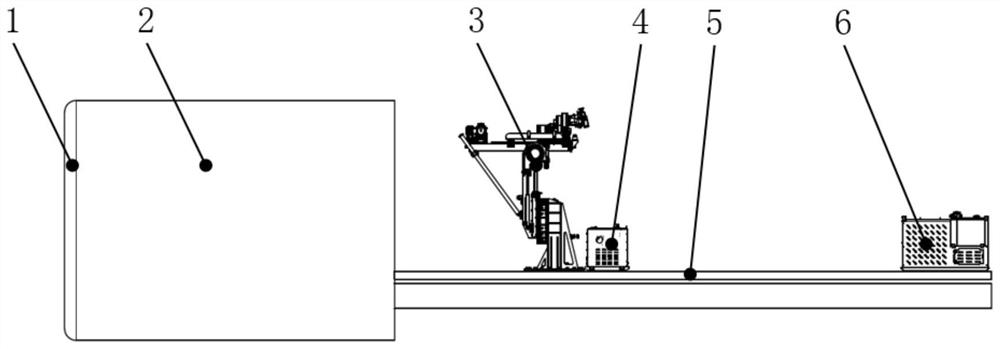

Coal mine TBM advanced exploration split type remote control drilling machine and advanced exploration construction method

The invention relates to a drilling machine and a construction method, belongs to the technical field of drilling, and particularly relates to a coal mine TBM (Tunnel Boring Machine) advanced exploration split type remote control drilling machine and an advanced exploration construction method. Compared with a conventional TBM advanced exploration drilling machine with the construction capacity of 30-50 m, the drilling machine is a special deep hole drilling machine with the larger torque and propulsive force, advanced drilling construction of deep holes with the length larger than 300 m can be completed, for coal mine roadway tunneling construction with the mandatory requirement of exploration before tunneling, the drilling and tunneling alternating frequency can be greatly reduced, and the comprehensive construction efficiency is effectively improved. The main machine part of the drilling machine is of an independent structure and is arranged on a trailer platform behind a TBM propelling mechanism, and the large-range adjustment of a circumferential angle, a main shaft inclination angle and a working radius can be achieved so as to meet the special advanced hole exploration site requirement of TBM. The drilling machine is controlled through electric control and remote control, and an operation table and a pump station can be flexibly arranged according to the TBM layout. In addition, the invention further provides the advanced exploration construction method suitable for the coal mine TBM.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method and device for web interface layout

InactiveCN105760155AMeet layout requirementsAchieve regulationExecution for user interfacesUser needsHuman–computer interaction

The invention provides a method and device for web interface layout.The method includes the steps that corresponding control attribute setting tables are configured for at least one control; according to the at least one configured control attribute setting table, a data grouping target is generated; controls in the data grouping target are grouped and sorted; interface layout is displayed according to the grouped and sorted data grouping target.According to the scheme, when a user needs to adjust interface layout, the user only needs to modify the configured control attribution setting tables according to the requirement of the user for interface layout.Sorting and display of the controls can be achieved according to the control attribution setting tables configured by the user, so that adjustment of web interface layout can be achieved through an empty page, and requirements of different users for web interface layout can be met.

Owner:INSPUR COMMON SOFTWARE

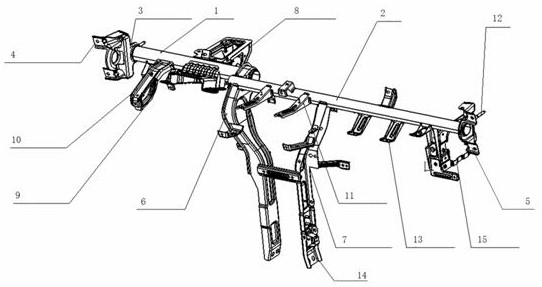

Staggered pipe type steering support assembly

PendingCN114275056AMeet layout requirementsImprove experienceSuperstructure subunitsSuperstructure connectionsVehicle frameEngineering

The invention discloses a staggered pipe type steering supporting assembly. Transverse pipes are divided into a first transverse pipe and a second transverse pipe, and the first transverse pipe and the second transverse pipe are connected through a first floor connecting support. A first connecting hole and a second connecting hole are formed in the upper portion of the first floor connecting support and used for positioning the connecting ends of the first transverse pipe and the second transverse pipe respectively, the first connecting hole or the second connecting hole is designed to be a strip-shaped hole, and staggered arrangement of the transverse pipes is achieved by adjusting the hole positions of the first transverse pipe and the second transverse pipe; the other end of the first transverse pipe is connected with the frame through a first transverse pipe connecting bracket; the other end of the second transverse pipe is connected with the frame through a second transverse pipe connecting bracket; a second floor connecting support arranged in parallel with the first floor connecting support is further arranged to support the second transverse pipe. And the position of the cross beam is adjusted by adjusting the transverse pipe mounting hole position of the transverse pipe connecting bracket, so that the mountable surface of the steering support is improved, and the mounting arrangement of various intelligent parts is met.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com