Chain-type slag-off controlling cooler for fluidized bed boiler

A technology for fluidized bed boilers and controlled cooling, applied in the field of fluidized bed boilers, can solve the problems of large water consumption, control of boiler slag, wear and other problems, and achieve the effects of improving heat exchange efficiency, improving cooling efficiency, and reasonable air volume distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

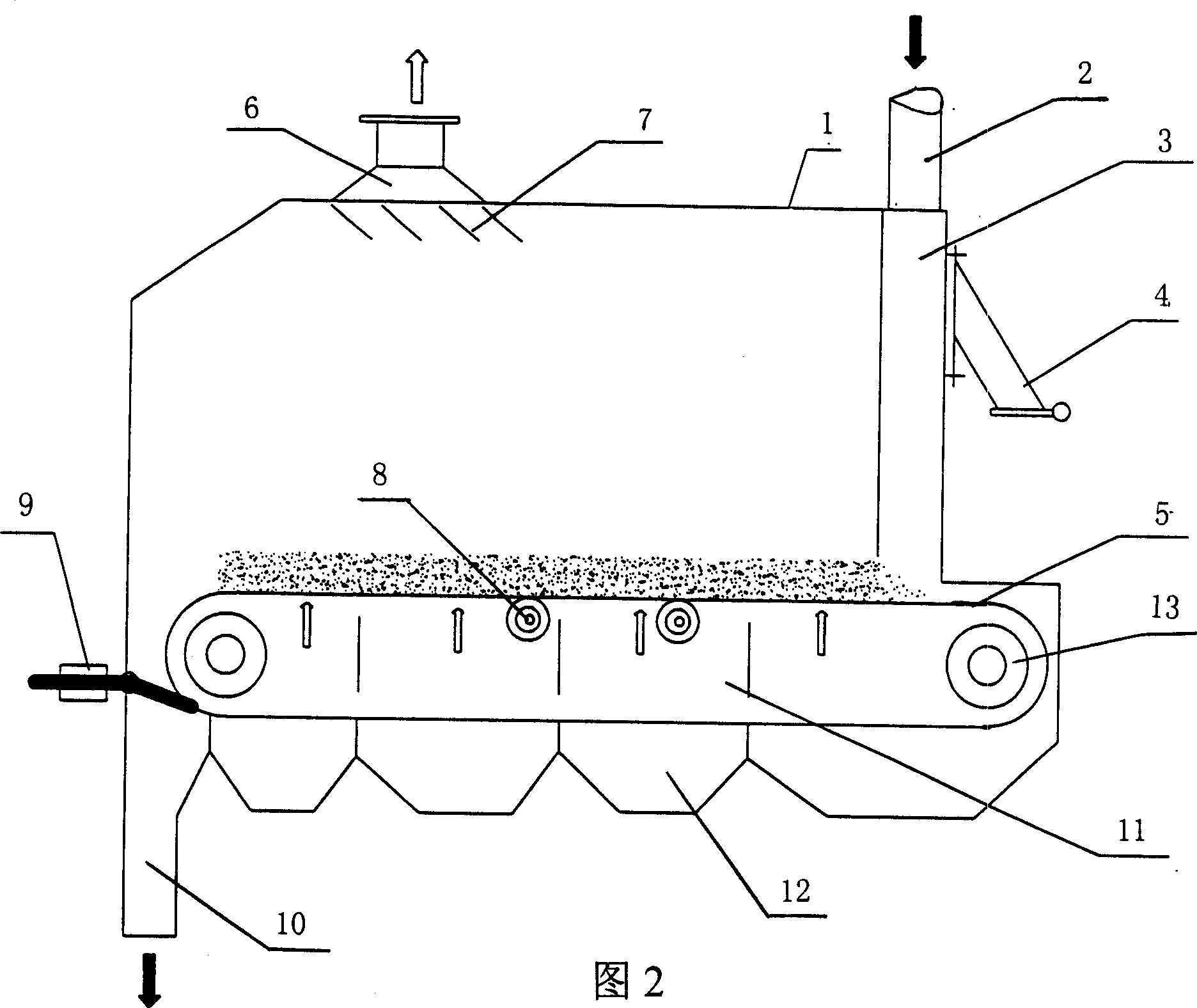

[0029] The invention is the key equipment for the bottom slag treatment of the fluidized bed boiler, which is used for controlling and cooling the slag discharge of the fluidized bed boiler, recovering the waste heat of slagging, and providing necessary conditions for the subsequent continuous slagging system. like figure 1 , 2, and 3, the high-temperature hot slag discharged from the fluidized bed boiler enters the slag discharge uniform flow tank 3 through the slag inlet 2, and then falls on the adjustable-speed chain-belt grate 5. By adjusting the grate speed, Control the amount of slag discharge of the fluidized bed boiler, and at the same time, the fire grate is used as the air distribution device of the slag discharge control cooler to cool the slag during the process of introducing and transporting slag into and out of the slag discharge control cooler. The grate type can be chain or belt, so it is collectively called chain belt slag discharge control cooler. The cold ...

example 2

[0033] When high ash coal is used, air-water combined cooling chain belt type slag discharge control cooler can be used, as shown in Figure 4 and 5. The air-water combined cooling chain belt-type slag discharge control cooler includes a tubular heating surface 14 , an inlet and outlet water header 15 , and a partition wall 16 . The partition wall 16 divides the slag discharge control cooler into a high-temperature section and a low-temperature section, and a water-cooled heating surface 14 is arranged in the high-temperature section to cool the hot air in the high-temperature section. The hot slag in the lower part is in direct contact with the cold air for heat exchange, and the hot air in the upper high-temperature section exchanges heat with the water-cooled heating surface, and the discharged hot air is used as the secondary air of the fluidized bed boiler. The fluidized bed boiler itself still has a secondary air preheater. The cold air of the slag discharge control cool...

Embodiment 3

[0035] When it is necessary to arrange the chain-belt grate obliquely, such as Image 6 As shown, tilt the chain-belt grate at a certain angle, adjust the movement speed of the chain-belt grate, and control the amount of slag. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com