External rotor hub motor driving assembly

A hub motor and drive assembly technology, which is applied in the direction of electric components, magnetic circuit rotating parts, electromechanical devices, etc., can solve the problems of compact motor structure, and the lack of large-scale industrial application of hub motors, and achieve good braking performance , shorten the structure size of the motor, and meet the layout requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

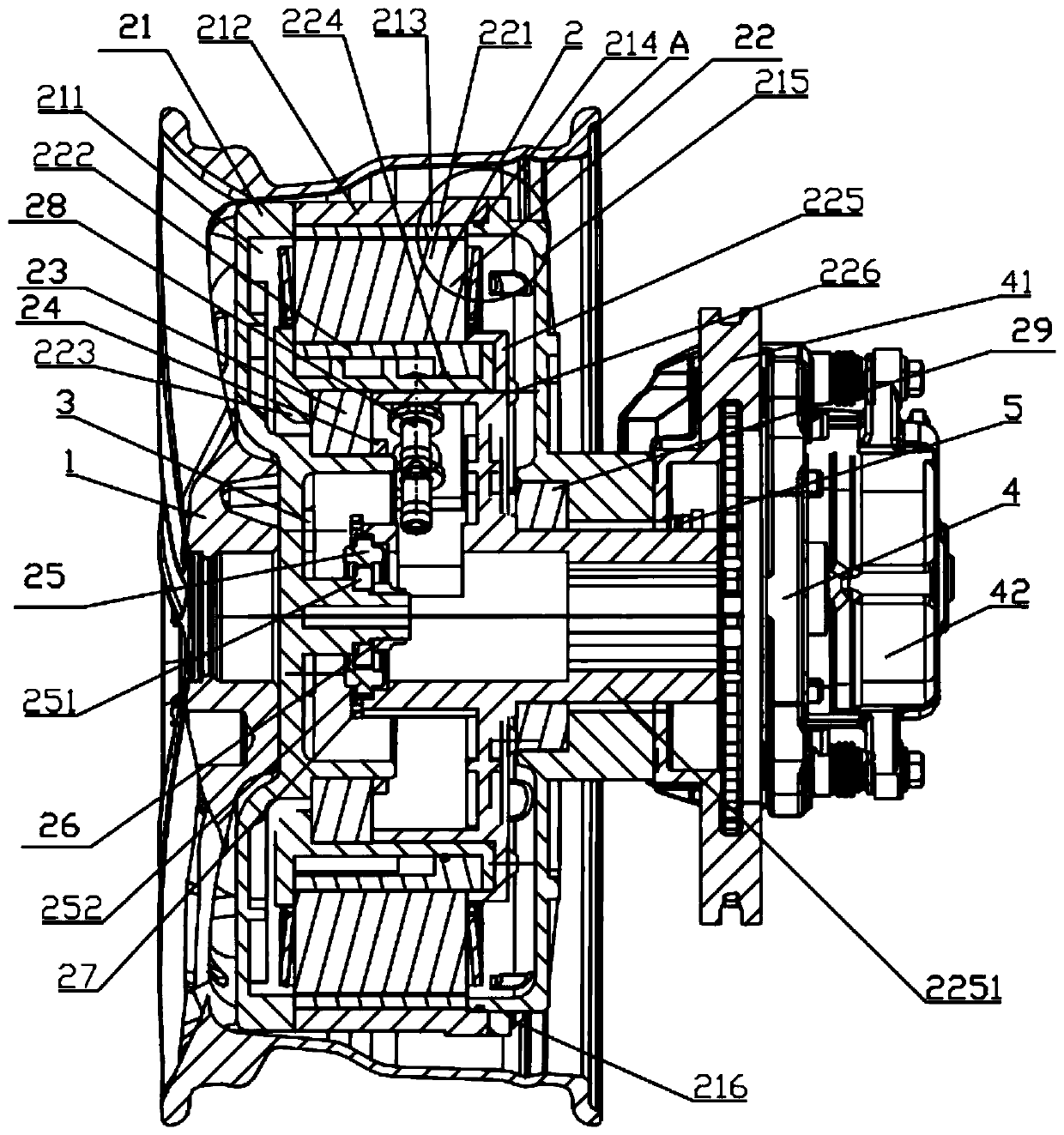

[0022] An outer rotor hub motor drive assembly, including a hub 1, a motor 2, and a brake 4; the motor 2 is installed in the hub 1, the motor 2 includes a rotor assembly 21 and a stator assembly 22, and the rotor assembly 21 is installed on the stator Outside the assembly 22, the stator assembly 22 is connected to the power supply to drive the rotor assembly 21 to drive the wheel hub 1 to rotate, and the motor 2 is also connected to the brake 4 and brakes the rotor assembly 21 through the brake 4 to stop the wheel hub 1 from rotating.

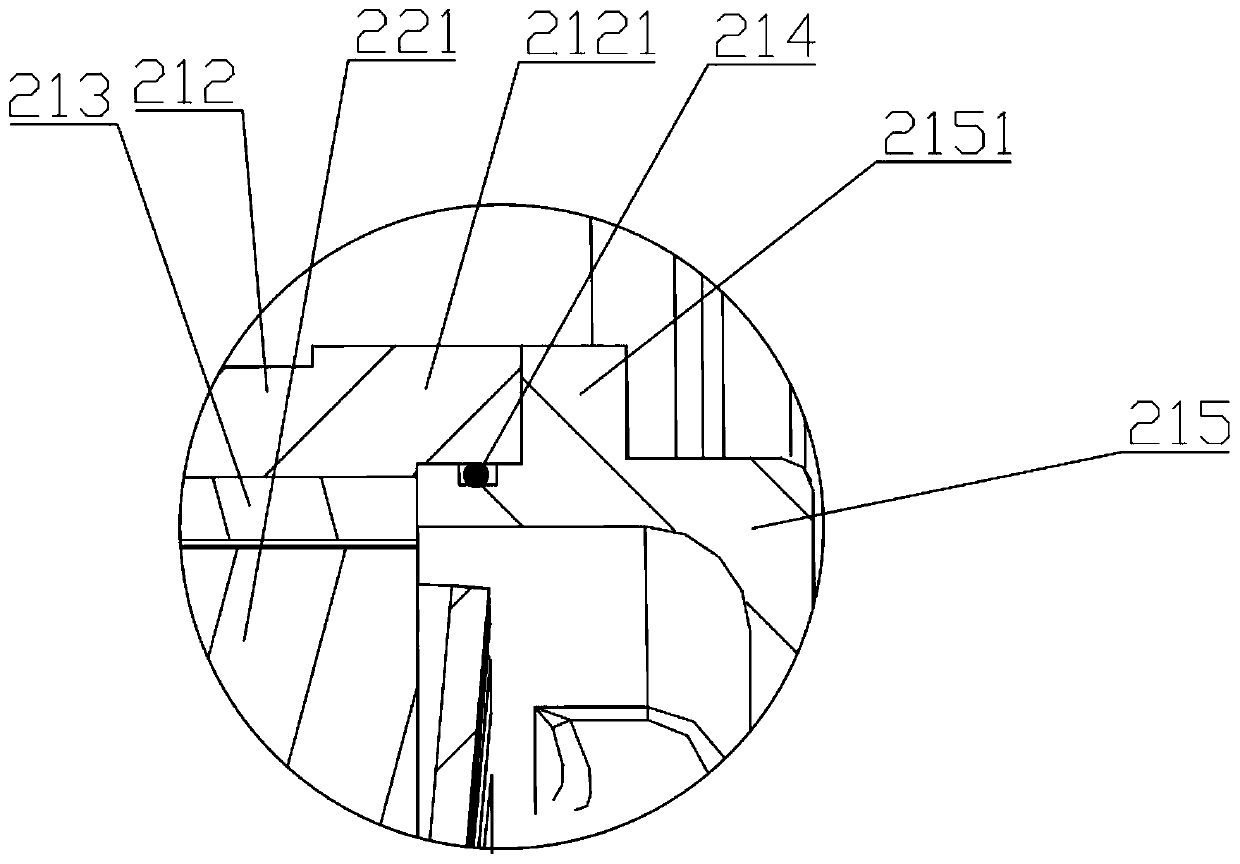

[0023] The rotor assembly 21 also includes an iron core 212. The inner wall of the iron core 212 is fixed with a magnetic steel 213. The two ends of the iron core 212 are respectively connected to the outer ends of the rotor left bracket 211 and the rotor right bracket 215 through fasteners. The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com