TiZrNbMoxHfy multi-principal component high temperature alloy and preparation method thereof

A superalloy and multi-principal technology, which is applied in the field of new TiZrNbMoxHfy multi-principal superalloy and its preparation, can solve the problems that do not involve changes in structure and properties, do not involve Hf element alloy system, and do not give

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

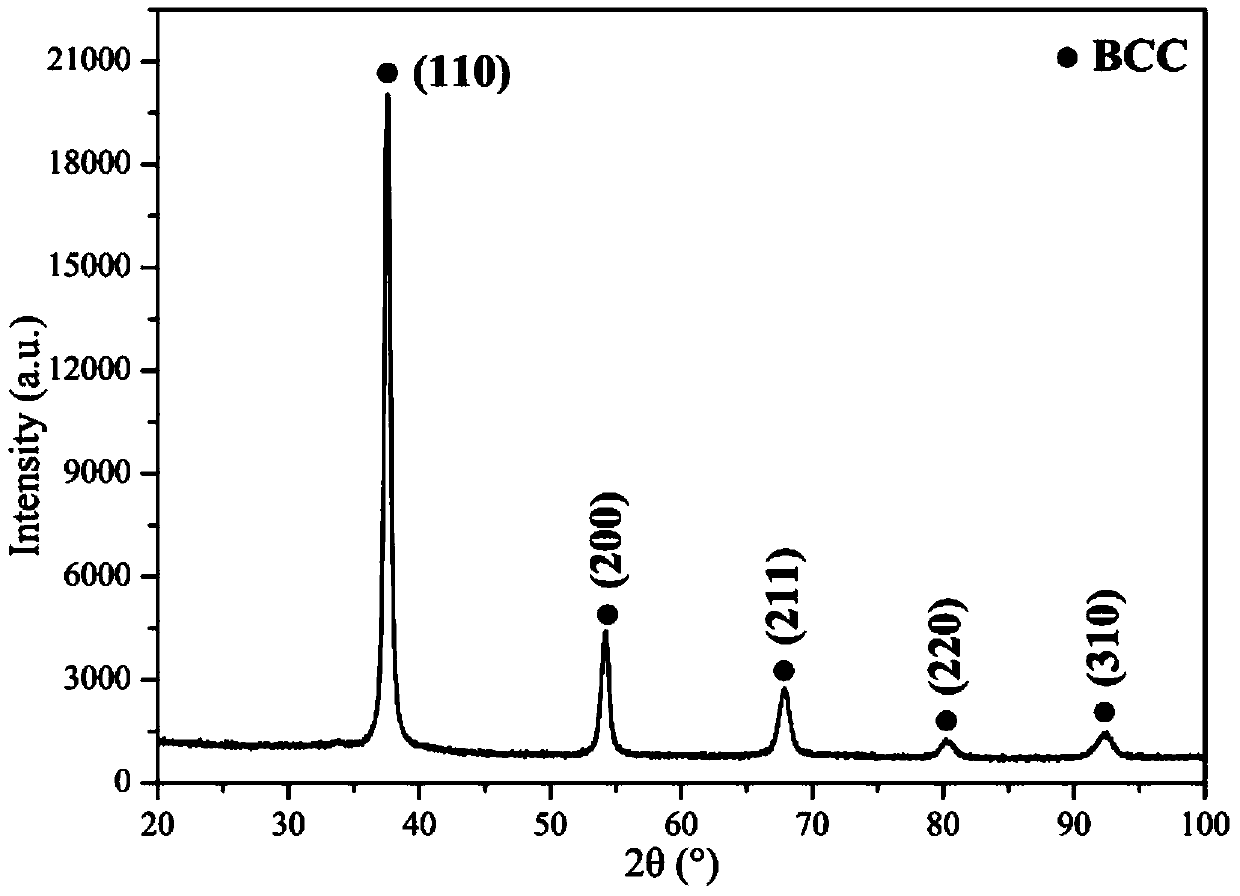

[0030] Specific embodiment one: a kind of TiZrNbMo of this embodiment x f y Multi-principal superalloy, the alloy composition is TiZrNbMo x f y , wherein, x and y are molar ratios, and the value ranges of x and y are both 0.1-1.0.

specific Embodiment approach 2

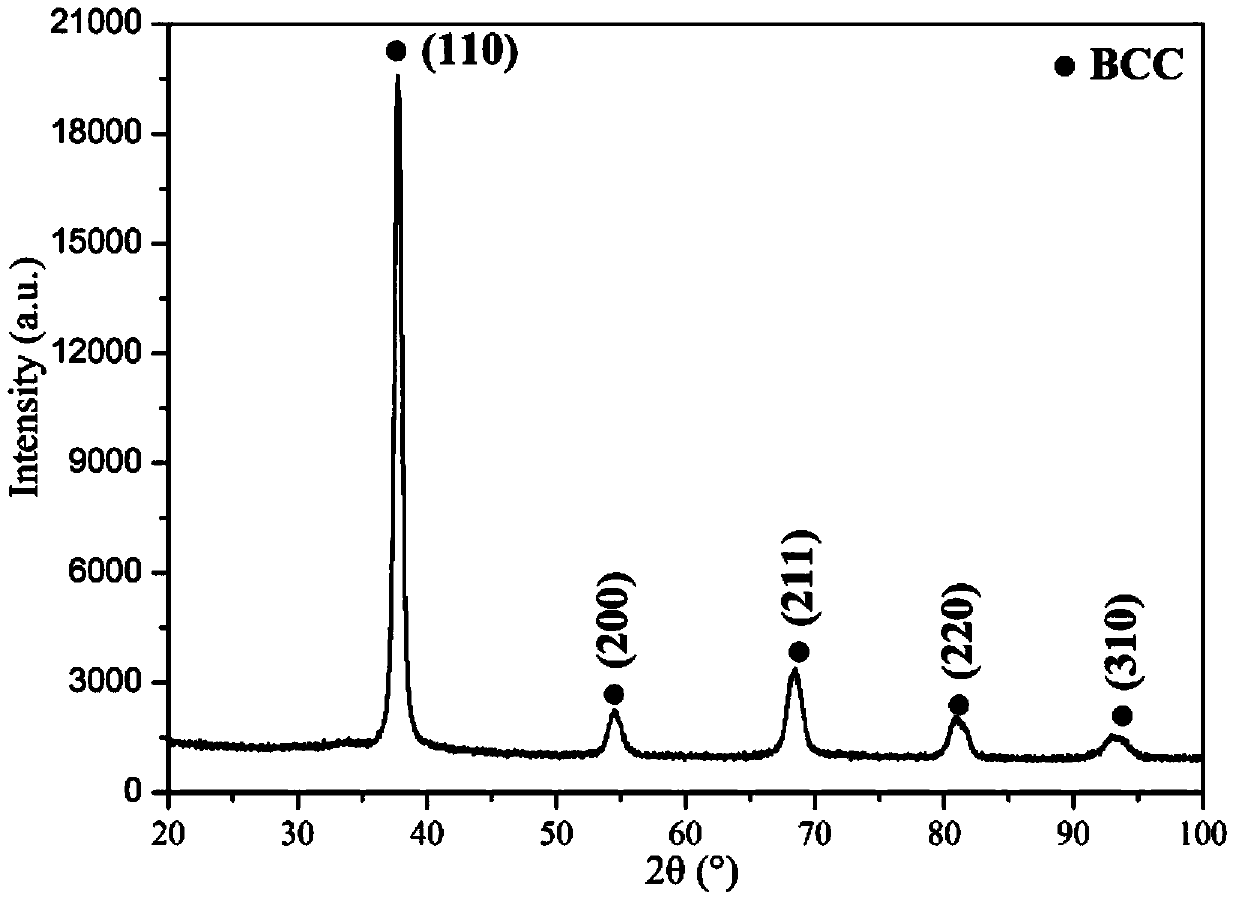

[0031] Embodiment 2: This embodiment is different from Embodiment 1 in that the value ranges of x and y are 0.1-0.9. Others are the same as Embodiment 1.

specific Embodiment approach 3

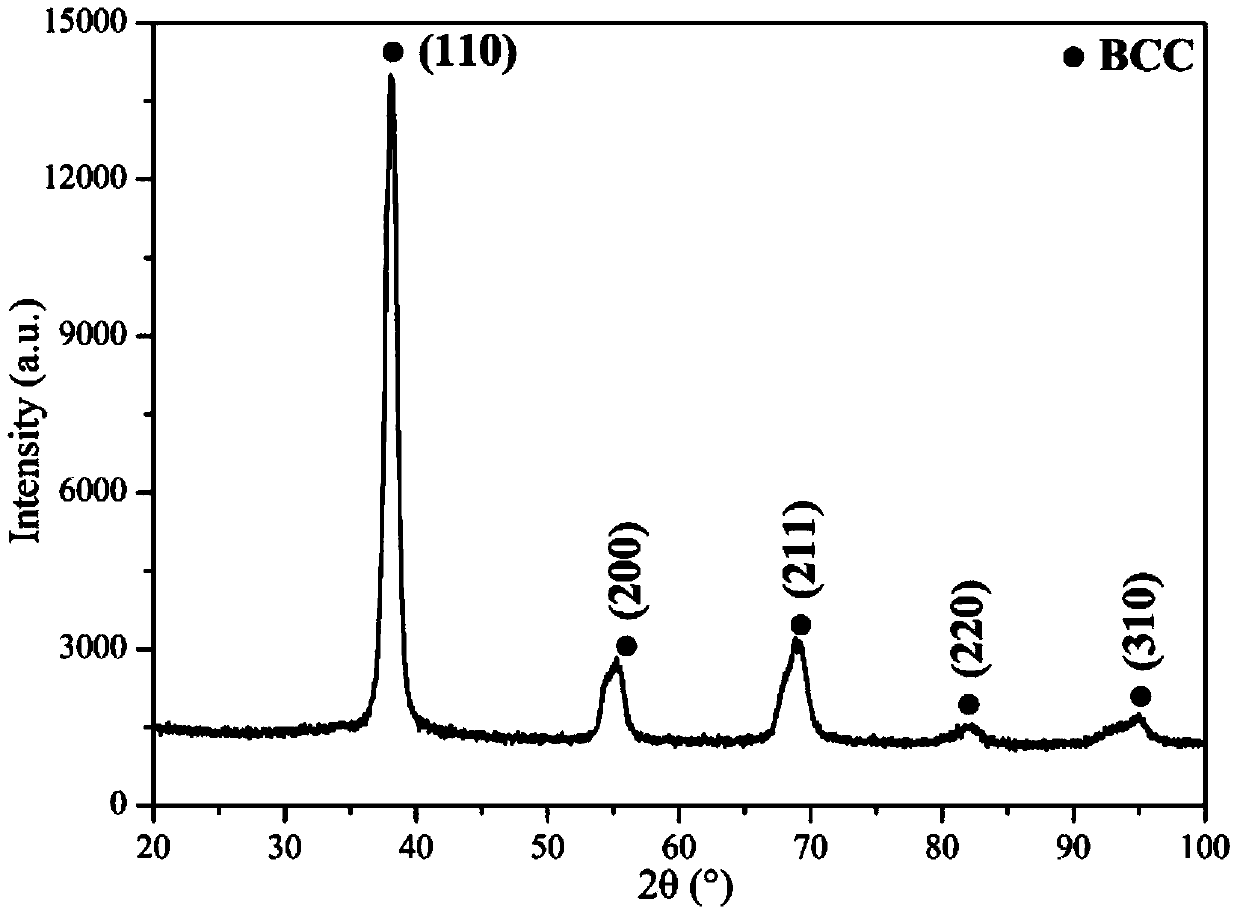

[0032] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the values of x and y range from 0.1 to 0.8. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com