Method for preparing plane hollow microneedle for transdermal administration

A hollow micro- and micro-needle technology, used in micro-needles, processes for producing decorative surface effects, and pharmaceutical devices, etc. The polymer is easy to fall off and other problems to achieve the effect of enhancing drug delivery efficiency, reducing process complexity, and long-term delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

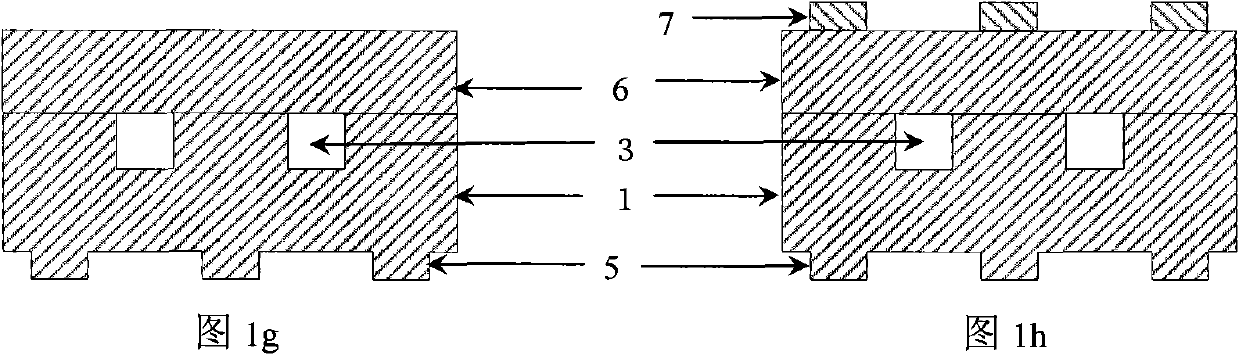

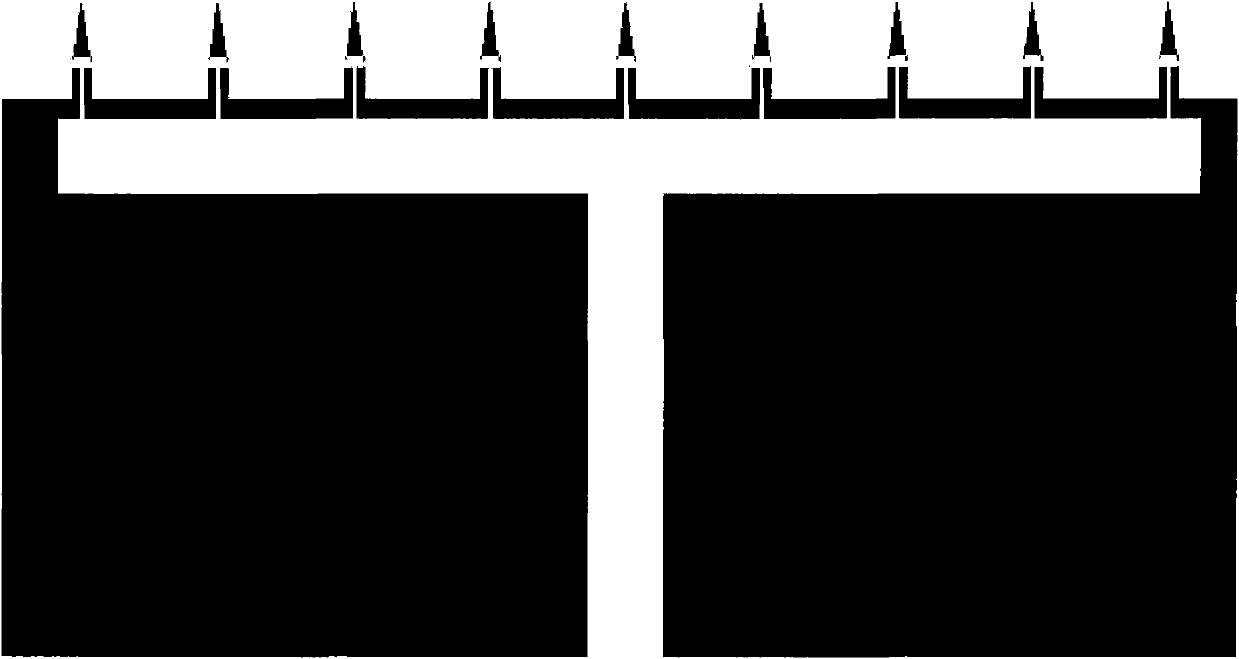

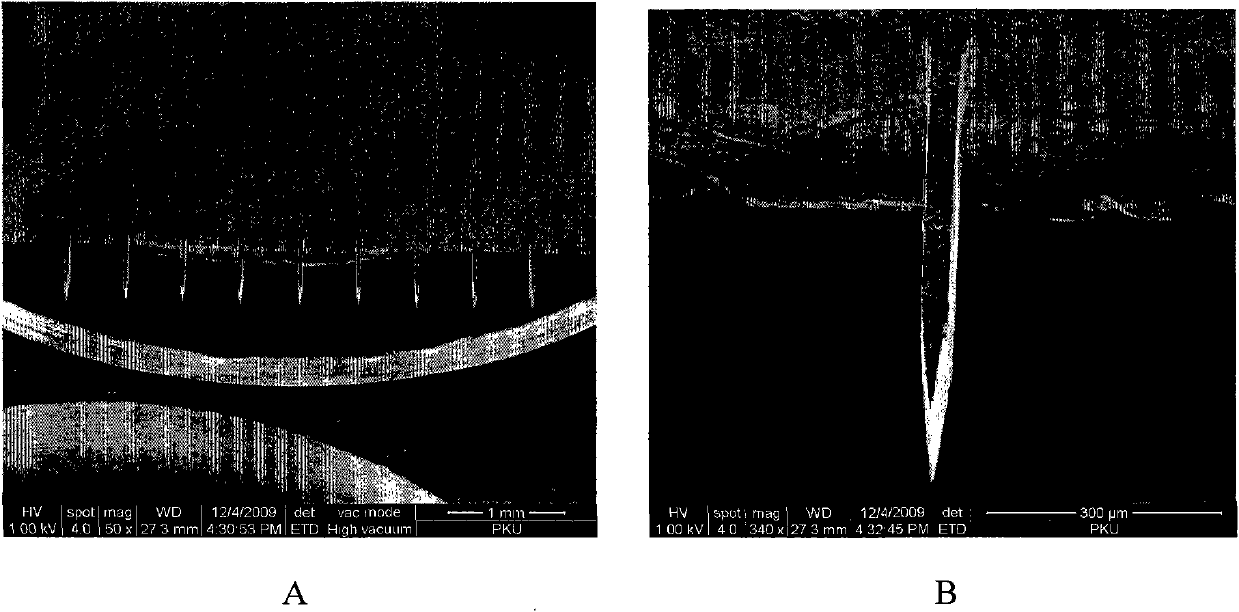

[0030] Below in conjunction with the accompanying drawings, the present invention is further described in detail through the embodiments, but the scope of the present invention is not limited in any way.

[0031] Through mechanical processing of chemically pure titanium materials, four-inch titanium-based wafers are prepared by wire cutting. Low-temperature vacuum annealing and chemical-mechanical polishing are performed to obtain a 200 μm thick four-inch titanium-based wafer polished on both sides or one side. Using this titanium-based disc to prepare planar hollow microneedles according to the following steps:

[0032] 1. Form a microneedle channel

[0033] A double-sided polished titanium-based wafer was taken as the first titanium substrate 1, and a 15 μm-thick SU83010 photoresist 2 was spin-coated on one side of the polished surface, and left to stand for 24 hours. After pre-baking on a hot plate (from 45°C to 95°C for 2 minutes at every 10°C for 10 minutes, then cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com